ASTM C1767-12

(Specification)Standard Specification for Stainless Steel Jacketing for Insulation

Standard Specification for Stainless Steel Jacketing for Insulation

ABSTRACT

This specification covers stainless steel jacketing for thermal, acoustical, and fire protective insulation operating at either above or below ambient temperatures and in both indoor and outdoor locations. It does not cover insulation jacketing made from other materials such as mastics, fiber reinforced plastic, PVC, aluminum, or coated carbon steel (for example, aluminum-zinc, galvanized steel, or aluminized steel) nor does it cover the details of thermal, acoustical, or fire protective insulation systems. While not intended to cover use inside the containment buildings of nuclear power plants, this specification does not preclude use of Class E material which does not have a moisture barrier in this containment building application. This specification provides physical requirements for stainless steel jacketing for thermal and acoustical insulation.

SCOPE

1.1 This specification covers stainless steel jacketing for thermal, acoustical, and fire protective insulation operating at either above or below ambient temperatures and in both indoor and outdoor locations. It does not cover insulation jacketing made from other materials such as mastics, fiber reinforced plastic, PVC, aluminum, or coated carbon steel (for example, aluminum-zinc, galvanized steel, or aluminized steel) nor does it cover the details of thermal, acoustical, or fire protective insulation systems.

1.2 While not intended to cover use inside the containment buildings of nuclear power plants, this standard does not preclude use of Class E material which does not have a moisture barrier in this containment building application.

1.3 This specification provides physical requirements for stainless steel jacketing for thermal and acoustical insulation. Guide C1423 provides guidance in selecting jacketing materials and their safe use.

1.4 This is a material specification and does not imply any performance of the installed system using the materials specified herein. For information about installation of stainless steel jacketing, see (1).2

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1767 −12

StandardSpecification for

Stainless Steel Jacketing for Insulation

This standard is issued under the fixed designation C1767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers stainless steel jacketing for

A167 Specification for Stainless and Heat-Resisting

thermal, acoustical, and fire protective insulation operating at

Chromium-Nickel Steel Plate, Sheet, and Strip

either above or below ambient temperatures and in both indoor

A240/A240M Specification for Chromium and Chromium-

and outdoor locations. It does not cover insulation jacketing

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

made from other materials such as mastics, fiber reinforced

Vessels and for General Applications

plastic, PVC, aluminum, or coated carbon steel (for example,

A480/A480M Specification for General Requirements for

aluminum-zinc, galvanized steel, or aluminized steel) nor does

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

it cover the details of thermal, acoustical, or fire protective

Sheet, and Strip

insulation systems.

C168 Terminology Relating to Thermal Insulation

1.2 While not intended to cover use inside the containment

C450 Practice for Fabrication of Thermal Insulating Fitting

buildings of nuclear power plants, this standard does not

Covers for NPS Piping, and Vessel Lagging

preclude use of Class E material which does not have a

C585 Practice for Inner and Outer Diameters of Thermal

moisture barrier in this containment building application.

Insulation for Nominal Sizes of Pipe and Tubing

1.3 This specification provides physical requirements for

C835 Test Method for Total Hemispherical Emittance of

stainless steel jacketing for thermal and acoustical insulation.

Surfaces up to 1400°C

Guide C1423 provides guidance in selecting jacketing materi-

C1371 Test Method for Determination of Emittance of

als and their safe use.

Materials Near Room Temperature Using Portable Emis-

someters

1.4 This is a material specification and does not imply any

C1423 Guide for Selecting Jacketing Materials for Thermal

performance of the installed system using the materials speci-

Insulation

fied herein. For information about installation of stainless steel

C1729 Specification for Aluminum Jacketing for Insulation

jacketing, see (1).

E84 Test Method for Surface Burning Characteristics of

1.5 The values stated in inch-pound units are to be regarded

Building Materials

as standard. The values given in parentheses are mathematical

F1249 Test Method for Water Vapor Transmission Rate

conversions to SI units that are provided for information only

Through Plastic Film and Sheeting Using a Modulated

and are not considered standard.

Infrared Sensor

1.6 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Definitions—Definitions in Terminology C168 apply to

priate safety and health practices and determine the applica- terms used in this specification.

bility of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 box rib—stainless steel sheet formed to have alternat-

ing parallel grooves and ridges with a cross section approxi-

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

mating a square wave.

Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

Systems.

