ASTM D7862-13

(Specification)Standard Specification for Butanol for Blending with Gasoline for Use as Automotive Spark-Ignition Engine Fuel

Standard Specification for Butanol for Blending with Gasoline for Use as Automotive Spark-Ignition Engine Fuel

ABSTRACT

This specification covers butanol intended to be blended with gasoline at 1 to 12.5 volume % for use as an automotive spark-ignition engine fuel. It addresses performance requirements, workmanship, sampling, containers, sample handling, and test methods.

SIGNIFICANCE AND USE

A1.5. Significance and Use

A1.5.1 Butanol is a potential blendstock for blending with gasoline provided that it meets a purity specification of >96.0 % butanol in accordance with Specification D7862. This test method provides a method of determining the percentage of butanol (purity) of the butanol for blending with gasoline.

SCOPE

1.1 This specification covers butanol intended to be blended with gasoline at 1 to 12.5 volume % for use as an automotive spark-ignition engine fuel.

1.1.1 Butanol contains 22 mass % oxygen. The mass % of oxygen of a butanol blend with gasoline depends on the volume % of butanol blended, the density of the butanol isomer and the density of the base blendstock.

1.1.2 The maximum limit on blending is not a performance limit but a current regulatory limit in the United States.

1.2 This specification covers three butanol isomers:1-butanol, 2-butanol, and 2-methyl-1-propanol. This specification specifically excludes 2-methyl-2-propanol (that is, tert-butyl alcohol).

1.2.1 Tert-butyl alcohol has different physical properties (melting point, water miscibility) than the other three isomers.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7862 −13

StandardSpecification for

Butanol for Blending with Gasoline for Use as Automotive

Spark-Ignition Engine Fuel

This standard is issued under the fixed designation D7862; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1613 Test Method for Acidity in Volatile Solvents and

Chemical Intermediates Used in Paint, Varnish, Lacquer,

1.1 This specification covers butanol intended to be blended

and Related Products

with gasoline at 1 to 12.5 volume % for use as an automotive

D2622 Test Method for Sulfur in Petroleum Products by

spark-ignition engine fuel.

Wavelength Dispersive X-ray Fluorescence Spectrometry

1.1.1 Butanol contains 22 mass % oxygen. The mass % of

D3120 Test Method for Trace Quantities of Sulfur in Light

oxygen of a butanol blend with gasoline depends on the

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

volume%ofbutanolblended,thedensityofthebutanolisomer

lometry

and the density of the base blendstock.

D4052 Test Method for Density, Relative Density, and API

1.1.2 The maximum limit on blending is not a performance

Gravity of Liquids by Digital Density Meter

limit but a current regulatory limit in the United States.

D4057 Practice for Manual Sampling of Petroleum and

1.2 This specification covers three butanol isomers:1-

Petroleum Products

butanol, 2-butanol, and 2-methyl-1-propanol. This specifica-

D4175 Terminology Relating to Petroleum, Petroleum

tion specifically excludes 2-methyl-2-propanol (that is, tert-

Products, and Lubricants

butyl alcohol).

D4177 Practice for Automatic Sampling of Petroleum and

1.2.1 Tert-butyl alcohol has different physical properties

Petroleum Products

(melting point, water miscibility) than the other three isomers.

D4306 Practice for Aviation Fuel Sample Containers for

Tests Affected by Trace Contamination

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this D4814 Specification for Automotive Spark-Ignition Engine

Fuel

standard.

D5453 Test Method for Determination of Total Sulfur in

1.4 This standard does not purport to address all of the

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel

safety concerns, if any, associated with its use. It is the

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

responsibility of the user of this standard to establish appro-

D5854 Practice for Mixing and Handling of Liquid Samples

priate safety and health practices and determine the applica-

of Petroleum and Petroleum Products

bility of regulatory limitations prior to use.

D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

2. Referenced Documents

Measurement System Performance

2.1 ASTM Standards:

D7319 Test Method for Determination of Existent and Po-

D381 Test Method for Gum Content in Fuels by Jet Evapo-

tential Sulfate and Inorganic Chloride in Fuel Ethanol by

ration

Direct Injection Suppressed Ion Chromatography

D1298 Test Method for Density, Relative Density, or API

E29 Practice for Using Significant Digits in Test Data to

Gravity of Crude Petroleum and Liquid Petroleum Prod-

Determine Conformance with Specifications

ucts by Hydrometer Method

E203 Test Method for Water Using Volumetric Karl Fischer

Titration

E300 Practice for Sampling Industrial Chemicals

This specification is under the jurisdiction of ASTM Committee D02 on

E1064 Test Method for Water in Organic Liquids by Coulo-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

metric Karl Fischer Titration

D02.A0 on Gasoline and Oxygenated Fuels.

