ASTM B809-95(2008)

(Test Method)Standard Test Method for Porosity in Metallic Coatings by Humid Sulfur Vapor ("Flowers-of-Sulfur")

Standard Test Method for Porosity in Metallic Coatings by Humid Sulfur Vapor ("Flowers-of-Sulfur")

SIGNIFICANCE AND USE

A major use of this test procedure is for determining coating quality. Porosity tests are indications of the completeness of protection or coverage offered by the coatings, since the coatings described in 1.2 are intended to be protective when properly applied. The porosity test results are therefore a measure of the deposition process control.

A particular purpose of the humid sulfur vapor test is for determining the quality of underplates of nickel or nickel alloy in those finish systems that have thin, 1.2 μm or less (50 μin. or less) top layers above the nickel, since porosity in the underplate usually continues into such top layers.

The humid sulfur vapor test is often used as an environmental test to simulate many indoor humid atmosphere tarnishing and tarnish creepage effects. However, the chemistry and properties of these tarnish films may not resemble those found in other service environments. For such product performance evaluations, the test should only be used in combination with other performance evaluation tests, as specified in the referencing document for that product.

Porosity tests differ from corrosion and aging tests, since the latter are intended to measure the chemical inertness of the coating. In contrast, in a good porosity test procedure the corrosive agent should not attack the coating. It must instead, clean, depolarize, or activate the substrate metal exposed by the pore, or both, and attack it sufficiently to cause reaction products to fill the pore to the surface of the coating.

The humid sulfur test is highly sensitive, and is capable of detecting virtually all porosity that penetrates down to copper or copper alloys. Since nickel is not attacked by moist sulfur vapor at 100°C or less, this test will not detect pores or cracks in the top coating if such pores or cracks do not penetrate through the nickel underplate overlaying the copper.

The level of porosity in the coating that may be tolerable depends on the severity of th...

SCOPE

1.1 This standard covers equipment and test methods for determining the porosity of metallic coatings, where the pores penetrate down to a silver, copper, or copper-alloy substrate.

1.2 This test method is suitable for coatings consisting of single or combined layers of any coating that does not significantly tarnish in a reduced sulfur atmosphere, such as gold, nickel, tin, tin-lead, and palladium, or their alloys.

1.3 This test method is designed to determine whether the porosity level is less than or greater than some value which by experience is considered by the user to be acceptable for the intended application.

1.4 Recent reviews of porosity testing and testing methods can be found in the literature. , Guide B 765 is suitable to assist in the selection of porosity tests for electrodeposits and related metallic coatings. Other porosity test standards are Test Methods B 735, B 741, B 798, and B 799.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B809 − 95(Reapproved 2008)

Standard Test Method for

Porosity in Metallic Coatings by Humid Sulfur Vapor

(“Flowers-of-Sulfur”)

This standard is issued under the fixed designation B809; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This standard covers equipment and test methods for 2.1 ASTM Standards:

determining the porosity of metallic coatings, where the pores B374Terminology Relating to Electroplating

penetrate down to a silver, copper, or copper-alloy substrate. B542Terminology Relating to Electrical Contacts andTheir

Use

1.2 This test method is suitable for coatings consisting of

B735Test Method for Porosity in Gold Coatings on Metal

single or combined layers of any coating that does not

Substrates by Nitric Acid Vapor

significantly tarnish in a reduced sulfur atmosphere, such as

B741Test Method for Porosity In Gold Coatings On Metal

gold, nickel, tin, tin-lead, and palladium, or their alloys.

Substrates By Paper Electrography (Withdrawn 2005)

1.3 This test method is designed to determine whether the

B765GuideforSelectionofPorosityandGrossDefectTests

porosity level is less than or greater than some value which by

for Electrodeposits and Related Metallic Coatings

experience is considered by the user to be acceptable for the

B798Test Method for Porosity in Gold or Palladium Coat-

intended application.

ings on Metal Substrates by Gel-Bulk Electrography

B799Test Method for Porosity in Gold and Palladium

1.4 Recent reviews of porosity testing and testing methods

2,3

Coatings by Sulfurous Acid/Sulfur-Dioxide Vapor

can be found in the literature. Guide B765 is suitable to

assist in the selection of porosity tests for electrodeposits and

3. Terminology

related metallic coatings. Other porosity test standards areTest

3.1 Definitions—Many terms used in this test method are

Methods B735, B741, B798, and B799.

defined in Terminologies B374 and B542.

