ASTM C233-00

(Test Method)Standard Test Method for Air-Entraining Admixtures for Concrete

Standard Test Method for Air-Entraining Admixtures for Concrete

SCOPE

1.1 This test method covers the testing of materials proposed for use as air-entraining admixtures in the field.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 233 – 00

Standard Test Method for

Air-Entraining Admixtures for Concrete

This standard is issued under the fixed designation C 233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 231 Test Method for Air Content of Freshly Mixed

Concrete by the Pressure Method

1.1 This test method covers the testing of materials pro-

C 232 Test Methods for Bleeding of Concrete

posed for use as air-entraining admixtures in the field.

C 260 Specification for Air-Entraining Admixtures for Con-

1.2 The values stated in SI units are to be regarded as the

crete

standard. The values given in parentheses are for information

C 403/C 403M Test Method for Time of Setting of Concrete

purposes only.

Mixtures by Penetration Resistance

1.3 This standard does not purport to address all of the

C 666 Test Method for Resistance of Concrete to Rapid

safety concerns, if any, associated with its use. It is the

Freezing and Thawing

responsibility of the user of this standard to establish appro-

C 670 Practice for Preparing Precision and Bias Statements

priate safety and health practices and determine the applica-

for Test Methods for Construction Materials

bility of regulatory limitations prior to use.

D 75 Practice for Sampling Aggregates

1.4 The text of this test method references notes and

D 1193 Specification for Reagent Water

footnotes which provide explanatory material. These notes and

E 70 Test Method for pH of Aqueous Solutions with the

footnotes (excluding those in tables and figures) shall not be

Glass Electrode

considered as requirements of the standard.

2.2 ACI Standards:

2. Referenced Documents

ACI 211.1 Recommended Practice for Selecting Propor-

tions for Normal, Heavyweight, and Mass Concrete

2.1 ASTM Standards:

C 33 Specification for Concrete Aggregates

3. Significance and Use

C 39 Test Method for Compressive Strength of Cylindrical

3.1 This test method is used to develop data for comparison

Concrete Specimens

with the requirements of Specification C 260. These tests are

C 78 Test Method for Flexural Strength of Concrete (Using

based on arbitrary stipulations permitting highly standardized

Simple Beam with Third-Point Loading)

testing in the laboratory, and are not intended to simulate actual

C 136 Test Method for Sieve Analysis of Fine and Coarse

job conditions.

Aggregates

C 143/C 143M Test Method for Slump of Hydraulic Ce-

4. Materials

ment Concrete

3 4.1 Cement—The cement used in any series of tests shall be

C 150 Specification for Portland Cement

either the cement proposed for specific work in accordance

C 157 Test Method for Length Change of Hardened

2 with 4.4, a Type I or Type II cement conforming to Specifica-

Hydraulic-Cement Mortar and Concrete

2 tion C 150, or a blend of two or more cements, in equal parts.

C 172 Practice for Sampling Freshly Mixed Concrete

Each cement of the blend shall conform to the requirements of

C 173 Test Method for Air Content of Freshly Mixed

2 either Type I or Type II, Specification C 150. If a blend of

Concrete by the Volumetric Method

cements is used, it shall be a combination which produces an

C 185 Test Method for Air Content of Hydraulic Cement

3 air content of less than 10 % when tested in accordance with

Mortar

Test Method C 185 (Note 3).

C 192/C 192M Test Method for Making and Curing Con-

2 4.2 Aggregates—Except when tests are made in accordance

crete Test Specimens in the Laboratory

with 4.4, using the aggregates proposed for specific work, the

fine and coarse aggregates used in any series of tests shall come

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.23 on Chemical Admixtures. Annual Book of ASTM Standards, Vol 04.03.

Current edition approved Jan. 10, 2000. Published April 2000. Originally Annual Book of ASTM Standards, Vol 11.01.

published as C 233 – 49 T. Last previous edition C 233 – 97a. Annual Book of ASTM Standards, Vol 15.05.

