ASTM D3052-23

(Practice)Standard Practice for Rating Water-Emulsion Floor Polishes

Standard Practice for Rating Water-Emulsion Floor Polishes

SIGNIFICANCE AND USE

3.1 When comparing different floor polishes for an actual field performance, it is important that all surfaces used be prepared in the same way. When this procedure is followed, variations in the test surfaces are minimized.

SCOPE

1.1 This practice covers the comparison of the performance of water-emulsion floor polishes on test floors against a reference material. It is applicable to the following types of polishes:

1.1.1 Wax emulsion polishes,

1.1.2 Nonbuffable emulsion polishes,

1.1.3 Detergent-resistant emulsion polishes, household type, and

1.1.4 Detergent-resistant emulsion polishes, industrial type.

1.2 Gloss, leveling, discoloration, traffic marking, slip resistance, and removal ease of these types of floor polishes is rated in comparison to a reference material. Where applicable, detergent resistance is also evaluated. This method is not to be considered as a recommended maintenance procedure.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3052 − 23

Standard Practice for

1

Rating Water-Emulsion Floor Polishes

This standard is issued under the fixed designation D3052; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice covers the comparison of the performance

D523 Test Method for Specular Gloss

of water-emulsion floor polishes on test floors against a

2.2 HCPA Bulletin:

reference material. It is applicable to the following types of

245-70 Comparative Determination of Slip Resistance of

polishes:

3

Floor Polishes

1.1.1 Wax emulsion polishes,

1.1.2 Nonbuffable emulsion polishes,

3. Significance and Use

1.1.3 Detergent-resistant emulsion polishes, household type,

3.1 When comparing different floor polishes for an actual

and

field performance, it is important that all surfaces used be

1.1.4 Detergent-resistant emulsion polishes, industrial type.

prepared in the same way. When this procedure is followed,

variations in the test surfaces are minimized.

1.2 Gloss, leveling, discoloration, traffic marking, slip

resistance, and removal ease of these types of floor polishes is

4. Apparatus

rated in comparison to a reference material. Where applicable,

4

4.1 Test Tile, Official Vinyl Composition Tile (OVCT).

detergent resistance is also evaluated. This method is not to be

considered as a recommended maintenance procedure.

4.2 Glossmeter, 60°—The instrument and the reference

standards shall conform to the requirements prescribed in Test

1.3 The values stated in inch-pound units are to be regarded

Method D523, using an angle of reflection of 60°.

as the standard. The values given in parentheses are for

4.3 Floor Machine.

information only.

