ASTM D2712-91(1996)

(Test Method)Standard Test Method for Hydrocarbon Traces in Propylene Concentrates By Gas Chromatography

Standard Test Method for Hydrocarbon Traces in Propylene Concentrates By Gas Chromatography

SCOPE

1.1 This test method covers the determination of 5 to 500 ppm each of ethylene, total butylenes, acetylene, methyl acetylene, propadiene, and butadiene in propylene concentrates.

1.2 The values stated in SI units are to be regarded as standard. The values stated in inch-pound units are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety practices and to determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2712 – 91 (Reapproved 1996)

Standard Test Method for

Hydrocarbon Traces in Propylene Concentrates By Gas

Chromatography

This standard is issued under the fixed designation D 2712; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Molecular Weight and Specific Gravity

1. Scope

Specific

1.1 This test method covers the determination of 5 to 500

Molecular

Compound Gravity,

Weight

ppm each of ethylene, total butylenes, acetylene, methyl

60/60

acetylene, propadiene, and butadiene in propylene concen- Propylene 42.08 0.5220

Propane 44.09 0.5077

trates.

1.2 The values stated in SI units are to be regarded as

standard. The values stated in inch-pound units are for infor-

mation only.

5. Apparatus

1.3 This standard does not purport to address all of the

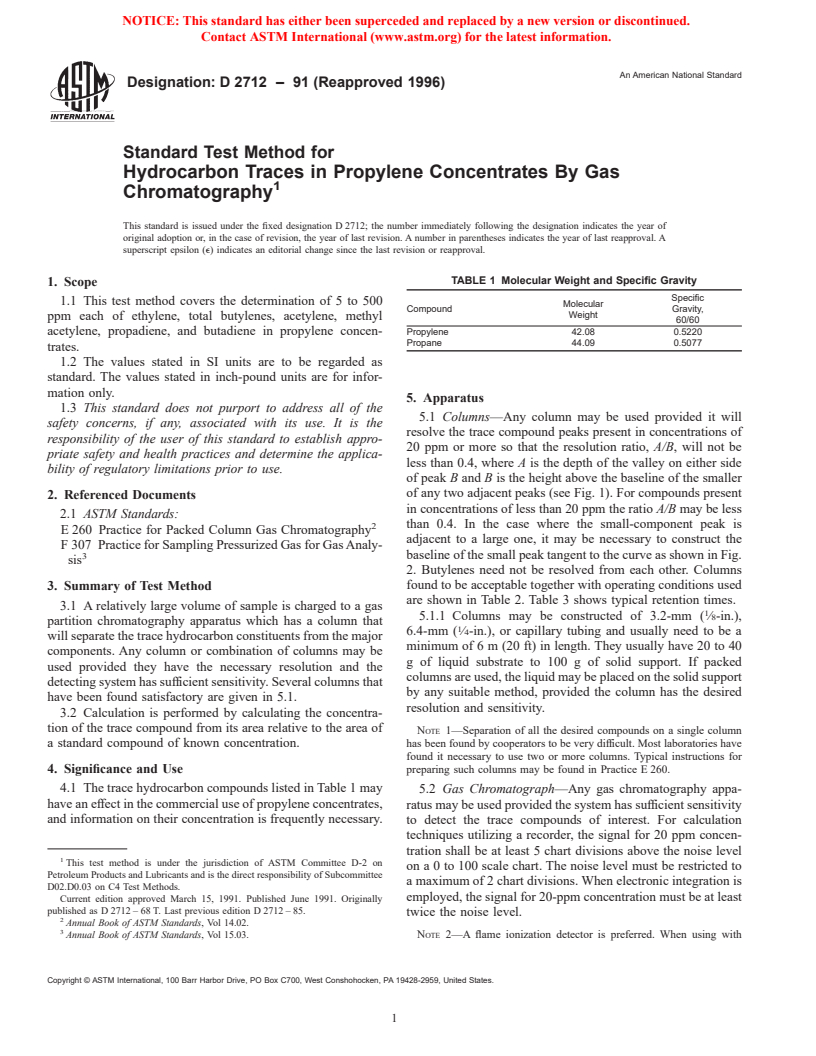

5.1 Columns—Any column may be used provided it will

safety concerns, if any, associated with its use. It is the

resolve the trace compound peaks present in concentrations of

responsibility of the user of this standard to establish appro-

20 ppm or more so that the resolution ratio, A/B, will not be

priate safety and health practices and determine the applica-

less than 0.4, where A is the depth of the valley on either side

bility of regulatory limitations prior to use.

