ASTM D4002-81(2023)

(Practice)Standard Practice for Evaluation of Buffable Shoe Polish

Standard Practice for Evaluation of Buffable Shoe Polish

SIGNIFICANCE AND USE

3.1 This practice is intended to define the properties to be tested, the apparatus to use, and the comparisons of product performance. It is recognized that considerable discretion exists among formulators and marketers of shoe polish on what properties or performance characteristics are best for their products. This practice will be flexible to honor this fact within the confines of the shoe polish definition in 2.1.

SCOPE

1.1 This practice covers the definition of properties to test and the apparatus to use, in evaluating the performance of buffable shoe polishes.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4002 − 81 (Reapproved 2023)

Standard Practice for

Evaluation of Buffable Shoe Polish

This standard is issued under the fixed designation D4002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope product, a modified formulation of the test polish, etc. The one

stipulation is that, the control polish be of the same or similar

1.1 This practice covers the definition of properties to test

type as the test polish. For example, if the test polish is an

and the apparatus to use, in evaluating the performance of

aerosol-emulsion polish, the control should be an aerosol-

buffable shoe polishes.

emulsion polish. It would not be meaningful to select a paste or

1.2 This standard does not purport to address all of the

liquid product as a control for comparison to an aerosol-

safety concerns, if any, associated with its use. It is the

emulsion test polish.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4.3 Test Substrates—The test substrate should be one for

mine the applicability of regulatory limitations prior to use.

which the test polish is intended. Separate tests should be

1.3 This international standard was developed in accor-

conducted for smooth-grained leather substrates to which the

dance with internationally recognized principles on standard-

most current leather finishes have been applied at a tannery.

ization established in the Decision on Principles for the

The finished leather should be the exact type normally used by

Development of International Standards, Guides and Recom-

the shoe manufacturer to fabricate everyday dress shoes. Test

mendations issued by the World Trade Organization Technical

substrates of man-made materials should be obtained in the

Barriers to Trade (TBT) Committee.

same manner. The test surface should be in good physical

condition, not badly cracked, scratched, or otherwise damaged

2. Terminology

so as to interfere with evaluation of polish properties. Various

2.1 shoe polish—aids in cleaning, improving the

colors are required, see Section 9.

appearance, and protecting leather or other shoe materials from

4.4 Applicators—Several methods of shoe polish applica-

such common damaging effects as scuffs, water, salt water, and

tion to substrates should be tested. Various types of applicators

other surface deposits, commonly encountered with the use of

include brush, cloth, and foam. The same type of applicator

shoes outdoors or indoors. A buffable shoe polish requires

buffing to obtain appearance improvements. should be used to apply the polish for both the control and test

polish.

3. Significance and Use

4.5 Polishing Cloth—The same type of polishing cloth

3.1 This practice is intended to define the properties to be

should be used for each sample. Materials such as washed

tested, the apparatus to use, and the comparisons of product

cheese cloth, rumple cloth, flannel, cotton diaper cloth, and

performance. It is recognized that considerable discretion

nonwoven fabrics are suitable for this purpose. Felt or paper

exists among formulators and marketers of shoe polish on what

should not be used.

properties or performance characteristics are best for their

products. This practice will be flexible to honor this fact within 4.6 Polishing Brush—A separate horsehair brush or horse-

the confines of the shoe polish definition in 2.1. hair composition shoe brush should be used with each sample.

4.7 Cleaning Solvent—Aliphatic solvents with kauri-

4. Apparatus and Materials

butanol values less than 38.

4.1 Test Polish.

4.8 Eye Droppers and Tap Water.

4.2 Control Polish—The control polish is selected subjec-

tively for comparison to the test polish. It may be a competitive

4.9 Sharp Metal Knife.

4.10 Light-Colored Wool, Polyester/Cotton Pieces, of trou-

This practice is under the jurisdiction of ASTM Committee D21 on Polishes

ser or dress clothing.

and is the direct responsibility of Subcommittee D21.04 on Performance Tests.

Current edition approved Sept. 1, 2023. Published September 2023. Originally 4.11 Thermometer.

approved in 1981. Last previous edition approved in 2016 as D4002 – 81 (2016).

DOI: 10.1520/D4002-81R23. 4.12 Humidity Gauge.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4002 − 81 (2023)

5. Precautions 8.1.1 These four positionings should be written on tags and

drawn randomly by each of the four who apply the polishes.

5.1 The temperature and relative humidity of the test runs

should be measured and recorded. The temperature should be 8.2 Method B—A controlled, randomized method of laying

within 13 °C to 29 °C (55 °F to 85 °F) with a relative humidity out the test (X) and control (C) polishes is represented as

of 20 % to 80 %. follows:

Test Panel Left Right

5.2 The substrate should have the same temperature as the

1 C X

surrounding area.

2 X C

3 C X

5.3 Comparisons should not be made between two separate

4 X C

swatches (or leather objects) since leather substrates may vary

8.2.1 These four positionings should be written on tags and

widely.

drawn randomly by each of the four who apply the polishes.