1.5 The values stated in SI units are to be regarded as the

3.2 Definitions of Terms Specific to This Standard:

standard. The values given in parentheses are for information

3.2.1 corrosion products—reaction products of the basis

only.

metal or underplate, that protrude from, or are otherwise

1.6 This standard does not purport to address all of the

attached to, the coating surface after the test exposure.

safety concerns, if any, associated with its use. It is the

3.2.2 measurement area—in this test method,thatportionor

responsibility of the user of this standard to establish appro-

portions of the surface that is examined for the presence of

priate safety and health practices and determine the applica-

porosity. The measurement area shall be indicated on the

bilityofregulatorylimitationspriortouse.Forspecifichazards

drawings of the parts, or by the provision of suitably marked

statements, see Section 8.

samples.

3.2.3 metallic coatings—in this test method, include

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic platings, claddings, or other metallic coatings applied to the

and Inorganic Coatingsand is the direct responsibility of Subcommittee B08.10 on

substrate. The coating can comprise a single metallic layer or

Test Methods.

a combination of metallic layers.

Current edition approved Aug. 1, 2008. Published September 2008. Originally

approved in 1990. Last previous edition approved in 2003 as B809–95 (2003).

DOI: 10.1520/B0809-95R08. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Clarke, M., “Porosity and Porosity Tests,” Properties of Electrodeposits, Sard, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Leidheiser, and Ogburn, eds., The Electrochemical Society, 1975, p. 122. Standards volume information, refer to the standard’s Document Summary page on

Krumbein, S. J., “Porosity Testing of Contact Platings,” Transactions of the the ASTM website.

Connectors and Interconnection Technology Symposium, Philadelphia, PA, October The last approved version of this historical standard is referenced on

1987, p. 47. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B809 − 95 (2008)

3.2.4 porosity—the presence of any discontinuity, crack, or tarnishingandtarnishcreepageeffects.However,thechemistry

hole in the coating that exposes a different underlying metal and properties of these tarnish films may not resemble those

(see Guide B765). found in other service environments. For such product perfor-

manceevaluations,thetestshouldonlybeusedincombination

3.2.5 significant surface— of a coated part, is that portion

with other performance evaluation tests, as specified in the

(or portions) of the coating surface that is essential to the

referencing document for that product.

serviceability or function of the part, or which can be the

sourceofcorrosionproductsortarnishfilmsthatinterferewith

5.4 Porositytestsdifferfromcorrosionandagingtests,since

the function of the part. For many plated products, the critical

the latter are intended to measure the chemical inertness of the

surface is identical to the measurement area.

coating. In contrast, in a good porosity test procedure the

corrosive agent should not attack the coating. It must instead,

3.2.6 tarnish—reaction products of copper or silver with

clean,depolarize,oractivatethesubstratemetalexposedbythe

oxygen or reduced sulfur (that is, hydrogen sulfide (H S) and

pore, or both, and attack it sufficiently to cause reaction

elemental sulfur vapor, but not sulfur dioxide (SO ) or other

products to fill the pore to the surface of the coating.

sulfur oxides). They consist of thin films or spots that do not

protrude significantly from the surface of the metallic coating

5.5 The humid sulfur test is highly sensitive, and is capable

(in contrast to corrosion products).

of detecting virtually all porosity that penetrates down to

3.2.7 tarnish creepage—movement of tarnish films across

copper or copper alloys. Since nickel is not attacked by moist

the surface of the coating, the tarnish having originated either

sulfur vapor at 100°C or less, this test will not detect pores or

fromporesorcracksinthecoatingorfromareasofbaresilver,

cracks in the top coating if such pores or cracks do not

copper, or copper alloy near the measurement area (as in a cut

penetrate through the nickel underplate overlaying the copper.

edge).

5.6 Thelevelofporosityinthecoatingthatmaybetolerable

3.2.8 underplate(s)—ametalliccoatinglayer(s)betweenthe

depends on the severity of the environment that the product is

substrate and the topmost layer or layers. The thickness of an

likelytoencounterduringserviceorstorage.Also,thelocation

underplate is usually greater than 1 µm (40 µin.).

of the pores on the surface is important. If the pores are few in

number or away from the significant surfaces, their presence

4. Summary of Test Method

can often be tolerated.

4.1 The test specimens are suspended over “flowers-of-

5.7 The present test method can be used on samples of

sulfur” (powdered sulfur) in a vented container at controlled

variousgeometries,suchascurvedsurfaces.Itcanalsobeused

elevated relative humidity and temperature. Elemental sulfur

for selective area coatings, if allowance is made for tarnish

vapor, which always exists in equilibrium with sulfur power in

creepage from bare copper alloy areas.

a closed system, attacks any exposed silver, copper, or copper

alloy, such as at the bottom of pores. Brown or black tarnish

5.8 This test method is destructive in that it reveals the

spots indicate porosity.

presence of porosity by contaminating the surface with tarnish

films. Any parts exposed to this test method should not be

4.2 Exposure periods may vary, depending on the extent of

placed in service.

porosity to be revealed.