2 7

Annual Book of ASTM Standards, Vol 04.02. American Concrete Institute Manual of Concrete Practice, Part 1, pp. 211-1 to

Annual Book of ASTM Standards, Vol 04.01. 211-38 (1993).

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 233

from single lots of well-graded, sound materials that conform “neutralized Vinsol resin.”

to the requirements of Specification C 33, except that the 4.4 Materials for Tests for Specific Uses—When it is desired

grading of the aggregates shall conform to the following to test an air-entraining admixture for use in specific work, the

requirements: cement and aggregates used shall be representative of those

proposed for use in the work, and the concrete mixtures shall

4.2.1 Fine Aggregate Grading—The fine aggregate shall

be designed to have the cement content specified for use in the

meet the requirements for the fine aggregate in Specification

work (Note 3). If the maximum size of coarse aggregate is

C 33.

greater than 25.0 mm (1 in.), the freshly mixed concrete shall

4.2.2 Coarse Aggregate Grading—The coarse aggregate

be screened over a 25.0-mm (1-in.) sieve prior to fabricating

shall meet the requirements for size number 57 of Specification

the test specimens in accordance with the wet sieving proce-

C 33.

dure described in Practice C 172.

4.5 Preparation and Weighing—All materials shall be pre-

NOTE 1—Take care in loading and delivery to avoid segregation.

pared and all weighings shall be made as prescribed in Test

4.2.3 The coarse aggregate used for each set of reference

Method C 192/C 192M.

concrete and comparable test admixture-treated concrete shall

NOTE 3—It is recommended that whenever practicable, tests be made in

be essentially the same. Therefore, a set of test concrete

accordance with 4.4 using the cement and pozzolanic or chemical

consists of one reference concrete and as many test admixture-

admixtures, if any, proposed for specific work.

containing concretes as are intended to be compared to that one

5. Concrete Mixtures

reference. Thus, coarse aggregate for one set shall consist of

enough material for one reference concrete, the test admixture-

5.1 Proportions—Using ACI 211.1, all concrete shall be

containing concrete to be compared with that reference, and the

proportioned to conform to the following requirements:

sample for grading analysis testing. 5.1.1 The cement content shall be 307 6 3 kg/m (517 6 5

lb/yd ) except when tests are being made for specific uses (see

4.2.3.1 Prepare coarse aggregate for a set, comprising a

4.4).

sample large enough for concrete trials, as follows: Fill tared

5.1.2 The first trial mixture shall contain the amount of

containers, one each for a sample, a batch of reference concrete

coarse aggregate shown in Table 6.3.6 of ACI Recommended

and one or more test concretes to the required mass from the

Practice 211.1 for the maximum size of aggregate and for the

aggregate stockpile. Accomplish this by starting with a scoop-

fineness modulus of the sand being used.

ful into the first container and repeat this procedure until all

NOTE 4—Values in Table 6.3.6 of ACI Recommended Practice 211.1-

containers have their required mass. Repeat the process for

77 are intended to ensure workable mixtures with the least favorable

each of the three or more sets needed. One or more spare sets

combinations of aggregate likely to be used. It is suggested, therefore, that

may be needed. See the Appendix of Practice D 75, Sampling

for a closer approximation of the proportions required for this test, the

from Stockpiles, and the Manual of Aggregate and Concrete

values selected from Table 6.3.6 be increased by about 7 % for the first

Testing for guidance for conditions and procedures.

trial mixture.

4.2.4 Test coarse aggregate samples representing each set by

5.1.3 The air content used in the computation of proportions

Test Method C 136 requirements for the sieves shown below.

for all concrete shall be 5.5 % except where the admixture

Discard any set for which the sample does not comply with

under test is for use in specific work (see 4.4). In this case the

Size 57. Average test results for samples which comply with

air content used in selecting proportions shall be the median of

Size 57 for each sieve size. Discard any set for which the

the range to be permitted in the work. If lightweight aggregates

sample deviates from this average by more than the amount

are to be used in specific work, the unit weight of concrete used

shown in column 3. Continue the process of preparation,

in selecting proportions shall be the median of the range

testing and averaging until sufficient sets of aggregate within permitted in the work.