1.4 The values stated in inch-pound units are to be regarded

5. Procedure

as standard. The values given in parentheses are mathematical

5.1 The preferred substrate shall be OVCT.

conversions to SI units that are provided for information only

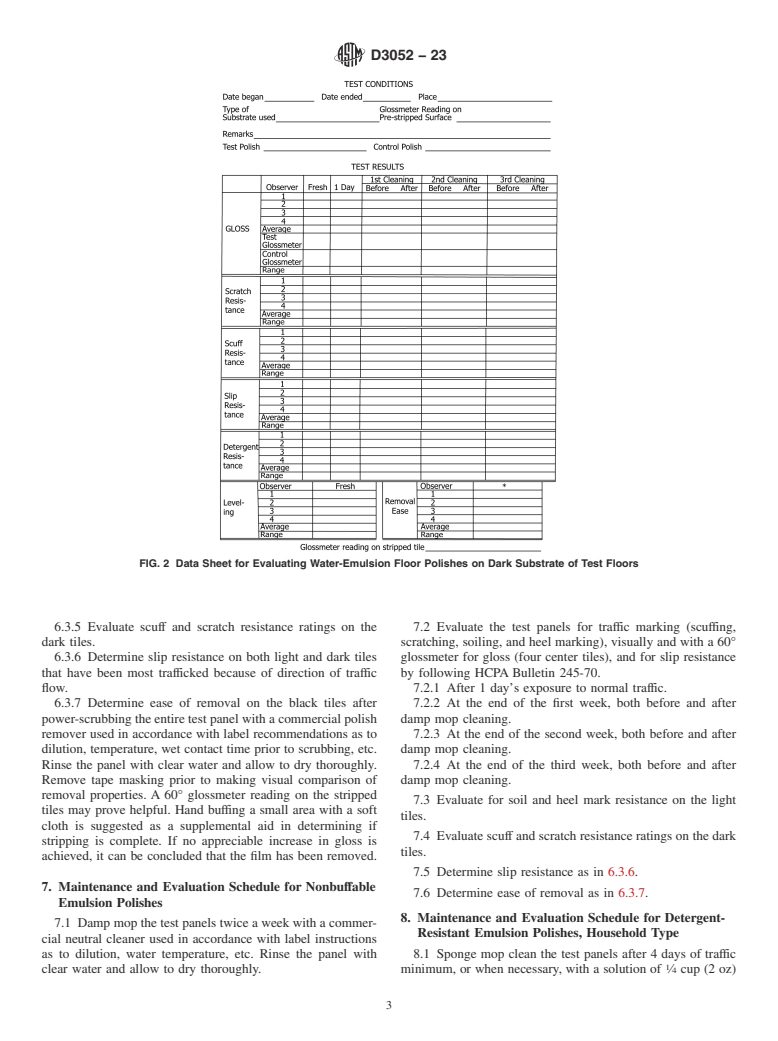

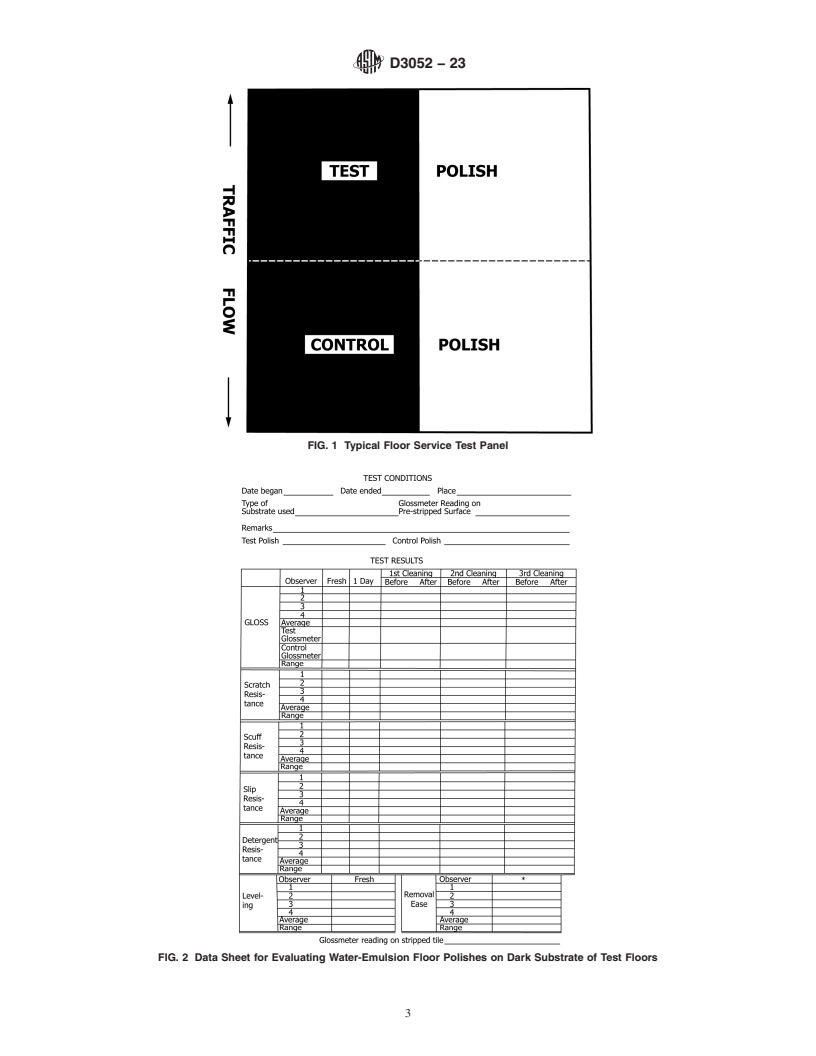

5.2 The test floor shall include both dark (black) and light

and are not considered standard.

