ASTM C1506-01

(Test Method)Standard Test Method for Water Retention of Hydraulic Cement-Based Mortars and Plasters

Standard Test Method for Water Retention of Hydraulic Cement-Based Mortars and Plasters

SCOPE

1.1 This test method provides for the determination of water retention of hydraulic cement-based mortars and plasters.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1506 – 01

Standard Test Method for

Water Retention of Hydraulic Cement-Based Mortars and

Plasters

This standard is issued under the fixed designation C 1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ability of mortars and plasters to retain water under suction.

Test results may be used to determine compliance with

1.1 This test method provides for the determination of water

specifications.

retention of hydraulic cement-based mortars and plasters.

4.2 The results obtained using this test method can be used

1.2 The values stated in SI units are to be regarded as the

to compare the relative ability of mortars and plasters to retain

standard.

water under suction.

1.3 This standard does not purport to address all of the

4.3 The results obtained using this test method for masonry

safety concerns, if any, associated with its use. It is the

mortars do not necessarily indicate the degree of water

responsibility of the user of this standard to establish appro-

retention when used with masonry units, since the amount of

priate safety and health practices and determine the applica-

water absorbed by the unit depends on the rate of absorption of

bility of regulatory limitations prior to use. (Warning—Fresh

the masonry unit.

hydraulic cementitious mixtures are caustic and may cause

4.4 The results obtained using this test method for plasters

chemical burns to skin and tissue upon prolonged exposure.)

(stucco) do not necessarily indicate the degree of water

2. Referenced Documents retention when the plaster is applied as a second coat on the

surface of a previously applied plaster base coat, since the

2.1 ASTM Standards:

amount of water absorbed from the second coat of plaster

C 109/C 109M Test Method for Compressive Strength of

depends on the rate of absorption of the base coat. This is also

Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube

true when a plaster is applied as a coating on masonry units.

Specimens)

C 185 Test Method for Air Content of Hydraulic Cement

5. Apparatus

Mortar

5.1 Tamper, conforming to Test Method C 109/C 109M.

C 230 Specification for Flow Table for Use in Tests of

3 5.2 Straightedge, conforming to Test Method C 185.

Hydraulic Cement

5.3 Flow Table, conforming to Specification C 230.

C 305 Practice for Mechanical Mixing of Hydraulic Cement

3 5.4 Mixing Apparatus, conforming to the requirements pre-

Pastes and Mortars of Plastic Consistency

scribed in Practice C 305.

