ASTM D6111-97

(Test Method)Standard Test Method for Bulk Density and Specific Gravity of Plastic Lumber and Shapes by Displacement

Standard Test Method for Bulk Density and Specific Gravity of Plastic Lumber and Shapes by Displacement

SCOPE

1.1 This test method covers the determination of the bulk density and specific gravity of plastic lumber and shapes in their "as manufactured" form. As such, this is a test method for evaluating the properties of plastic lumber or shapes as a product and not a material property test method.

1.2 This test method is suitable for determining the bulk specific gravity or bulk density by immersion of the entire item or a representative cross section in water. This test method involves the weighing of a one piece specimen in water, using a sinker with plastics that are lighter than water. this test method is suitable for products that are wet by, but otherwise not affected by water for the duration of the test.

1.3 Plastic lumber and plastic shapes are currently made predominately from recycled plastics. However, this test method would also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogenous in the cross-section.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1- There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6111 – 97

Standard Test Method for

Bulk Density And Specific Gravity of Plastic Lumber and

Shapes by Displacement

This standard is issued under the fixed designation D 6111; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 6108 Test Method for Compressive Properties of Plastic

Lumber and Shapes

1.1 This test method covers the determination of the bulk

E 1 Specification for ASTM Thermometers

density and specific gravity of plastic lumber and shapes in

E 12 Terminology Relating to Density and Specific Gravity

their “as manufactured” form. As such, this is a test method for

of Solids, Liquids, and Gases

evaluating the properties of plastic lumber or shapes as a

product and not a material property test method.

3. Terminology

1.2 This test method is suitable for determining the bulk

3.1 Definitions:

specific gravity or bulk density by immersion of the entire item

3.1.1 density, bulk—the weight per unit volume of a mate-

or a representative cross section in water. This test method

rial including voids inherent in material as tested. (See Termi-

involves the weighing of a one piece specimen in water, using

nology D 883.)

a sinker with plastics that are lighter than water. This test

3.1.1.1 Discussion—Specific gravity at 23/23°C can be

method is suitable for products that are wet by, but otherwise

converted to density 23°C, g/cm , as follows:

not affected by water for the duration of the test.

23C 3

1.3 Plastic lumber and plastic shapes are currently made

D , g/cm 5 sp gr 23/23°C 3 0.9976 (1)

predominately from recycled plastics. However, this test

3.1.2 plastic lumber, n—a manufactured product composed

method would also be applicable to similar manufactured

of more than 50 weight percent resin, and in which the product

plastic products made from virgin resins where the product is

generally is rectangular in cross-section and typically supplied

non-homogeneous in the cross-section.

in board and dimensional lumber sizes, may be filled or

1.4 The values stated in SI units are to be regarded as the

unfilled, and may be composed of single or multiple resin

standard.

blends.

1.5 This standard does not purport to address all of the

3.1.3 plastic shape, n—a manufactured product composed

safety concerns, if any, associated with its use. It is the

of more than 50 weight percent resin, and in which the product

responsibility of the user of this standard to establish appro-

generally is not rectangular in cross-section, may be filled or

priate safety and health practices and determine the applica-

unfilled, and may be composed of single or multiple resin

bility of regulatory limitations prior to use.

blends.

3.1.4 resin, n—a solid or pseudosolid organic material often

NOTE 1—There is no similar or equivalent ISO standard.

of high molecular weight, which exhibits a tendency to flow

2. Referenced Documents

when subjected to stress, usually has a softening or melting

2.1 ASTM Standards:

range, and usually fractures conchoidally. (See Terminology

D 618 Practice for Conditioning Plastics for Testing

D 883.)

D 883 Terminology Relating to Plastics

3.1.4.1 Discussion—In a broad sense, the term is used to

D 1622 Test Method for Apparent Density of Rigid Cellular

designate any polymer that is a basic material for plastics.

Plastics

3.1.5 specific gravity, bulk (of solids)—the ratio of the

D 1898 Practice for Sampling of Plastics

weight in air of a unit volume of a permeable material

D 5033 Guide for the Development of Standards Relating to

(including both permeable and impermeable voids normal to

the Proper Use of Recycled Plastics

the material) at a stated temperature to the weight in air of

equal density of an equal volume of gas-free distilled water at

a stated temperature. The form of expression shall be the

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics following:

and is the direct responsibility of Subcommittee D20.20 on Plastic Products (Section

D20.20.01).

Current edition approved July 10, 1997. Published February 1998.

2 4

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 14.03.

3 5

Annual Book of ASTM Standards, Vol 08.03. Annual Book of ASTM Standards, Vol 15.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6111

bulk specific gravity x/y°C (2)

where:

x = temperature of the material, and

y = temperature of the water.

3.1.5.1 Discussion—The accuracy of bulk density determi-

nations is so low that corrections for air buoyancy and

variations in the value for the acceleration of gravity are not

warranted. Hence, this definition is based on weights in air.

(See Terminology E 12.)

3.2 Additional definition of terms applying to this test

method appear in Terminology D 883 and Guide D 5033.

4. Summary of Test Method

4.1 Determine the weight of a specimen of the plastic

lumber or shape in air. The specimen is then immersed in

water, its weight upon immersion is determined, and its bulk

specific gravity calculated.

