ASTM D6068-96

(Test Method)Standard Test Method for Determining J-R Curves of Plastic Materials

Standard Test Method for Determining J-R Curves of Plastic Materials

SCOPE

1.1 This test method covers the determination of the J-integral versus crack growth resistance (J-R) curves for polymeric materials.

1.2 This test method is intended to characterize the slow, stable crack growth resistance of bend-type specimens in such a manner that it is geometry insensitive within limits set forth in this test method.

1.3 The recommended specimens are the three-point bend (SE(B)) and pin-loaded compact tension (C(T)) specimens. Both specimens have in-plane dimensions of constant proportionality for all sizes. Specimen configurations other than those recommended in this test method may require different procedures and validity requirements.

1.4 This test method describes a multiple specimen method that requires optical measurement of crack extension from fracture surfaces. It is not recommended for use with materials in which the crack front cannot be distinguished from additional deformation processes in advance of the crack tip.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1- There is no equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6068 – 96

Standard Test Method for

Determining J-R Curves of Plastic Materials

This standard is issued under the fixed designation D 6068; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 399 Test Method for Plane-Strain Fracture Toughness of

Metallic Materials

1.1 This test method covers the determination of the

E 616 Terminology Relating to Fracture Testing

J-integral versus crack growth resistance (J-R) curves for

E 1152 Test Method for Determining J-R Curves

polymeric materials.

E 1737 Test Method for J-Integral Characterization of Frac-

1.2 This test method is intended to characterize the slow,

ture Toughness

stable crack growth resistance of bend-type specimens in such

F 1473 Test Method for Notch Tensile Test to Measure the

a manner that it is geometry insensitive within limits set forth

Resistance to Slow Crack Growth of Polyethylene Pipes

in this test method.

and Resins

1.3 The recommended specimens are the three-point bend

(SE (B)) and pin-loaded compact tension (C (T)) specimens.

3. Terminology

Both specimens have in-plane dimensions of constant propor-

3.1 Definitions—Terminology related to fracture testing

tionality for all sizes. Specimen configurations other than those

contained in Terminology E 616 is applicable to this test

recommended in this test method may require different proce-

method.

dures and validity requirements.

3.2 Definitions of Terms Specific to This Standard:

1.4 This test method describes a multiple specimen method

−1

3.2.1 J-integral, J (FL )—a mathematical expression, a

that requires optical measurement of crack extension from

line or surface integral over a path that encloses the crack front

fracture surfaces. It is not recommended for use with materials

from one crack surface to the other, used to characterize the

in which the crack front cannot be distinguished from addi-

local stress-strain field around the crack front. See Terminology

tional deformation processes in advance of the crack tip.

E 616 for additional discussion.

1.5 The values stated in SI units are to be regarded as the

3.2.2 J-R curve—a plot of resistance to stable physical crack

standard.

extension, Da .

p

1.6 This standard does not purport to address all of the

3.2.3 net thickness, B (L)—the distance between the roots

N

safety concerns, if any, associated with its use. It is the

of the side grooves in side grooved specimens.

responsibility of the user of this standard to establish appro-

3.2.4 original crack size, a (L)—the physical crack size at

priate safety and health practices and determine the applica-

the start of testing.

bility of regulatory limitations prior to use.

3.2.5 original uncracked ligament, b (L)—the distance

NOTE 1—There is no equivalent ISO standard.

from the original crack front to the back edge of the specimen

(b =W−a8 ).

0 0

2. Referenced Documents

3.2.6 physical crack extension, Da (L)—an increase in

p

2.1 ASTM Standards:

physical crack size (Da =a −a ).

p p 0

D 618 Practice for Conditioning Plastics and Electrical

3.2.7 physical crack size, a (L)—the distance from a

p

Insulating Materials for Testing

reference line to the observed crack front. The distance may be

D 4066 Specification for Nylon Injection and Extrusion

a calculated average of several measurements along the crack

Materials

front. The reference line depends on the specimen geometry

D 5045 Test Methods for Plane-Strain Fracture Toughness

and is normally defined as in 3.2.10. The reference line is

and Strain Energy Release Rate of Plastic Materials

defined prior to specimen deformation.