Current edition approved Oct. 15, 2012. Published December 2012. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1767-12. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1767−12

3.2.2 cladding (as related to insulation jacketing)— 3.2.12.1 Discussion—A splice roll occurs when the metal

synonymous with jacketing. coil being used to form the roll jacketing reaches its end before

3.2.2.1 Discussion—The three terms “jacketing”, “lagging”, the required roll length is obtained.

and “cladding” are considered synonymous in most applica-

3.2.13 split roll—synonymous with splice roll.

tions and geographies. However, in some cases in the power

3.2.14 surface finish (as related to insulation jacketing)—

industry in North America the term “lagging” has a different

the final texture of the stainless steel jacketing surface.

meaning than “jacketing” or “cladding” and refers specifically

to a heavier gauge of jacketing.

4. Significance and Use

3.2.3 crevice corrosion—a type of corrosion occurring on

4.1 Thisspecificationisusedtospecifymaterialbyphysical

metal jacketing caused by differences in oxygen concentration

propertyrequirementsthataddresstheprerequisitesinSections

in the electrolyte in adjacent regions of the material.

6to10.Thedesignerofaninsulationsystem,afterdetermining

3.2.3.1 Discussion—These differences lead to a concentra-

the system requirements, shall use this specification to specify

tion cell and the oxygen starved region on the metal jacketing

the appropriate stainless steel jacketing.

is subject to corrosion.

5. Classification

3.2.4 cross crimped—synonymous with ⁄16 in. corrugated.

5.1 Classification of stainless steel jacketing is based on

3.2.5 deep corrugated—stainless steel sheet formed to have

three factors:

alternating parallel grooves and ridges with a cross section

5.1.1 Outer Surface Treatment and Emittance (ε):

approximating a sine wave.

5.1.1.1 Type I = Bare surface, ε = 0.3

3.2.6 gore—jacketing for elbows, fittings, or other non-

5.1.2 Alloy and Temper per Specification A240/A240M:

straightportionsofthepipingsystemmadefromamultitudeof

5.1.2.1 Grade 1 = Alloy T-304/T-304L, annealed temper

similar overlapping pieces.

5.1.2.2 Grade 2 = Alloy T-316/T-316L, annealed temper

3.2.7 lagging (as related to insulation jacketing)—

NOTE 1—The “L” in the alloy is an indication of low carbon content.

synonymous with jacketing.

Since the low carbon alloy will avoid corrosion problems caused by

3.2.7.1 Discussion—The three terms “jacketing”, “lagging”,

welding, a low carbon alloy is required on those rare occasions when the

and “cladding” are considered synonymous in most applica- stainless steel jacketing will be subjected to direct welding or the heat

from welding nearby metal. The low carbon and standard alloys are

tions and geographies. However, in some cases in the power

considered interchangeable for use as insulation jacketing.

industry in North America the term “lagging” has a different

5.1.3 Moisture Retarder:

meaning than “jacketing” or “cladding” and refers specifically

5.1.3.1 Class A = polysurlyn, 3 mil thick

to a heavier gauge of jacketing.

5.1.3.2 Class C = polykraft per section 3.2.10

3.2.8 mill finish—the appearance of the stainless steel sur-

5.1.3.3 ClassE=no moisture retarder

face as supplied from the metal mill.

NOTE 2—ClassesB&Dare omitted to maintain consistency with the

3.2.9 moisture retarder (moister barrier)—a layer of plastic

similar standard for aluminum jacketing, Specification C1729.

film or other material applied to the inner side of metal

jacketing to inhibit jacket corrosion by interfering with the

6. Materials and Manufacture

formation of a galvanic cell between the dissimilar metals of

6.1 Stainless steel jacketing materials are composed of a

the pipe and jacket or by preventing crevice corrosion.

single material or a lamination of several components. The

3.2.9.1 Discussion—Amoisture retarder is not an insulation

materials are supplied in the form of rolls or sheets or

system water vapor retarder and does not perform the same

preformedtofitthesurfacetowhichtheyaretobeapplied.The

function.

materials are applied in the field or as a factory-applied

3.2.10 polykraft—a multilayer composite film used as a

composite with the insulation.

moisture retarder on metal jacketing consisting of at least one

6.2 Material shall be stainless steel with a mill finish of

layer of minimum 40 lb Kraft paper and one or more layers of

either 2B or 2D per Specification A240/A240M unless an

plastic film, usually polyethylene at a minimum thickness of

alternative finish is agreed to by both buyer and seller.

1.5 mils.

