ASTM B601-01

(Classification)Standard Classification for Temper Designations for Copper and Copper Alloys-Wrought and Cast

Standard Classification for Temper Designations for Copper and Copper Alloys-Wrought and Cast

SCOPE

1.1 This is a classification of temper designations for copper and copper alloys-wrought and cast. The temper designations are classified by the process or processes used in manufacturing the product involved and its resulting qualities. It is not a specification of copper and copper alloy products.

1.2 The property requirements for the tempers are given in the applicable product specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 601 – 01

Standard Classification for

Temper Designations for Copper and Copper Alloys—

1

Wrought and Cast

This standard is issued under the fixed designation B 601; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

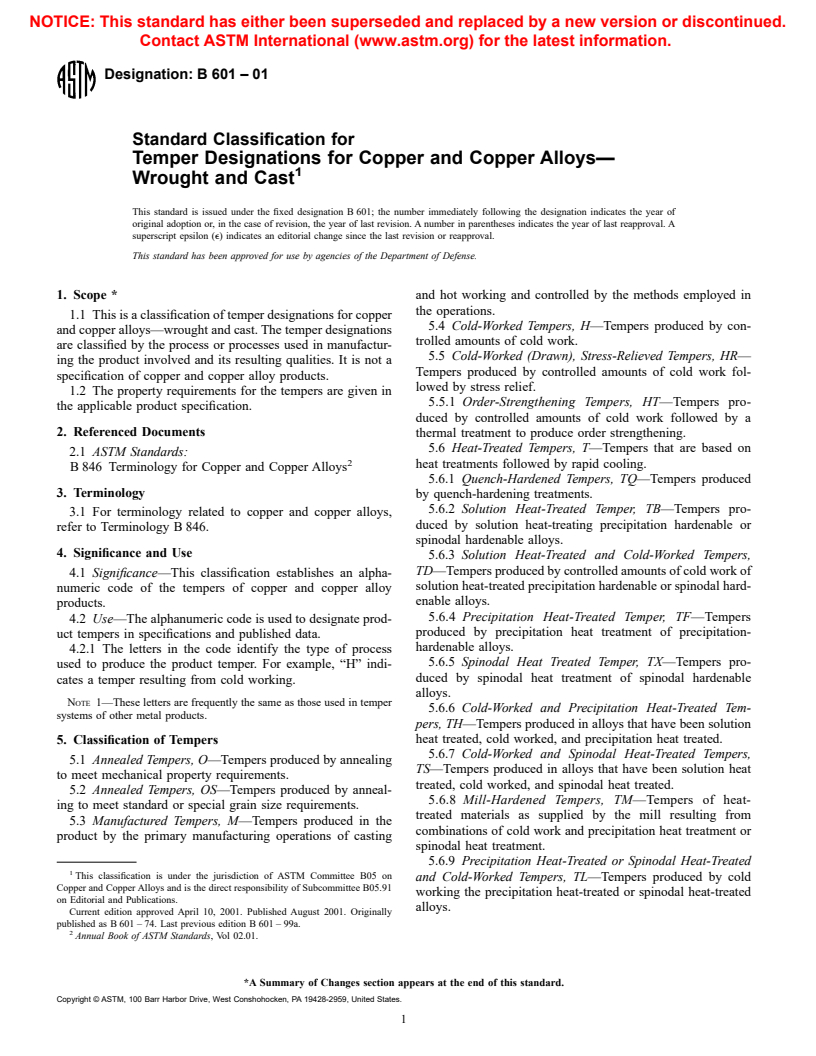

1. Scope * and hot working and controlled by the methods employed in

the operations.

1.1 This is a classification of temper designations for copper

5.4 Cold-Worked Tempers, H—Tempers produced by con-

and copper alloys—wrought and cast. The temper designations

trolled amounts of cold work.

are classified by the process or processes used in manufactur-

5.5 Cold-Worked (Drawn), Stress-Relieved Tempers, HR—

ing the product involved and its resulting qualities. It is not a

Tempers produced by controlled amounts of cold work fol-

specification of copper and copper alloy products.

lowed by stress relief.

1.2 The property requirements for the tempers are given in

5.5.1 Order-Strengthening Tempers, HT—Tempers pro-

the applicable product specification.

duced by controlled amounts of cold work followed by a

2. Referenced Documents thermal treatment to produce order strengthening.

5.6 Heat-Treated Tempers, T—Tempers that are based on

2.1 ASTM Standards:

2

heat treatments followed by rapid cooling.

B 846 Terminology for Copper and Copper Alloys

5.6.1 Quench-Hardened Tempers, TQ—Tempers produced

3. Terminology

by quench-hardening treatments.

5.6.2 Solution Heat-Treated Temper, TB—Tempers pro-

3.1 For terminology related to copper and copper alloys,

duced by solution heat-treating precipitation hardenable or

refer to Terminology B 846.

spinodal hardenable alloys.

4. Significance and Use

5.6.3 Solution Heat-Treated and Cold-Worked Tempers,

TD—Tempers produced by controlled amounts of cold work of

4.1 Significance—This classification establishes an alpha-

solution heat-treated precipitation hardenable or spinodal hard-

numeric code of the tempers of copper and copper alloy

enable alloys.

products.