3.2.8 specimen span, S(L)—the distance between specimen

supports for the SE(B) specimen.

3.2.9 specimen thickness, B(L)—the side-to-side dimension

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

of the test specimen (shown in Fig. 2).

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved Dec. 10, 1996. Published January 1997.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 08.03.

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6068

length and crack extension on the fracture surfaces after each

test.

5. Significance and Use

5.1 A J-R curve produced in accordance with this test

method characterizes the crack growth resistances of a wide

range of tough polymers and polymer blends (1-5) that cannot

be obtained in sufficient size and thickness for valid character-

ization by linear elastic fracture mechanics in Test Methods

D 5045.

5.2 The J-R curve characterizes, within the limits set forth in

this test method, the resistance of a polymeric material to slow

stable crack growth after initiation from a preexisting sharp

flaw.

5.3 A J-R curve can be used as an index of material

toughness for blend or alloy design, material selection, mate-

rials processing, and quality assurance (6).

5.4 The J-R curves from bend specimens represent lower

bound estimates of J capacity as a function of crack extension,

and have been observed to be conservative relative to those

obtained from specimen configurations under tensile loading.

5.5 The J-R curves for a given material of constant micro-

structure tend to exhibit lower slope (flatter) with increasing

thickness. Thus, it is recommended that the largest possible

FIG. 1 Specimen Configurations

specimen with representative microstructure be used.

5.6 The J-R curve can be used to assess the stability of

cracks in structures in the presence of ductile tearing, with

awareness of the differences that may exist between laboratory

test and field conditions.

5.7 A J-R curve may depend on the orientation and propa-

gation of the crack in relation to the anisotropy of the material

which may be induced by specimen fabrication methods.

5.8 Because of the possibility of rate dependence of crack

growth resistance, J-R curves can be determined at displace-

ment rates other than that specified in this test method (7).

6. Apparatus

6.1 Measurements of applied load and load-line displace-

ment are needed to obtain the total energy absorbed by the

specimen. Load versus load-line displacement may be recorded

digitally or autographically.

6.2 Testing Machine—The J-integral tests are to be con-

ducted under displacement control to maximize the attainable

amount of stable crack extension in the test specimens.

FIG. 2 Bending Rig NOTE 2—The extent to which the crack grows in a stable manner is

dependent on the machine stiffness (8) and the mode of control of loading

(9).

3.2.10 specimen width, W(L)—a physical dimension on a

6.3 Bend Test Fixture—A suggested fixture for SE (B)

test specimen measured from the rear surface of the specimen

specimens is shown in Fig. 2. The fixture may have either

to a reference line (for example, the front edge of a bend

stationary or moving rollers of sufficiently large diameter to

specimen or the load line of a compact specimen).

minimize excessive plastic indentation.

6.4 Grips for C (T) Specimens—A suggested clevis and pin

4. Summary of Test Method

arrangement for gripping compact specimens is given in Test

4.1 This test method describes a multiple specimen tech-

Method E 399. This arrangement accommodates specimens

nique for determining the J-R curve for polymeric materials.

with B = 0.5 W.

The J-R curve consists of a plot of J versus crack extension in

the region of J-controlled growth as determined by the data

qualification requirement of 9.2. 7

The boldface numbers given in parentheses refer to a list of references at the

4.2 This test method uses optical measurements of crack end of the text.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6068

6.5 Displacement Measurement:

6.5.1 Load-line displacement measurements are needed to

calculate J from the area under the load-displacement record.

6.5.2 The remote displacement measurement can be per-

formed using the stroke or position transducer on the testing

machine. Data obtained in this manner must be corrected for

extraneous displacements (such as indentation effects, pin

penetration, or machine compliance) by conducting a separate

indentation measurement described in 8.7.

