ASTM D3826-18

(Practice)Standard Practice for Determining Degradation End Point in Degradable Polyethylene and Polypropylene Using a Tensile Test

Standard Practice for Determining Degradation End Point in Degradable Polyethylene and Polypropylene Using a Tensile Test

SIGNIFICANCE AND USE

4.1 The tensile elongation property determined by this practice is of value for the characterization of degradable materials. It is possible that the tensile elongation property will vary with specimen thickness, method of preparation, speed of testing, type of grips used, and manner of measuring test extension. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

4.2 It is acceptable to use the tensile elongation property to provide data for research and development and engineering design as well as quality control specifications. However, data from such tests cannot be considered significant for applications differing widely from the load-time scale of the test employed.

4.3 Materials that fail by tearing give anomalous data that cannot be compared with those from normal failure.

4.4 Before proceeding with this test method, reference needs to be made to the specifications of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters or a combination thereof, covered in the material specifications shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This practice covers the determination of a degradation-end point (a brittle point) for degradable polyethylene/polypropylene films and sheeting less than 1.0 mm (0.04 in.) thick. This practice is not intended for determination of the rate or degree of degradation of a polyethylene/polypropylene film or sheet, but rather, to assess when in the course of its degradation under some condition, a brittle point is reached. If one wishes to monitor tensile elongation during the degradation process (such as when the tensile elongation is significantly greater than 5 %), Test Method D882 is recommended. This practice is not to be considered the only way of determining a degradation-end point.

1.2 Tensile properties of plastics 1.0 mm (0.04 in.) or greater in thickness shall be determined in accordance with Test Method D638.

1.3 Use a static weighing-constant rate of grip separation test. This procedure employs a constant rate of separation of the grips holding the sample and a static load cell.

Note 1: This procedure is based on the use of grip separation as a measure of extension; however, the desirability of using extension indicators accurate to ±1.0 % or better as specified in Test Method D638 is recognized, and a provision for the use of such instrumentation is incorporated in the procedure.

1.4 This procedure has been successful for determining the degradation end point of ethylene-carbon-monoxide copolymers and has screened successfully two other additive-type polyethylenes in a round robin test.

1.5 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 There is no equivalent ISO standard.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3826 − 18

Standard Practice for

Determining Degradation End Point in Degradable

1

Polyethylene and Polypropylene Using a Tensile Test

This standard is issued under the fixed designation D3826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 There is no equivalent ISO standard.

1.8 This international standard was developed in accor-

1.1 This practice covers the determination of a degradation-

dance with internationally recognized principles on standard-

end point (a brittle point) for degradable polyethylene/

ization established in the Decision on Principles for the

polypropylene films and sheeting less than 1.0 mm (0.04 in.)

Development of International Standards, Guides and Recom-

thick.This practice is not intended for determination of the rate

mendations issued by the World Trade Organization Technical

or degree of degradation of a polyethylene/polypropylene film

Barriers to Trade (TBT) Committee.

or sheet, but rather, to assess when in the course of its

degradation under some condition, a brittle point is reached. If

2. Referenced Documents

one wishes to monitor tensile elongation during the degrada-

2

tion process (such as when the tensile elongation is signifi-

2.1 ASTM Standards:

cantly greater than 5 %), Test Method D882 is recommended.

D374/D374M Test Methods for Thickness of Solid Electri-

This practice is not to be considered the only way of deter-

cal Insulation

mining a degradation-end point.

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

1.2 Tensile properties of plastics 1.0 mm (0.04 in.) or

D882 Test Method for Tensile Properties of Thin Plastic

greater in thickness shall be determined in accordance with

Sheeting

Test Method D638.

D883 Terminology Relating to Plastics

1.3 Use a static weighing-constant rate of grip separation

D5208 Practice for Fluorescent Ultraviolet (UV) Exposure

test. This procedure employs a constant rate of separation of

of Photodegradable Plastics

the grips holding the sample and a static load cell.

D5947 Test Methods for Physical Dimensions of Solid

NOTE 1—This procedure is based on the use of grip separation as a

Plastics Specimens

measure of extension; however, the desirability of using extension

E691 Practice for Conducting an Interlaboratory Study to

indicators accurate to 61.0 % or better as specified in Test Method D638

Determine the Precision of a Test Method

is recognized, and a provision for the use of such instrumentation is

incorporated in the procedure.

3. Terminology

1.4 This procedure has been successful for determining the

3.1 Definitions of Terms—For definitions of terms used in

degradation end point of ethylene-carbon-monoxide copoly-

this specification associated with plastics issues refer to the

mers and has screened successfully two other additive-type

terminology contained in Terminology D883.

polyethylenes in a round robin test.

3.2 Definitions:

1.5 The values stated in SI units are to be regarded as the

3.2.1 Definitions of terms and symbols relating to tension

standard. The values in parentheses are for information only.

testing of plastics appear in the Annex to Test Method D638.

1.6 This standard does not purport to address all of the

3.2.2 line grips, n—in tensile testing machines, grips having

safety concerns, if any, associated with its use. It is the

faces designed to concentrate the entire gripping force along a

responsibility of the user of this standard to establish appro-

single line perpendicular to the direction of testing stress.

priate safety, health, and environmental practices and deter-

3.2.3 tear failure, n—in tensile testing of films, a failure

mine the applicability of regulatory limitations prior to use.

characterized by fracture initiating at one edge of the specimen

1

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and

isthedirectresponsibilityofSubcommitteeD20.96onEnvironmentallyDegradable

2

Plastics and Biobased Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2018. Published November 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2013 as D3826 – 98 (2013). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D3826-18. the ASTM website.