5.4 Leather substrates are normally used only one time.

9. Evaluation

6. Personnel and Instructions

9.1 Compare the test polish and the control as follows:

6.1 The application and evaluation of the test and control 9.1.1 Application and Buffıng Properties (ease of rub-up to

polishes require four individuals. They should be capable of maximum gloss)—During application and buffing of the

making discriminating judgments of subjective physical and polishes, note the time and ease with which each product

aesthetic properties. Training and orientation to specific prod- develops maximum gloss.

uct performance characteristics may be required. 9.1.2 Final Properties—Evaluate any or all of the following

properties no sooner than 5 min following application:

6.1.1 The four persons should apply the polishes to one of

9.1.2.1 Gloss—Evaluate as depth of gloss and buffing.

each of the four test substrates. All persons then rate all

properties, except application properties, on the remaining 9.1.2.2 Uniformity—Observe the surface for streaks, unpol-

ished dry spots, and general uniformity.

three panels that they did not apply polish to. The persons

applying the polishes should rate ease of use and other 9.1.2.3 Film Clarity—Observe the clearness or sharpness of

an object’s image in the surface of the polish. Overhead lights,

application properties. This means there will be only four

readings on application properties. The three rating the other face, hand, or other objects may be used for reflection. This test

may be eliminated for low-lustre surfaces that do not possess

properties, do not observe the application because they rate

properties of each polish “blind.” mirror-like finishes.

9.1.2.4 Smear and Scuff Resistance—Smear is the degree of

oiliness or greasiness after the polish is rubbed-up to the

7. Procedure

desired polish appearance. Scuff is the degree of film damage

7.1 Cleaning of Test Substrates—An aliphatic solvent hav-

resulting from a glancing blow to the polish substrate. Check

ing a kauri-butanol value less than 38 should be used to lightly

smear by making a design such as an “S” with one’s finger. A

wipe the test substrate. Soft cotton towels may be used to apply

glancing blow with one’s knuckles or soft object such as a

the solvent to the surface and to wipe it clean. New or

book or magazine may be used for determining the degree of

adequately laundered towels should be used each time.

scuff.

7.2 Surface Subdivision—The precleaned surface of each

9.1.2.5 Film Healing—Observe the length of time required

test substrate should be divided and outlined by tape with

for the smear or scuff in 9.1.2.4 to disappear from the polish

uniform squares.

film, should it occur.

9.1.2.6 Rebuffability—Observe the ease of completeness or

7.3 Application of polish or wax—Assuming the control

repairability when the smears and scuffs are buffed with a

polish or the test polish is a commercially available product,

polishing cloth. The amount of physical effort and length of

follow the directions on the container as far as possible. When

time required is noted.

in doubt on the method of use, the

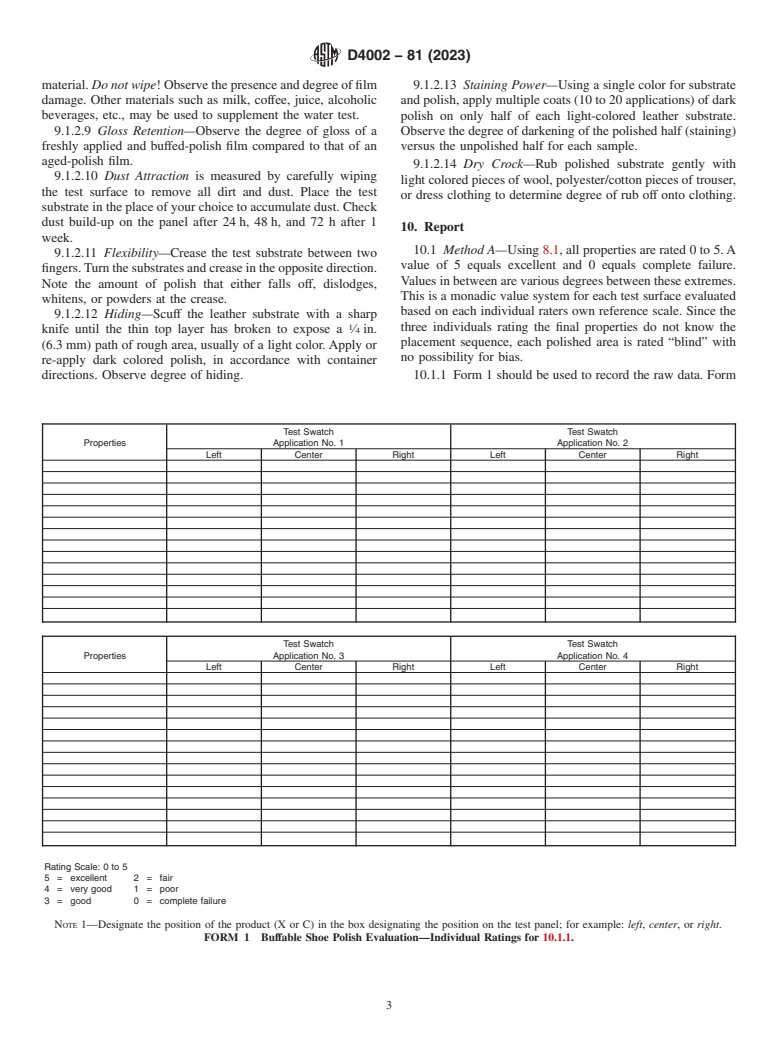

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.