ASTM B601-99A

(Classification)Standard Classification for Temper Designations for Copper and Copper Alloys-Wrought and Cast

Standard Classification for Temper Designations for Copper and Copper Alloys-Wrought and Cast

SCOPE

1.1 This is a classification of temper designations for copper and copper alloys-wrought and cast. The temper designations are classified by the process or processes used in manufacturing the product involved and its resulting qualities. It is not a specification of copper and copper alloy products.

1.2 The property requirements for the tempers are given in the applicable product specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 601 – 99a

Standard Practice for

Temper Designations for Copper and Copper Alloys—

Wrought and Cast

This standard is issued under the fixed designation B 601; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope a product resulting from thermal or mechanical processing

treatments.

1.1 This practice defines the terminology in general use for

2.2 Basic Processes Used to Produce the Different Tem-

indicating the temper of copper and copper alloy products. The

pers:

designations used in ASTM specifications under the jurisdic-

2.2.1 anneal (annealing)—a thermal treatment to change

tion of Committee B-5 will conform to this practice.

the properties or grain structure of the product.

1.2 It defines the terminology of the processes that produce

2.2.1.1 When applied to a cold-worked product having a

the tempers and the observable changes in the product that

single phase; to produce softening by recrystallization or

result from the processes.

recrystallization and grain growth, with the accompanying

1.3 It establishes an alphanumeric code for use in designat-

changes in properties.

ing the product tempers.

2.2.1.2 When applied to a product having two or more

1.3.1 The letters in the code identify the type of process

phases: to produce softening by changes in phase relationships

used to produce the product temper. For example, “H” indi-

which may include recrystallization and grain growth.

cates a temper resulting from cold working. These letters are

2.2.2 cold work—controlled mechanical operations for

frequently the same as those used in temper systems of other

changing the form or cross section of a product and for

metals, and are applied to copper products in accordance with

producing a strain-hardened product at temperatures below the

this practice.

recrystallization temperature.

1.3.2 The numbers in the code were chosen subjectively for

2.2.3 drawn stress relieved (DSR)—a thermal treatment of a

general tempers, and objectively to indicate grain size for

cold-drawn product to reduce residual stress variations, thus

annealed tempers or reductions for cold-worked tempers.

reducing susceptibility of product to stress corrosion or season

1.4 The use of this code is recommended for all product

cracking, without significantly affecting its tensile strength or

tempers in specifications and published data. Its use will

microstructure.

simplify the presentation of property data when in tabular

2.2.4 hot working—controlled mechanical operations for

form.

shaping a product at temperatures above the recrystallization

1.5 The property requirements for the tempers are given in

temperature.

applicable product specifications.

2.2.5 order strengthening—a thermal treatment of a cold-

1.6 Where the word “product” is used, it means a copper or

worked product at a temperature below its recrystallization

copper alloy product.

temperature causing ordering to occur to obtain an increase in

1.7 This standard does not purport to address all of the

yield strength.

safety concerns, if any, associated with its use. It is the

2.2.6 precipitation heat treatment—a thermal treatment of a

responsibility of the user of this standard to establish appro-

solution heat-treated product to produce property changes such

priate safety and health practices and determine the applica-

as hardening, strengthening, and conductivity increase by

bility of regulatory limitations prior to use.

precipitation of constituents from the supersaturated solid

2. Terminology

solution. This treatment has also been called “age hardened”

and “precipitation hardened.”

2.1 Definitions:

2.2.7 quench hardening—a treatment for copper-aluminum

2.1.1 temper—the metallurgical structure and properties of

alloy products consisting of heating above the betatizing

temperature followed by quenching to produce a hard marten-

This practice is under the jurisdiction of ASTM Committee B05 on Copper and

sitic structure.

Copper Alloys and is the direct responsibility of Subcommittee B05.91 on Editorial

2.2.8 solution heat treatment—a thermal treatment of a

and Publications.

product to put alloying elements into solution in the base metal

Current edition approved Sept. 10, 1999. Published January 2000. Originally

published as B 601 – 74. Last previous edition B 601 – 99. by heating into the temperature range of solid solubility,

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 601

followed by cooling at a sufficient rate to retain them in a produced by precipitation heat treatment of precipitation-

supersaturated solid solution. hardenable alloys.

