ASTM D6726-01(2007)

(Guide)Standard Guide for Conducting Borehole Geophysical LoggingElectromagnetic Induction

Standard Guide for Conducting Borehole Geophysical Logging<char: emdash>Electromagnetic Induction

SIGNIFICANCE AND USE

An appropriately developed, documented, and executed guide is essential for the proper collection and application of induction logs. This guide is to be used in conjunction with Guide D5753.

The benefits of its use include improving: selection of induction logging methods and equipment; induction log quality and reliability; and usefulness of the induction log data for subsequent display and interpretation.

This guide applies to commonly used induction logging methods for geotechnical applications.

It is essential that personnel (see Section 8.3.2, Guide D5753) consult up-to-date textbooks and reports on the induction technique, application, and interpretation methods.

SCOPE

1.1 This guide is focused on the general procedures necessary to conduct electromagnetic-induction, induction, electromagnetic-conductivity, or electromagnetic-resistivity logging (hereafter referred as induction logging) of boreholes, wells, access tubes, caissons, or shafts (hereafter referred as boreholes) as commonly applied to geologic, engineering, groundwater and environmental (hereafter referred as geotechnical) investigations. Induction logging for minerals or petroleum applications is excluded.

1.2 This guide defines an induction log as a record of formation electrical conductivity or resistivity with depth as measured by the induction method in a borehole.

1.2.1 Induction logs are treated quantitatively and should be interpreted with other logs and data whenever possible.

1.2.2 Induction logs are commonly used to: (1) delineate lithology; (2) evaluate formation water quality and effective porosity, and (3) correlate stratigraphy between boreholes.

1.3 This guide is restricted to induction measurements that are at a frequency of less than 50 KHz; are non-directional; and average formation properties around the circumference of the borehole; which are the most common induction measurement devices used in geotechnical applications.

1.4 This guide provides an overview of induction logging including (1) general procedures; (2) specific documentation; (3) calibration and standardization; and (4) log quality and interpretation.

1.5 To obtain additional information on induction logs see References section in this guide.

1.6 This guide is to be used in conjunction with Standard Guide D5753.

1.7 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This guide should not be used as a sole criterion for induction logging and does not replace education, experience, and professional judgement. Induction logging procedures should be adapted to meet the needs of a range of applications and stated in general terms so that flexibility or innovation are not suppressed. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged without consideration of a project's many unique aspects. The word standard in the title of this document means that the document has been approved through the ASTM consensus process.

1.8 The geotechnical industry uses English or SI units. The induction log is typically recorded in millisiemens per meter (mS/m) or millimhos per meter (mmhos/m).

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6726 − 01(Reapproved 2007)

Standard Guide for

Conducting Borehole Geophysical Logging—

Electromagnetic Induction

This standard is issued under the fixed designation D6726; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope induction logging and does not replace education, experience,

and professional judgement. Induction logging procedures

1.1 This guide is focused on the general procedures neces-

should be adapted to meet the needs of a range of applications

sary to conduct electromagnetic-induction, induction,

and stated in general terms so that flexibility or innovation are

electromagnetic-conductivity, or electromagnetic-resistivity

not suppressed. Not all aspects of this guide may be applicable

logging (hereafter referred as induction logging) of boreholes,

in all circumstances. This ASTM standard is not intended to

wells, access tubes, caissons, or shafts (hereafter referred as

representorreplacethestandardofcarebywhichtheadequacy

boreholes) as commonly applied to geologic, engineering,

of a given professional service must be judged without

groundwater and environmental (hereafter referred as geotech-

consideration of a project’s many unique aspects. The word

nical) investigations. Induction logging for minerals or petro-

standard in the title of this document means that the document

leum applications is excluded.

has been approved through the ASTM consensus process.

1.2 This guide defines an induction log as a record of

1.8 The geotechnical industry uses English or SI units. The

formation electrical conductivity or resistivity with depth as

induction log is typically recorded in millisiemens per meter

measured by the induction method in a borehole.

(mS/m) or millimhos per meter (mmhos/m).

1.2.1 Induction logs are treated quantitatively and should be

1.9 This standard does not purport to address all of the

interpreted with other logs and data whenever possible.

safety concerns, if any, associated with its use. It is the

1.2.2 Induction logs are commonly used to: (1) delineate

responsibility of the user of this standard to establish appro-

lithology; (2) evaluate formation water quality and effective

priate safety and health practices and determine the applica-

porosity, and (3) correlate stratigraphy between boreholes.

bility of regulatory requirements prior to use.

