ASTM C813-90(2009)

(Test Method)Standard Test Method for Hydrophobic Contamination on Glass by Contact Angle Measurement

Standard Test Method for Hydrophobic Contamination on Glass by Contact Angle Measurement

SIGNIFICANCE AND USE

The contact angle test is nondestructive and may be used for control and evaluation of processes for the removal of hydrophobic contaminants. The test may also be used for the detection and control of hydrophobic contaminants in processing ambients. For this application, a surface free of hydrophobic films is exposed to the ambient conditions and is subsequently tested.

SCOPE

1.1 This test method covers the detection of hydrophobic contamination on glass surfaces by means of contact angle measurements. When properly conducted, the test will enable detection of fractions of monomolecular layers of hydrophobic organic contaminants. Very rough or porous surfaces may significantly decrease the sensitivity of the test.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C813 − 90(Reapproved 2009)

Standard Test Method for

Hydrophobic Contamination on Glass by Contact Angle

Measurement

This standard is issued under the fixed designation C813; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope anglesappreciablygreaterthanzero:generallygreaterthan45°

for the advancing angle.

1.1 This test method covers the detection of hydrophobic

contamination on glass surfaces by means of contact angle

3.1.4 receding angle—the smallest angle observable when a

measurements. When properly conducted, the test will enable

liquid droplet is decreased in size.

detection of fractions of monomolecular layers of hydrophobic

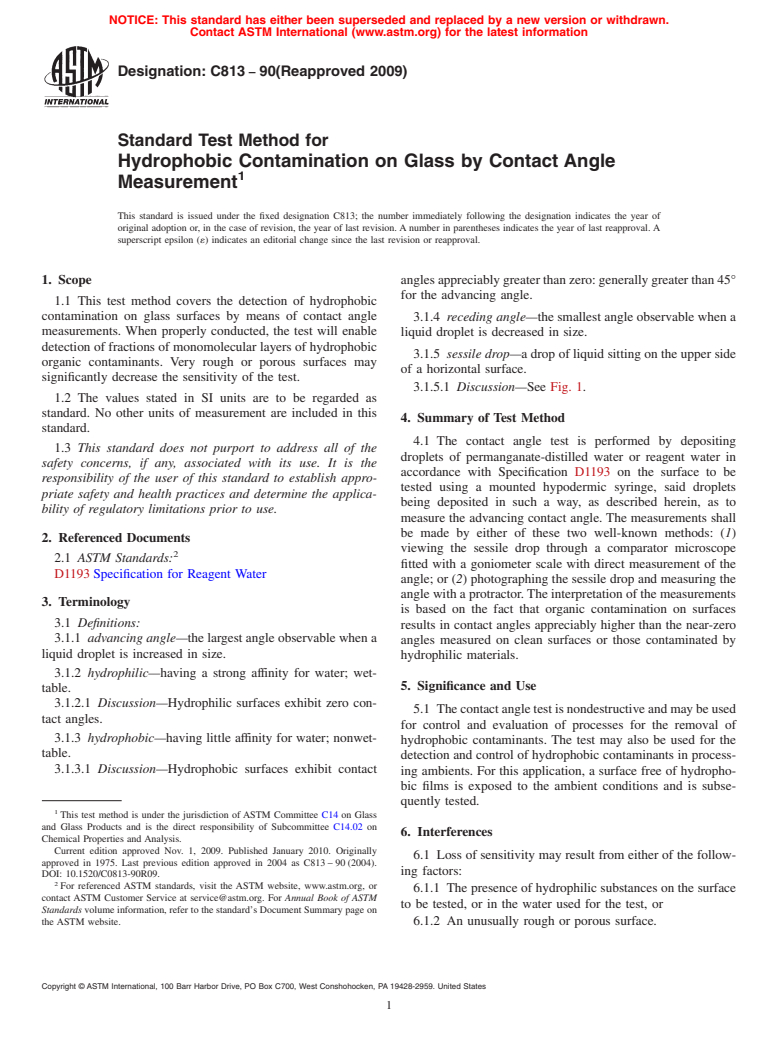

3.1.5 sessile drop—a drop of liquid sitting on the upper side

organic contaminants. Very rough or porous surfaces may

of a horizontal surface.

significantly decrease the sensitivity of the test.

3.1.5.1 Discussion—See Fig. 1.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

4.1 The contact angle test is performed by depositing

1.3 This standard does not purport to address all of the

droplets of permanganate-distilled water or reagent water in

safety concerns, if any, associated with its use. It is the

accordance with Specification D1193 on the surface to be

responsibility of the user of this standard to establish appro-

tested using a mounted hypodermic syringe, said droplets

priate safety and health practices and determine the applica-

being deposited in such a way, as described herein, as to

bility of regulatory limitations prior to use.

measure the advancing contact angle. The measurements shall

be made by either of these two well-known methods: (1)

2. Referenced Documents

viewing the sessile drop through a comparator microscope

2.1 ASTM Standards:

fitted with a goniometer scale with direct measurement of the

D1193Specification for Reagent Water

angle; or (2) photographing the sessile drop and measuring the

anglewithaprotractor.Theinterpretationofthemeasurements

3. Terminology

is based on the fact that organic contamination on surfaces

3.1 Definitions:

results in contact angles appreciably higher than the near-zero

3.1.1 advancing angle—thelargestangleobservablewhena

angles measured on clean surfaces or those contaminated by

liquid droplet is increased in size.

hydrophilic materials.

3.1.2 hydrophilic—having a strong affinity for water; wet-

5. Significance and Use

table.

3.1.2.1 Discussion—Hydrophilic surfaces exhibit zero con-

5.1 Thecontactangletestisnondestructiveandmaybeused

tact angles.

for control and evaluation of processes for the removal of

3.1.3 hydrophobic—having little affinity for water; nonwet-

hydrophobic contaminants. The test may also be used for the

table.

detection and control of hydrophobic contaminants in process-

3.1.3.1 Discussion—Hydrophobic surfaces exhibit contact

ing ambients. For this application, a surface free of hydropho-

bic films is exposed to the ambient conditions and is subse-

quently tested.

This test method is under the jurisdiction of ASTM Committee C14 on Glass

and Glass Products and is the direct responsibility of Subcommittee C14.02 on

6. Interferences

Chemical Properties and Analysis.

Current edition approved Nov. 1, 2009. Published January 2010. Originally

6.1 Loss of sensitivity may result from either of the follow-

approved in 1975. Last previous edition approved in 2004 as C813–90(2004).

ing factors:

DOI: 10.1520/C0813-90R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.1 The presence of hydrophilic substances on the surface

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to be tested, or in the water used for the test, or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.1.2 An unusually rough or porous surface.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C813 − 90 (2009)

10. Procedure

10.1 Randomlyselectatleasttwositeswheremeasurements

will be made on the test surface. Bring the syringe needle into

close proximity to the test surface and, with the test surface in

a horizontal position, manipulate the hypodermic syringe so as

to force a drop having a volume of 0.02 to 0.05 mL onto the

surfacetogiveanadvancingangle(Note1).Theneedleshould

remain immersed in the drop and should be centered in the

drop. Care must be taken that when the syringe plunger is

FIG. 1 Schematic Diagram Indicating Measurement of Contact

releasednomotionisimpartedtotheplungersoastocauseany

Angle

retraction of the drop. Any retraction will cause the contact

angle to be less than the true advan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.