ASTM D5753-05(2010)

(Guide)Standard Guide for Planning and Conducting Borehole Geophysical Logging

Standard Guide for Planning and Conducting Borehole Geophysical Logging

SIGNIFICANCE AND USE

An appropriately developed, documented, and executed guide is essential for the proper collection and application of borehole geophysical logs.

The benefits of its use include improving the following:

Selection of logging methods and equipment,

Log quality and reliability, and

Usefulness of the log data for subsequent display and interpretation.

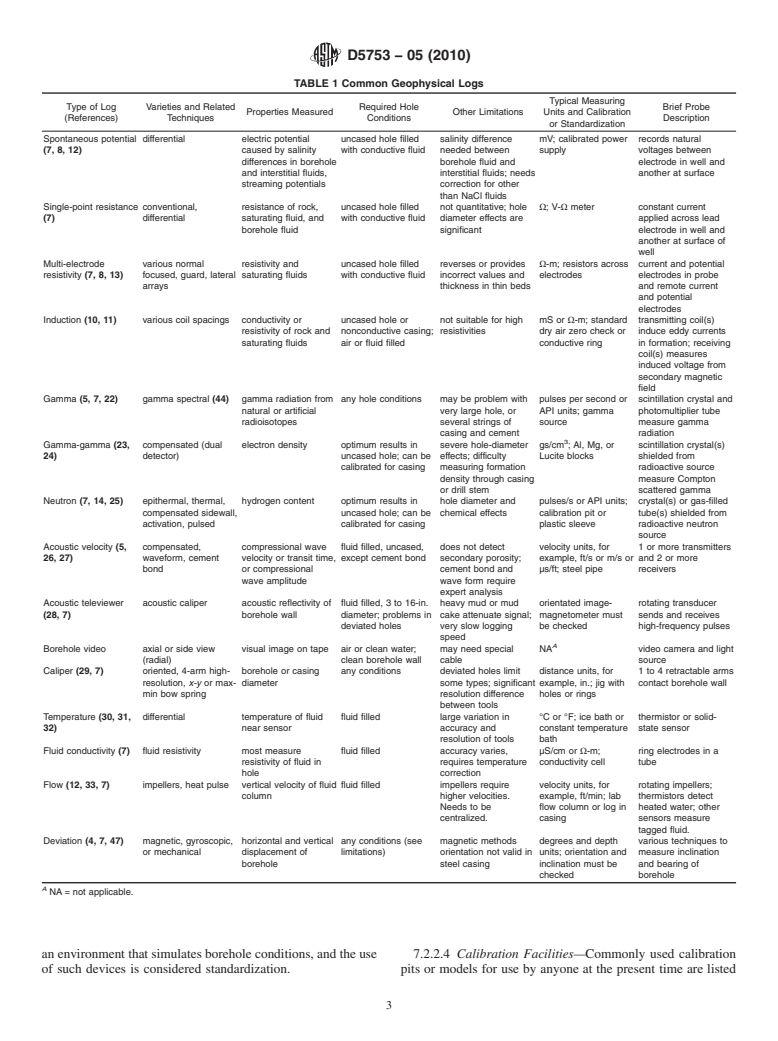

This guide applies to commonly used logging methods (see Table 1 and Table 2) for geotechnical investigations.

It is essential that personnel (see 7.3.3) consult up-to-date textbooks and reports on each of the logging techniques, applications, and interpretation methods. A partial list of selected publications is given at the end of this guide.

This guide is not meant to describe the specific or standard procedures for running each type of geophysical log and is limited to measurements in a single borehole.

SCOPE

1.1 This guide covers the documentation and general procedures necessary to plan and conduct a geophysical log program as commonly applied to geologic, engineering, groundwater, and environmental (hereafter referred to as geotechnical) investigations. It is not intended to describe the specific or standard procedures for running each type of geophysical log and is limited to measurements in a single borehole. It is anticipated that standard guides will be developed for specific methods subsequent to this guide.

1.2 Surface or shallow-depth nuclear gages for measuring water content or soil density (that is, those typically thought of as construction quality assurance devices), measurements while drilling (MWD), cone penetrometer tests, and logging for petroleum or minerals are excluded.

1.3 Borehole geophysical techniques yield direct and indirect measurements with depth of the (1) physical and chemical properties of the rock matrix and fluid around the borehole, (2) fluid contained in the borehole, and (3) construction of the borehole.

