ASTM A278/A278M-01

(Specification)Standard Specification for Gray Iron Castings for Pressure-Containing Parts for Temperatures Up to 650°F (350°C)

Standard Specification for Gray Iron Castings for Pressure-Containing Parts for Temperatures Up to 650°F (350°C)

SCOPE

1.1 This specification covers gray iron for castings suitable for pressure-containing parts for use at temperatures up to 650°F (350°C).

1.2 Classes of Iron:

1.2.1 Castings of all classes are suitable for use up to 450°F (230°C). For temperatures above 450°F and up to 650°F, only Class 40, 45, 50, 55, and 60 castings are suitable.

1.2.2 Castings of all classes are suitable for use up to 230°C. For temperatures above 230°C and up to 350°C, only Class 275, 300, 325, 350, 380, and 415 castings are suitable.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 278/A 278M – 01

Standard Specification for

Gray Iron Castings for Pressure-Containing Parts for

Temperatures Up to 650°F (350°C)

This standard is issued under the fixed designationA 278/A 278M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Ordering Information

1.1 This specification covers gray iron for castings suitable 5.1 Orders for material in this specification should include

for pressure-containing parts for use at temperatures up to the following information:

650°F (350°C). 5.1.1 ASTM designation and year date,

1.2 Classes of Iron: 5.1.2 Class of iron required and service temperature,

1.2.1 Castings of all classes are suitable for use up to 450°F 5.1.3 Quantity,

(230°C). For temperatures above 450°F and up to 650°F, only 5.1.4 Heat Treatment:

Class 40, 45, 50, 55, and 60 castings are suitable. 5.1.4.1 Whether or not heat treatment is required for Class

1.2.2 Castingsofallclassesaresuitableforuseupto230°C. 40, 45, 50, 55, and 60 castings to be used at temperatures at

For temperatures above 230°C and up to 350°C, only Class 450°F or less (see 6.2),

275, 300, 325, 350, 380, and 415 castings are suitable. 5.1.4.2 Whether or not heat treatment is required for Class

275, 300, 325, 350, 380, and 415 castings to be used at

2. Referenced Documents

temperatures at 230°C or less (see 6.2),

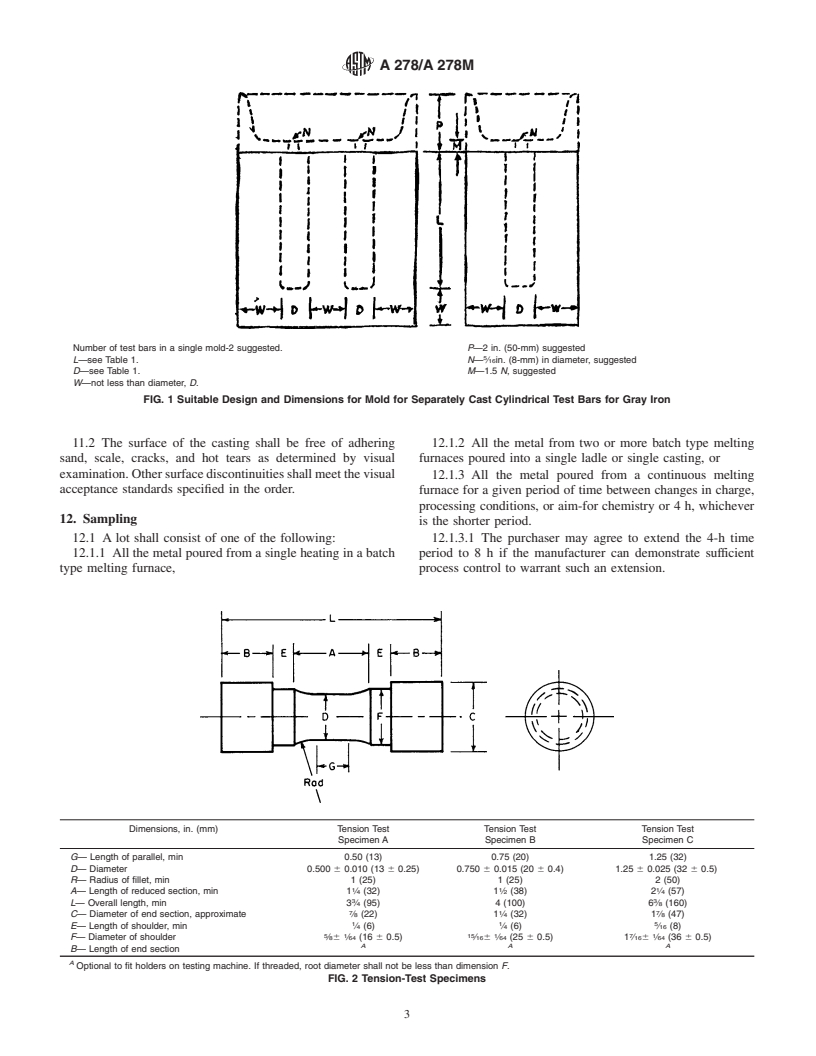

2.1 ASTM Standards: 5.1.5 The size of separately cast test bar to be poured (see

A 644 Terminology Relating to Iron Castings

Section 9 and Table 1),

E 8 Test Methods forTensionTesting of Metallic Materials 5.1.6 The size of test specimen to be machined from test

