ASTM F2922-12

(Specification)Standard Specification for Polyethylene (PE) Corrugated Wall Stormwater Collection Chambers

Standard Specification for Polyethylene (PE) Corrugated Wall Stormwater Collection Chambers

ABSTRACT

This specification covers requirements, test methods, materials, and marking for polyethylene (PE), open bottom, buried arch-shaped chambers of corrugated wall construction used for collection, detention, and retention of stormwater runoff. These collection chambers can be used as commercial, residential, agricultural, and highway drainage, including installation under parking lots and roadways. This specification indicates the classifications, tolerances, and dimensions of the chambers. It also lists the test methods that examine the physical and mechanical properties of finished chambers.

SCOPE

1.1 This specification covers requirements, test methods, materials, and marking for polyethylene (PE), open bottom, buried arch-shaped chambers of corrugated wall construction used for collection, detention, and retention of stormwater runoff. Applications include commercial, residential, agricultural, and highway drainage, including installation under parking lots and roadways.

1.2 Chambers are produced in arch shapes with dimensions based on chamber rise, chamber span, and wall stiffness. Chambers are manufactured with integral feet that provide base support. Chambers may include perforations to enhance water flow. Chambers must meet test requirements for arch stiffness, flattening, and accelerated weathering.

1.3 Analysis and experience have shown that the successful performance of this product depends upon the type and depth of bedding and backfill, and care in installation. This specification includes requirements for the manufacturer to provide chamber installation instructions to the purchaser.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 6, of this specification:

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F2922 −12

StandardSpecification for

Polyethylene (PE) Corrugated Wall Stormwater Collection

Chambers

This standard is issued under the fixed designation F2922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Table 1 was editorially corrected in September 2012.

1. Scope 2. Referenced Documents

1.1 This specification covers requirements, test methods, 2.1 ASTM Standards:

materials, and marking for polyethylene (PE), open bottom, D618 Practice for Conditioning Plastics for Testing

buried arch-shaped chambers of corrugated wall construction D1600 Terminology forAbbreviatedTerms Relating to Plas-

used for collection, detention, and retention of stormwater tics

runoff. Applications include commercial, residential, D2122 Test Method for Determining Dimensions of Ther-

agricultural, and highway drainage, including installation un- moplastic Pipe and Fittings

der parking lots and roadways. D2412 Test Method for Determination of External Loading

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.2 Chambers are produced in arch shapes with dimensions

D2990 Test Methods for Tensile, Compressive, and Flexural

based on chamber rise, chamber span, and wall stiffness.

Creep and Creep-Rupture of Plastics

Chambersaremanufacturedwithintegralfeetthatprovidebase

D3350 Specification for Polyethylene Plastics Pipe and Fit-

support. Chambers may include perforations to enhance water

tings Materials

flow. Chambers must meet test requirements for arch stiffness,

D4329 Practice for Fluorescent UV Exposure of Plastics

flattening, and accelerated weathering.

D4703 Practice for Compression Molding Thermoplastic

1.3 Analysis and experience have shown that the successful

Materials into Test Specimens, Plaques, or Sheets

performance of this product depends upon the type and depth

D6992 Test Method for Accelerated Tensile Creep and

of bedding and backfill, and care in installation. This specifi-

Creep-Rupture of Geosynthetic Materials Based on Time-

cation includes requirements for the manufacturer to provide

Temperature Superposition Using the Stepped Isothermal

chamber installation instructions to the purchaser.

Method

F412 Terminology Relating to Plastic Piping Systems

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical F2136 Test Method for Notched, Constant Ligament-Stress

(NCLS) Test to Determine Slow-Crack-Growth Resis-

conversions to SI units that are provided for information only

and are not considered standard. tance of HDPE Resins or HDPE Corrugated Pipe

F2787 Practice for Structural Design of Thermoplastic Cor-

1.5 The following safety hazards caveat pertains only to the

rugated Wall Stormwater Collection Chambers

test method portion, Section 6, of this specification:This

standard does not purport to address all of the safety concerns,

3. Terminology

if any, associated with its use. It is the responsibility of the user

3.1 Definitions—Definitions used in this specification are in

of this standard to establish appropriate safety and health

accordance with the definitions in Terminology F412, and

practices and determine the applicability of regulatory limita-

abbreviations are in accordance with Terminology D1600,

tions prior to use.

unless otherwise indicated.