2.2.9 spinodal heat treatment—a thermal treatment of a 3.6.5 Spinodal Heat Treated Temper, TX—Tempers pro-

solution heat-treated product to produce property changes such duced by spinodal heat treatment of spinodal hardenable

as hardening, strengthening, and conductivity increase by alloys.

spinodal decomposition of a solid solution. This treatment has 3.6.6 Cold-Worked and Precipitation Heat-Treated Tem-

also been called “age hardened,” “spinodal hardened,” or pers, TH—Tempers produced in alloys that have been solution

“spinodally decomposed.” heat treated, cold worked, and precipitation heat treated.

2.2.10 strain hardening—the increase in strength and hard- 3.6.7 Cold-Worked and Spinodal Heat-Treated Tempers,

ness and decrease in ductility as a result of permanent TS—Tempers produced in alloys that have been solution heat

deformation of the structure by cold working. treated, cold worked, and spinodal heat treated.

2.2.11 stress relief—a treatment of a product to reduce 3.6.8 Mill-Hardened Tempers, TM—Tempers of heat-

residual stresses. treated materials as supplied by the mill resulting from

2.2.11.1 by thermal treatment—without causing recrystalli- combinations of cold work and precipitation heat treatment or

zation. spinodal heat treatment.

2.2.11.2 by mechanical treatment—without causing a sig- 3.6.9 Precipitation Heat-Treated or Spinodal Heat-Treated

nificant change in size. and Cold-Worked Tempers, TL—Tempers produced by cold

2.2.12 temper annealing—a thermal treatment above the working the precipitation heat-treated or spinodal heat-treated

eutectoid temperature for copper-aluminum alloy products to alloys.

minimize the presence of the stable eutectoid structure. 3.6.10 Precipitation Heat-Treated or Spinodal Heat-

2.2.13 tempering—a thermal treatment of a quench- Treated, Cold-Worked, and Thermal Stress-Relieved Tempers,

hardened product to improve ductility. TR—Tempers produced in the cold-worked precipitation heat-

2.2.14 thermal treatment—a controlled heating; time at treated or spinodal heat-treated alloys by thermal stress relief.

maximum temperature-cooling cycle as needed to satisfy the 3.7 Tempers of Welded Tubes, W—(Welded tubes are pro-

property and grain structure requirements of the temper. duced from strip of various tempers and essentially have the

temper of the strip except in the heat-affected zone.)

3. Classification of Tempers

3.7.1 Tube, As-Welded Tempers, WM—Tempers that result

from forming and welding when producing tube.

NOTE 1—In the following paragraphs, tempers are classified according

to terminology used by U.S. manufacturers of copper and copper alloy

3.7.2 Tube, Welded and Annealed Temper, WO—Temper

products and are arranged in alphabetical order with their designated code

that results from forming, welding, and annealing when pro-

letters.

ducing tube.

3.1 Annealed Tempers, O—Tempers produced by annealing

3.7.3 Tube, Welded and Cold-Worked Tempers, WH—

to meet mechanical property requirements.

Tempers that result from forming, welding, and cold working

3.2 Annealed Tempers, OS—Tempers produced by anneal-

when producing tube.

ing to meet standard or special grain size requirements.

3.7.4 Tube, Welded, Cold-Worked and Stress-Relieved Tem-

3.3 Manufactured Tempers, M—Tempers produced in the

pers, WR—Tempers that result from forming, welding, cold

product by the primary manufacturing operations of casting

working, and stress relieving when producing tube.

and hot working and controlled by the methods employed in

3.7.5 Tube, Welded, and Fully Finished Tempers, O, OS,

the operations.