5.6.4 Precipitation Heat-Treated Temper, TF—Tempers

4.2 Use—The alphanumeric code is used to designate prod-

produced by precipitation heat treatment of precipitation-

uct tempers in specifications and published data.

hardenable alloys.

4.2.1 The letters in the code identify the type of process

5.6.5 Spinodal Heat Treated Temper, TX—Tempers pro-

used to produce the product temper. For example, “H” indi-

duced by spinodal heat treatment of spinodal hardenable

cates a temper resulting from cold working.

alloys.

NOTE 1—These letters are frequently the same as those used in temper

5.6.6 Cold-Worked and Precipitation Heat-Treated Tem-

systems of other metal products.

pers, TH—Tempers produced in alloys that have been solution

heat treated, cold worked, and precipitation heat treated.

5. Classification of Tempers

5.6.7 Cold-Worked and Spinodal Heat-Treated Tempers,

5.1 Annealed Tempers, O—Tempers produced by annealing

TS—Tempers produced in alloys that have been solution heat

to meet mechanical property requirements.

treated, cold worked, and spinodal heat treated.

5.2 Annealed Tempers, OS—Tempers produced by anneal-

5.6.8 Mill-Hardened Tempers, TM—Tempers of heat-

ing to meet standard or special grain size requirements.

treated materials as supplied by the mill resulting from

5.3 Manufactured Tempers, M—Tempers produced in the

combinations of cold work and precipitation heat treatment or

product by the primary manufacturing operations of casting

spinodal heat treatment.

5.6.9 Precipitation Heat-Treated or Spinodal Heat-Treated

1

This classification is under the jurisdiction of ASTM Committee B05 on

and Cold-Worked Tempers, TL—Tempers produced by cold

Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.91

working the precipitation heat-treated or spinodal heat-treated

on Editorial and Publications.

alloys.

Current edition approved April 10, 2001. Published August 2001. Originally

published as B 601 – 74. Last previous edition B 601 – 99a.

2

Annual Book of ASTM Standards, Vol 02.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 601

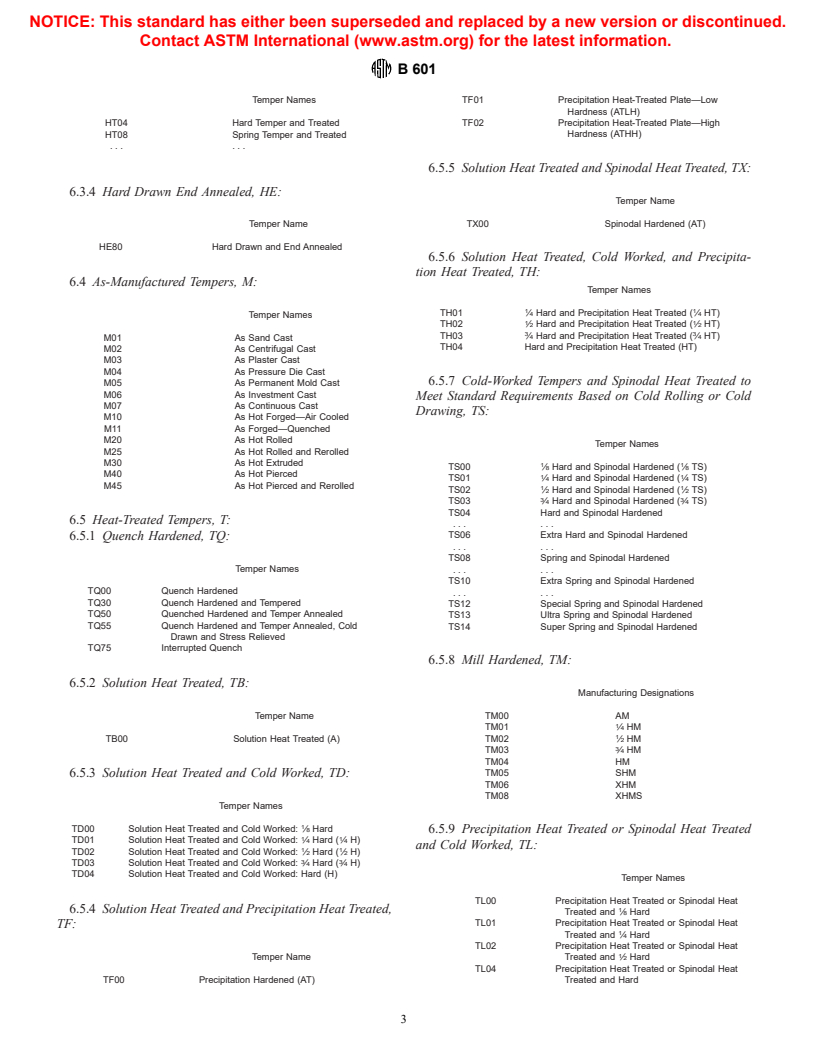

5.6.10 Precipitation Heat-Treated or Spinodal Heat-

OS150 0.150

OS200 0.200

Treated, Cold-Worked, and Thermal Stress-Relieved Tempers,

TR—Temp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.