1.3 This guide is restricted to induction measurements that

areatafrequencyoflessthan50KHz;arenon-directional;and

2. Referenced Documents

average formation properties around the circumference of the

2.1 ASTM Standards:

borehole; which are the most common induction measurement

D420 Guide to Site Characterization for Engineering Design

devices used in geotechnical applications.

and Construction Purposes (Withdrawn 2011)

1.4 This guide provides an overview of induction logging

D653 Terminology Relating to Soil, Rock, and Contained

including (1) general procedures; (2) specific documentation;

Fluids

(3 ) calibration and standardization; and (4) log quality and

D5088 Practice for Decontamination of Field Equipment

interpretation.

Used at Waste Sites

1.5 To obtain additional information on induction logs see

D5608 Practices for Decontamination of Field Equipment

References section in this guide.

Used at Low Level Radioactive Waste Sites

D5730 Guide for Site Characterization for Environmental

1.6 This guide is to be used in conjunction with Standard

Purposes With Emphasis on Soil, Rock, the Vadose Zone

Guide D5753.

and Groundwater (Withdrawn 2013)

1.7 This guide offers an organized collection of information

D5753 Guide for Planning and Conducting Borehole Geo-

oraseriesofoptionsanddoesnotrecommendaspecificcourse

physical Logging

of action. This guide should not be used as a sole criterion for

1 2

This guide is under the jurisdiction ofASTM Committee D18 on Soil and Rock For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D18.01 on Surface and Subsurface contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Characterization. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2007. Published August 2007. Originally the ASTM website.

approved in 2001. Last previous edition approved in 2001 as D6727 – 01. DOI: The last approved version of this historical standard is referenced on

10.1520/D6726-01R07. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6726 − 01 (2007)

D6167 Guide for Conducting Borehole Geophysical Log- 5.4 It is essential that personnel (see Section 8.3.2, Guide

ging: Mechanical Caliper D5753) consult up-to-date textbooks and reports on the induc-

D6235 Practice for Expedited Site Characterization of Va- tion technique, application, and interpretation methods.

dose Zone and Groundwater Contamination at Hazardous

Waste Contaminated Sites

6. Interferences

D6274 Guide for Conducting Borehole Geophysical Log-

6.1 Most extraneous effects on induction logs are caused by

ging - Gamma

logging procedures, instrument problems, borehole conditions,

D6429 Guide for Selecting Surface Geophysical Methods

and geologic conditions.

D6431 Guide for Using the Direct Current Resistivity

6.2 Logging procedures include incorrect range setting,

Method for Subsurface Investigation

incorrect calibration, and logging too fast.

3. Terminology 6.3 Instrument problems include electrical leakage and tem-

perature drift.

3.1 Definitions—Definitions shall be in accordance with

6.3.1 Induction probes need to warm up and stabilize with

terms and symbols given in Terminology D653.

the borehole environment. Some probes record internal elec-

3.2 Definitions of Terms Specific to This Standard:

tronic temperature; this temperature record should not be

3.2.1 accuracy—how close a measured log value ap-

confused with a borehole fluid temperature log.

proaches true value. It is determined in a controlled environ-

6.4 Effects of borehole fluid is dependent on probe design,

ment. A controlled environment represents a homogeneous

borehole diameter, and borehole-fluid conductivity. Induction

sample volume with known properties.

measurements can be made in air-, water-, or mud-filled

3.2.2 depth of investigation—the radial distance from the

boreholes.Inductionprobesaredesignedtominimizeeffectsof

measurement point to a point where the predominant measured

borehole fluid. Conductivity of borehole fluid will significantly

response may be considered centered, which is not to be

affect induction response only in larger diameter boreholes

confused with borehole depth (for example, distance) mea-

(typically, greater than 8 to 10 in. (20 to 25 cm) diameter).

sured from the surface.

6.4.1 Effects of mud-invasion zone is dependent on probe

3.2.3 measurement resolution—the minimum change in

design, invasion depth, and mud and formation conductivity.

measured value that can be detected.

6.4.2 Steel or other conductive material interferes and may

prohibit induction measurements. PVC casing and other non-

3.2.4 repeatability—the difference in magnitude of two

conductive casing does not affect induction response. Clay

measurements with the same equipment and in the same

seals and sand/gravel packs may affect induction response in

environment.

largerdiameterboreholes(typically,greaterthan8to10in.(20

3.2.5 vertical resolution—the minimum thickness that can

to 25 cm) diameter).

be separated into distinct units.

