ASTM F3265-17(2023)

(Test Method)Standard Test Method for Grid-Video Obstacle Measurement

Standard Test Method for Grid-Video Obstacle Measurement

SIGNIFICANCE AND USE

4.1 Assuming the vehicle stays on its path and an obstacle appears within the stop zone, the vehicle will collide with the obstacle. Even within the stop zone, obstacle detection should cause the vehicle to slow down as early as possible using non-contact sensing or contact bumpers. ANSI/ITSDF B56.5:2012 discusses a test method to detect standard test pieces beyond the minimum vehicle stopping distance at 50 % and 100 % of vehicle rated speeds.

4.2 This test method can apply to A-UGVs for testing obstacle-sensing capabilities and automatic guided industrial vehicles in automatic mode of operation in non-restricted areas as described in ANSI/ITSDF B56.5.

4.3 Researchers2, 3 used two-dimensional (2D) laser detection and ranging (LADAR) sensors mounted to an A-UGV. In contrast to the earlier experiments in which the test piece was static, in these experiments the A-UGV and the test piece were both moving. The 2D sensor was mounted to the A-UGV to scan horizontally with the beam approximately 10 cm (4 in.) above and parallel to the floor and confined to detecting the vehicle path (vehicle width) at the maximum stopping distance (coasting or braking). Note that the sensor scan width can be set to any width, including the ANSI/ITSDF B56.5 standard, non-hazard zone vehicle path width of the vehicle plus 0.5 m (1.6 ft). The test piece entered the A-UGV path within the exception zone, was detected by the safety sensor, and the distance of the test piece to the A-UGV and the A-UGV stopping distance measurements were calculated and analyzed.

SCOPE

1.1 This test method measures an automatic/automated/autonomous-unmanned ground vehicle (A-UGV) kinetic energy reduction when objects appear in the A-UGV path and within the stop-detect range of the vehicle safety sensors in situations in which the desired reaction is for the vehicle to stop as opposed to avoiding the obstacle by traveling on an alternative path. The test method measures the performance of the A-UGV only and does not measure the effect on the stability of loads. This test method describes the use of one test piece as described in ANSI/ITSDF B56.5. Other test pieces from ANSI/ITSDF B56.5 could be used. This test method is intended for use by A-UGV manufacturers, installers, and users. This test method does not substitute for required safety testing under ANSI/ITSDF B56.5 or other normative standards.

1.2 Performing Location—This test method shall be performed in a testing laboratory or the location where the apparatus and environmental test conditions are implemented. Environmental conditions are recorded as specified in Practice F3218.

1.3 Units—The values stated in SI units are to be regarded as the standard. The values given in parentheses are not precise mathematical conversion to inch-pound units. They are close approximate equivalents for the purpose of specifying material dimensions or quantities that are readily available to avoid excessive fabrication costs of test apparatuses while maintaining repeatability and reproducibility of the test method results. These values given in parentheses are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3265 − 17 (Reapproved 2023)

Standard Test Method for

Grid-Video Obstacle Measurement

This standard is issued under the fixed designation F3265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Safe control of automatic/automated/autonomous-unmanned ground vehicles (A-UGVs) is critical

in industrial environments where workers are or may be present. A-UGV safe control is typically

based on sensors that detect stationary standard test pieces (used in ANSI/ITSDF B56.5) representing

2, 3

humans. This and other test method developments have been experimented and published. The

experimental results were used to recommend improvements to the ANSI/ITSDF B56.5 safety

standard stopping distance exception language in 2014. Subcommittee consensus changed ANSI/

ITSDF B56.5 to make it mandatory to reduce vehicle kinetic energy should an object (for example,

person, materials, or equipment) appear in the vehicle path and within the stop detect range of the

vehicle safety sensors. The language that has been proposed as an amendment to the ANSI/ITSDF

B56.5 standard is: “Should an object suddenly appear in the path of the vehicle between the leading

edge of the sensing field and the vehicle (for example, an object falling from overhead or a pedestrian

stepping into the path of a vehicle at the last instant), the vehicle shall initiate braking in accordance

with brake system (see 8.8.1), but may not be expected to stop in time to prevent contact with object.”

While manufacturers of A-UGVs may have access to internal system logs and data that demonstrate

the successful initiation of braking as required, users may not have access to that information. This test

method provides an optional, standard performance test method for A-UGVs to enable industrial

vehicle manufacturers and users to implement a common test to demonstrate expected vehicle

operation in the case of objects appearing in the A-UGV path and within the stop-detect range of the

vehicle safety sensors.