6.5.3 A direct displacement measurement can be performed

using a separate displacement transducer. This arrangement is

shown in Fig. 2 for SE (B) specimens. For C (T) specimens, the

displacement gage should be placed in the notch on the load

line.

7. Specimen Configuration, Size, and Preparation

7.1 Specimen Size:

7.1.1 The initial selection of specimen size and dimensions

can only be based on J results estimated from previous

experience. Generally, the largest available specimens are

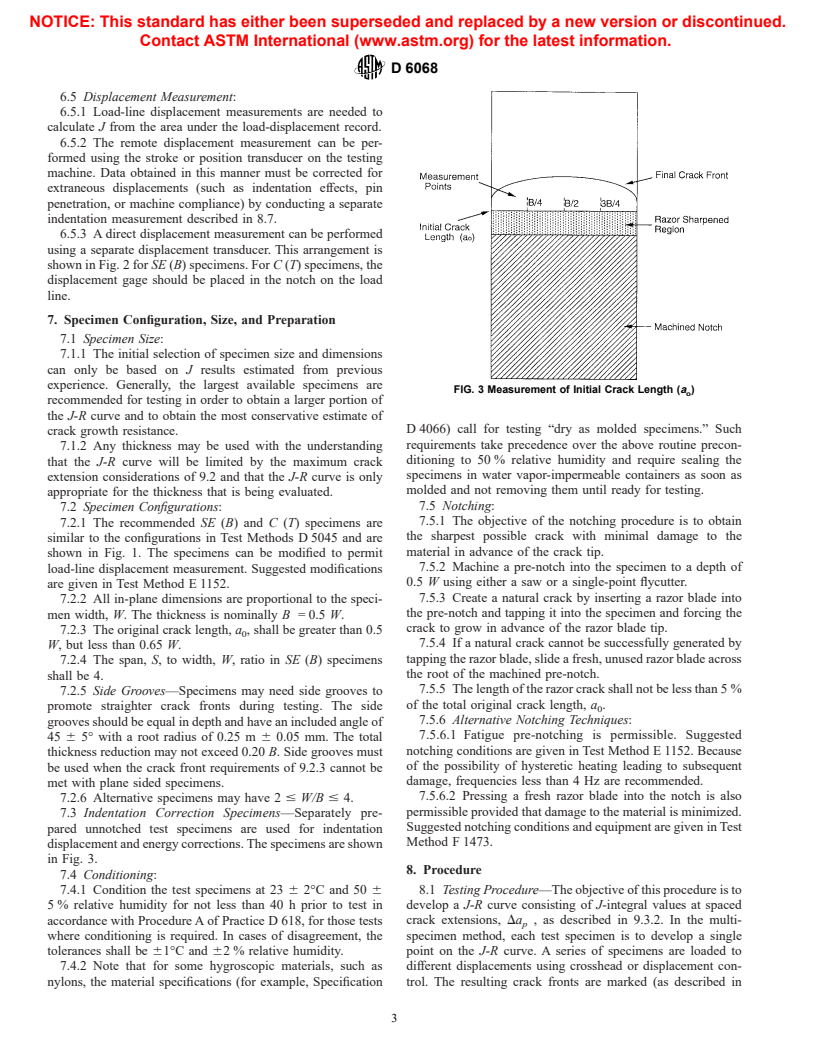

FIG. 3 Measurement of Initial Crack Length (a )

o

recommended for testing in order to obtain a larger portion of

the J-R curve and to obtain the most conservative estimate of

D 4066) call for testing “dry as molded specimens.” Such

crack growth resistance.

requirements take precedence over the above routine precon-

7.1.2 Any thickness may be used with the understanding

ditioning to 50 % relative humidity and require sealing the

that the J-R curve will be limited by the maximum crack

specimens in water vapor-impermeable containers as soon as

extension considerations of 9.2 and that the J-R curve is only

molded and not removing them until ready for testing.

appropriate for the thickness that is being evaluated.

