ASTM D6534-18

(Practice)Standard Practice for Determining the Peak Force-to-Actuate of a Mechanical Pump Dispenser

Standard Practice for Determining the Peak Force-to-Actuate of a Mechanical Pump Dispenser

ABSTRACT

This test method covers the procedures for determining the peak force-to-actuate of a mechanical pump dispenser. The apparatus required to perform the tests include a motorized compression tester or custom force-to-action machine, a device that can display the resulting force, and a means to rigidly hold the mechanical pump dispenser during testing. Appropriate machine operating and substance handling should be taken and calibration should be performed on the equipment before testing the clean, dry, and unused pump dispensers.

SCOPE

1.1 This practice covers the determination of the peak force-to-actuate, sometimes called force-to-actuate (FTA), of a mechanical pump dispenser.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 5.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6534 − 18

Standard Practice for

Determining the Peak Force-to-Actuate of a Mechanical

1

Pump Dispenser

This standard is issued under the fixed designation D6534; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Apparatus

1.1 This practice covers the determination of the peak

4.1 Motorized Compression Tester, or Custom Force-to-

force-to-actuate, sometimes called force-to-actuate (FTA), of a

Action Machine, with the capability to actuate the mechanical

mechanical pump dispenser.

pump dispenser at a constant velocity and adjustable stroke

lengths while accurately measuring the resulting force (that is,

1.2 The values stated in SI units are to be regarded as the

load cell).

standard. The inch-pound units given in parentheses are for

information only.

NOTE 1—Since the velocity during actuation will affect the FTA of

certain mechanical pump dispenser designs, care must be taken in

1.3 This standard does not purport to address all of the

selecting the correct type of equipment with the sufficient actuation

safety concerns, if any, associated with its use. It is the

velocity.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 4.2 A device connected to the compression tester that can

mine the applicability of regulatory limitations prior to use. display the resulting force in newtons (N) or pounds force (lbf)

of 0.1 accuracy.

Specific precautionary statements are given in Section 5.

1.4 This international standard was developed in accor-

4.3 Ameans to rigidly hold the mechanical pump dispenser

dance with internationally recognized principles on standard-

during testing (that is, glass bottle or a holding fixture; see Fig.

ization established in the Decision on Principles for the

1).

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Precautions

Barriers to Trade (TBT) Committee.

5.1 Appropriate handling considerations should be given to

2. Referenced Documents

flammable, toxic, caustic, or other potentially hazardous ma-

2

2.1 ASTM Standards: terials used.

D3890 Test Method for Number of Strokes to Prime a

5.2 Appropriate operating considerations should be taken

Mechanical Pump Dispenser

with pinch points on the motorized compression tester.

3. Significance and Use

5.3 Ensure that the exit orifice of the mechanical pump

3.1 This practice can be used to compare the peak force-to- dispenser is pointed away from the operator and other people.

actuate performance of different mechanical pump dispensers.

5.4 Ensure that the motorized compression tester is properly

3.2 This practice can be used to determine the perceived

calibrated.

ease of use of a mechanical pump dispenser.

5.5 ActuationRateforFingerPumps—Care should be taken

3.3 This practice can be used to determine the peak force-

when selecting the travel speed of the ram. For some mechani-

to-actuate of a mechanical pump dispenser.

cal pump dispenser styles, the speed of actuation and length of

stroke can affect the peak force to actuate. As a rule of thumb,

1

This practice is under the jurisdiction of ASTM Committee F02 on Primary

mechanical pump dispensers with a stroke length of 7 mm or

Barrier Packaging and is the direct responsibility of Subcommittee F02.30 on

greater should use an actuation velocity of 35 to 75 mm per

Mechanical Dispensers.

second,whilemechanicalpumpdispenserswithastrokelength

Current edition approved May 1, 2018. Published June 2018. Originally

of less than 7 mm should use an actuation velocity of 35 mm

approved in 2000. Last previous edition approved in 2010 as D6534 – 05(2010).

DOI: 10.1520/D6534-18.

per second or less. Especially for fine mist spray pumps, the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

above mentioned rates are preferred. A different rate may be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

used; however, the true force-to-actuate during use may not be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. measured. The actuation rate used should be recorded in 10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6534 − 18

recommended method for trigger sprayers.

9.1 Fill

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6534 − 05 (Reapproved 2010) D6534 − 18

Standard Test Method Practice for

Determining the Peak Force-to-Actuate of a Mechanical

1

Pump Dispenser

This standard is issued under the fixed designation D6534; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method practice covers the determination of the peak force-to-actuate, sometimes called force-to-actuate (FTA),

of a mechanical pump dispenser.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for

information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 5.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D3890 Practice for Number of Strokes to Prime a Mechanical Pump Dispenser

3. Significance and Use

3.1 This test method practice can be used to compare the peak force-to-actuate performance of different mechanical pump

dispensers.