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Drainage. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved March 1, 2012. Published March 2012. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2922–12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2922−12

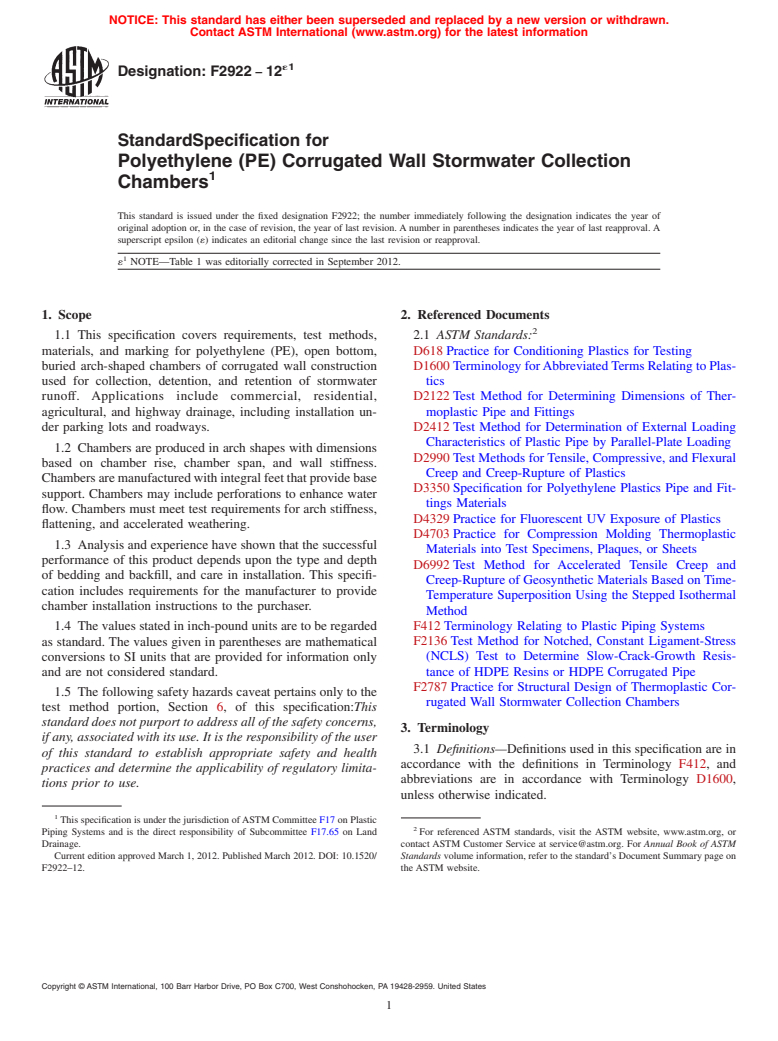

3.2 Definitions of Terms Specific to This Standard: 3.2.12 rise—the vertical distance from the chamber base

3.2.1 chamber—an arch-shaped structure manufactured of (bottom of the chamber foot) to the inside of a chamber wall

thermoplastic with an open-bottom that is supported on feet valley element at the crown as depicted in Fig. 1.

and may be joined into rows that begin with, and are termi-

3.2.13 span—the horizontal distance from the interior of

nated by, end caps (see Fig. 1).

one sidewall valley element to the interior of the other sidewall

3.2.2 chamber storage capacity—the bare chamber storage

valley element as depicted in Fig. 1.

capacity excluding storage in end caps, stone porosity, distri-

3.2.14 valley—the element of a corrugated wall located at

bution piping or other distribution components.

