ASTM D2386-06(2012)

(Test Method)Standard Test Method for Freezing Point of Aviation Fuels

Standard Test Method for Freezing Point of Aviation Fuels

SIGNIFICANCE AND USE

The freezing point of an aviation fuel is the lowest temperature at which the fuel remains free of solid hydrocarbon crystals that can restrict the flow of fuel through filters if present in the fuel system of the aircraft. The temperature of the fuel in the aircraft tank normally falls during flight depending on aircraft speed, altitude, and flight duration. The freezing point of the fuel must always be lower than the minimum operational tank temperature.

Freezing point is a requirement in Specifications D910 and D1655.

SCOPE

1.1 This test method covers the determination of the temperature below which solid hydrocarbon crystals may form in aviation turbine fuels and aviation gasoline.

Note 1—The interlaboratory program that generated the precisions for this test method did not include aviation gasoline.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 5.4, Section 6, and 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2386 − 06(Reapproved 2012)

Standard Test Method for

Freezing Point of Aviation Fuels

This standard is issued under the fixed designation D2386; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D3117Test Method for Wax Appearance Point of Distillate

Fuels (Withdrawn 2010)

1.1 This test method covers the determination of the tem-

D4057Practice for Manual Sampling of Petroleum and

perature below which solid hydrocarbon crystals may form in

Petroleum Products

aviation turbine fuels and aviation gasoline.

D4177Practice for Automatic Sampling of Petroleum and

NOTE 1—The interlaboratory program that generated the precisions for

Petroleum Products

this test method did not include aviation gasoline.

E1Specification for ASTM Liquid-in-Glass Thermometers

1.2 The values stated in SI units are to be regarded as

E77Test Method for Inspection and Verification of Ther-

standard. No other units of measurement are included in this

mometers

standard.

2.2 Energy Institute Standard:

1.3 WARNING—Mercury has been designated by many

IP Standards for Petroleum and Its Products, Part 1

regulatory agencies as a hazardous material that can cause

central nervous system, kidney and liver damage. Mercury, or 3. Terminology

its vapor, may be hazardous to health and corrosive to

3.1 Definitions of Terms Specific to This Standard:

materials.Cautionshouldbetakenwhenhandlingmercuryand

3.1.1 freezing point, n—in aviation fuels, the fuel tempera-

mercury containing products. See the applicable product Ma-

ture at which solid hydrocarbon crystals, formed on cooling,

terial Safety Data Sheet (MSDS) for details and EPA’s

disappear when the temperature of the fuel is allowed to rise

website—http://www.epa.gov/mercury/faq.htm—for addi-

under specified conditions of test.

tional information. Users should be aware that selling mercury

and/or mercury containing products into your state or country

4. Significance and Use

may be prohibited by law.

4.1 The freezing point of an aviation fuel is the lowest

1.4 This standard does not purport to address all of the

temperature at which the fuel remains free of solid hydrocar-

safety concerns, if any, associated with its use. It is the

bon crystals that can restrict the flow of fuel through filters if

responsibility of the user of this standard to establish appro-

presentinthefuelsystemoftheaircraft.Thetemperatureofthe

priate safety and health practices and determine the applica-

fuel in the aircraft tank normally falls during flight depending

bility of regulatory limitations prior to use. For specific

on aircraft speed, altitude, and flight duration. The freezing

warning statements, see 5.4, Section 6, and 8.2.

point of the fuel must always be lower than the minimum

operational tank temperature.

2. Referenced Documents

4.2 Freezing point is a requirement in Specifications D910

2.1 ASTM Standards:

and D1655.

D910Specification for Leaded Aviation Gasolines

D1655Specification for Aviation Turbine Fuels

5. Apparatus

5.1 Jacketed Sample Tube—A double-walled, unsilvered

vessel, similar to a Dewar flask, the space between the inner

This test method is under the jurisdiction of ASTM Committee D02 on

and outer tube walls being filled at atmospheric pressure with

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.07 on Flow Properties. dry nitrogen or air. The mouth of the sample tube shall be

Current edition approved April 15, 2012. Published April 2012. Originally

approved in 1965. Last previous edition approved in 2006 as D2386–06. DOI:

10.1520/D2386-06R12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K., http://www.energyinst.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2386 − 06 (2012)