1. Scope stability of loads. This test method describes the use of one test

piece as described in ANSI/ITSDF B56.5. Other test pieces

1.1 This test method measures an automatic/automated/

from ANSI/ITSDF B56.5 could be used. This test method is

autonomous-unmanned ground vehicle (A-UGV) kinetic en-

intended for use by A-UGV manufacturers, installers, and

ergy reduction when objects appear in the A-UGV path and

users. This test method does not substitute for required safety

within the stop-detect range of the vehicle safety sensors in

testing under ANSI/ITSDF B56.5 or other normative standards.

situations in which the desired reaction is for the vehicle to stop

as opposed to avoiding the obstacle by traveling on an

1.2 Performing Location—This test method shall be per-

alternative path. The test method measures the performance of

formed in a testing laboratory or the location where the

the A-UGV only and does not measure the effect on the

apparatus and environmental test conditions are implemented.

Environmental conditions are recorded as specified in Practice

This test method is under the jurisdiction of ASTM Committee F45 on

F3218.

Robotics, Automation, and Autonomous Systems and is the direct responsibility of

Subcommittee F45.03 on A-UGV Object Detection and Protection.

1.3 Units—The values stated in SI units are to be regarded

Current edition approved Dec. 1, 2023. Published January 2024. Originally

as the standard. The values given in parentheses are not precise

approved in 2017. Last previous edition approved in 2017 as F3265 – 17. DOI:

10.1520/F3265-17R23. mathematical conversion to inch-pound units. They are close

Bostelman, Roger, Shackleford, Will, Cheok, Geraldine, and Saidi, Kamel,

approximate equivalents for the purpose of specifying material

“Safe Control of Manufacturing Vehicles Research Towards Standard Test

dimensions or quantities that are readily available to avoid

Methods,” Progress in Material Handling Practice, Book Chapter, June 2012.

Bostelman, Roger, Norcross, Richard, Falco, Joe, and Marvel, Jeremy, “Devel- excessive fabrication costs of test apparatuses while maintain-

opment of Standard Test Methods for Unmanned and Manned Industrial Vehicles

ing repeatability and reproducibility of the test method results.

Used Near Humans,” SPIE 2013, Baltimore, Maryland, May 2013.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3265 − 17 (2023)

These values given in parentheses are provided for information 3.2.8 stop zone, n—the area in front of the direction of travel

only and are not considered standard. of the A-UGV where activation of the obstruction sensor

causes a safety stop of the vehicle as per ANSI/ITSDF B56.5.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.9 stopping distance, n—distance required for vehicle to

responsibility of the user of this standard to establish appro- stop after detecting obstruction.

priate safety, health, and environmental practices and deter-

3.2.10 repetition, n—performance of a task.

mine the applicability of regulatory limitations prior to use.

3.2.11 task, n—sequence of movements and measurements

1.5 This international standard was developed in accor-

that compromise one repetition within a test.

dance with internationally recognized principles on standard-

3.2.12 test, n—a collection of task repetitions.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 Assuming the vehicle stays on its path and an obstacle

Barriers to Trade (TBT) Committee.

appears within the stop zone, the vehicle will collide with the

obstacle. Even within the stop zone, obstacle detection should

2. Referenced Documents

cause the vehicle to slow down as early as possible using

2.1 ASTM Standards:

non-contact sensing or contact bumpers. ANSI/ITSDF

F3200 Terminology for Robotics, Automation, and Autono-

B56.5:2012 discusses a test method to detect standard test

mous Systems

pieces beyond the minimum vehicle stopping distance at 50 %

F3218 Practice for Documenting Environmental Conditions

and 100 % of vehicle rated speeds.

for Utilization with A-UGV Test Methods

4.2 This test method can apply to A-UGVs for testing

2.2 ANSI/ITSDF Standard:

obstacle-sensing capabilities and automatic guided industrial

ANSI/ITSDF B56.5 Safety Standard for Driverless, Auto-

vehicles in automatic mode of operation in non-restricted areas

matic Guided Industrial Vehicles and Automated Func-

as described in ANSI/ITSDF B56.5.

tions of Manned Industrial Vehicles

2, 3

4.3 Researchers used two-dimensional (2D) laser detec-

tion and ranging (LADAR) sensors mounted to an A-UGV. In

3. Terminology

contrast to the earlier experiments in which the test piece was

3.1 Terms not defined herein are defined in Terminology

static, in these experiments the A-UGV and the test piece were

F3200.

both moving. The 2D sensor was mounted to the A-UGV to

3.2 Definitions of Terms Specific to This Standard:

scan horizontally with the beam approximately 10 cm (4 in.)