barsCorS,and

3. Terminology

5.1.7 Special requirements.

3.1 Definitions of many terms common to gray iron castings

6. Materials and Manufacture

may be found in Terminology A 644.

6.1 Castings intended for use above 450°F (230°C) shall be

4. Classification

stress-relieved by placing them in a suitable furnace at a

4.1 Classification by tensile strength.

temperature not exceeding 400°F (200°C) and heating them

4.1.1 Castings ordered to this specification are classified

uniformly to the temperatures and for the times specified in

based upon the minimum tensile strength of the iron in ksi, in

Table 2. The heating and cooling rates shall be uniform and

English units. Class 25 has a minimum specified tensile

shall not be more than 400°F/h (250°C/h) for castings of 1-in.

strength of 25 ksi.

(25-mm) maximum section. For heavier sections the maximum

4.1.2 Castings ordered to this specification are classified

heating and cooling rates in degrees Fahrenheit per hour shall

based upon the minimum tensile strength of the iron in MPa, in

be 400 divided by the maximum section thickness.

Metric units. Class 150 has a minimum specified tensile

6.2 Heat Treatment and Cooling Rate:

strength of 150 MPa.

6.2.1 Castings of Class Nos. 45, 50, 55, and 60, which are to

be used at temperatures below 450°F, may be heat treated in

accordance with 6.1 or they shall be cooled in the mold to

This specification is under the jurisdiction of ASTM Committee A04 on Iron

500°F at an average rate of not more than 100°F/h for castings

CastingsandisthedirectresponsibilityofSubcommitteeA04.01onGrayandWhite

up to 1 in. in section. For heavier sections the maximum

Iron Castings.

cooling rate in degrees Fahrenheit per hour shall be 100

Current edition approved June 10, 2001. Published September 2001. Originally

published as A 278 – 44T. Last previous edition A 278 – 93.

divided by the maximum section thickness.

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

6.2.2 Castings of Class Nos. 275, 300, 325, 350, 380, and

cation SA-278 in Section II of that Code.

415,whicharetobeusedattemperaturesbelow230°C,maybe

Annual Book of ASTM Standards, Vol 01.02.

Annual Book of ASTM Standards, Vol 03.01. heat treated in accordance with 6.1 or they shall be cooled in

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 278/A 278M

TABLE 1 Diameters and Lengths of Cast Test Bars TABLE 4 Tensile Requirements (SI)

Test As-Cast Diameter, in. (mm) Length, in. (mm) Class Tensile Strength,

Bar min, MPa

Minimum Maximum Minimum Maximum

(Bottom) (Top) (Specified) (Recommended) No. 150 150

No. 175 175

A 0.88 (23) 0.85 (22) 0.96 (25) 5.0 (125) 6.0 (1.50)

No. 200 200

B 1.20 (33) 1.14 (32) 1.32 (36) 7.0 (150) 9.0 (230)

No. 225 225

C 2.00 (54) 1.90 (53) 2.10 (58) 6.0 (175) 10.0 (255)

No. 250 250

A

S

No. 275 275

A

AlldimensionsofTestBarSshallbeagreeduponbythemanufacturerandthe No. 300 300

purchaser. No. 325 325

No. 350 350

No. 380 380

TABLE 2 Stress Relieving Requirements

No. 415 415

A

Class Metal Temperature, °F Holding Time, h

(°C)

40, 45, 50, 55, 60 1050 to 1200 2 12

B B

(275, 300, 325, 350, (565 to 650) (2 min) (12 max)

9. Test Bars

380, 415)