of peak B and B is the height above the baseline of the smaller

of any two adjacent peaks (see Fig. 1). For compounds present

2. Referenced Documents

in concentrations of less than 20 ppm the ratio A/B may be less

2.1 ASTM Standards:

than 0.4. In the case where the small-component peak is

E 260 Practice for Packed Column Gas Chromatography

adjacent to a large one, it may be necessary to construct the

F 307 Practice for Sampling Pressurized Gas for Gas Analy-

baseline of the small peak tangent to the curve as shown in Fig.

sis

2. Butylenes need not be resolved from each other. Columns

found to be acceptable together with operating conditions used

3. Summary of Test Method

are shown in Table 2. Table 3 shows typical retention times.

3.1 A relatively large volume of sample is charged to a gas

5.1.1 Columns may be constructed of 3.2-mm ( ⁄8-in.),

partition chromatography apparatus which has a column that

6.4-mm ( ⁄4-in.), or capillary tubing and usually need to be a

will separate the trace hydrocarbon constituents from the major

minimum of 6 m (20 ft) in length. They usually have 20 to 40

components. Any column or combination of columns may be

g of liquid substrate to 100 g of solid support. If packed

used provided they have the necessary resolution and the

columns are used, the liquid may be placed on the solid support

detecting system has sufficient sensitivity. Several columns that

by any suitable method, provided the column has the desired

have been found satisfactory are given in 5.1.

resolution and sensitivity.

3.2 Calculation is performed by calculating the concentra-

tion of the trace compound from its area relative to the area of

NOTE 1—Separation of all the desired compounds on a single column

a standard compound of known concentration. has been found by cooperators to be very difficult. Most laboratories have

found it necessary to use two or more columns. Typical instructions for

4. Significance and Use

preparing such columns may be found in Practice E 260.

4.1 The trace hydrocarbon compounds listed in Table 1 may

5.2 Gas Chromatograph—Any gas chromatography appa-

have an effect in the commercial use of propylene concentrates,

ratus may be used provided the system has sufficient sensitivity

and information on their concentration is frequently necessary.

to detect the trace compounds of interest. For calculation

techniques utilizing a recorder, the signal for 20 ppm concen-

tration shall be at least 5 chart divisions above the noise level

This test method is under the jurisdiction of ASTM Committee D-2 on

ona0to100 scale chart. The noise level must be restricted to

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

a maximum of 2 chart divisions. When electronic integration is

D02.D0.03 on C4 Test Methods.

employed, the signal for 20-ppm concentration must be at least

Current edition approved March 15, 1991. Published June 1991. Originally

published as D 2712 – 68 T. Last previous edition D 2712 – 85.

twice the noise level.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 15.03. NOTE 2—A flame ionization detector is preferred. When using with

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2712 – 91 (1996)

6.8 Stainless Steel Sample Cylinder, 300 to 500-cm capac-

ity, capable of withstanding a minimum of 1723 kPa gage (250

psig).

6.9 Silicone Rubber Septum, with suitable fittings for attach-

ment to sample cylinder.

6.10 Gas Syringe, 10-cm .

6.11 Vacuum Pump, capable of evacuating sample cylinder

to less than 2 mm Hg absolute pressure.

6.12 Aluminum or Stainless Steel Tubing, 0.61 m (2 ft), 3.2

1 1

mm ( ⁄8 in.), or 1.6 mm ( ⁄16 in.), outside diameter with fittings

on one end to connect to butadiene cylinder and the other end

modified so as to have an opening with an inside diameter of

FIG. 1 Illustration of A/B Ratio about 0.5 mm larger than the outside diameter of the gas

syringe needle.

NOTE 3—Warning: Liquified petroleum gas under pressure and flam-

mable.

NOTE 4—Warning: Compressed gas under pressure.

NOTE 5—Warning: Compressed gas under pressure and flammable.

