ASTM C1086-09

(Specification)Standard Specification for Glass Fiber Mechanically Bonded Felt Thermal Insulation

Standard Specification for Glass Fiber Mechanically Bonded Felt Thermal Insulation

ABSTRACT

This specification covers glass fiber unsupported needled felt binder-free thermal insulations. This material is used as the thermal insulation component in the fabrication of insulation systems for use on machinery and equipment, such as steam turbines, boilers, boiler feed pumps, and piping at specified elevated temperatures. Thermal insulations should adhere to the following physical requirements: apparent thermal conductivity, hot surface performance, tensile strength, non-combustibility, and dimensions (nominal thickness, mass per unit area, length, and width).

SCOPE

1.1 This specification covers glass fiber unsupported needled felt (mechanically bonded) binder-free insulation for thermal insulation. This material is used as the thermal insulation component in the fabrication of insulation systems for use on machinery and equipment, such as steam turbines, boilers, boiler feed pumps, and piping at temperatures from ambient up to 1200°F (650°C).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 See Supplementary Requirements for modifications to paragraphs in this standard when using Specification C 1086 in lieu of the United States Department of Defense, Department of Navy, Naval Sea Systems Command, in Washington, DC. Military Specifications No.(s) MIL-I-16411F.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1086 −09

Standard Specification for

1

Glass Fiber Mechanically Bonded Felt Thermal Insulation

This standard is issued under the fixed designation C1086; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C390Practice for Sampling and Acceptance of Thermal

Insulation Lots

1.1 This specification covers glass fiber unsupported

C411Test Method for Hot-Surface Performance of High-

needled felt (mechanically bonded) binder-free insulation for

Temperature Thermal Insulation

thermal insulation. This material is used as the thermal

C518Test Method for Steady-State Thermal Transmission

insulation component in the fabrication of insulation systems

Properties by Means of the Heat Flow Meter Apparatus

for use on machinery and equipment, such as steam turbines,

C1045Practice for Calculating Thermal Transmission Prop-

boilers, boiler feed pumps, and piping at temperatures from

erties Under Steady-State Conditions

ambient up to 1200°F (650°C).

C1058Practice for Selecting Temperatures for Evaluating

1.2 This standard does not purport to address all of the

and Reporting Thermal Properties of Thermal Insulation

safety concerns, if any, associated with its use. It is the

D123Terminology Relating to Textiles

responsibility of the user of this standard to establish appro-

D578Specification for Glass Fiber Strands

priate safety and health practices and determine the applica-

2.2 U.S. Federal Standard:

bility of regulatory limitations prior to use. 3

FED-STD-191Textile Test Methods

1.3 The values stated in inch-pound units are to be regarded

2.3 U.S. Military Standards:

as standard. The values given in parentheses are mathematical

3

MIL-I-16411FInsulation Felt, Thermal, Glass Fiber

conversions to SI units that are provided for information only

MIL-STD-1623Fire Performance Requirements and Ap-

and are not considered standard.

proved Specifications for Interior Finish Materials and

3

1.4 See Supplementary Requirements for modifications to

Furnishings (Naval Shipboard Use)

paragraphs in this standard when using Specification C1086 in

3. Terminology

lieu of the United States Department of Defense, Department

of Navy, Naval Sea Systems Command, in Washington, DC.

3.1 Definitions:

Military Specifications No.(s) MIL-I-16411F.

3.1.1 Terminology C168 and D123 shall be considered as

applying to the terms used in this specification.

2. Referenced Documents

3.1.2 Definitions in Specification D578 shall be considered

2

as applying to the terms used in defining glass fiber composi-

2.1 ASTM Standards:

tion code, process, and fiber diameter.

C167Test Methods forThickness and Density of Blanket or

Batt Thermal Insulations

4. Classification

C168Terminology Relating to Thermal Insulation

C177Test Method for Steady-State Heat Flux Measure- 4.1 Thermal insulation shall be glass fiber, unsupported

ments and Thermal Transmission Properties by Means of needled felt insulation, for use on surfaces with temperatures

the Guarded-Hot-Plate Apparatus up to 1200°F (650°C).

C335Test Method for Steady-State HeatTransfer Properties

5. Ordering Information

of Pipe Insulation

5.1 The purchase order or contract shall specify the follow-

ing:

1

This specification is under the jurisdiction of ASTM Committee C16 on

5.1.1 Quantity of each thickness (10.1).

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

5.1.2 Any special requirements for nonstandard sizes or

Blanket and Loose Fill Insulation.

dimensions (10.2 and 10.3).