6.5 Geologic Conditions:

3.2.6 volume of investigation—the volume that contributes

6.5.1 In high-conductivity formations and groundwater, the

90 percent of the measured response. It is determined by a

electrical conductivity measured by induction is less than the

combination of theoretical and empirical modeling. The vol-

true electrical conductivity due to skin effects. Some probes

ume of investigation is non-spherical and has gradational

correct for skin effect assuming a homogeneous medium.

boundaries.

6.5.2 In steeply dipping formations (greater than 60

degrees), electrical anisotropy affects apparent bed thickness

4. Summary of Guide

andlocationofbedcontactsandcorrectionsneedtobeapplied.

4.1 This guide applies to induction logging and is to be use

6.6 Theoretical and empirical tool response curves and

in conjunction with Guide D5753.

inversion algorithms may be applied to correct for many

4.2 This guide briefly describes the significance and use,

interferences.

apparatus, calibration and standardization, procedures and

reports for conducting induction logging.

7. Apparatus

7.1 Ageophysical logging system has been described in the

5. Significance and Use

general guide (Section 6, Guide D5753).

5.1 An appropriately developed, documented, and executed

7.2 Induction logs are collected with probes that have

guide is essential for the proper collection and application of

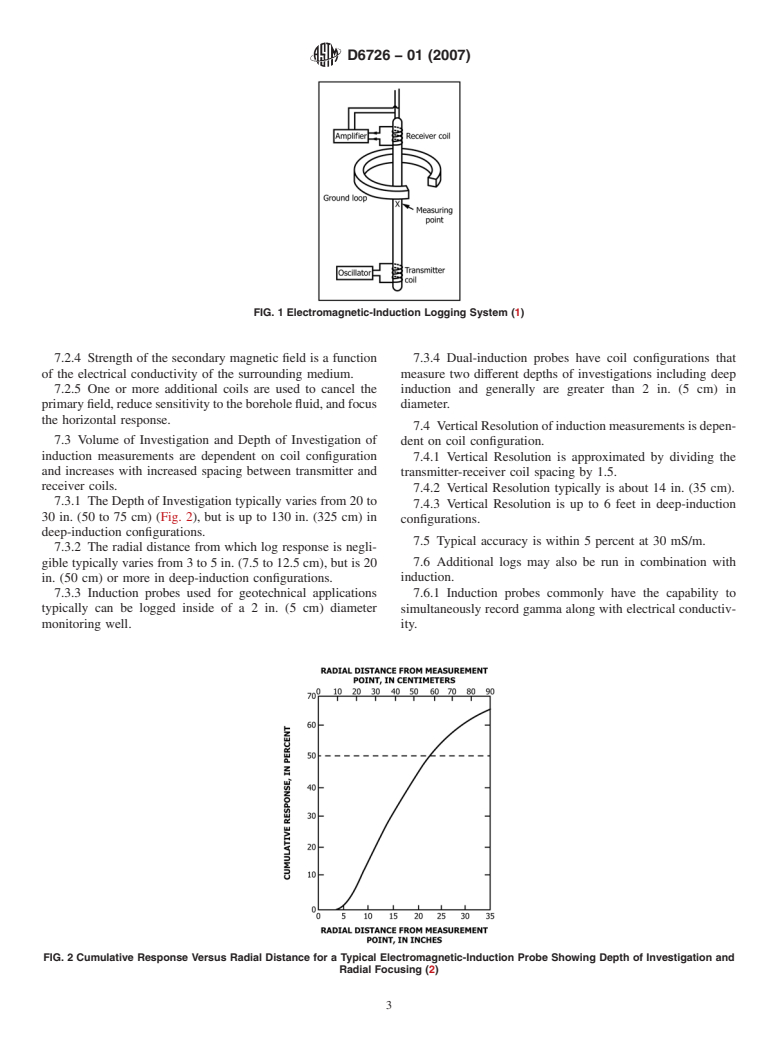

electromagnetic transmitter and receiver coils (Fig. 1).

induction logs. This guide is to be used in conjunction with

7.2.1 Transmitter and receiver coils typically are spaced

Guide D5753.

about 20 in. (50 cm) apart. In deep-induction configurations,

5.2 The benefits of its use include improving: selection of

coils are spaced at about 40 in (1 m) apart.

induction logging methods and equipment; induction log

7.2.2 The transmitter coil emits an electromagnetic signal in

quality and reliability; and usefulness of the induction log data

the range of 20 to 40 KHz that induces eddy currents in the

for subsequent display and interpretation.

medium surrounding the borehole.

