ASTM F913-01

(Specification)Standard Specification for Thermoplastic Elastomeric Seals (Gaskets) for Joining Plastic Pipe

Standard Specification for Thermoplastic Elastomeric Seals (Gaskets) for Joining Plastic Pipe

SCOPE

1.1 This specification covers thermoplastic elastomeric seals (gaskets) used to seal the joints of plastic pipe and fittings used for gravity and low-pressure applications. This specification refers to push-on joints that require no internal or external pressure to effect the initial seal.

1.2 Requirements are given for thermoplastic elastomers.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: F 913 – 01 An American National Standard

Standard Specification for

Thermoplastic Elastomeric Seals (Gaskets) for Joining

1

Plastic Pipe

This standard is issued under the fixed designation F 913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope unless otherwise specified.

3.2 Terms relating to rubber or elastomer shall be as defined

1.1 This specification covers thermoplastic elastomeric

in Terminology D 1566 and Definitions F 118.

seals (gaskets) used to seal the joints of plastic pipe and fittings

2

3.3 Definitions of Terms Specific to This Standard:

used for gravity and low-pressure applications. This specifi-

3.3.1 gravity and low pressure applications—pressure be-

cation refers to push-on joints that require no internal or

low 50-ft head of water or 21 psi.

external pressure to effect the initial seal.

1.2 Requirements are given for thermoplastic elastomers.

4. Materials and Manufacture

1.3 The following precautionary caveat pertains only to the

4.1 The gasket shall be fabricated from a high-grade ther-

test methods portion, Section 8, of this specification: This

moplastic elastomer meeting the requirements in Table 1.

standard does not purport to address all of the safety concerns,

4.2 The gasket shall meet the stress relaxation requirements

if any, associated with its use. It is the responsibility of the user

of 5.1.3.

of this standard to establish appropriate safety and health

4.3 The thermoplastic elastomer used must be noncrazing to

practices and determine the applicability of regulatory limita-

pipe. The gasket shall not cause craze marks, pits, or blisters in

tions prior to use.

contact with the plastic pipe. Staining of the plastic pipe in the

2. Referenced Documents area of gasket contact is acceptable. Test in accordance with

8.8 to qualify thermoplastic elastomers for pipe made from the

2.1 ASTM Standards:

3 plastic polymer in question.

D 412 Test Methods for Rubber Properties in Tension

4.4 Where the particular joint design utilizing a TPEL

D 471 Test Method for Rubber Property—Effect of Liq-

3

gasket dictates the use of lubricant to facilitate assembly, the

uids

lubricant shall be of such composition that will in no way

D 573 Test Method for Rubber—Deterioration in an Air

3

damage the gasket or pipe due to prolonged exposure and shall

Oven

not adversely affect the sealing capability of the gasket.

D 1149 Test Method for Rubber Deterioration—Surface

3

Ozone Cracking in a Chamber (Flat Specimens)

NOTE 1—By agreement between the purchaser and the manufacturer,

4

D 1414 Test Methods for Rubber O-Rings chemical analysis may be required and limits established for elements or

3,4

compounds not specified.

D 1566 Terminology Relating to Rubber

D 1600 Terminology for Abbreviated Terms Relating to

5. Physical Requirements

5

Plastics

5.1 The sealing portion of the gasket shall comply with the

D 2240 Test Method for Rubber Property—Durometer

3

physical requirements listed in Table 1 when tested in accor-

Hardness

6

dance with the methods in Section 8.

F 412 Terminology Relating to Plastic Piping Systems

4

F 118 Definitions of Terms Relating to Gaskets

NOTE 2—Some gasket incorporated a high durometer elastomeric or

nonelastomeric, that is, metal or plastic material, as a reinforcement or

3. Terminology

retaining feature, or both. These materials do not alter the physical

properties of the sealing portion of the gasket and should not be tested as

3.1 Definitions—are in accordance with Terminology F 412,

such, or expected to meet the material requirements listed in Table 1.

and abbreviations are in accordance with Terminology D 1600,

NOTE 3—The materials used for retaining or reinforcement, or both,

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

should not encroach upon the sealing surfaces of the gasket, and have

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

physical properties which are adequate for the anticipated usage of the

Current edition approved April 10, 2001. Published June 2001. Originally

gasket.

published as F 913 – 86. Last previous edition F 913 – 95.

2

Supporting data are available at ASTM Headquarters. Request RR:F17-1035.

5.1.1 Hardness—A variation of 65 points of Type A

3

Annual Book of ASTM Standards, Vol 09.01.

durometer from the manufacturer’s specified hardness shall be

4

Annual Book of ASTM Standards, Vol 09.02.

5

allowed when tested in accordance with 8.3.

Annual Book of ASTM Standards, Vol 08.01.

6

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

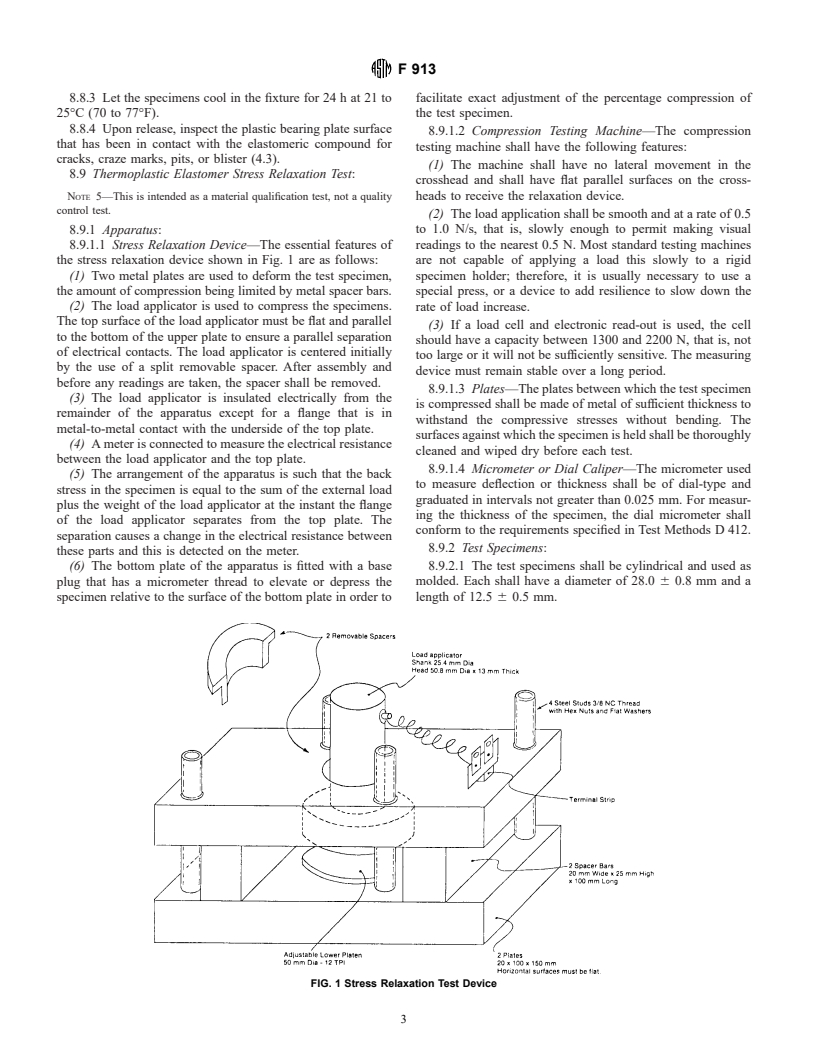

F 913

TABLE 1 Physical Property Requirements for Seals Made from The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.