Current edition approved June 15, 2013. Published August 2013. DOI: 10.1520/

D7862-13.

3. Terminology

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1 For general terminology, refer to Terminology D4175.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 1—The user is advised that the definitions used by various

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7862−13

industries, marketers, and regulatory bodies can differ from those specific

5.2 The product shall be free of any adulterant or contami-

to this specification. It is the responsibility of the user to ensure that the

nant that can render the material unacceptable for its com-

terms used in a particular context are clearly understood.

monly used applications.

3.2 Definitions:

5.2.1 Manufacturers and importers of butanol shall avoid

3.2.1 gasoline, n—a volatile mixture of liquid

butanol contaminated by silicon-containing materials. Silicon

hydrocarbons, generally containing small amounts of

contamination of gasoline-oxygenate blends has led to fouled

additives, suitable for use as a fuel in spark-ignition, internal

vehicle components (for example, spark plugs, exhaust oxygen

combustion engines. D4814

sensors, catalytic converters) requiring parts replacement and

3.2.2 oxygenate, n—an oxygen-containing, ashless, organic repairs.

compound, such as an alcohol or ether, which may be used as 5.2.2 Manufacturers and importers of butanol shall avoid

a fuel or fuel supplement. D4814

butanol contaminated by acetone. Acetone contamination of

gasoline-oxygenate blends can degrade elastomers used in fuel

3.3 Definitions of Terms Specific to This Standard:

system components as well as paint and/or clearcoat finishes

3.3.1 butanol, n—butanol or butyl alcohol refers to

used on vehicles.

1-butanol, 2-butanol, and 2-methyl 1-propanol, three isomeric

alcohols with the molecular formula C H OH, either individu-

4 9

6. Sampling, Containers, and Sample Handling

ally or as mixtures.

6.1 The user is strongly advised to review all intended test

4. Performance Requirements

methods prior to sampling to understand the importance and

4.1 Butanol—Butanol shall conform to the requirements

effects of sampling technique, proper containers, and special

shown in Table 1 at the time of blending with a gasoline. (See

handling required for each test method.

Note 2.)

6.2 Correct sampling procedures are critical to obtain a

NOTE 2—Commercial processes used to manufacture butanol from

sample representative of the lot intended to be tested. Use

biological feedstock typically yield some fusel oil or alcohols such as

appropriate procedures in Practice D4057 or Practice E300 for

pentanol and other higher alcohols.

manual method sampling and in Practice D4177 for automatic

4.1.1 For purposes of determining conformance with these

method sampling, as applicable.

specification limits, an observed value or a calculated value

6.3 The correct sample volume and appropriate container

shall be rounded “to the nearest unit” in the right-most

selection are important decisions that can impact test results.

significant digit used in expressing the specification limit, in

Refer to Practice D4306 for aviation fuel container selection

accordance with the rounding method of Practice E29. For a

for tests sensitive to trace contamination. Refer to Practice

specification limit expressed as an integer, a trailing zero is

D5854 for procedures on container selection and sample

significantonlyifthedecimalpointisspecified.Foraspecified

mixing and handling. All sampling and storage containers

limit expressed as an integer, and the right-most digit is

should be evaluated for durability and contamination of buta-

non-zero, the right-most digit is significant without a decimal

nol prior to use. Butanol may be sampled in glass containers;

point being specified. This convention applies to specified

however sodium leaching from glass containers has been

limits in Table 1 and will not be observed in the remainder of

shown to interfere with sulfate analysis. HDPE (high density

this specification.

polyethylene)containersmaybeusedinplaceofglasstoavoid

4.2 Other Properties—Limits more restrictive than those

sodium leaching. If samples must be collected in metal

specified above, or the specification of additional properties

containers,donotusesolderedmetalcontainers.Solderingflux

suchascolor,maybeagreeduponbetweenthesupplierandthe

in the containers and lead in the solder can contaminate the

purchaser.

sample.

5. Workmanship 6.4 Sample Size—A minimum of about 1 L or 1 U.S. qt is

recommended.