6.3 Material shall be stainless steel and shall have a surface

3.2.10.1 Discussion—Kraft paper is commonly referred to

finish that is smooth, ⁄16 in. corrugated, or stucco embossed.

by its basis weight which is the mass per area in units of

The dimensions of corrugations (pitch and depth) must be

lbs/3000 ft . In Metric units, this mass per area is called the

agreed to by manufacturer and purchaser to achieve

grammage and is in units of g/m . 40 lb Kraft has a basis

2 2

interchangeability, constant rigidity, and appearance.

weight of 40 lbs/3000 ft and a grammage of 65 g/m .

6.4 In most cases, the inner surface of stainless steel

3.2.11 polysurlyn—a multilayer film used as a moisture

retarder on metal jacketing consisting of at least one layer of jacketing material is coated or covered with a moisture

resistant film to retard possible galvanic or chemical corrosion,

ethylene/methacrylicacidcopolymerandoneormorelayersof

other polymers, usually polyethylene. or both, of the jacketing and underlying pipe or equipment.

3.2.12 splice roll—metal jacketing sold in roll form where 6.5 The stainless steel used in this jacketing shall comply

the package contains two separate pieces of metal jacketing with the general, chemical composition, and mechanical prop-

rolled approximately end to end. erty requirements of Specification A240/A240M—alloys

C1767−12

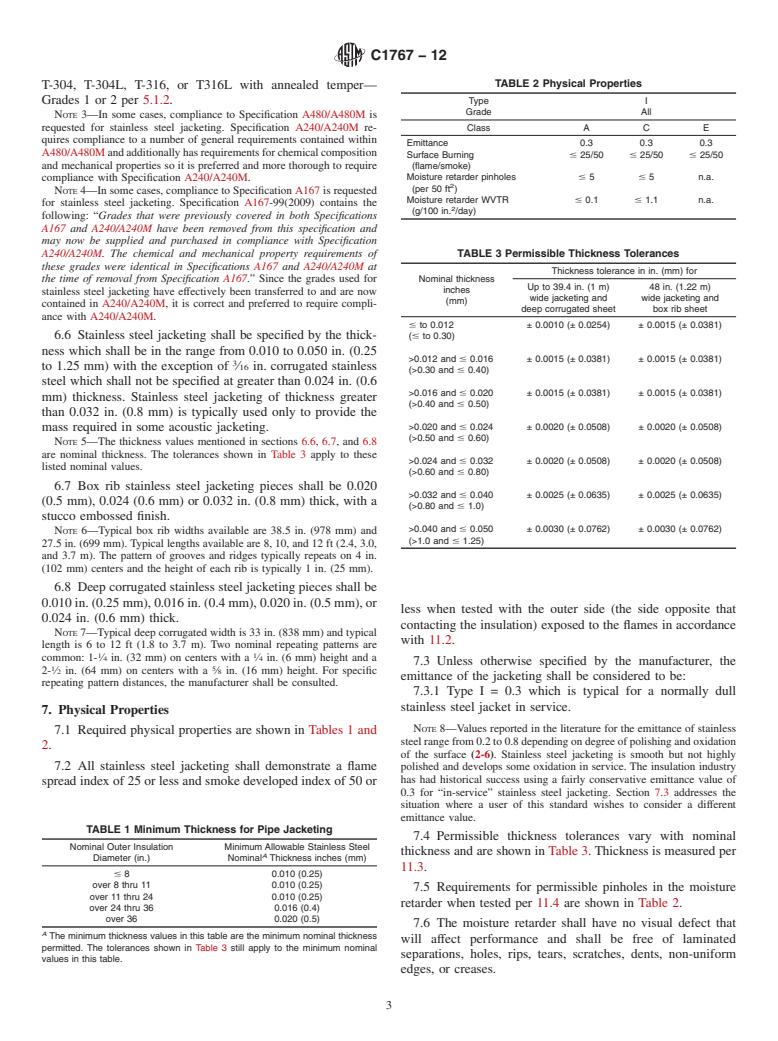

TABLE 2 Physical Properties

T-304, T-304L, T-316, or T316L with annealed temper—

Grades 1 or 2 per 5.1.2. Type I

Grade All

NOTE 3—In some cases, compliance to Specification A480/A480M is

requested for stainless steel jacketing. Specification A240/A240M re- Class A C E

quires compliance to a number of general requirements contained within

Emittance 0.3 0.3 0.3

A480/A480Mandadditionallyhasrequirementsforchemicalcomposition

Surface Burning # 25/50 # 25/50 # 25/50

and mechanical properties so it is preferred and more thorough to require

(flame/smoke)

Moisture retarder pinholes # 5 # 5 n.a.

compliance with Specification A240/A240M.