Copyright © ASTM Internat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3826 − 98 (Reapproved 2013) D3826 − 18

Standard Practice for

Determining Degradation End Point in Degradable

1

Polyethylene and Polypropylene Using a Tensile Test

This standard is issued under the fixed designation D3826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the determination of a degradation-end point (a brittle point) for degradable polyethylene/

polypropylene films and sheeting less than 1.0 mm (0.04 in.) thick. This practice is not intended for determination of the rate ofor

degree of degradation of a polyethylene/polypropylene film or sheet, but rather, to assess when in the course of its degradation

under some condition, a brittle point is reached. If one wishes to monitor tensile elongation during the degradation process (such

as when the tensile elongation is significantly greater than 5 %), Test Method D882 is recommended. This practice shouldis not

to be considered the only way of determining a degradation-end point.

1.2 Tensile properties of plastics 1.0 mm (0.04 in.) or greater in thickness shall be determined in accordance with Test Method

D638.

1.3 Use a static weighing-constant rate of grip separation test. This procedure employs a constant rate of separation of the grips

holding the sample and a static load cell.

NOTE 1—This procedure is based on the use of grip separation as a measure of extension; however, the desirability of using extension indicators

accurate to 61.0 % or better as specified in Test Method D638 is recognized, and a provision for the use of such instrumentation is incorporated in the

procedure.

1.4 This procedure has been successful for determining the degradation end point of ethylene-carbon-monoxide copolymers and

has screened successfully two other additive-type polyethylenes in a round robin test.

1.5 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 There is no equivalent ISO standard.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

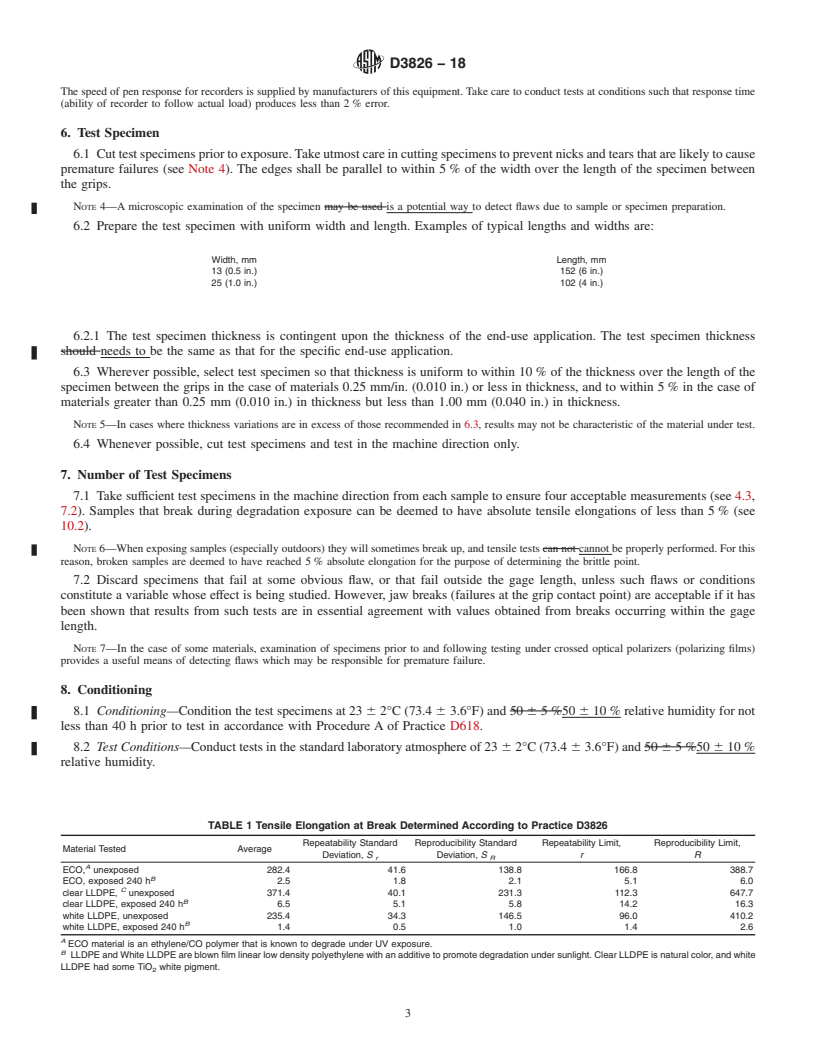

D374D374/D374M Test Methods for Thickness of Solid Electrical Insulation (Metric) D0374_D0374M

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D883 Terminology Relating to Plastics

D5208 Practice for Fluorescent Ultraviolet (UV) Exposure of Photodegradable Plastics

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

1

This practice is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.96 on Environmentally Degradable

Plastics and Biobased Products.

Current edition approved Feb. 1, 2013Nov. 1, 2018. Published February 2013November 2018. Originally approved in 1991. Last previous edition approved in 20082013

as D3826 – 98 (2008).(2013). DOI: 10.1520/D3826-98R13.10.1520/D3826-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3826 − 18

3. Terminology

3.1 Definitions of Terms—For definitions of terms used in this specification associated with plastics issues refer to the

terminology contained in Terminology D883.

3.2 Definitions:

3.2.1 Definitions of terms

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.