5.3 This guide applies to commonly used induction logging 7.2.3 The receiver coil senses the primary and secondary

methods for geotechnical applications. magnetic fields.

D6726 − 01 (2007)

FIG. 1 Electromagnetic-Induction Logging System (1)

7.2.4 Strength of the secondary magnetic field is a function 7.3.4 Dual-induction probes have coil configurations that

of the electrical conductivity of the surrounding medium. measure two different depths of investigations including deep

7.2.5 One or more additional coils are used to cancel the induction and generally are greater than 2 in. (5 cm) in

primaryfield,reducesensitivitytotheboreholefluid,andfocus diameter.

the horizontal response.

7.4 VerticalResolutionofinductionmeasurementsisdepen-

7.3 Volume of Investigation and Depth of Investigation of

dent on coil configuration.

induction measurements are dependent on coil configuration

7.4.1 Vertical Resolution is approximated by dividing the

and increases with increased spacing between transmitter and

transmitter-receiver coil spacing by 1.5.

receiver coils.

7.4.2 Vertical Resolution typically is about 14 in. (35 cm).

7.3.1 The Depth of Investigation typically varies from 20 to

7.4.3 Vertical Resolution is up to 6 feet in deep-induction

30 in. (50 to 75 cm) (Fig. 2), but is up to 130 in. (325 cm) in

configurations.

deep-induction configurations.

7.5 Typical accuracy is within 5 percent at 30 mS/m.

7.3.2 The radial distance from which log response is negli-

7.6 Additional logs may also be run in combination with

gible typically varies from 3 to 5 in. (7.5 to 12.5 cm), but is 20

in. (50 cm) or more in deep-induction configurations. induction.

7.3.3 Induction probes used for geotechnical applications 7.6.1 Induction probes commonly have the capability to

typically can be logged inside of a 2 in. (5 cm) diameter simultaneously record gamma along with electrical conductiv-

monitoring well. ity.

FIG. 2 Cumulative Response Versus Radial Distance for a Typical Electromagnetic-Induction Probe Showing Depth of Investigation and

Radial Focusing (2)

D6726 − 01 (2007)

7.6.2 Induction and gamma logs can be collected in open or 8.2.6 Calibration also can be established in a body of water

boreholes cased with non-conductive materials (PVC, such as a lake with a known electrical conductivity that is large

fiberglass, etc.) that are air, water, or mud filled. enough to be infinite with respect of the Volume of Investiga-

7.6.3 Some induction probes may also record magnetic tion of the probe.

susceptibility simultaneously with the electric conductivity

8.2.7 Calibration should be performed when the probe

measurement. Note induction probes typically are not opti-

temperature is as close to the borehole temperature as possible.

mized for magnetic susceptibility measurements.

This is most readily performed by recalibrating immediately

after logging a borehole.

7.7 Measurement resolution of induction probes is deter-

mined by probe design. Measurement resolution is typically

8.3 Standardization is the process of checking logging

0.01 mS/m.

response to show evidence of repeatability and consistency.

8.3.1 Calibration insures standardization.

7.8 A variety of induction logging equipment available is

8.3.2 Arepresentative borehole may be used to periodically

for geotechnical investigations. It is not practical to list all of

check induction probe response providing the borehole and

the sources of potentially acceptable equipment.

surroundingenvironmentdoesnotchangewithtimeorchanges

and their effects on induction response can be documented.

8. Calibration and Standardization of Electromagnetic-

Induction Logs

9. Procedure

8.1 General:

9.1 See Section 8, Guide D5753 for planning a logging

8.1.1 National Institute of Standards and Technology

program, data formats, personnel qualifications, field

(NIST) calibration and standardization procedures do not exist

documentation, and header documentation.

for induction logging.

9.1.1 Induction specific information (for example, coil

8.1.2 Induction logs can be used in a qualitative (for

example, comparative) or quantitative manner depending upon spacing, transmitter frequency) should be documented.

the project objectives.

9.2 Identify induction-logging objectives.

8.1.3 Induction calibration methods and frequency shall be

9.3 Select appropriate equipment to meet objectives.

sufficient to meet project objectives.

9.3.1 Induction logs are commonly run with gamma logs to

8.1.3.1 Calibrationandstandardizationshouldbeperformed

aid in lithologic and water-quality interpretations. Although

each time an induction probe is suspected to be damaged,

less commonly run, neutron logs also aid interpretations.

modified, repaired, and at periodic intervals.

9.3.2 Combination induction and gamma probes commonly

8.1.3.2 Induction probe calibration is sensitive to the effects

ha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.