ASTM C604-02(2007)e1

(Test Method)Standard Test Method for True Specific Gravity of Refractory Materials by Gas-Comparison Pycnometer

Standard Test Method for True Specific Gravity of Refractory Materials by Gas-Comparison Pycnometer

SIGNIFICANCE AND USE

The true specific gravity of a material is the ratio of its true density, determined at a specific temperature, to the true density of water, determined at a specific temperature. Thus, the true specific gravity of a material is a primary property which is related to chemical and mineralogical composition.

This test method is particularly useful for hydratable materials which are not suitable for test with Test Method C 135.

For refractory raw materials and products the true specific gravity is a useful value for: classification, detecting differences in chemical composition between supposedly like samples, indicating mineralogical phases or phase changes, calculating total porosity when the bulk density is known, and for any other test method that requires this value for the calculation of results.

This test method is a primary standard method which is suitable for use in specifications, quality control, and research and development. It can also serve as a referee test method in purchasing contracts or agreements.

Fundamental assumptions inherent in this test method are the following:

The sample is representative of the material in general,

The total sample has been reduced to the particle size specified,

No contamination has been introduced during processing of the sample,

The ignition of the sample has eliminated all free or combined water without inducing sintering or alteration,

An inert gas (helium) has been used in the test, and

The test method has been conducted in a meticulous manner.

Deviation from any of these assumptions negates the usefulness of the results.

In interpreting the results of this test method it must be recognized that the specified sample particle size is significantly finer than specified for Test Method C 135. Even this finer particle size for the sample does not preclude the presence of some closed pores, and the amount of residual closed pores may vary between materials or even between samples of the...

SCOPE

1.1 This test method covers the determination of the true specific gravity of solid materials, and is particularly useful for materials that easily hydrate which are not suitable for test with Test Method C 135. This test method may be used as an alternate for Test Method C 135, Test Method C 128, and Test Method C 188 for determining true specific gravity.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—In 7.3 the equivalent SI unit is expressed in parenthesis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C604 −02(Reapproved 2007)

Standard Test Method for

True Specific Gravity of Refractory Materials by Gas-

Comparison Pycnometer

This standard is issued under the fixed designation C604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units of measure statement was added editorially in March 2009.

1. Scope of a carefully weighed powdered sample which has first been

heated to drive off moisture and undesired combined water is

1.1 This test method covers the determination of the true

measured by the gas-comparison pycnometer. Density is cal-

specific gravity of solid materials, and is particularly useful for

culated from the sample weight in grams divided by its volume

materialsthateasilyhydratewhicharenotsuitablefortestwith

in cubic centimetres. This is also the specific gravity of the

Test Method C135. This test method may be used as an

sample at room temperature compared to water at 4°C.