3.2.1 collide time, n—when the automatic/automated/

above and parallel to the floor and confined to detecting the

autonomous-unmanned ground vehicle (A-UGV) collides with

vehicle path (vehicle width) at the maximum stopping distance

the test piece.

(coasting or braking). Note that the sensor scan width can be

3.2.2 defined areas, n—space constrained by test method set to any width, including the ANSI/ITSDF B56.5 standard,

boundaries for A-unmanned ground vehicle (A-UGV) opera-

non-hazard zone vehicle path width of the vehicle plus 0.5 m

tion. (1.6 ft). The test piece entered the A-UGV path within the

exception zone, was detected by the safety sensor, and the

3.2.3 enter time, n—when the test piece enters the stop zone

distance of the test piece to the A-UGV and the A-UGV

triggering photosensor 1.

stopping distance measurements were calculated and analyzed.

3.2.4 start line, n—line across the path of the vehicle used to

signal when the test piece can be inserted into the stop 5. Apparatus

detection range as measured in 7.3.

5.1 List of Materials:

3.2.5 start location, n—the initial zero velocity position of

5.1.1 Grid printed on paper or marked on the floor at regular

A-UGV at beginning of each test repetition; the start location

intervals.

should be at a point from which the vehicle can accelerate up

5.1.2 Photosensors 1 and 2.

to test speed before the leading edge crosses the start line along

5.1.3 Lights 1 and 2.

the test trajectory.

5.1.4 Video camera and recorder with nominal 30 frames

per second (fps) frame rate or higher.

3.2.6 start time, n—when the A-UGV crosses the start line

5.1.5 Straight bar and clamp (or optional length of rope or

while traveling at speed.

string, or both, not shown in Fig. 1).

3.2.7 stop time, n—when the A-UGV stops because of

5.1.6 A-UGV.

detection of the test piece.

5.1.7 Vertical cylinder test piece, 70 mm (2.75 in.) diameter

by 400 mm (16 in.), as described in safety standards and

representing a human leg.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.8 Onboard A-UGV camera or sighting scope (optional)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on (see Fig. 2).

the ASTM website.

5.1.9 Timer to be placed in camera field of view.

Available from the Industrial Truck Standards Development Foundation

(ITSDF), 1750 K St. Nw, Suite 460, Washington, DC 20006, www.itsdf.org. 5.2 Experimental Setup:

F3265 − 17 (2023)

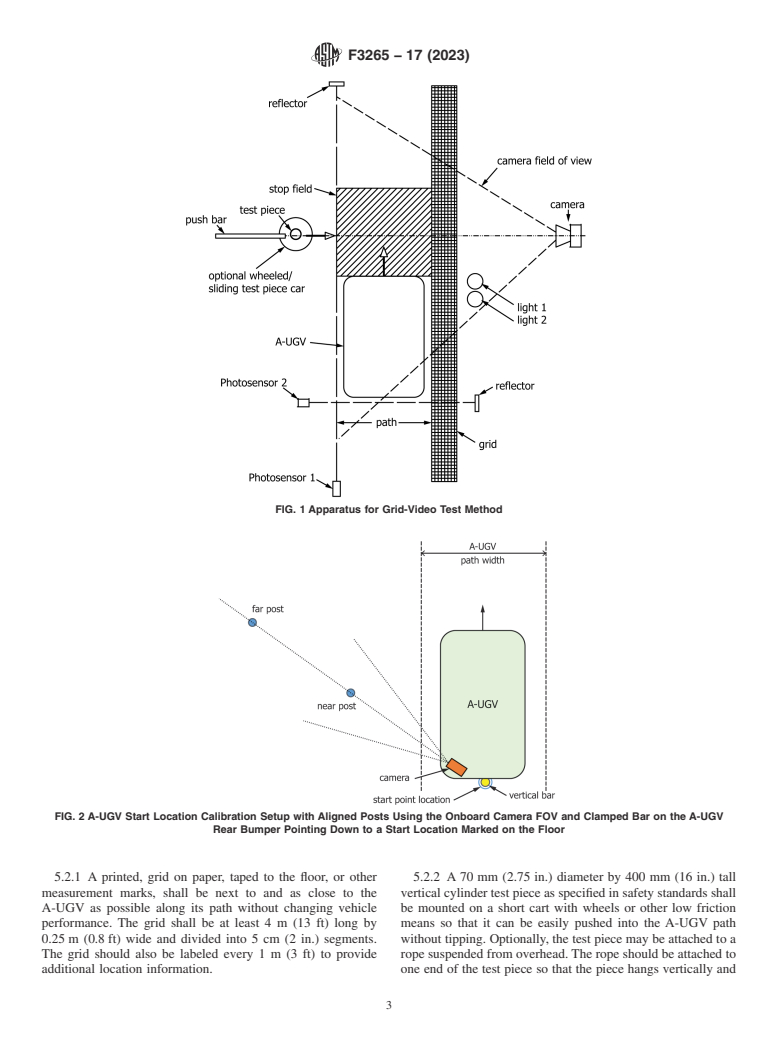

FIG. 1 Apparatus for Grid-Video Test Method

FIG. 2 A-UGV Start Location Calibration Setup with Aligned Posts Using the Onboard Camera FOV and Clamped Bar on the A-UGV

