ASTM B32-04

(Specification)Standard Specification for Solder Metal

Standard Specification for Solder Metal

SCOPE

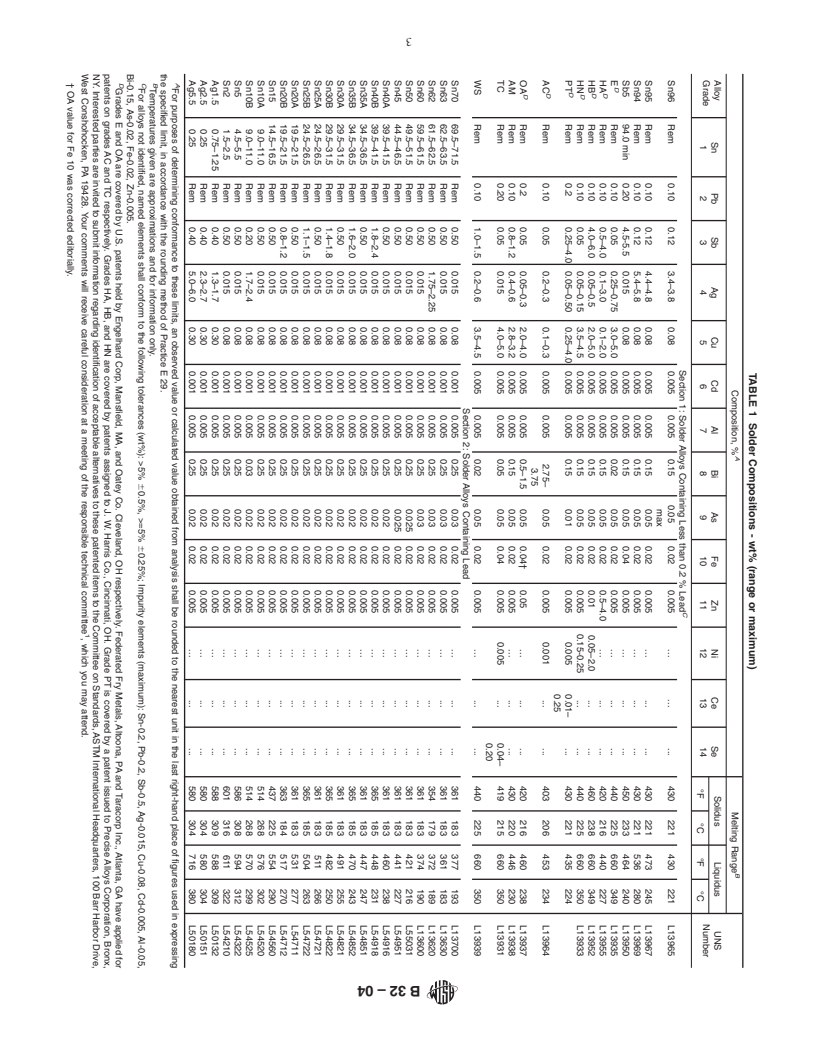

1.1 This specification covers solder metal alloys (commonly known as soft solders) used in non-electronic applications, including but not limited to, tin-lead, tin-antimony, tin-antimony-copper-silver, tin-antimony-copper-silver-nickel, tin-silver, tin-copper-silver, and lead-tin-silver, used for the purpose of joining together two or more metals at temperatures below their melting points. Electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications are not covered by this specification as they are under the auspices of IPC - Association Connecting Electronic Industries.

1.1.1 These solders include those alloys having a liquidus temperature not exceeding 800°F (430°C).

1.1.2 This specification includes solders in the form of solid bars, ingots, powder and special forms, and in the form of solid and flux-core ribbon, wire, and solder paste.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 32 – 04

Standard Specification for

1

Solder Metal

ThisstandardisissuedunderthefixeddesignationB32;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Store Products Including Tall Oil and Other Related

Products

1.1 Thisspecificationcoverssoldermetalalloys(commonly

D465 Test Methods for Acid Number of Naval Stores

known as soft solders) used in non-electronic applications,

Products Including Tall Oil and Other Related Products

including but not limited to, tin-lead, tin-antimony, tin-

D509 Test Methods of Sampling and Grading Rosin

antimony-copper-silver,tin-antimony-copper-silver-nickel,tin-

E28 Test Methods for Softening Point of Resins Derived

silver, tin-copper-silver, and lead-tin-silver, used for the pur-

from Naval Stores by Ring-and-Ball Apparatus

pose of joining together two or more metals at temperatures

E29 Practice for Using Significant Digits in Test Data to

below their melting points. Electronic grade solder alloys and

Determine Conformance with Specifications

fluxed and non-fluxed solid solders for electronic soldering

E46 Test Methods for Chemical Analysis of Lead- and

applications are not covered by this specification as they are

3

Tin-Base Solder

undertheauspicesofIPC–AssociationConnectingElectronic

E51 Method for Spectrographic Analysis of Tin Alloys by

Industries.

3

the Powder Technique

1.1.1 These solders include those alloys having a liquidus

E55 PracticeforSamplingWroughtNonferrousMetalsand

temperature not exceeding 800°F (430°C).

Alloys for Determination of Chemical Composition

1.1.2 Thisspecificationincludessoldersintheformofsolid

E87 Methods for Chemical Analysis of Lead, Tin, Anti-

bars,ingots,powderandspecialforms,andintheformofsolid

3

mony, and Their Alloys (Photometric Method)

and flux-core ribbon, wire, and solder paste.

E88 Practice for Sampling Nonferrous Metals and Alloys

1.2 The values stated in inch-pound units are to be regarded

in Cast Form for Determination of Chemical Composition

as the standard. The values given in parentheses are for

4

2.2 Federal Standard:

information only.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.3 This standard does not purport to address all of the

5

2.3 Military Standard:

safety concerns, if any, associated with its use. It is the

MIL-STD-129 Marking for Shipment and Storage

responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

3. Terminology

Material Safety Data Sheet for this product/material as pro-

3.1 Definition:

vided by the manufacturer, to establish appropriate safety and

3.1.1 producer, n—the primary manufacturer of the mate-

health practices, and determine the applicability of regulatory

rial.

limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.2.1 lot, n—The term “lot” as used in this specification is

2

defined as follows:

2.1 ASTM Standards:

3.2.1.1 Discussion—For solid solder metal, a lot consists of

D269 TestMethodforInsolubleMatterinRosinandRosin

all solder of the same type designation, produced from the

Derivatives

same batch of raw materials under essentially the same

D464 Test Methods for Saponification Number of Naval

conditions, and offered for inspection at one time.

3.2.1.2 Discussion—For flux–core solder, a lot consists of

all solder of the same core mixture, produced from the same

1

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

Current edition approved Nov. 1, 2004. Published November 2004. Originally

3

approved in 1919. Last previous edition approved in 2003 as B32-03. Withdrawn.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Global Engineering Documents, 15 Inverness Way East,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Englewood, CO 80112.

5

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B32–04

batch of raw materials under essentially the same conditions 7.2.1 Type R—The flux is composed of Grade WW or WG

and offered for inspection at one time. gum ros

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.