5. Significance and Use

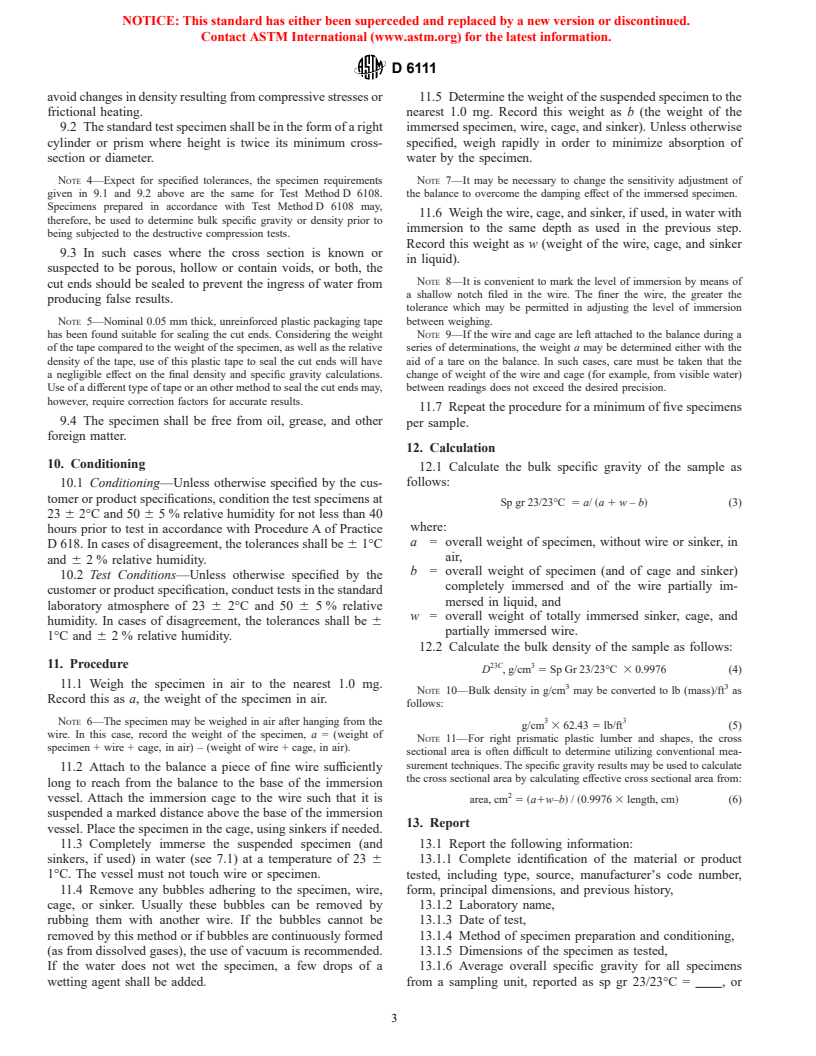

5.1 The specific gravity or density of a solid is a property FIG. 1 Typical Configuration of Test Apparatus

that can be measured conveniently to follow physical changes

in a sample, to indicate degree of uniformity among different

corrosion-resistant; have a specific gravity of not less than 7.0;

sampling units or specimens, or to indicate the average density

have smooth surfaces and a regular shape; and be slightly

of a large item.

heavier than necessary to sink the specimen, and should be

5.2 Variations in density of a particular plastic lumber or

easily attached to the cage.

shapes specimen may be due to changes in crystallinity, loss of

6.3 Immersion Vessel—A beaker, bucket, or other wide-

plasticizer/solvent content, differences in degree of foaming, or

mouthed vessel for holding the water and immersed cage.

to other causes. Portions of a sample may differ in density

6.4 Thermometer—A thermometer having not fewer than

because of difference in crystallinity, thermal history, porosity,

four divisions per °C over a temperature range of not less than

and composition (types or proportions of resin, plasticizer,

5°C above and below the standard temperature, and having an

pigment, or filler).

ice point for calibration. A thermometer short enough to be

handled inside the balance case will be found convenient.

NOTE 2—Reference is made to Test Method D 1622.

ASTM Thermometer 23C (see Specification E 1) and

5.3 Density is useful for calculating strength to weight and

Anschütz-type thermometers have been found satisfactory for

cost to weight ratios.

this purpose.

5.4 If the cross-sectional area of the specimen is required for

future testing on a particular sample, it may be determined

7. Materials

from a specific gravity measurement, see Note 10 (Eq 5).

7.1 Water—The water shall be distilled, deionized, or dem-

ineralized.

6. Apparatus

6.1 Balance—A balance large enough to accommodate the

8. Sampling

specimen conveniently, with a precision within 1.0 mg, accu-

8.1 The sampling units used for the determination of spe-

racy within 0.05 % relative (that is 0.05 % of the weight of the

cific gravity shall be representative of the quantity of product

specimen in air), and equipped with a means of support for the

for which the data are required, in accordance with Practice

immersion cage.

D 1898.

8.2 Plastic lumber and shapes are typically foamed, layered

NOTE 3—Assurance that the balance meets the performance require-

ments should be provided by frequent checks on adjustments of zero point

or hollow, varying in material properties over the cross section.

and sensitivity and by periodic calibration for absolute accuracy, using

To establish the overall specific gravity for a section, complete

standard masses.

unmachined elements or representative cross sections of these

6.2 Immersion Cage: elements shall be used.

6.2.1 Wire—A corrosion-resistant wire for suspending the

9. Test Specimens

cage.

6.2.2 Cage—A device large enough to support the bottom of 9.1 Test specimens for determining the bulk specific gravity

the specimen and when weighted will transfer the sinker force or bulk density of plastic lumber and shapes shall be cut from

to the specimen to keep it from floating. Refer to the sample the“ as manufactured” profile. Plastic lumber is gene

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.