the interior surface of the chamber wall, spanning between two

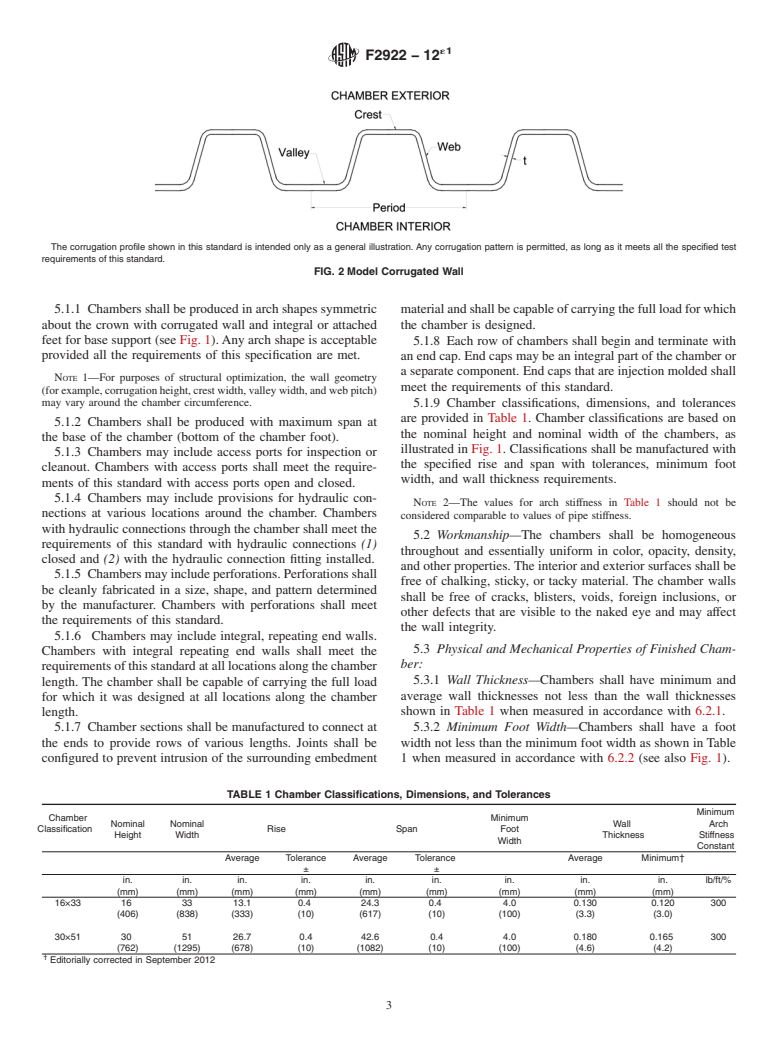

3.2.3 corrugated wall—a wall profile consisting of a regular

webs (see Fig. 2).

pattern of alternating crests and valleys (see Fig. 2).

3.2.15 web—the element of a corrugated wall that connects

3.2.4 crest—the element of a corrugation located at the

a crest element to a valley element (see Fig. 2).

exterior surface of the chamber wall, spanning between two

web elements (see Fig. 2).

4. Materials and Manufacture

3.2.5 crown—the center section of a chamber typically

4.1 The chamber and end caps shall be made of virgin PE

located at the highest point as the chamber is traversed

plastic compound meeting the requirements of Specification

circumferentially.

D3350 cell classification 516500C or 516500E, except that the

3.2.6 end cap—a bulkhead provided to begin and terminate

carbon black content shall not exceed 3%. Compounds that

a chamber, or row of chambers, and prevent intrusion of

have a higher cell classification in one or more properties shall

surrounding embedment materials.

be permitted provided all other product requirements are met.

3.2.7 foot—a flat, turned out section that is manufactured

For slow crack growth resistance, acceptance of resins shall be

with the chamber to provide a bearing surface for transfer of

determined by using the notched constant ligament-stress

vertical loads to the bedding (see Fig. 1).