NOTE 6—Warning: Hexamethylphosphoramide is a potential carcino-

gen.

7. Sampling

7.1 This section is to be followed on all samples including

unknown samples and the synthetic standards.

7.2 Samples should be supplied to the laboratory in high-

pressure sample cylinders, obtained using the procedures

described in Practice F 307 or similar methods.

FIG. 2 Illustration of A/B Ratio for Small-Component Peak

7.3 Place the cylinder in a horizontal position in a safe

location such as a hood. Check to see that the container is at

least one-half full by slightly opening the valve. If liquid is

relatively volatile liquid phases, such as HMPA, an additional 0.31-m

emitted (a white cloud of vapors) the container is at least

(1-ft) section of column containing uncoated solid support will aid in

one-half full. Do not analyze any samples or use any synthetic

reducing noise.

standard if the liquid in the container is less than this amount.

5.3 Sample Introduction—Means shall be provided for in-

7.4 Place the cylinder in a vertical position and repressure to

troducing a measured quantity of sample into the apparatus.

1723 kPa gage (250 psig) with the chromatographic carrier gas

Pressure sampling devices may be used to inject a small

through the valve at the top of the cylinder, ensuring that no air

amount of the liquid directly into the carrier gas. Introduction

enters during the operation.

may be by means of a gas valve to charge the vaporized liquid.

7.5 Use either of the following two procedures for obtaining

a sample from the container:

6. Reagents and Materials

7.5.1 Using a Liquid Valve—Connect the cylinder to the

6.1 Hydrocarbons, for peak identification, including propy- liquid valve on the chromatograph using a minimum length of

lene, ethylene, ethane, acetylene, methyl acetylene, propadi-

connecting tubing, so that sample is withdrawn from the

ene, propane, 1,3-butadiene, isobutylene, 1-butene, cis and bottom of the cylinder and a liquid sample is obtained. The

trans 2-butene, iso- and normal butane, and cyclopropane.

liquid valve on the chromatograph must be designed in such a

(Warning—See Note 3.) Mixtures of these hydrocarbons may manner that full sample pressure can be maintained through the

be used for calibration provided there is no uncertainty as to the

valve without leaking and that means are provided for trapping

identity of the desired compound. a liquid sample in the chromatograph valve under static

6.2 Propane or Propylene, for synthetic base stock contain- conditions of flow. With the exit of the chromatograph valve

ing less than 2 ppm by weight of acetylene or 1,3-butadiene. closed open the valve on the cylinder. Slowly open the exit

(Warning—See Note 3.) from the chromatograph valve so that liquid flows through the

6.3 Calibration Compounds—Acetylene and 1,3-butadiene connecting line and valve. Close the exits so that the liquid

99 % minimum purity. (Warning—See Note 3.) sample is trapped in the valve. Perform the necessary opera-

6.4 Carrier Gases—Helium or Nitrogen.(Warning— tions to introduce the liquid sample into the chromatograph

See Note 4.) column.

6.5 Hydrogen.(Warning—See Note 5.) 7.5.2 Vaporized Sample—Assemble the apparatus similar to

6.6 Liquid Phase for Column—See Table 2. (Warning— that illustrated in Fig. 3. Disconnect the 1700-cm cylinder at

See Note 6.) E and evacuate. Close valve B and open valves C and D,

6.7 Solid Support—C firebrick or diatomaceous earth, allowing the liquid sample to flow into the small cylinder.

usually 40 to 60 or 60 to 80 mesh. Slowly open valve B and allow the sample to flow through until

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2712 – 91 (1996)