alternate for Test Method C135, Test Method C128, and Test

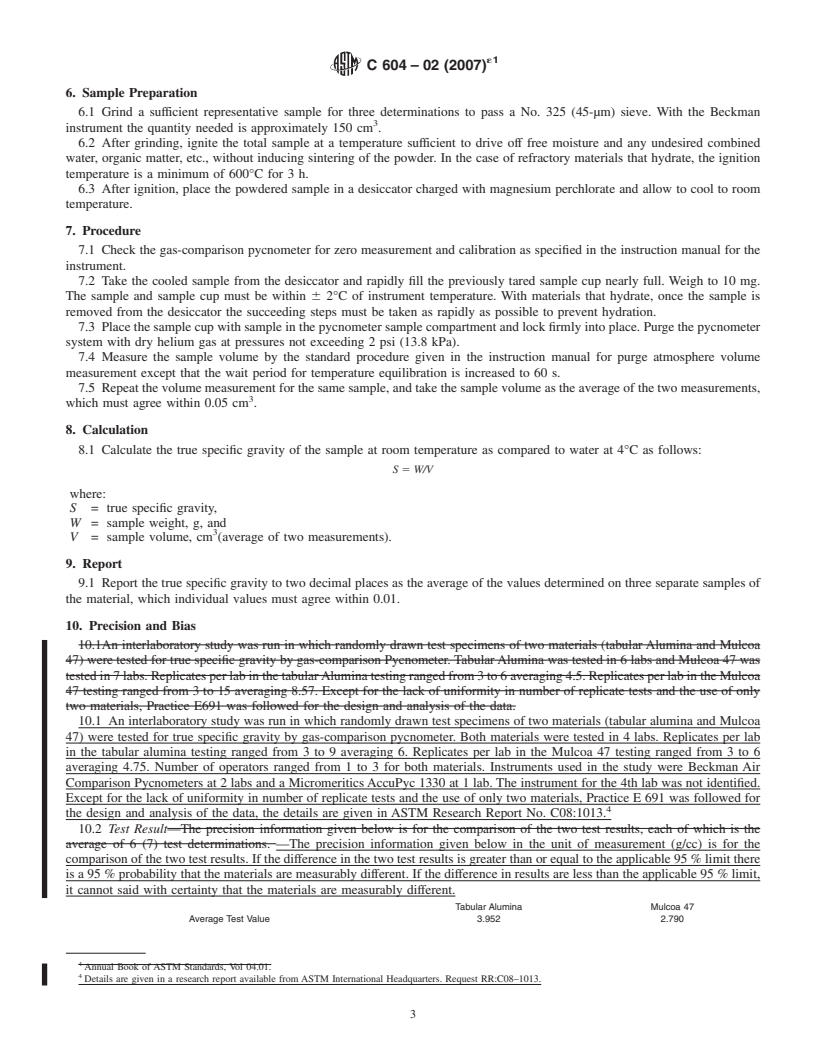

Method C188 for determining true specific gravity. 3.2 The principle of the gas-comparison pycnometer is as

follows: There are two chambers and two pistons as sketched

1.2 Units—The values stated in SI units are to be regarded

in Fig. 1. For purposes of illustration, the chambers are

as standard. No other units of measurement are included in this

assumed to be equal in volume, and there is no sample in either

standard.

cylinder. Under these conditions, with the coupling valve

1.2.1 Exception—In 7.3 the equivalent SI unit is expressed

closed, any change in the position of one piston must be

in parenthesis.

duplicated by an identical stroke in the other in order to

1.3 This standard does not purport to address all of the

maintain the same pressure on each side of the differential

safety concerns, if any, associated with its use. It is the

pressure indicator.

responsibility of the user of this standard to establish appro-

3.3 If a sample,V , is inserted into chamberB , the coupling

x

priate safety and health practices and determine the applica-

valve closed and both pistons advanced the same amount from

bility of regulatory limitations prior to use.

position1 to position2, the pressures will not remain the same.

However the pressures can be maintained equal if piston B

2. Referenced Documents

instead is moved only to position 3. Then the remaining

2.1 ASTM Standards:

displacement d , from position 3 to position 2 , is equal to the

x

C128 Test Method for Density, Relative Density (Specific

volume of the sample, V . If piston A always is advanced

x

Gravity), and Absorption of Fine Aggregate

exactly the same distance each time a measurement is made,

C135 Test Method for True Specific Gravity of Refractory

the distance that piston B differs from position 2, when the

Materials by Water Immersion

pressures in both cylinders are equal, will always be propor-

C188 Test Method for Density of Hydraulic Cement

tional to the volume, V . The distance (d ) between positions 2

x x

and 3 can be calibrated and made to read directly in terms of

3. Summary of Test Method

cubic centimetres, employing a digital counter.

3.1 The sample is powdered to ensure permeation of gas

4. Significance and Use

into all pores. For practical purposes this is assumed to be true

when the sample passes a No. 325 (45-µm) sieve. The volume

4.1 The true specific gravity of a material is the ratio of its

true density, determined at a specific temperature, to the true

density of water, determined at a specific temperature. Thus,

This test method is under the jurisdiction of ASTM Committee C08 on

the true specific gravity of a material is a primary property

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

which is related to chemical and mineralogical composition.

Properties.

Current edition approved March 1, 2007. Published April 2007. Originally

4.2 This test method is particularly useful for hydratable

approved in 1967. Last previous edition approved in 2002 as C604 – 02. DOI:

materials which are not suitable for test with Test Method

10.1520/C0604-02R07E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

C135.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.3 For refractory raw materials and products the true

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specific gravity is a useful value for: classification, detecting

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C604−02 (2007)

FIG. 1 Simplified Schematic Diagram

differences in chemical composition between supposedly like recognition of potentially inherent differences between the

samples, indicating mineralogical phases or phase changes, materials being compared or the test method used.

calculating total porosity when the bulk density is known, and

5. Apparatus

for any other test method that requires this value for the

5.1 Analytical Balance, 200-g capacity, minimum sensitiv-

calculation of results.

ity 10 mg.

4.4 This test method is a primary standard method which is

5.2 Desiccator, charged with magnesium perchlorate.

suitable for use in specifications, quality control, and research

and development. It can also serve as a referee test method in 5.3 Muffle Furnace, capable of heating to 1000°C.

purchasing contracts or agreements.

5.4 Cylinder of Dry Helium Gas, with regulator and gage.

4.5 Fundamental assumptions inherent in this test method

5.5 Equipment for Grinding Sample, to pass a No. 325

are the following:

(45-µm) sieve without contamination.

4.5.1 Thesampleisrepresentativeofthematerialingeneral, 3

5.6 Gas-Comparison Pycnometer, equipped with external

4.5.2 The total sample has been reduced to the particle size

purge manifold.

specified,

4.5.3 Nocontaminationhasbeenintroducedduringprocess- 6. Sample Preparation

ing of the sample,

6.1 Grind a sufficient representative sample for three deter-

4.5.4 The ignition of the sample has eliminated all free or

minations to pass a No. 325 (45-µm) sieve. With the Beckman

combined water without inducing sintering or alteration,

instrument the quantity needed is

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:C 604–98 Designation: C 604 – 02 (Reapproved 2007)

Standard Test Method for

True Specific Gravity of Refractory Materials by Gas-

Comparison Pycnometer

This standard is issued under the fixed designation C 604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units of measure statement was added editorially in March 2009.