(NCLS) test on a finished compounded resin according to the

procedure described in 6.2.11. The chamber sample shall be

3.2.8 inspection port—an opening in the chamber wall that

ground and a test plaque made in accordance with Practice

allows access to the chamber interior.

D4703 Procedure C at a cooling rate of 15°C/min (27°F/min)

3.2.9 nominal height—a designation describing the approxi-

and tested per 6.2.11. The average failure time of test speci-

mate vertical dimension of the chamber at its crown (see Fig.

mens from plaques shall not be less than 100 h.

1).

4.2 Rework Material—In lieu of virgin PE, clean rework

3.2.10 nominal width—a designation describing the ap-

materialgeneratedfromthemanufacturer’sownchambersmay

proximate outside horizontal dimension of the chamber at its

be used, provided the material meets the cell class require-

feet (see Fig. 1).

ments of 4.1.

3.2.11 period—the length of a single repetition of the

repeated corrugation, defined as the distance from the center-

5. Requirements

line of a valley element to the centerline of the next valley

element (see Fig. 2). 5.1 Chamber Description:

The model chamber shown in this standard is intended only as a general illustration. Any arch-shape chamber configuration is permitted, as long as it meets all the

specified requirements of this standard.

FIG. 1Model Chamber

´1

F2922−12

The corrugation profile shown in this standard is intended only as a general illustration.Any corrugation pattern is permitted, as long as it meets all the specified test

requirements of this standard.

FIG. 2Model Corrugated Wall

5.1.1 Chambers shall be produced in arch shapes symmetric materialandshallbecapableofcarryingthefullloadforwhich

about the crown with corrugated wall and integral or attached the chamber is designed.

feet for base support (see Fig. 1).Any arch shape is acceptable 5.1.8 Each row of chambers shall begin and terminate with

provided all the requirements of this specification are met.

an end cap. End caps may be an integral part of the chamber or

a separate component. End caps that are injection molded shall

NOTE 1—For purposes of structural optimization, the wall geometry

meet the requirements of this standard.

(forexample,corrugationheight,crestwidth,valleywidth,andwebpitch)

may vary around the chamber circumference. 5.1.9 Chamber classifications, dimensions, and tolerances

are provided in Table 1. Chamber classifications are based on

5.1.2 Chambers shall be produced with maximum span at

the nominal height and nominal width of the chambers, as

the base of the chamber (bottom of the chamber foot).

illustrated in Fig. 1. Classifications shall be manufactured with

5.1.3 Chambers may include access ports for inspection or

the specified rise and span with tolerances, minimum foot

cleanout. Chambers with access ports shall meet the require-

width, and wall thickness requirements.

ments of this standard with access ports open and closed.

5.1.4 Chambers may include provisions for hydraulic con-

NOTE 2—The values for arch stiffness in Table 1 should not be

nections at various locations around the chamber. Chambers

considered comparable to values of pipe stiffness.

with hydraulic connections through the chamber shall meet the

5.2 Workmanship—The chambers shall be homogeneous

requirements of this standard with hydraulic connections (1)

throughout and essentially uniform in color, opacity, density,

closed and (2) with the hydraulic connection fitting installed.

and other properties. The interior and exterior surfaces shall be

5.1.5 Chambersmayincludeperforations.Perforationsshall

free of chalking, sticky, or tacky material. The chamber walls

be cleanly fabricated in a size, shape, and pattern determined

shall be free of cracks, blisters, voids, foreign inclusions, or

by the manufacturer. Chambers with perforations shall meet

other defects that are visible to the naked eye and may affect

the requirements of this standard.

the wall integrity.

5.1.6 Chambers may include integral, repeating end walls.

5.3 Physical and Mechanical Properties of Finished Cham-

Chambers with integral repeating end walls shall meet the

ber:

requirementsofthisstandardatalllocationsalongthechamber

5.3.1 Wall Thickness—Chambers shall have minimum and

length. The chamber shall be capable of carrying the full load

average wall thicknesses not less than the wall thicknesses

for which it was designed at all locations along the chamber

shown in Table 1 when measured in accordance with 6.2.1.

length.