3.2 This test method practice can be used to determine the perceived ease of use of a mechanical pump dispenser.

3.3 This test method practice can be used to determine the peak force-to-actuate of a mechanical pump dispenser.

4. Apparatus

4.1 Motorized Compression Tester, or Custom Force-to-Action Machine, with the capability to actuate the mechanical pump

dispenser at a constant velocity and adjustable stroke lengths while accurately measuring the resulting force (that is, load cell).

NOTE 1—Since the velocity during actuation will affect the FTA of certain mechanical pump dispenser designs, care must be taken in selecting the

correct type of equipment with the sufficient actuation velocity.

4.2 A device connected to the compression tester that can display the resulting force in newtons (N) or pounds force (lbf) of

0.1 accuracy.

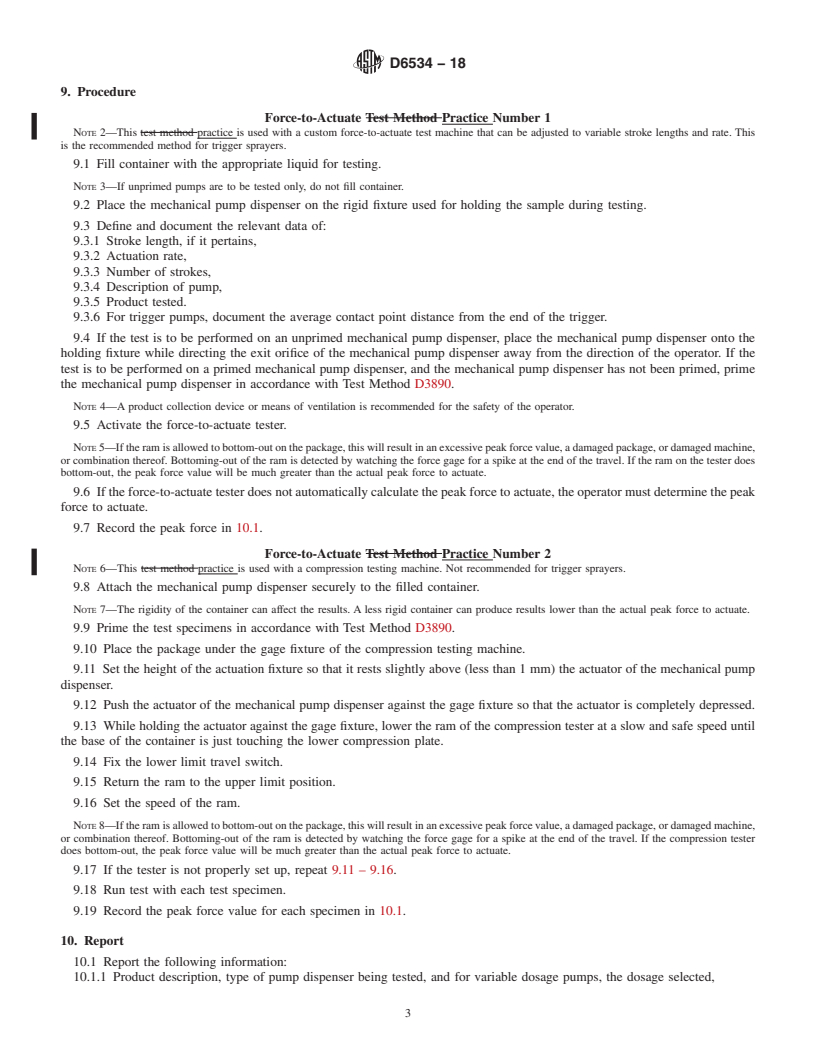

4.3 A means to rigidly hold the mechanical pump dispenser during testing (that is, glass bottle or a holding fixture; see Fig. 1).

5. Precautions

5.1 Appropriate handling considerations should be given to flammable, toxic, caustic, or other potentially hazardous materials

used.

1

This test method practice is under the jurisdiction of ASTM Committee F02 on FlexiblePrimary Barrier Packaging and is the direct responsibility of Subcommittee F02.30

on Mechanical Pump Dispensers.

Current edition approved Oct. 1, 2010May 1, 2018. Published March 2011June 2018. Originally approved in 2000. Last previous edition approved in 20052010 as

D6534 – 05.D6534 – 05(2010). DOI: 10.1520/D6534-05R10.10.1520/D6534-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6534 − 18

FIG. 1 Example of a Compression Test Machine

5.2 Appropriate operating considerations should be taken with pinch points on the motorized compression tester.

5.3 Ensure that the exit orifice of the mechanical pump dispenser is pointed away from the operator and other people.

5.4 Ensure that the motorized compression tester is properly calibrated.

5.5 Actuation Rate for Finger Pumps—Care should be taken when selecting the travel speed of the ram. For some mechanical

pump dispenser styles, the speed of actuation and length of stroke can affect the peak force to actuate. As a rule of thumb,

mechanical pump dispensers with a stroke length of 7 mm or greater should use an actuation velocity of 35 to 75 mm per second,

while mechanical pump dispensers with a stroke length of less th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.