5.1 The butanol shall be visually free of sediment and

suspended matter. It shall be clear and bright at the ambient 6.5 Lot Size—A lot shall normally consist of the amount

temperature or 21°C, whichever is higher. contained in a tanker compartment or other bulk container in

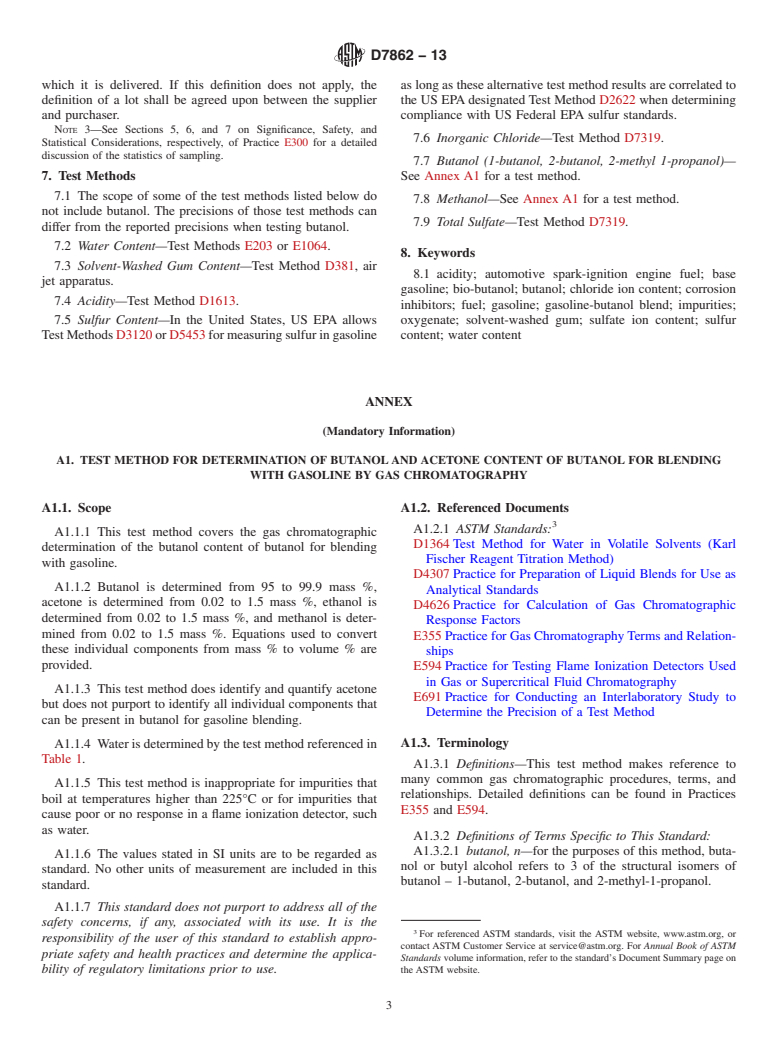

TABLE 1 Requirements

Property Limit Method

Butanol, volume %, min 96.0 Annex A1

1-butanol, volume % Report Annex A1

2-butanol, volume % Report Annex A1

2-methyl 1-propanol, volume % Report Annex A1

Methanol, volume % max 0.4 Annex A1

Water content, volume %, max 1.0 E203 or E1064

Acidity (as acetic acid CH COOH), mass % (mg/L), max 0.007 (56) D1613

Inorganic Chloride, mg/kg (mg/L), max 8 (6) D7319

Solvent-washed gum, mg/100 mL, max 5.0 D381

Sulfur, mg/kg, max 30. D2622, D5453

Existent sulfate, mg/kg, max 4. D7319

D7862−13

which it is delivered. If this definition does not apply, the as long as these alternative test method results are correlated to

definition of a lot shall be agreed upon between the supplier the US EPAdesignated Test Method D2622 when determining

and purchaser. compliance with US Federal EPA sulfur standards.

NOTE 3—See Sections 5, 6, and 7 on Significance, Safety, and

7.6 Inorganic Chloride—Test Method D7319.

Statistical Considerations, respectively, of Practice E300 for a detailed

discussion of the statistics of sampling.

7.7 Butanol (1-butanol, 2-butanol, 2-methyl 1-propanol)—

7. Test Methods See Annex A1 for a test method.

7.1 The scope of some of the test methods listed below do

7.8 Methanol—See Annex A1 for a test method.

not include butanol. The precisions of those test methods can

7.9 Total Sulfate—Test Method D7319.

differ from the reported precisions when testing butanol.