7.5 Notching:

7.2 Specimen Configurations:

7.5.1 The objective of the notching procedure is to obtain

7.2.1 The recommended SE (B) and C (T) specimens are

the sharpest possible crack with minimal damage to the

similar to the configurations in Test Methods D 5045 and are

material in advance of the crack tip.

shown in Fig. 1. The specimens can be modified to permit

7.5.2 Machine a pre-notch into the specimen to a depth of

load-line displacement measurement. Suggested modifications

0.5 W using either a saw or a single-point flycutter.

are given in Test Method E 1152.

7.5.3 Create a natural crack by inserting a razor blade into

7.2.2 All in-plane dimensions are proportional to the speci-

the pre-notch and tapping it into the specimen and forcing the

men width, W. The thickness is nominally B = 0.5 W.

crack to grow in advance of the razor blade tip.

7.2.3 The original crack length, a , shall be greater than 0.5

7.5.4 If a natural crack cannot be successfully generated by

W, but less than 0.65 W.

tapping the razor blade, slide a fresh, unused razor blade across

7.2.4 The span, S, to width, W, ratio in SE (B) specimens

the root of the machined pre-notch.

shall be 4.

7.5.5 The length of the razor crack shall not be less than 5 %

7.2.5 Side Grooves—Specimens may need side grooves to

of the total original crack length, a .

promote straighter crack fronts during testing. The side

7.5.6 Alternative Notching Techniques:

grooves should be equal in depth and have an included angle of

7.5.6.1 Fatigue pre-notching is permissible. Suggested

45 6 5° with a root radius of 0.25 m 6 0.05 mm. The total

notching conditions are given in Test Method E 1152. Because

thickness reduction may not exceed 0.20 B. Side grooves must

of the possibility of hysteretic heating leading to subsequent

be used when the crack front requirements of 9.2.3 cannot be

damage, frequencies less than 4 Hz are recommended.

met with plane sided specimens.

7.5.6.2 Pressing a fresh razor blade into the notch is also

7.2.6 Alternative specimens may have 2 # W/B # 4.

permissible provided that damage to the material is minimized.

7.3 Indentation Correction Specimens—Separately pre-

Suggested notching conditions and equipment are given in Test

pared unnotched test specimens are used for indentation

Method F 1473.

displacement and energy corrections. The specimens are shown

in Fig. 3.

8. Procedure

7.4 Conditioning:

7.4.1 Condition the test specimens at 23 6 2°C and 50 6 8.1 Testing Procedure—The objective of this procedure is to

5 % relative humidity for not less than 40 h prior to test in develop a J-R curve consisting of J-integral values at spaced

accordance with Procedure A of Practice D 618, for those tests crack extensions, Da , as described in 9.3.2. In the multi-

p

where conditioning is required. In cases of disagreement, the specimen method, each test specimen is to develop a single

tolerances shall be 61°C and 62 % relative humidity. point on the J-R curve. A series of specimens are loaded to

7.4.2 Note that for some hygroscopic materials, such as different displacements using crosshead or displacement con-

nylons, the material specifications (for example, Specification trol. The resulting crack fronts are marked (as described in

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6068

Appendix X1) and the crack extensions are measured from the

fracture surface. An independent indentation measurement is

also conducted to correct for non-fracture related energy

dissipation. The J value is then calculated from the indentation

corrected energy for fracture. Each specimen has thus provided

a set of J, Da values to describe the J-R curve.

p

8.2 Measure specimen dimensions B, B , and W to the

N

nearest 0.050 mm or 0.5 % accuracy, whichever is larger.

8.3 Because of the viscoelastic nature of polymers, the J-R

curve may be dependent on test temperature and displacement

rate. Therefore, record these conditions with the results.

8.3.1 Provided that stable, well-defined crack growth can be

achieved, any test temperature may be used.

8.3.2 Similarly, any test speed that leads to stable, well-

defined crack growth may be used. However, test speeds that

lead to loading times (time to maximum load) that are less than

1 ms are not recommended for this procedure due to dynamic

effects on the loading signal that can lead to erroneous results.

8.3.3 For general characterization, the suggested test condi-

FIG. 4 Measurement of Crac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.