Rear Bumper Pointing Down to a Start Location Marked on the Floor

5.2.1 A printed, grid on paper, taped to the floor, or other 5.2.2 A 70 mm (2.75 in.) diameter by 400 mm (16 in.) tall

measurement marks, shall be next to and as close to the vertical cylinder test piece as specified in safety standards shall

A-UGV as possible along its path without changing vehicle be mounted on a short cart with wheels or other low friction

performance. The grid shall be at least 4 m (13 ft) long by means so that it can be easily pushed into the A-UGV path

0.25 m (0.8 ft) wide and divided into 5 cm (2 in.) segments. without tipping. Optionally, the test piece may be attached to a

The grid should also be labeled every 1 m (3 ft) to provide rope suspended from overhead. The rope should be attached to

additional location information. one end of the test piece so that the piece hangs vertically and

F3265 − 17 (2023)

hangs just short of making contact with the floor. Setting the 6. Hazards

rope vertically, with the target in position, a length of rope is

6.1 In addition to the requirements of 1.4, which addresses

attached to the top of the target and extended horizontally to

the human safety and health concerns, users of this test method

the tester location.

shall also address the equipment preservation concerns and

5.2.3 A video camera shall be mounted in a fixed location,

human A-UGV coexistence concerns.

with the image plane parallel to the travel surface and aligned

NOTE 1—The test requestor and test supervisor agree upon and have the

with the A-UGV path to capture simultaneously both the test

authority to decide upon the environmental conditions under which the

piece and A-UGV motions and stop positions. The video

test(s) is/are to be conducted. Such conditions can be stressful not only to

camera shall have a high enough resolution to capture simul-

the humans but also to the A-UGVs, such as, high or low temperatures,

taneously and clearly, frame-by-frame, the floor grid, test

excessive moisture, and rough terrain that can damage the A-UGV

components or cause unexpected A-UGV motions. Testing of an A-UGV

piece, and A-UGV throughout the test piece motions and stops

may result in exposing the A-UGV, the test area and equipment, and

and the location where the A-UGV detects test piece motion

observers to extraordinary risks. In addition to any other warnings or

and subsequently travels and stops or decelerates. Video

concerns, the test designer shall include a safety plan specific to the

recording shall continue for at least 5 s after the full A-UGV

A-UGV being tested and the test method being used. This plan shall be

crosses the point of entry of the test piece or the A-UGV stops. briefed to all personnel involved and shall include an emergency response

plan should an uncontrolled event occur.

5.2.4 Along the path, a photosensor, Photosensor 1, shall be

placed on or within 400 mm (16 in.) above the floor next to the

7. Calibration

A-UGV so that the emitted beam is along the edge of the

A-UGV stop zone and detects the crossing test piece. The 7.1 Calibration of the A-UGV and Start Location:

emitted beam shall reflect back to the photosensor by a 7.1.1 The A-UGV shall be calibrated to move at 50 % and

reflector placed beyond the A-UGV stop zone. Photosensor 1 100 % of rated speed before testing.

shall control a light, Light 1, on/off that is pointed towards the 7.1.2 The A-UGV shall be positioned at the same start

video camera upon detection of the test piece crossing into the location and orientation for each trial. A calibration method,

A-UGV path. Light 1 shall be simultaneously detected by the shown in Fig. 2, independent of A-UGV sensors, shall be used

video camera during the test. This simplifies identifying the to determine vehicle pose. An example method includes the use

time that the test piece crosses into the stop zone boundary. of a video camera or sighting scope mounted to the vehicle and

5.2.5 Similarly, the beam from a second photosensor, Pho- two posts spaced at approximately 5 m and 10 m along a line

tosensor 2, shall cross the A-UGV path to detect the approach- at an angle other than 0° and 90° from the A-UGV. When the

ing A-UGV and shall be used to turn on a second light, Light A-UGV is at the start location, the two posts are aligned in the

2. Light 2 sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.