tolerance are obtained. 5.1.4 The water content and sand content shall be adjusted

1 1

to obtain a slump of 90 6 15 mm (3 ⁄2 6 ⁄2 in.). The

Specification C 33, No. 57 Maximum variation from

Sieve Percent Passing average/passing

workability of the concrete mixture shall be suitable for

37.5-mm 100 00

consolidation by hand rodding and the concrete mixture shall

25.0-mm 95 to 100 1.0

have the minimum water content possible. These conditions

12.5-mm 25 to 60 4.0

4.75-mm 0 to 10 4.0

shall be achieved by final adjustments in the proportion of fine

2.36-mm 0 to 5 1.0

aggregate to total aggregate, in the amount of total aggregate,

or both, while maintaining the yield and slump in the required

NOTE 2—All of the results required for demonstrating compliance

ranges.

under this specification are dependent on the uniformity of the aggregate

samples prepared and used. Careful, skilled and well-supervised work is

5.2 Conditions—Concrete mixtures shall be prepared both

essential.

with the air-entraining admixture under test and with the

4.3 Reference Admixture—For this test method, unless oth-

erwise requested by the purchaser, the reference admixture

Vinsol resin is manufactured by Hercules Inc., Wilmington, DE. Neutralization

used in the concrete mixture specified in Section 4 shall be

may be accomplished by treating 100 parts of the Vinsol resin with 9 to 15 parts of

NaOH by weight. In an aqueous solution, the ratio of water to the resinate shall not

exceed 12:1 by weight.

C 233

reference admixture. The admixtures shall be added in the be found to be manifestly faulty, the test results thereof shall be

amounts necessary to produce the air content selected in disregarded. Should more than one specimen representing a

accordance with 5.1.3 within a tolerance of 60.5 % of the given test at a given age be found manifestly faulty, either

volume of concrete. before or after testing, the entire test shall be disregarded and

repeated. The test result reported shall be the average of the

6. Mixing

individual test results of the specimens tested or, in the event

6.1 Machine mix the concrete as prescribed in Test Method that one specimen or one result has been discarded, it shall be

C 192/C 192M. the average of the test results of the remaining specimens.