7.2 Water Content—Test Methods E203 or E1064.

8. Keywords

7.3 Solvent-Washed Gum Content—Test Method D381, air

8.1 acidity; automotive spark-ignition engine fuel; base

jet apparatus.

gasoline; bio-butanol; butanol; chloride ion content; corrosion

7.4 Acidity—Test Method D1613.

inhibitors; fuel; gasoline; gasoline-butanol blend; impurities;

7.5 Sulfur Content—In the United States, US EPA allows oxygenate; solvent-washed gum; sulfate ion content; sulfur

TestMethodsD3120orD5453formeasuringsulfuringasoline content; water content

ANNEX

(Mandatory Information)

A1. TEST METHOD FOR DETERMINATION OF BUTANOL AND ACETONE CONTENT OF BUTANOL FOR BLENDING

WITH GASOLINE BY GAS CHROMATOGRAPHY

A1.1. Scope A1.2. Referenced Documents

A1.2.1 ASTM Standards:

A1.1.1 This test method covers the gas chromatographic

D1364 Test Method for Water in Volatile Solvents (Karl

determination of the butanol content of butanol for blending

Fischer Reagent Titration Method)

with gasoline.

D4307 Practice for Preparation of Liquid Blends for Use as

A1.1.2 Butanol is determined from 95 to 99.9 mass %,

Analytical Standards

acetone is determined from 0.02 to 1.5 mass %, ethanol is

D4626 Practice for Calculation of Gas Chromatographic

determined from 0.02 to 1.5 mass %, and methanol is deter-

Response Factors

mined from 0.02 to 1.5 mass %. Equations used to convert

E355 Practice for Gas ChromatographyTerms and Relation-

these individual components from mass % to volume % are

ships

provided.

E594 Practice for Testing Flame Ionization Detectors Used

in Gas or Supercritical Fluid Chromatography

A1.1.3 This test method does identify and quantify acetone

E691 Practice for Conducting an Interlaboratory Study to

but does not purport to identify all individual components that

Determine the Precision of a Test Method

can be present in butanol for gasoline blending.

A1.3. Terminology

A1.1.4 Waterisdeterminedbythetestmethodreferencedin

Table 1.

A1.3.1 Definitions—This test method makes reference to

many common gas chromatographic procedures, terms, and

A1.1.5 This test method is inappropriate for impurities that

relationships. Detailed definitions can be found in Practices

boil at temperatures higher than 225°C or for impurities that

E355 and E594.

cause poor or no response in a flame ionization detector, such

as water.

A1.3.2 Definitions of Terms Specific to This Standard:

A1.3.2.1 butanol, n—for the purposes of this method, buta-

A1.1.6 The values stated in SI units are to be regarded as

nol or butyl alcohol refers to 3 of the structural isomers of

standard. No other units of measurement are included in this

butanol – 1-butanol, 2-butanol, and 2-methyl-1-propanol.

standard.

A1.1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of the user of this standard to establish appro-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

priate safety and health practices and determine the applica-

Standards volume information, refer to the standard’s Document Summary page on

bility of regulatory limitations prior to use. the ASTM website.

D7862−13

A1.3.2.1.1 Discussion—Thismethodhasnotbeenevaluated noted that inadequate splitter design, poor injection technique,

for use with the butanol isomer 2-methyl-2-propanol. and overloading the column can result in poor resolution.

Avoid overloading, particularly of the butanol peak(s), and

A1.4. Summary of Test Method

eliminate this condition during analysis.

A1.4.1 A representative aliquot of the butanol sample is

A1.6.3 Column,Thistestmethodutilizesafusedsilicaopen

introduced into a gas chromatograph equipped with a polydim-

tubular column with non-polar polydimethylsiloxane bonded

ethylsiloxane bonded phase capillary column. Helium carrier

(cross-linked)phaseinternalcoating.Anycolumnwithequiva-

gas transports the vaporized aliquot through the column where

lent or better chromatographic efficiency and selectivity to

the components are separated by the chromatographic process.

those described in A1.6.3.1 may be used.

Components are sensed by a flame ionization detector as they

A1.6.3.1 Open tubular column with a non-polar polydim-

elute from the column. The detector signal is processed by an

ethylsiloxane bonded (cross-linked) p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.