ASTM D2593-23

(Test Method)Standard Test Method for Butadiene Purity and Hydrocarbon Impurities by Gas Chromatography

Standard Test Method for Butadiene Purity and Hydrocarbon Impurities by Gas Chromatography

SIGNIFICANCE AND USE

4.1 The trace hydrocarbon compounds listed can have an effect in the commercial use of butadiene. This test method is suitable for use in process quality control and in setting specifications.

SCOPE

1.1 This test method covers the determination of butadiene-1,3 purity and impurities such as propane, propylene, isobutane, n-butane, butene-1, isobutylene, propadiene, trans-butene-2, cis-butene-2, butadiene-1,2, pentadiene-1,4, and, methyl, dimethyl, ethyl, and vinyl acetylene in polymerization grade butadiene by gas chromatography. Impurities including butadiene dimer, carbonyls, inhibitor, and residue are measured by appropriate ASTM procedures and the results used to normalize the component distribution obtained by chromatography.

Note 1: Other impurities present in commercial butadiene must be calibrated and analyzed. Other impurities were not tested in the cooperative work on this test method.

Note 2: This test method can be used to check for pentadiene-1,4 and other C5s instead of Test Method D1088.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.1 and 9.3.

1.3.1 The user is advised to obtain LPG safety training for the safe operation of this test method procedure and related activities.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2593 − 23

Standard Test Method for

Butadiene Purity and Hydrocarbon Impurities by Gas

1

Chromatography

This standard is issued under the fixed designation D2593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers the determination of butadiene- 2.1 ASTM Standards:

1,3 purity and impurities such as propane, propylene, D1088 Method of Test for Boiling Point Range of

3

isobutane, n-butane, butene-1, isobutylene, propadiene, trans- Polymerization-Grade Butadiene (Withdrawn 1983)

4

butene-2, cis-butene-2, butadiene-1,2, pentadiene-1,4, and,

2.2 Energy Institute Standards:

methyl, dimethyl, ethyl, and vinyl acetylene in polymerization

IP 194 Analysis of Butadiene-1,3 Polymerization Grade

grade butadiene by gas chromatography. Impurities including

3. Summary of Test Method

butadiene dimer, carbonyls, inhibitor, and residue are measured

by appropriate ASTM procedures and the results used to

3.1 A representative sample is introduced into a gas-liquid

normalize the component distribution obtained by chromatog-

partition column. The butadiene and other components are

raphy.

separated as they are transported through the column by an

inert carrier gas. Their presence in the effluent is measured by

NOTE 1—Other impurities present in commercial butadiene must be

a detector and recorded as a chromatogram. The chromatogram

calibrated and analyzed. Other impurities were not tested in the coopera-

tive work on this test method.

of the sample is interpreted by applying component attenuation

NOTE 2—This test method can be used to check for pentadiene-1,4 and

and detector response factors to the peak areas or peak heights

other C s instead of Test Method D1088.

5

and the relative concentration determined by relating indi-

1.2 The values stated in SI units are to be regarded as

vidual peak response to total peak response. Impurities includ-

standard. No other units of measurement are included in this

ing butadiene dimer, carbonyls, inhibitor, and residue are

standard.

measured by appropriate ASTM procedures and the results

used to normalize the distribution obtained by gas chromatog-

1.3 This standard does not purport to address all of the

raphy.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 4.1 The trace hydrocarbon compounds listed can have an

For specific warning statements, see 6.1 and 9.3. effect in the commercial use of butadiene. This test method is

1.3.1 The user is advised to obtain LPG safety training for suitable for use in process quality control and in setting

the safe operation of this test method procedure and related specifications.

activities.