1.4 To obtain detailed information on operating methods, publications (for example, 2, 5, 7, 18, 24, 29, 34, 35, and 36) should be consulted. A limited amount of tutorial information is provided, but other publications listed herein, including a glossary of terms and general texts on the subject, should be consulted for more complete background information.

1.5 This guide provides an overview of the following: (1) the uses of single borehole geophysical methods, (2) general logging procedures, (3) documentation, (4) calibration, and (5) factors that can affect the quality of borehole geophysical logs and their subsequent interpretation. Log interpretation is very important, but specific methods are too diverse to be described in this guide.

1.6 Logging procedures must be adapted to meet the needs of a wide range of applications and stated in general terms so that flexibility or innovation are not suppressed.

1.7 This standard does not purport to address all of the safety and liability concerns, if any, (for example, lost or lodged probes and radioactive sources ) associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.8 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through the ASTM consensus process.

WITHDRAWN RATIONALE

This guide...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5753 − 05 (Reapproved 2010)

Standard Guide for

Planning and Conducting Borehole Geophysical Logging

This standard is issued under the fixed designation D5753; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 Logging procedures must be adapted to meet the needs

of a wide range of applications and stated in general terms so

1.1 This guide covers the documentation and general pro-

that flexibility or innovation are not suppressed.

cedures necessary to plan and conduct a geophysical log

1.7 This standard does not purport to address all of the

program as commonly applied to geologic, engineering,

safety and liability concerns, if any, (for example, lost or

groundwater, and environmental (hereafter referred to as geo-

lodged probes and radioactive sources ) associated with its

technical) investigations. It is not intended to describe the

use. It is the responsibility of the user of this standard to

specific or standard procedures for running each type of

establish appropriate safety and health practices and deter-

geophysical log and is limited to measurements in a single

mine the applicability of regulatory limitations prior to use.

borehole. It is anticipated that standard guides will be devel-

1.8 This guide offers an organized collection of information

oped for specific methods subsequent to this guide.

or a series of options and does not recommend a specific

1.2 Surface or shallow-depth nuclear gages for measuring

course of action. This document cannot replace education or

water content or soil density (that is, those typically thought of

experienceandshouldbeusedinconjunctionwithprofessional

as construction quality assurance devices), measurements

judgment. Not all aspects of this guide may be applicable in all

while drilling (MWD), cone penetrometer tests, and logging

circumstances. This ASTM standard is not intended to repre-

for petroleum or minerals are excluded.

sent or replace the standard of care by which the adequacy of

a given professional service must be judged, nor should this

1.3 Borehole geophysical techniques yield direct and indi-

document be applied without consideration of a project’s many

rect measurements with depth of the (1) physical and chemical

unique aspects. The word “Standard” in the title of this

properties of the rock matrix and fluid around the borehole, (2)

document means only that the document has been approved

fluid contained in the borehole, and (3) construction of the

through the ASTM consensus process.

borehole.

1.4 To obtain detailed information on operating methods,

2. Referenced Documents

publications (for example, 1, 2, 3, 4, 5, 6, 7, 8, and 9) should

2.1 ASTM Standards:

be consulted. A limited amount of tutorial information is

D653 Terminology Relating to Soil, Rock, and Contained

provided, but other publications listed herein, including a

Fluids

glossary of terms and general texts on the subject, should be

D5088 Practice for Decontamination of Field Equipment

consulted for more complete background information.

Used at Waste Sites

D5608 Practices for Decontamination of Field Equipment

1.5 This guide provides an overview of the following: (1)

the uses of single borehole geophysical methods, (2) general Used at Low Level Radioactive Waste Sites

logging procedures, (3) documentation, (4) calibration, and (5)

3. Terminology

factors that can affect the quality of borehole geophysical logs

and their subsequent interpretation. Log interpretation is very

3.1 Definitions—Definitions shall be in accordance with

important, but specific methods are too diverse to be described

Terminology D653.

in this guide.

3.2 Descriptions of Terms Specific to This Standard—Terms

shall be in accordance with Ref (10).