5.9 The relationship of porosity levels revealed by this test

4.3 This test involves tarnish or oxidation (corrosion) reac-

method to product performance and service life must be made

tions in which the products delineate defect sites in coatings.

by the user of the test through practical experience or by

Since the chemistry and properties of these products may not

judgment. Thus, absence of porosity in the coating may be a

resemble those found in natural or service environments, this

requirement for some applications, while a few pores on the

testisnotrecommendedforpredictionofproductperformance

significant surfaces may be acceptable for others.

unless correlation is first established with service experience

(but see 5.3).

6. Apparatus

5. Significance and Use

6.1 TestVessel—Maybeanyconvenient-sizevesselofglass,

5.1 A major use of this test procedure is for determining

acrylic-resin (or of any other material that is not affected by

coating quality. Porosity tests are indications of the complete-

high humidity or sulfur), such as a glass desiccator of 9 to 10

nessofprotectionorcoverageofferedbythecoatings,sincethe

L capacity. It should have a lid or cover capable of being

coatings described in 1.2 are intended to be protective when

plugged with a stopper. The stopper shall havea1to4mm

properly applied. The porosity test results are therefore a

diameter hole through it to serve as a vent.

measure of the deposition process control.

6.2 Sample Fixture or Holders—Supports or hangers shall

5.2 Aparticularpurposeofthehumidsulfurvaportestisfor

be made from material such as glass or acrylic plastic that will

determining the quality of underplates of nickel or nickel alloy

not be affected by sulfur or high humidity, and shall be

inthosefinishsystemsthathavethin,1.2µmorless(50µin.or

arranged so that the samples will be at least 75 mm away from

less) top layers above the nickel, since porosity in the under-

the humidity controlling solution or sulfur powder (see 6.3).

plate usually continues into such top layers.

The samples shall also be at least 25 mm from the vessel walls

5.3 The humid sulfur vapor test is often used as an envi- and at least 10 mm from other samples or other surfaces. Do

ronmental test to simulate many indoor humid atmosphere notuseadesiccatorplate.Thefixtureshallnotcovermorethan

B809 − 95 (2008)

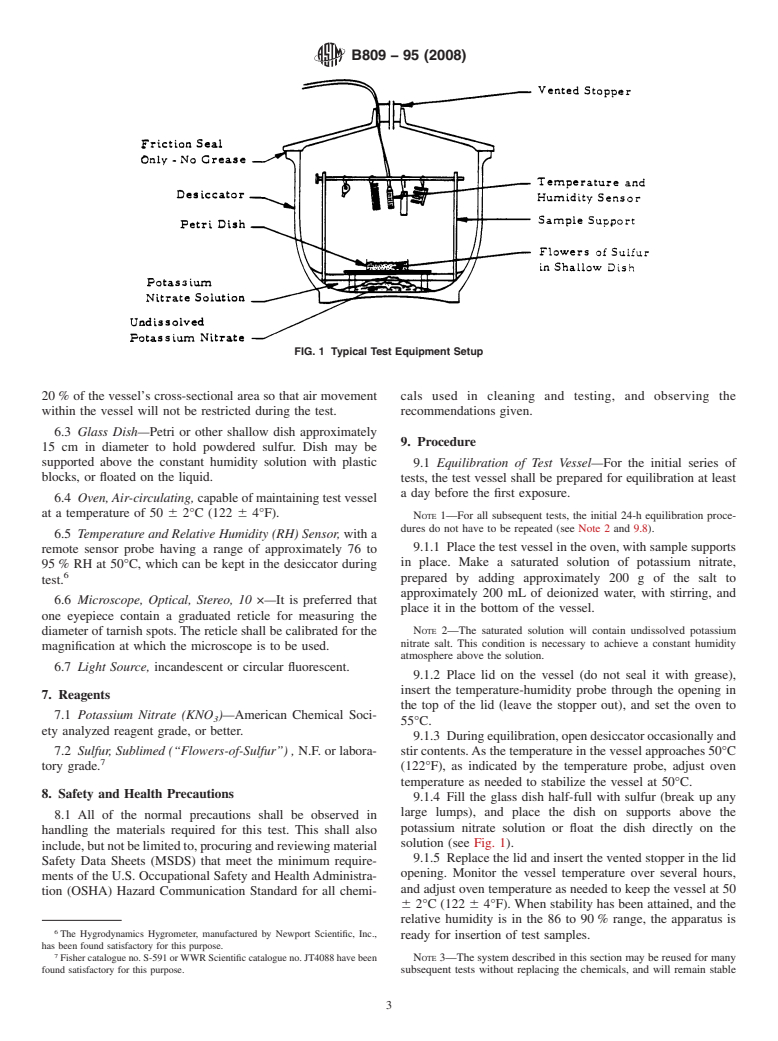

FIG. 1 Typical Test Equipment Setup

20% of the vessel’s cross-sectional area so that air movement cals used in cleaning and testing, and observing the

within the vessel will not be restricted during the test. recommendations given.