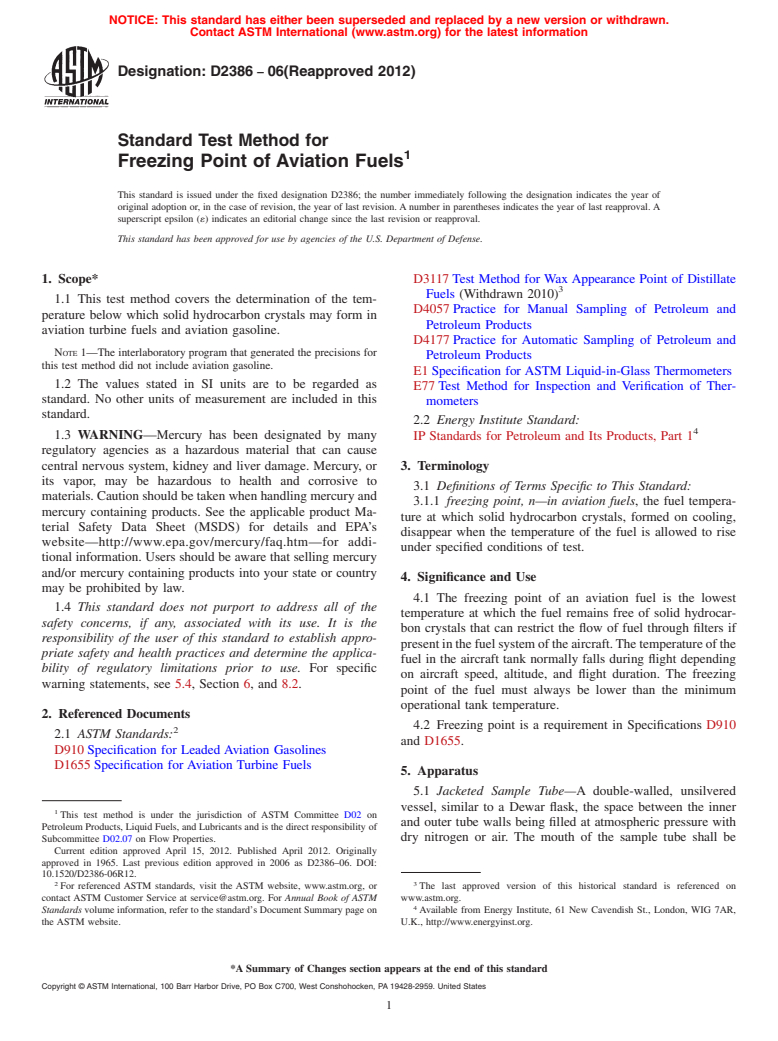

closed with a stopper supporting the thermometer and 6. Reagents and Materials

moisture-proof collar through which the stirrer passes (Fig. 1).