(per 50 ft )

NOTE 4—In some cases, compliance to Specification A167 is requested

Moisture retarder WVTR # 0.1 # 1.1 n.a.

for stainless steel jacketing. Specification A167-99(2009) contains the

(g/100 in. /day)

following: “Grades that were previously covered in both Specifications

A167 and A240/A240M have been removed from this specification and

may now be supplied and purchased in compliance with Specification

A240/A240M. The chemical and mechanical property requirements of TABLE 3 Permissible Thickness Tolerances

these grades were identical in Specifications A167 and A240/A240M at

Thickness tolerance in in. (mm) for

Nominal thickness

the time of removal from Specification A167.” Since the grades used for

Up to 39.4 in. (1 m) 48 in. (1.22 m)

inches

stainless steel jacketing have effectively been transferred to and are now

wide jacketing and wide jacketing and

(mm)

contained in A240/A240M, it is correct and preferred to require compli-

deep corrugated sheet box rib sheet

ance with A240/A240M.

# to 0.012 ± 0.0010 (± 0.0254) ± 0.0015 (± 0.0381)

6.6 Stainless steel jacketing shall be specified by the thick- (# to 0.30)

ness which shall be in the range from 0.010 to 0.050 in. (0.25

>0.012 and# 0.016 ± 0.0015 (± 0.0381) ± 0.0015 (± 0.0381)

to 1.25 mm) with the exception of ⁄16 in. corrugated stainless

(>0.30 and# 0.40)

steel which shall not be specified at greater than 0.024 in. (0.6

>0.016 and# 0.020 ± 0.0015 (± 0.0381) ± 0.0015 (± 0.0381)

mm) thickness. Stainless steel jacketing of thickness greater

(>0.40 and# 0.50)

than 0.032 in. (0.8 mm) is typically used only to provide the

>0.020 and# 0.024 ± 0.0020 (± 0.0508) ± 0.0020 (± 0.0508)

mass required in some acoustic jacketing.

(>0.50 and# 0.60)

NOTE 5—The thickness values mentioned in sections 6.6, 6.7, and 6.8

are nominal thickness. The tolerances shown in Table 3 apply to these

>0.024 and# 0.032 ± 0.0020 (± 0.0508) ± 0.0020 (± 0.0508)

listed nominal values.

(>0.60 and# 0.80)

6.7 Box rib stainless steel jacketing pieces shall be 0.020

>0.032 and# 0.040 ± 0.0025 (± 0.0635) ± 0.0025 (± 0.0635)

(0.5 mm), 0.024 (0.6 mm) or 0.032 in. (0.8 mm) thick, with a

(>0.80 and# 1.0)

stucco embossed finish.

>0.040 and# 0.050 ± 0.0030 (± 0.0762) ± 0.0030 (± 0.0762)

NOTE 6—Typical box rib widths available are 38.5 in. (978 mm) and

(>1.0 and# 1.25)

27.5 in. (699 mm). Typical lengths available are 8, 10, and 12 ft (2.4, 3.0,

and 3.7 m). The pattern of grooves and ridges typically repeats on 4 in.

(102 mm) centers and the height of each rib is typically 1 in. (25 mm).

6.8 Deep corrugated stainless steel jacketing pieces shall be

0.010in.(0.25mm),0.016in.(0.4mm),0.020in.(0.5mm),or

less when tested with the outer side (the side opposite that

0.024 in. (0.6 mm) thick.

contacting the insulation) exposed to the flames in accordance

NOTE 7—Typical deep corrugated width is 33 in. (838 mm) and typical

with 11.2.

length is 6 to 12 ft (1.8 to 3.7 m). Two nominal repeating patterns are

1 1

common: 1- ⁄4 in. (32 mm) on centers with a ⁄4 in. (6 mm) height and a

7.3 Unless otherwise specified by the manufacturer, the

1 5

2- ⁄2 in. (64 mm) on centers with a ⁄8 in. (16 mm) height. For specific

emittance of the jacketing shall be considered to be:

repeating pattern distances, the manufacturer shall be consulted.

7.3.1 Type I = 0.3 which is typical for a normally dull

stainless steel jacket in service.

7. Physical Properties

NOTE 8—Values reported in the literature for the emittance of stainless

7.1 Required physical properties are shown in Tables 1 and

steelrangefrom0.2to0.8dependingondegreeofpolishingandoxidation

2.

of the surface (2-6). Stainless steel jacketing is smooth but not highly

7.2 All stainless steel jacketing shall demonstrate a flame polished and develops some oxidation in service. The insulation industry

has had historical success using a fairly conservative emittance value of

spread index of 25 or less and smoke developed index of 50 or

0.3 for “in-service” stainless steel jacketing. Section

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.