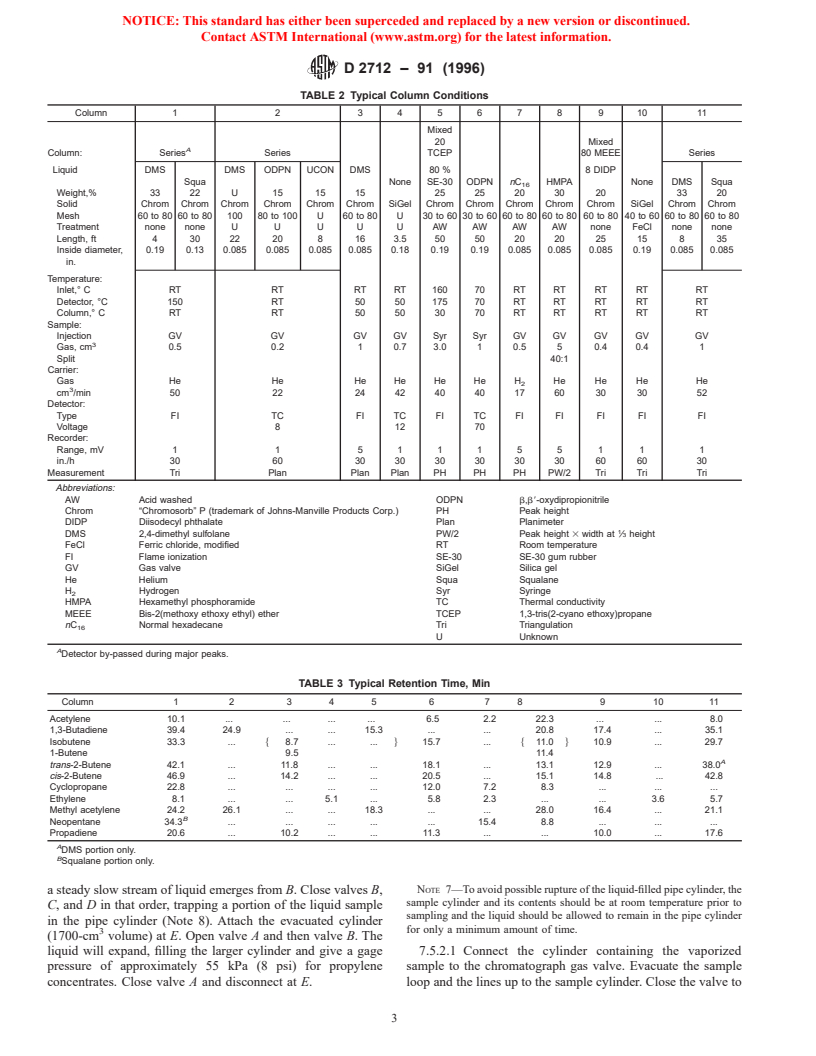

TABLE 2 Typical Column Conditions

Column 1 2 345678 9 10 11

Mixed

20 Mixed

A

Column: Series Series TCEP 80 MEEE Series

Liquid DMS DMS ODPN UCON DMS 80 % 8 DIDP

Squa None SE-30 ODPN nC HMPA None DMS Squa

Weight,% 33 22 U 15 15 15 25 25 20 30 20 33 20

Solid Chrom Chrom Chrom Chrom Chrom Chrom SiGel Chrom Chrom Chrom Chrom Chrom SiGel Chrom Chrom

Mesh 60 to 80 60 to 80 100 80 to 100 U 60 to 80 U 30 to 60 30 to 60 60 to 80 60 to 80 60 to 80 40 to 60 60 to 80 60 to 80

Treatment none none U U U U U AW AW AW AW none FeCl none none

Length, ft 4 30 22 20 8 16 3.5 50 50 20 20 25 15 8 35

Inside diameter, 0.19 0.13 0.085 0.085 0.085 0.085 0.18 0.19 0.19 0.085 0.085 0.085 0.19 0.085 0.085

in.

Temperature:

Inlet,° C RT RT RT RT 160 70 RT RT RT RT RT

Detector, °C 150 RT 50 50 175 70 RT RT RT RT RT

Column,° C RT RT 50 50 30 70 RT RT RT RT RT

Sample:

Injection GV GV GV GV Syr Syr GV GV GV GV GV

Gas, cm 0.5 0.2 1 0.7 3.0 1 0.5 5 0.4 0.4 1

Split 40:1

Carrier:

Gas He He He He He He H He He He He

cm /min 50 22 24 42 40 40 17 60 30 30 52

Detector:

Type FI TC FI TC FI TC FI FI FI FI FI

Voltage 8 12 70

Recorder:

Range, mV 1 1 511155 1 1 1

in./h 30 60 30 30 30 30 30 30 60 60 30

Measurement Tri Plan Plan Plan PH PH

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.