1. Scope

1.1 This test method covers the determination of the true specific gravity of solid materials, and is particularly useful for

materials that easily hydrate which are not suitable for test with Test Method C 135. This test method may be used as an alternate

for Test Method C 135, Test Method C 128, and Test Method C 188 for determining true specific gravity.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.2.1 Exception—In 7.3 the equivalent SI unit is expressed in parenthesis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 128 Test Method for Specific Gravity andAbsorption of FineAggregate Test Method for Density, Relative Density (Specific

Gravity), and Absorption of Fine Aggregate

C 135 Test Method for True Specific Gravity of Refractory Materials by Water Immersion

C 188 Test Method for Density of Hydraulic Cement

3. Summary of Test Method

3.1 The sample is powdered to ensure permeation of gas into all pores. For practical purposes this is assumed to be true when

the sample passes a No. 325 (45-µm) sieve. The volume of a carefully weighed powdered sample which has first been heated to

drive off moisture and undesired combined water is measured by the gas-comparison pycnometer. Density is calculated from the

sample weight in grams divided by its volume in cubic centimetres. This is also the specific gravity of the sample at room

temperature compared to water at 4°C.

3.2 The principle of the gas-comparison pycnometer is as follows: There are two chambers and two pistons as sketched in Fig.

1. For purposes of illustration, the chambers are assumed to be equal in volume, and there is no sample in either cylinder. Under

these conditions, with the coupling valve closed, any change in the position of one piston must be duplicated by an identical stroke

in the other in order to maintain the same pressure on each side of the differential pressure indicator.

3.3 If a sample, V , is inserted into chamber B , the coupling valve closed and both pistons advanced the same amount from

x

position 1 to position 2, the pressures will not remain the same. However the pressures can be maintained equal if piston B instead

is moved only to position 3. Then the remaining displacement d , from position 3 to position 2, is equal to the volume of the

x

sample, V . If piston A always is advanced exactly the same distance each time a measurement is made, the distance that piston

x

B differs from position 2, when the pressures in both cylinders are equal, will always be proportional to the volume, V . The

x

distance (d ) between positions 2 and 3 can be calibrated and made to read directly in terms of cubic centimetres, employing a

x

digital counter.

This test method is under the jurisdiction of ASTM Committee C-8 on Refractories, and is the direct responsibility of Subcommittee C08.03 on Physical Test and

Properties.

´1

Current edition approved Sept. 10, 1998. Published December 1998. Originally published as C604–67. Last previous edition C604–86 (Reapproved 1993) .

This test method is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.03 on Physical Properties.

Current edition approved March 1, 2007. Published April 2007. Originally approved in 1967. Last previous edition approved in 2002 as C 604 – 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 04.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

C 604 – 02 (2007)

FIG. 1 Simplified Schematic Diagram

4. Significance and Use

4.1 The true specific gravity of a material is the ratio of its true density, determined at a specific temperature, to the true density

of water, determined at a specific temperature. Thus, the true specific gravity of a material is a primary property which is related

to chemical and mineralogical composition.

4.2 This test method is particularly useful for hydratable materials which are not suitable for test with Test Method C 135.

4.3 For refractory raw materials and products the true specific gravity is a useful value for: classification, detecting differences

in chemical composition between supposedly like samples, indicating mineralogical phases or phase changes, calculating total

porosity when the bulk density is known, and for any other test method that requires this value for the calculation of results.

4.4 This test method is a primary standard method which is suitable for use in specifications, quality control, and research and

development. It can also serve as a referee test method in purchasing contracts or agreements.

4.5 Fundamental assumptions inherent in this test method are the following:

4.5.1 The sample is representative of the material in general,

4.5.2 The total sample has been reduced to the particle size specified,

4.5.3 No contamination has been introduced during processing of the sample,

4.5.4 The ignition of the sample has eliminated all free or combined water without inducing sintering or alteration,

4.5.5 An inert gas (helium) has been used in the test, and

4.5.6 The test method has been conducted in a meticulous manner.

4.5.7 Deviation from any of these assumptions negates the usefulness of the results.

4.6 Ininterpretingtheresultsofthistestmethoditmustberecognizedthatthespecifiedsampleparticlesizeissignificantlyfiner

than specified for Test Method C 135. Even this finer particle size for the sample does not preclude the presence of some closed

pores, and the amount of residual closed pores may vary between materials or even between samples of the same or like materials.

The values generated by this test method may, therefore, be very close approximations rather than accurate representations of true

specific gravities. Thus, comparisons of results should only be judiciously made between like materials

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.