7. Tests and Properties of Freshly Mixed Concrete 9. Test Specimens of Hardened Concrete

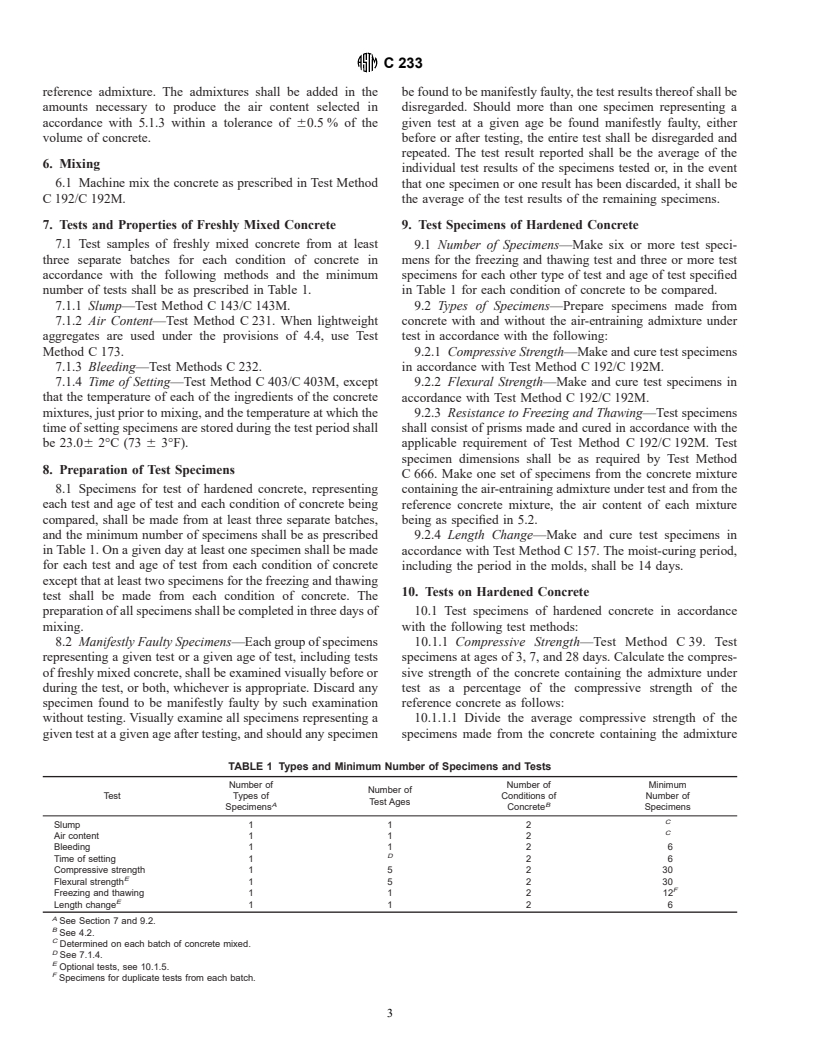

7.1 Test samples of freshly mixed concrete from at least 9.1 Number of Specimens—Make six or more test speci-

three separate batches for each condition of concrete in mens for the freezing and thawing test and three or more test

accordance with the following methods and the minimum specimens for each other type of test and age of test specified

number of tests shall be as prescribed in Table 1. in Table 1 for each condition of concrete to be compared.

7.1.1 Slump—Test Method C 143/C 143M. 9.2 Types of Specimens—Prepare specimens made from

7.1.2 Air Content—Test Method C 231. When lightweight concrete with and without the air-entraining admixture under

aggregates are used under the provisions of 4.4, use Test test in accordance with the following:

Method C 173. 9.2.1 Compressive Strength—Make and cure test specimens

7.1.3 Bleeding—Test Methods C 232. in accordance with Test Method C 192/C 192M.

7.1.4 Time of Setting—Test Method C 403/C 403M, except 9.2.2 Flexural Strength—Make and cure test specimens in

that the temperature of each of the ingredients of the concrete accordance with Test Method C 192/C 192M.

mixtures, just prior to mixing, and the temperature at which the 9.2.3 Resistance to Freezing and Thawing—Test specimens

time of setting specimens are stored during the test period shall shall consist of prisms made and cured in accordance with the

be 23.06 2°C (73 6 3°F). applicable requirement of Test Method C 192/C 192M. Test

specimen dimensions shall be as required by Test Method

8. Preparation of Test Specimens

C 666. Make one set of specimens from the concrete mixture

8.1 Specimens for test of hardened concrete, representing

containing the air-entraining admixture under test and from the

each test and age of test and each condition of concrete being reference concrete mixture, the air content of each mixture

compared, shall be made from at least three separate batches, being as specified in 5.2.

and the minimum number of specimens shall be as prescribed 9.2.4 Length Change—Make and cure test specimens in

in Table 1. On a given day at least one specimen shall be made accordance with Test Method C 157. The moist-curing period,

for each test and age of test from each condition of concrete including the period in the molds, shall be 14 days.

except that at least two specimens for the freezing and thawing

10. Tests on Hardened Concrete

test shall be made from each condition of concrete. The

preparation of all specimens shall be completed in three days of 10.1 Test specimens of hardened concrete in accordance

mixing. with the following test methods:

8.2 Manifestly Faulty Specimens—Each group of specimens 10.1.1 Compressive Strength—Test Method C 39. Test

representing a given test or a given age of test, including tests specimens at ages of 3, 7, and 28 days. Calculate the compres-

of freshly mixed concrete, shall be examined visually before or sive strength of the concrete containing the admixture under

during the test, or both, whichever is appropriate. Discard any test as a percentage of the compressive strength of the

specimen found to be manifestly faulty by such examination reference concrete as follows:

without testing. Visually examine all specimens representing a 10.1.1.1 Divide the average compressive strength of the

given test at a given age after testing, and shou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.