Current edition approved May 1, 2009. Published June 2009. Originally

5.1.3 Any requirements for certification (19.1).

approved in 1987. Last previous edition approved in 2008 as C1086–08. DOI:

10.1520/C1086-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1086−09

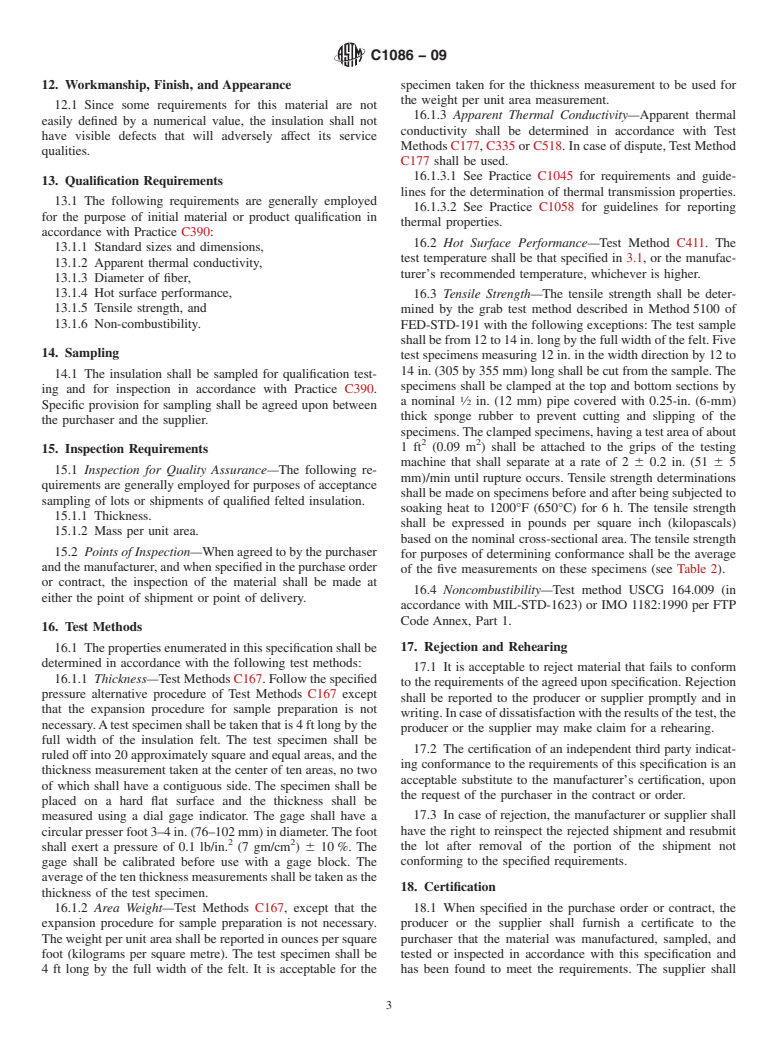

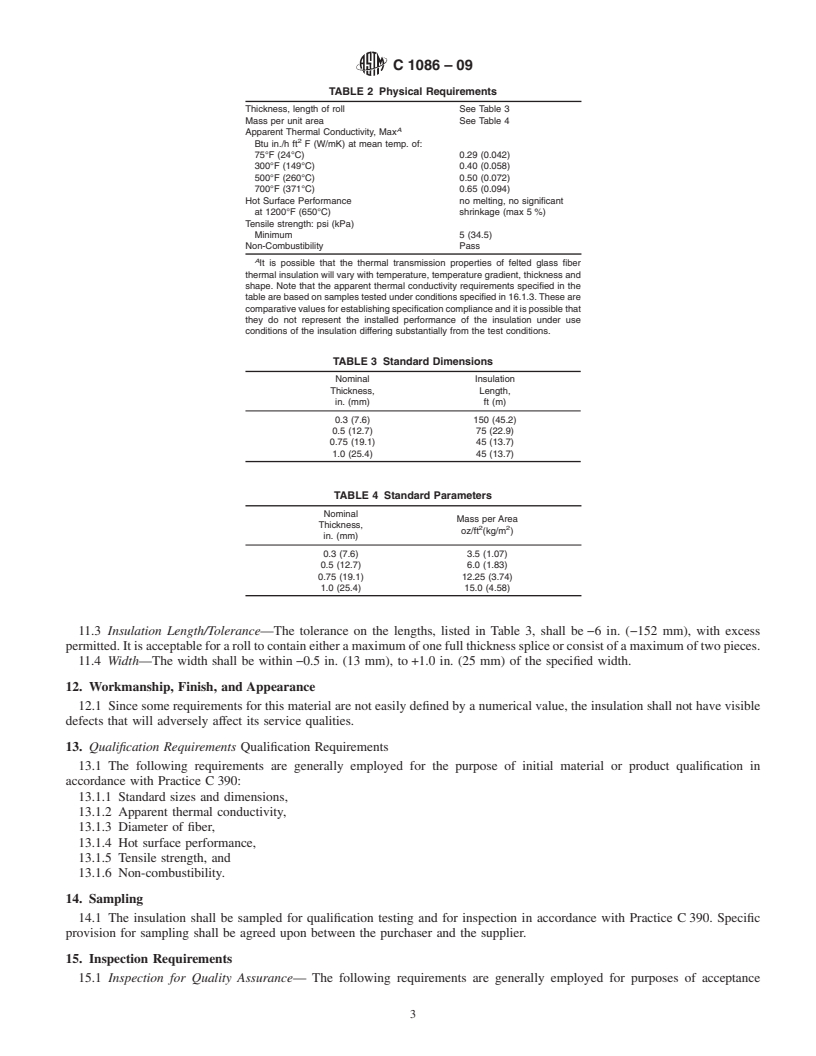

TABLE 2 Physical Requirements

5.1.4 Any special requirements for supplementary testing

requirements (9.1). and Thickness, length of roll See Table 3

Mass per unit area See Table 4

5.1.5 Any special packaging information.

A

Apparent Thermal Conductivity, Max

2

Btu in./h ft F (W/mK) at mean temp. of:

6. Materials and Manufacture

75°F

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1086–08 Designation: C 1086 – 09

Standard Specification for

1

Glass Fiber Mechanically Bonded Felt Thermal Insulation

This standard is issued under the fixed designation C1086; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers glass fiber unsupported needled felt (mechanically bonded) binder-free insulation for thermal

insulation.This material is used as the thermal insulation component in the fabrication of insulation systems for use on machinery

andequipment,suchassteamturbines,boilers,boilerfeedpumps,andpipingattemperaturesfromambientupto1200°F(650°C).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.3The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information only.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 See Supplementary Requirements for modifications to paragraphs in this standard when using Specification C1086 in lieu

of the United States Department of Defense, Department of Navy, Naval Sea Systems Command, in Washington, DC. Military

Specifications No.(s) MIL-I-16411F.

2. Referenced Documents

2

2.1 ASTM Standards:

C167 Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C335 Test Method for Steady-State Heat Transfer Properties of Pipe Insulation

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C411 Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

C1045 Practice for Calculating Thermal Transmission Properties Under Steady-State Conditions

C1058 Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

D123 Terminology Relating to Textiles

D578 Specification for Glass Fiber Strands

2.2 U.S. Federal Standard:

3

FED-STD-191 Textile Test Methods

2.3 U.S. Military Standards:

3

MIL-I-16411F Insulation Felt, Thermal, Glass Fiber

MIL-STD-1623 Fire Performance Requirements and Approved Specifications for Interior Finish Materials and Furnishings

3

(Naval Shipboard Use)

3. Terminology

3.1 Definitions:

3.1.1 Terminology C168 and D123 shall be considered as applying to the terms used in this specification.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeC16onThermalInsulationandisthedirectresponsibilityofSubcommitteeC16.23onBlanketandLoose

Fill Insulation.

Current edition approved Aug.May 1, 2008.2009. Published September 2008.June 2009. Originally approved in 1987. Last previous edition approved in 20042008 as

C1086–96(2004).C1086–08.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1086–09

3.1.2 Definitions in Specification D578 shall be considered as applying to the terms used in defining glass fiber composition

code, process, and fiber diameter.

4. Classification

4.1 Thermal insulation shall be glass fiber, unsupported needled felt insulation, for use on surfaces with temperatures up to

1200°F (650°C).

5. Ordering Information

5.1 The purchase order or contract shall specify the following:

5.1.1 Quantity of each thickness (10.1).

5.1.2 Any special requirements for nonstandard sizes or dim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.