H—Tempers that result from both annealing a welded and

3.4 Cold-Worked Tempers, H—Tempers produced by con-

cold-worked tube, or cold working, a welded cold-worked and

trolled amounts of cold work.

annealed tube. With these treatments, the weld area has been

3.5 Cold-Worked (Drawn), Stress-Relieved Tempers, HR—

transformed into a wrought structure, and the usual temper

Tempers produced by controlled amounts of cold work fol-

designations apply.

lowed by stress relief.

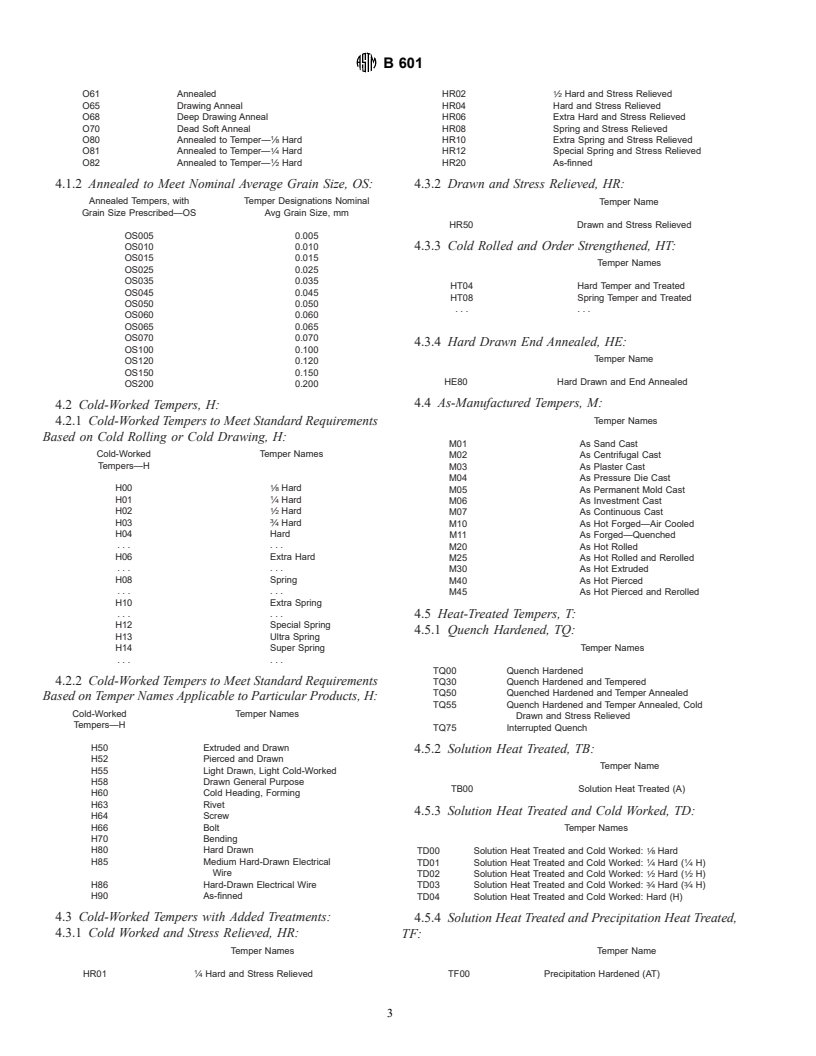

4. Temper Designation Codes

3.5.1 Order-Strengthening Tempers, HT—Tempers pro-

duced by controlled amounts of cold work followed by a

NOTE 2—Also shown are regular temper terms that are being retained

thermal treatment to produce order strengthening.

for an indefinite period.

3.6 Heat-Treated Tempers, T—Tempers that are based on

4.1 Annealed Tempers, O:

heat treatments followed by rapid cooling.

4.1.1 Annealed to Meet Mechanical Properties, O:

3.6.1 Quench-Hardened Tempers, TQ—Tempers produced

Annealed Temper Names

by quench-hardening treatments.

Tempers—O

3.6.2 Solution Heat-Treated Temper, TB—Tempers pro-

O10 Cast and Annealed (Homogenized)

duced by solution heat-treating precip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.