ThisguideisunderthejurisdictionofASTMCommitteeD18onSoilandRock

and is the direct responsibility of Subcommittee D18.01 on Surface and Subsurface The use of radioactive materials required for some log measurements is

Characterization. regulatedbyfederal,state,andlocalagencies.Specificrequirementsandrestrictions

Current edition approved May 1, 2010. Published September 2010. Originally must be addressed prior to their use.

approved in 1995. Last previous edition approved in 2005 as D5753–05. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D5753-05R10. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5753 − 05 (2010)

4. Summary of Guide 6.1.3 The draw works move the logging cable and probe up

and down the borehole and provide the connection with the

4.1 This guide applies to borehole geophysical techniques

interfaces and surface controls.

that are commonly used in geotechnical investigations. This

6.1.4 The depth measurement system provides probe depth

guide briefly describes the significance and use, apparatus,

information for the interfaces and surface controls and record-

calibration and standardization, procedures and reports for

ing systems.

planning and conducting borehole geophysical logging. These

6.1.5 Thesurfaceinterfacesandcontrolsprovidesomeorall

techniques are described briefly in Table 1 and their applica-

5 of the following: electrical connection, signal conditioning,

tions in Table 2.

power, and data transmission between the recording system

4.2 Many other logging techniques and applications are

and probe.

described in the textbooks in the reference list. There are a

6.1.6 The recording system includes the digital recorder and

number of logging techniques with potential geotechnical

an analog display or hard copy device.

applications that are either still in the developmental stage or

havelimitedcommercialavailability.Someofthesetechniques

7. Calibration and Standardization of Geophysical Logs

and a reference on each are as follows: buried electrode direct

7.1 General:

current resistivity (11), deeply penetrating electromagnetic

7.1.1 National Institute of Standards and Technology

techniques (12), gravimeter (13), magnetic susceptibility (14),

(NIST) calibration and operating procedures do not exist for

magnetometer, nuclear activation (15), dielectric constant (16),

the borehole geophysical logging industry. However, calibra-

radar (17), deeply penetrating seismic (13), electrical polariz-

tion or standardization physical models are available (see

ability (18), sequential fluid conductivity (19), and diameter

Appendix X1).

(20). Many of the guidelines described in this guide also apply

7.1.2 Geophysical logs can be used in a qualitative (for

totheuseofthesenewertechniquesthatarestillintheresearch

example, comparative) or quantitative manner, depending on

phase. Accepted practices should be followed at the present

the project objectives. (For example, a gamma-gamma log can

time for these techniques.

be used to indicate that one rock is more or less dense than

another, or it can be expressed in density units.)

5. Significance and Use

7.1.3 The calibration and standardization scope and fre-

5.1 An appropriately developed, documented, and executed

quency shall be sufficient for project objectives.

guide is essential for the proper collection and application of

7.1.3.1 Calibration or standardization should be performed

borehole geophysical logs.

eachtimealoggingprobeismodifiedorrepairedoratperiodic

5.1.1 The benefits of its use include improving the follow-

intervals.

ing:

7.2 Calibration:

5.1.1.1 Selection of logging methods and equipment,

7.2.1 Calibration is the process of establishing values for

5.1.1.2 Log quality and reliability, and

log response. It can be accomplished with a representative

5.1.1.3 Usefulness of the log data for subsequent display

physical model or laboratory analysis of representative

and interpretation.

samples. Calibration data values related to the physical prop-

5.1.2 Thisguideappliestocommonlyusedloggingmethods

erties (for example, porosity) may be recorded in units (for

(see Table 1 and Table 2) for geotechnical investigations.

example, pulses/s or µm/ft) that can be converted to apparent

5.1.3 It is essential that personnel (see 7.3.3) consult up-to-

porosity units.

date textbooks and reports on each of the logging techniques,

7.2.1.1 At least three, and preferably more, values are

applications, and interpretation methods. A partial list of

needed to establish a calibration curve, and the interface or

selected publications is given at the end of this guide.

contact between different values in the model should be

5.1.4 This guide is not meant to describe the specific or

recorded. Because of the variability in subsurface conditions,

standard procedures for running each type of geophysical log

many more values are needed if sample analyses are used for

and is limited to measurements in a single borehole.

calibration.

7.2.1.2 The statistical scatter in regression of core analysis

6. Apparatus

againstgeophysicallogvaluesmaybecausedbythedifference

6.1 Geophysical Logging System, including probes, cable,

between the sample size and geophysical volume of investiga-

draw works, depth measurement system, interfaces and surface

tion and may not represent measurement error.

controls, and digital and analog recording equipment.

7.2.2 Physical Models—A representative model simulates

6.1.1 Logging probes, also called sondes or tools, enclose

thechemicalandphysicalcompositionoftherockandfluidsto

the sensors, sources, electronics for transmitting and receiving

be measured.

signals, and power supplies.