6.3 Glass Dish—Petri or other shallow dish approximately

9. Procedure

15 cm in diameter to hold powdered sulfur. Dish may be

supported above the constant humidity solution with plastic 9.1 Equilibration of Test Vessel—For the initial series of

blocks, or floated on the liquid. tests, the test vessel shall be prepared for equilibration at least

a day before the first exposure.

6.4 Oven,Air-circulating,capableofmaintainingtestvessel

at a temperature of 50 6 2°C (122 6 4°F).

NOTE 1—For all subsequent tests, the initial 24-h equilibration proce-

dures do not have to be repeated (see Note 2 and 9.8).

6.5 Temperature and Relative Humidity (RH) Sensor, with a

9.1.1 Placethetestvesselintheoven,withsamplesupports

remote sensor probe having a range of approximately 76 to

in place. Make a saturated solution of potassium nitrate,

95% RH at 50°C, which can be kept in the desiccator during

prepared by adding approximately 200 g of the salt to

test.

approximately 200 mL of deionized water, with stirring, and

6.6 Microscope, Optical, Stereo, 10 ×—It is preferred that

place it in the bottom of the vessel.

one eyepiece contain a graduated reticle for measuring the

diameter of tarnish spots.The reticle shall be calibrated for the NOTE 2—The saturated solution will contain undissolved potassium

nitrate salt. This condition is necessary to achieve a constant humidity

magnification at which the microscope is to be used.

atmosphere above the solution.

6.7 Light Source, incandescent or circular fluorescent.

9.1.2 Place lid on the vessel (do not seal it with grease),

insert the temperature-humidity probe through the opening in

7. Reagents

the top of the lid (leave the stopper out), and set the oven to

7.1 Potassium Nitrate (KNO )—American Chemical Soci-

55°C.

ety analyzed reagent grade, or better.

9.1.3 Duringequilibration,opendesiccatoroccasionallyand

7.2 Sulfur, Sublimed (“Flowers-of-Sulfur”) , N.F. or labora- stircontents.Asthetemperatureinthevesselapproaches50°C

tory grade. (122°F), as indicated by the temperature probe, adjust oven

temperature as needed to stabilize the vessel at 50°C.

8. Safety and Health Precautions

9.1.4 Fill the glass dish half-full with sulfur (break up any

large lumps), and place the dish on supports above the

8.1 All of the normal precautions shall be observed in

potassium nitrate solution or float the dish directly on the

handling the materials required for this test. This shall also

solution (see Fig. 1).

include,butnotbelimitedto,procuringandreviewingmaterial

9.1.5 Replace the lid and insert the vented stopper in the lid

Safety Data Sheets (MSDS) that meet the minimum require-

opening. Monitor the vessel temperature over several hours,

ments of the U.S. Occupational Safety and HealthAdministra-

and adjust oven temperature as needed to keep the vessel at 50

tion (OSHA) Hazard Communication Standard for all chemi-

6 2°C (122 6 4°F). When stability has been attained, and the

relative humidity is in the 86 to 90% range, the apparatus is

The Hygrodynamics Hygrometer, manufactured by Newport Scientific, Inc.,

ready for insertion of test samples.

has been found satisfactory for this purpose.

Fishercatalogueno.S-591orWWRScientificcatalogueno.JT4088havebeen NOTE 3—The system described in this section may be reused for many

found satisfactory for this purpose. subsequent tests without replacing the chemicals, and will remain stable

B809 − 95 (2008)

for up to 6 months as long as the chemicals do not become contaminated

9.3 Place the clean samples in the test vessel, in as quick a

with corrosion products or dirt. If allowed to cool, the potassium nitrate

manner as possible, in order to minimize deviations from

mixture will solidify, but it will liquify again when the vessel is reheated

equilibrium conditions. A clean, unplated copper or copper-

and the solution stirred. Crusts and lumps of hardened potassium nitrate

alloy panel should also be put into the vessel each time a test

should be broken up and stirred into the slurry. Add a few millilitres of

isrunasan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.