5.1.7 Chamber sections shall be manufactured to connect at 5.3.2 Minimum Foot Width—Chambers shall have a foot

the ends to provide rows of various lengths. Joints shall be width not less than the minimum foot width as shown in Table

configured to prevent intrusion of the surrounding embedment 1 when measured in accordance with 6.2.2 (see also Fig. 1).

TABLE 1 Chamber Classifications, Dimensions, and Tolerances

Minimum

Chamber Minimum

Nominal Nominal Wall Arch

Classification Rise Span Foot

Height Width Thickness Stiffness

Width

Constant

Average Tolerance Average Tolerance Average Minimum†

± ±

in. in. in. in. in. in. in. in. in. lb/ft/%

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

16×33 16 33 13.1 0.4 24.3 0.4 4.0 0.130 0.120 300

(406) (838) (333) (10) (617) (10) (100) (3.3) (3.0)

30×51 30 51 26.7 0.4 42.6 0.4 4.0 0.180 0.165 300

(762) (1295) (678) (10) (1082) (10) (100) (4.6) (4.2)

†

Editorially corrected in September 2012

´1

F2922−12

5.3.3 Rise and Span Dimensions——Chambers shall meet Thechambermanufacturershallprovidethepurchaserwiththe

the rise and span dimension requirements shown in Table 1 requirements for the proper installation of chambers and the

when measured in accordance with Sections 6.2.3 and 6.2.4 minimum and maximum allowable cover height for specific

(see also Fig. 1). traffic and non-traffic loading conditions that meet the require-

5.3.4 Deviation From Straightness—The chamber and its ments of Practice F2787.

supportfeetshallnothaveadeviationfromstraightnessgreater

5.6 Design Data:

than L/100, where L is the length of an individual chamber,

5.6.1 Hydraulic Data—The manufacturer shall provide the

when measured in accordance with 6.2.5.

purchaser with data required for hydraulic design, including

NOTE 3—This check is to be made at the time of manufacture and is

chamber length, storage volume, stage-storage, and number,

included to prevent pre-installation deformations in a chamber that meets

size and location of access ports and perforations.

all other requirements of this standard.

5.6.2 Structural Data—If requested by the purchaser, the

5.3.5 Storage Capacity—Manufacturers shall provide the

chamber manufacturer shall provide data to enable verification

storage capacity of the bare chamber and end cap and a stage

of structural design safety factors, including chamber

storage table for the chamber and end cap. Reported values

geometry, wall centroid, wall area, wall moment of inertia, and

shall be based on components “as-assembled” to eliminate

material strain limits.

double counting storage at joints and end caps. Volume

5.7 Installation Qualification—The manufacturer shall

determination shall be in accordance with 6.2.6.

verify the installation requirements and design basis with

5.3.6 Creep Rupture Strength—Specimens fabricated in the

full-scale installation qualification testing of representative

samemannerandcomposedofthesamematerialsincludingall

chambersunderdesignearthandliveloads,inaccordancewith

additives, as the finished chambers shall have a 50 year creep

Practice F2787.

rupture tensile strength at 73 °F (23°C) not less than 700 psi

(4.8 MPa) when determined in accordance with 6.2.7.

6. Test Methods

5.3.7 Creep Modulus—Specimens fabricated in the same

manner and composed of the same materials including all 6.1 Conditioning—Condition all test specimens in accor-

additives, as the finished chambers shall have a 50 year tensile dance with ProcedureAof Practice D618 at 73.4 6 3.6 °F (23

creep modulus at 73 °F (23°C) of not less than 20,000 psi (138 6 2 °C) and 50 6 5% relative humidity for not less than 4 h

MPa) when tested at a stress level of 500 psi (3.5 MPa) or the

prior to test. Conduct tests under the same conditions of

design service stress, whichever is greater. The creep modulus temperatureandhu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.