7.2.2.1 Physical models include calibration pits, coils,

6.1.2 Loggingcableroutinelycarriessignalstoandfromthe

resistors, rings, temperature baths, etc.

logging probe and supports the weight of the probe.

7.2.2.2 The calibration of nuclear probes should be per-

formed in a physical model that is nearly infinite with respect

to probe response.

7.2.2.3 Some probes have internal devices such as resistors,

The references indicated in these tables should be consulted for detailed

information on each of these techniques and applications. but this does not substitute for checking the probe response in

D5753 − 05 (2010)

TABLE 1 Common Geophysical Logs

Typical Measuring

Type of Log Varieties and Related Required Hole Brief Probe

Properties Measured Other Limitations Units and Calibration

(References) Techniques Conditions Description

or Standardization

Spontaneous potential differential electric potential uncased hole filled salinity difference mV; calibrated power records natural

(7,8,12) caused by salinity with conductive fluid needed between supply voltages between

differences in borehole borehole fluid and electrode in well and

and interstitial fluids, interstitial fluids; needs another at surface

streaming potentials correction for other

than NaCl fluids

Single-point resistance conventional, resistance of rock, uncased hole filled not quantitative; hole Ω;V-Ω meter constant current

(7) differential saturating fluid, and with conductive fluid diameter effects are applied across lead

borehole fluid significant electrode in well and

another at surface of

well

Multi-electrode various normal resistivity and uncased hole filled reverses or provides Ω-m; resistors across current and potential

resistivity (7,8,13) focused, guard, lateral saturating fluids with conductive fluid incorrect values and electrodes electrodes in probe

arrays thickness in thin beds and remote current

and potential

electrodes

Induction (10, 11) various coil spacings conductivity or uncased hole or not suitable for high mS orΩ-m; standard transmitting coil(s)

resistivity of rock and nonconductive casing; resistivities dry air zero check or induce eddy currents

saturating fluids air or fluid filled conductive ring in formation; receiving

coil(s) measures

induced voltage from

secondary magnetic

field

Gamma (5,7,22) gamma spectral (44) gamma radiation from any hole conditions may be problem with pulses per second or scintillation crystal and

natural or artificial very large hole, or API units; gamma photomultiplier tube

radioisotopes several strings of source measure gamma

casing and cement radiation

Gamma-gamma (23, compensated (dual electron density optimum results in severe hole-diameter gs/cm ; Al, Mg, or scintillation crystal(s)

24) detector) uncased hole; can be effects; difficulty Lucite blocks shielded from

calibrated for casing measuring formation radioactive source

density through casing measure Compton

or drill stem scattered gamma

Neutron (7, 14, 25) epithermal, thermal, hydrogen content optimum results in hole diameter and pulses/s or API units; crystal(s) or gas-filled

compensated sidewall, uncased hole; can be chemical effects calibration pit or tube(s) shielded from

activation, pulsed calibrated for casing plastic sleeve radioactive neutron

source

Acoustic velocity (5, compensated, compressional wave fluid filled, uncased, does not detect velocity units, for 1 or more transmitters

26, 27) waveform, cement velocity or transit time, except cement bond secondary porosity; example, ft/s or m/s or and 2 or more

bond or compressional cement bond and µs/ft; steel pipe receivers

wave amplitude wave form require

expert analysis

Acoustic televiewer acoustic caliper acoustic reflectivity of fluid filled, 3 to 16-in. heavy mud or mud orientated image- rotating transducer

(28, 7) borehole wall diameter; problems in cake attenuate signal; magnetometer must sends and receives

deviated holes very slow logging be checked high-frequency pulses

speed

A

Borehole video axial or side view visual image on tape air or clean water; may need special NA video camera and light

(radial) clean borehole wall cable source

Caliper (29, 7) oriented, 4-arm high- borehole or casing any conditions deviated holes limit distance units, for 1 to 4 retractable arms

resolution, x-y or max- diameter some types; significant example, in.; jig with contact borehole wall

min bow spring resolution difference holes or rings

between tools

Temperature (30, 31, differential temperature of fluid fluid filled large variation in °C or °F; ice bath or thermistor or solid-

32) near sensor accuracy and constant temperature state sensor

resolution of tools bath

Fluid conductivity (7) fluid resistivity most measure fluid filled accuracy varies, µS/cm orΩ-m; ring el

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.