(white) colored tiles laid out so that one half of the panel is all

1.5 This standard does not purport to address all of the

white and the other half is all black.

safety concerns, if any, associated with its use. It is the

5.3 The minimum test panel size for each polish tested shall

responsibility of the user of this standard to establish appro-

be 3 ft (0.9 m) in width and 3 ft in length.

priate safety, health, and environmental practices and deter-

5.4 Prepare all of the test panels with scrub-cleaned new

mine the applicability of regulatory limitations prior to use.

tiles, or strip completely of dirt and old wax, rinse thoroughly,

1.6 This international standard was developed in accor-

and dry before application of the test polishes. Under no

dance with internationally recognized principles on standard-

circumstances should comparative tests be made on new versus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Barriers to Trade (TBT) Committee.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from the Household & Commercial Products Association, 1625 I

1

This practice is under the jurisdiction of ASTM Committee D21 on Polishes Street NW Suite 700, Washington, DC 20006.

4

and is the direct responsibility of Subcommittee D21.04 on Performance Tests. OVCT tile may be obtained through Armstrong Flooring from various home

Current edition approved Dec. 1, 2023. Published January 2024. Originally improvement stores. The following Armstrong tile substrates have been found to

approved in 1972. Last previous edition approved in 2017 as D3052 – 17. DOI: perform adequately for this test method: Armstrong Excelon Feature Tile: Black

10.1520/D3052-23. (56790).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3052 − 23

old tiles. Similarly, where old tiles are employed, care should to 90 °F (21.1 °C to 32.2 °C) and above 70 % relative humidity

be taken to employ tiles or panels with approximately equiva- may nec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3052 − 17 D3052 − 23

Standard Practice for

1

Rating Water-Emulsion Floor Polishes

This standard is issued under the fixed designation D3052; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the comparison of the performance of water-emulsion floor polishes on test floors against a reference

material. It is applicable to the following types of polishes:

1.1.1 Wax emulsion polishes,

1.1.2 Nonbuffable emulsion polishes,

1.1.3 Detergent-resistant emulsion polishes, household type, and

1.1.4 Detergent-resistant emulsion polishes, industrial type.

1.2 Gloss, leveling, discoloration, traffic marking, slip resistance, and removal ease of these types of floor polishes is rated in

comparison to a reference material. Where applicable, detergent resistance is also evaluated. This method is not to be considered

as a recommended maintenance procedure.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D523 Test Method for Specular Gloss

1

This practice is under the jurisdiction of ASTM Committee D21 on Polishes and is the direct responsibility of Subcommittee D21.04 on Performance Tests.

Current edition approved March 1, 2017Dec. 1, 2023. Published April 2017January 2024. Originally approved in 1972. Last previous edition approved in 20102017 as

D3052 – 87 (2010).D3052 – 17. DOI: 10.1520/D3052-17.10.1520/D3052-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3052 − 23

2.2 CSMAHCPA Bulletin:

3

245-70 Comparative Determination of Slip Resistance of Floor Polishes

3. Significance and Use

3.1 When comparing different floor polishes for an actual field performance, it is important that all surfaces used be prepared in

the same way. When this procedure is followed, variations in the test surfaces are minimized.

4. Apparatus

4

4.1 Test Tile, OVCT.Official Vinyl Composition Tile (OVCT).

4.2 Glossmeter, 60°—The instrument and the reference standards shall conform to the requirements prescribed in Test Method

D523, using an angle of reflection of 60°.

4.3 Floor Machine.

5. Procedure

5.1 The preferred substrate shall be Official Vinyl Composition Tile.OVCT.

5.2 The test floor shall include both dark (black) and light (white) colored tiles laid out so that one half of the panel is all white

and the other half is all black.

5.3 The minimum test panel size for each polish tested shall be 3 ft (0.9 m) in width and 3 ft in length.

5.4 Prepare all of the test panels with scrub-cleaned new tiles, or strip completely of dirt and old wax, rinse thoroughly, and dry

before application of the test polishes. Under no circumstances should comparative tests be made on new versus old tiles. Similarly,

where old tiles are employed, care should be taken to employ tiles or panels with approximately equivalent traffic history.

5.5 Mask a small portion of a black tile prior to polishing so as to provide an unpolished control area. The masking is to remain

during the entire traffic period.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.