5. Apparatus

1.4 This international standard was developed in accor-

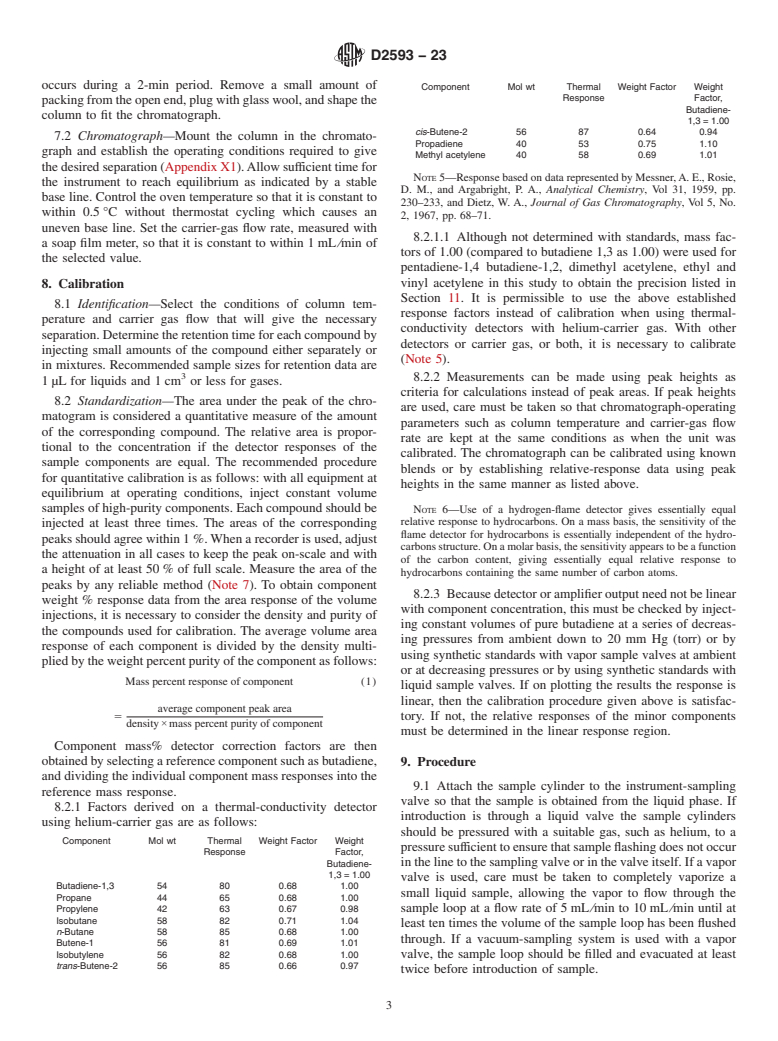

5.1 Chromatograph—Any chromatograph having either a

dance with internationally recognized principles on standard-

thermal-conductivity or flame ionization detector can be used

ization established in the Decision on Principles for the

provided the system has sufficient sensitivity and stability to

Development of International Standards, Guides and Recom-

obtain a recorder deflection of at least 2 mm at signal-to-noise

mendations issued by the World Trade Organization Technical

ratio of at least 5:1 for 0.01 % by mass of impurity.

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee D02 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee D02.D0.04 on C4 and C5 Hydrocarbons. the ASTM website.

3

This test method was adopted as a joint ASTM-IP Standard, IP 194, in 1972. The last approved version of this historical standard is referenced on

Current edition approved March 1, 2023. Published June 2023. Originally www.astm.org.

4

approved in 1967. Last previous edition approved in 2019 as D2593 – 19. DOI: Obsolete. Contact Energy Institute, 61 New Cavendish St., London, WIG 7AR,

10.1520/D2593-23. U.K., http://www.energyinst.org.uk.

*A Summary of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2593 − 19 D2593 − 23

Standard Test Method for

Butadiene Purity and Hydrocarbon Impurities by Gas

1

Chromatography

This standard is issued under the fixed designation D2593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of butadiene-1,3 purity and impurities such as propane, propylene, isobutane,

n-butane, butene-1, isobutylene, propadiene, trans-butene-2, cis-butene-2, butadiene-1,2, pentadiene-1,4, and, methyl, dimethyl,

ethyl, and vinyl acetylene in polymerization grade butadiene by gas chromatography. Impurities including butadiene dimer,

carbonyls, inhibitor, and residue are measured by appropriate ASTM procedures and the results used to normalize the component

distribution obtained by chromatography.

NOTE 1—Other impurities present in commercial butadiene must be calibrated and analyzed. Other impurities were not tested in the cooperative work

on this test method.

NOTE 2—This test method can be used to check for pentadiene-1,4 and other C s instead of Test Method D1088.

5

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific warning statements, see 6.1 and 9.3.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of

the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific warning statements, see 6.1 and 9.3.

1.3.1 The user is advised to obtain LPG safety training for the safe operation of this test method procedure and related activities.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.D0.04 on C4 and C5 Hydrocarbons.

This test method was adopted as a joint ASTM-IP Standard, IP 194, in 1972.

Current edition approved Dec. 1, 2019March 1, 2023. Published January 2020June 2023. Originally approved in 1967. Last previous edition approved in 20142019 as

D2593 – 93 (2014).D2593 – 19. DOI: 10.1520/D2593-19.10.1520/D2593-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2593 − 23

3

D1088 Method of Test for Boiling Point Range of Polymerization-Grade Butadiene (Withdrawn 1983)

4

2.2 Energy Institute Standards:

IP 194 Analysis of Butadiene-1,3 Polymerization Grade

3. Summary of Test Method

3.1 A representative sample is introduced into a gas-liquid partition column. The butadiene and other components are separated

as they are transported through the column by an inert carrier gas. Their presence in the effluent is measured by a detector and

recorded as a chromatogram. The chromatogram of the sample is interpreted by applying component attenuation and detector

response factors to the peak areas or peak heights and the relative concentration determined by relating individual peak response

to total peak response. Impurities including butadiene dimer, carbonyls, inhibitor, and residue are measured by appropriate ASTM

procedures and the results used to normalize the dis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.