6.1 Acetone—Technical Grade acetone is suitable for the

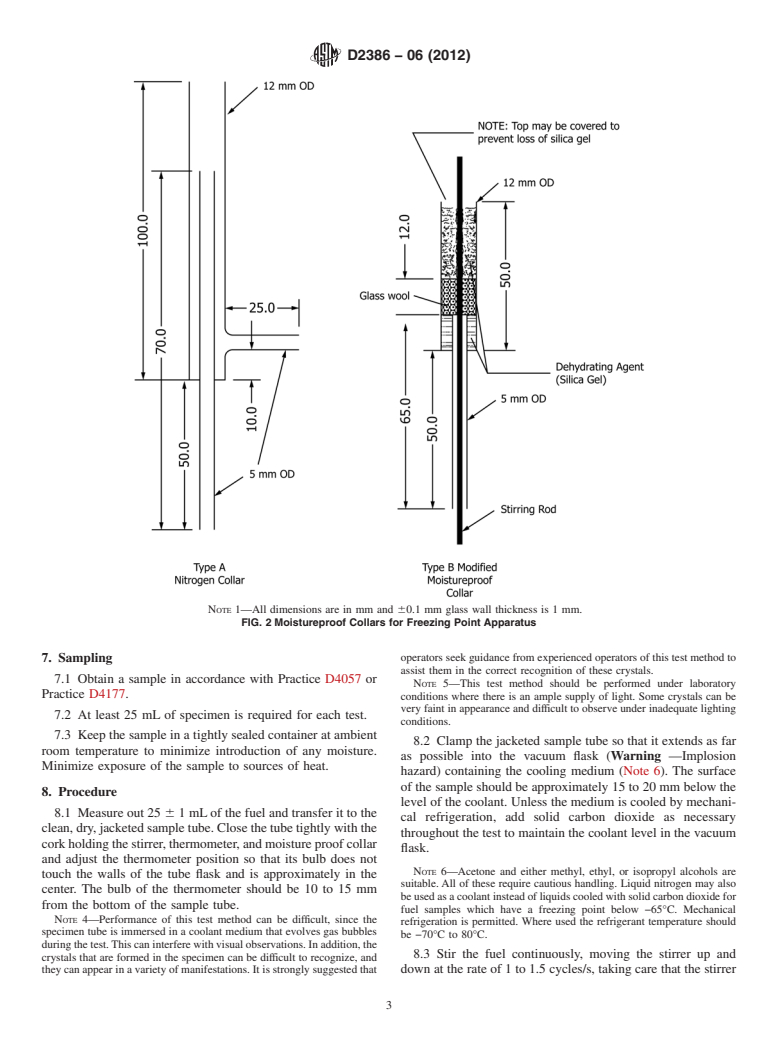

5.2 Collars—Moisture-proofcollarsasshowninFig.2shall

cooling bath, provided it does not leave a residue on drying.

be used to prevent condensation of moisture.

(Warning—Extremely flammable.)

5.3 Stirrer—Shall be made of 1.6-mm brass rod bent into a

6.2 Ethanol or Ethyl Alcohol—A commercial or technical

smooth three-loop spiral at the bottom.

grade of dry ethanol is suitable for the cooling bath.

NOTE 2—The stirrer may be mechanically actuated as described in the

(Warning—Extremely flammable.)

apparatus section of Test Method D3117.

6.3 Isopropyl Alcohol—Acommercial or technical grade of

5.4 Vacuum Flask—An unsilvered vacuum flask

dry isopropyl alcohol is suitable. (Warning—Extremely flam-

(Warning—Implosion hazard) having the minimum dimen-

mable.)

sionsshowninFig.1shallbeusedtoholdanadequatevolume

of cooling liquid and permit the necessary depth of immersion

6.4 Methanol or Methyl Alcohol—A commercial or techni-

of the jacketed sample tube.

cal grade of dry methanol is suitable for the cooling bath.

5.5 Thermometer—A total immersion type, having a range (Warning—Extremely flammable and toxic.)

from −80 to +20°C, designated as ASTM No. 114C/IP No.

6.5 Carbon Dioxide (Solid) or Dry Ice—A commercial

14C. (See Specification E1, or Appendix A, IP Standard

grade of dry ice is suitable for use in the cooling bath.

Thermometers, Volume 2, IP Standard Methods for Analysis

(Warning—Extremely cold, −78°C. Carbon dioxide (solid)

and Testing of Petroleum and Related Products.)

liberates gases that can cause suffocation. Contact with skin

NOTE 3—The accuracy of this thermometer is to be checked in

causes burns, freezing, or both.)

accordance with Test Method E77, at temperatures of 0, −40, −60, and

−75°C.

6.6 Liquid Nitrogen—A commercial or technical grade of

liquid nitrogen is suitable for the cooling bath when the

freezing point is lower than −65°C. (Warning—Extremely

5 cold, −196°C. Liquid nitrogen liberates gases that can cause

The U.S. National Bureau of Standards, Gaithersburg, MD, and the British

NationalPhysicalLaboratory,Teddington,Englandareabletocertifythermometers

suffocation. Contact with skin causes burns, freezing, or both.)

at these temperatures.

FIG. 1 Freezing Point Apparatus

D2386 − 06 (2012)

NOTE 1—All dimensions are in mm and 60.1 mm glass wall thickness is 1 mm.

FIG. 2 Moistureproof Collars for Freezing Point Apparatus

operators seek guidance from experienced operators of this test method to

7. Sampling

assist them in the correct recognition of these crystals.

7.1 Obtain a sample in accordance with Practice D4057 or

NOTE 5—This test method should be performed under laboratory

Practice D4177.

conditions where there is an ample supply of light. Some crystals can be

very faint in appearance and difficult to observe under inadequate lighting

7.2 At least 25 mL of specimen is required for each test.

conditions.

7.3 Keep the sample in a tightly sealed container at ambient

8.2 Clam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.