C 670 Practice Preparing Precision and Bias Statements for

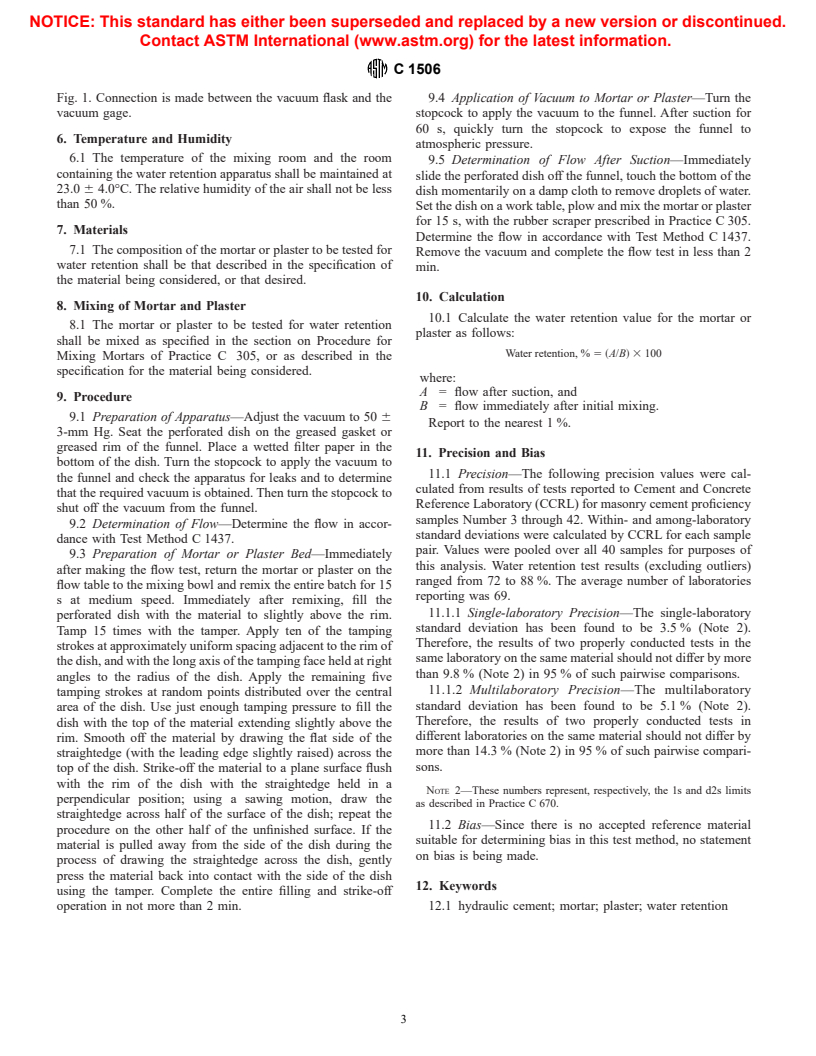

4 5.5 Filtration Assembly, an apparatus essentially as shown

Test Methods for Construction Materials

in Fig. 1 shall be used. This apparatus consists of a perforated

C 1437 Test Method for Flow of Hydraulic Cement Mortar

dish resting on a funnel, which is connected by a three-way

3. Summary of Test Method

stopcock to a vacuum flask, to which a controlled vacuum is

applied. The perforated dish shall be made of metal not

3.1 The flow of the mortar or plaster is determined. The

attacked by masonry mortar or plaster (Note 1). The metal base

mortar or plaster is then subjected to a controlled vacuum

of the dish shall have a thickness of 1.8 6 0.1 mm and shall

suction for 60 s, after which the flow is again determined. The

conform to the requirements given in Fig. 1. The stopcock bore

water retention is the final flow divided by the initial flow

shall have a 4.0 6 0.5-mm diameter, and the connecting glass

expressed as a percentage.

tubing shall have a minimum inside diameter of 4 mm. The

4. Significance and Use

length of the tubing projecting into the 1-L flask from the

stopcock shall extend at least 25 mm below the center line of

4.1 This test method provides a means for determining the

the vacuum connection. The contact surfaces of the funnel and

perforated dish shall be plane and may need to be lapped to

This test method is under the jurisdiction of ASTM Committee C01 on Cement

ensure intimate contact. An airtight seal shall be maintained

and is the direct responsibility of Subcommittee C01.22 on Workability.

between the funnel and the dish during the test. This shall be

Current edition approved Aug. 10, 2001. Published October 2001.

Section on Safety, Manual of Cement Testing, Annual Book of ASTM

accomplished by either of the following procedures. (1)A

Standards, Vol 04.01.

synthetic (grease-resistant) rubber gasket may be permanently

Annual Book of ASTM Standards, Vol 04.01.

4 sealed to the top of the funnel using petrolatum or light grease

Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1506

NOTE—The gasket is to be synthetic rubber. The stopcock and the bore of the tubing shall be at least 4-mm. A check valve or water trap, or both, is

suggested for the connection to the vacuum source.

FIG. 1 Apparatus Assembly for the Water-Retention Test

NOTE 1—Stainless steel, brass, and bronze are suitable metals for this

to ensure a seal between the gasket and dish. (2) The top of the

purpose.

funnel may be lightly coated with petroleum or light grease to

ensure a seal between the funnel and dish. Care should be taken 5.6 Controlled Vacuum Source:

to ensure that none of the holes in the perforated dish become 5.6.1 A vacuum gage capable of reading at least 70 mm of

clogged. Hardened, smooth, not rapid filter paper shall be used. Hg in 1-mm increments, connected to a miniature vacuum

It shall be 150 mm in diameter and be placed so as to regulator having a maximum 400-mm capacity, which is then

completely cover the perforations in the dish. connected to a vacuum pump or water aspirator as shown in

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1506

Fig. 1. Connection is mad

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.