A

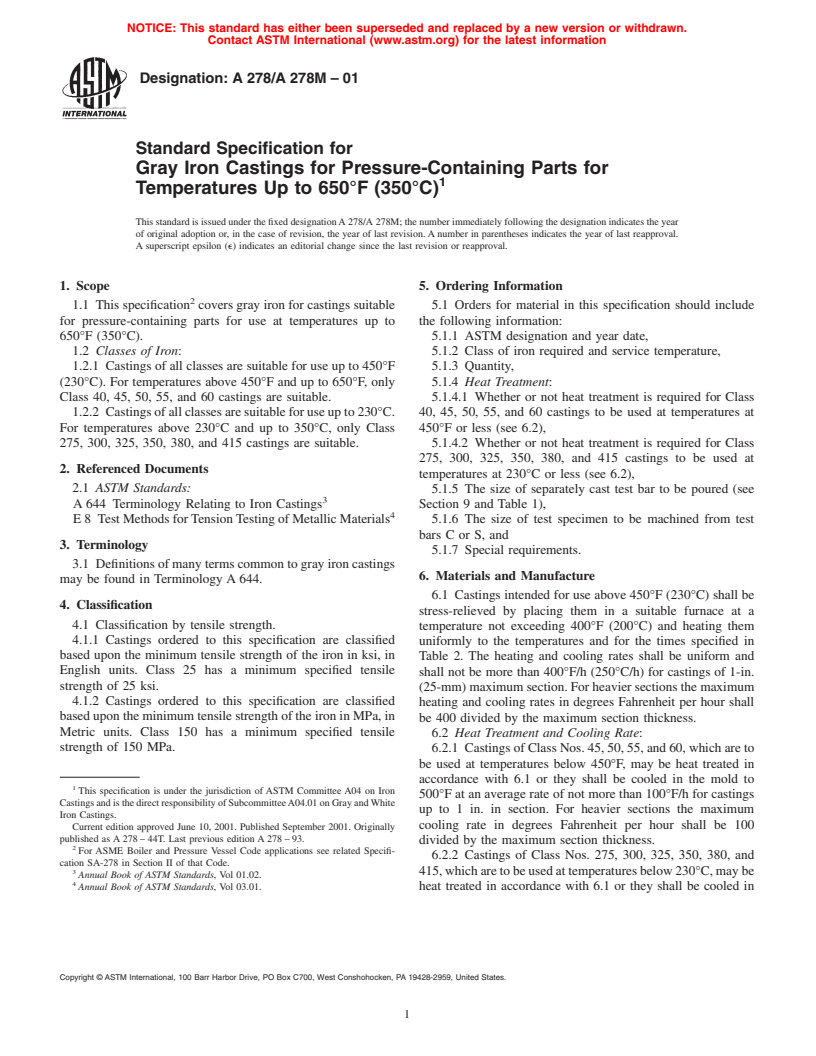

9.1 Separatelycasttestbarshavingthedimensionsshownin

In no case shall the holding time be less than 1 h/in. of maximum metal

section, or in excess of 12 h max, dependent upon which governs.

Table 1 shall be poured from the same lot as the castings

B

In no case shall the holding time be less than1hfor every 25-mm metal

represented. The size of the test bar to be poured shall be

section, or in excess of 12 h max, depending upon which governs.

selected by the purchaser using Table 5. In the event no choice

is made, the selection will be made by the manufacturer.

the mold to 250°C at an average rate of not more than 50°C/h 9.2 Separately cast test bars shall be heat treated in the same

for castings up to 25-mm in section. For heavier sections the furnace together with the castings represented.

maximum cooling rate in degrees Celsius per hour shall be 9.3 At the option of the manufacturer, test coupons may be

1250 divided by the maximum section thickness. removed from the casting at a location agreed upon between

the manufacturer and purchaser.

7. Chemical Composition

9.4 Castings weighing in excess of 2000 lb may be repre-

sented either by separately cast test bars (9.1) or by integrally

7.1 Carbon Equivalent:

cast test bars having a cooling rate closely approximating that

7.1.1 Class 40, 45, 50, 55, and 60 castings intended for

of the controlling section of the casting.

service above 450°F (230°C) shall have a maximum carbon

9.5 For castings weighing in excess of 10 000 lb or having

equivalent of 3.8 % as calculated from the equation CE = %C

a controlling section greater than 2 in., test bars may be

+ 0.3 (%Si + %P). The maximum phosphorus and sulfur

removed from the casting or integral projections having a cross

contents shall be 0.25 % and 0.12 %, respectively.

section no less than the controlling section. The minimum

7.1.2 Class 275, 300, 325, 350, 380, and 415 castings

tensile strength requirement for tension tests performed on

intended for service above 230°C shall have a maximum

either of these test bars shall be 80 % of the specified class.

carbon equivalent of 3.8 % as calculated from the equation CE

= %C + 0.3 (%Si + %P). The maximum phosphorus and sulfur

10. Molding and Pouring Test Bars

contents shall be 0.25 % and 0.12 %, respectively.

7.2 The chemical analysis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.