ASTM C210-95(2007)e1

(Test Method)Standard Test Method for Reheat Change of Insulating Firebrick

Standard Test Method for Reheat Change of Insulating Firebrick

SIGNIFICANCE AND USE

Insulating firebrick (IFB) are classified by their bulk density and reheat change (see Classification C 155). This test method defines thermal stability by measurement of IFB’reheat change following 24 h at a test temperature.

Since this test exposes the entire sample to an isothermal temperature condition, the user should be aware that most applications for IFB involve a thermal gradient which may cause the IFB’dimensions to change differentially.

SCOPE

1.1 This test method covers the determination of the permanent linear (and volume) change of insulating firebrick upon reheating under prescribed conditions.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C210 − 95(Reapproved 2007)

Standard Test Method for

Reheat Change of Insulating Firebrick

This standard is issued under the fixed designation C210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorially corrected Table 1 in March 2007.

1. Scope applications for IFB involve a thermal gradient which may

cause the IFB’s dimensions to change differentially.

1.1 This test method covers the determination of the perma-

nent linear (and volume) change of insulating firebrick upon

4. Apparatus

reheating under prescribed conditions.

4.1 The test kiln shall be capable of maintaining the

1.2 The values stated in inch-pound units are to be regarded

required temperature with a variation of not more than one half

as the standard. The values given in parentheses are for

a standard pyrometric cone over the hearth area during the

information only.

prescribed heating schedule. If a gas- or oil-fired kiln is used,

1.3 This standard does not purport to address all of the

it shall be of the downdraft type and of such a design as not to

safety concerns, if any, associated with its use. It is the

permit the flame from the burner to impinge upon the test

responsibility of the user of this standard to establish appro-

specimens.The kiln atmosphere during the test shall be kept as

priate safety and health practices and determine the applica-

oxidizing as is practicable.

bility of regulatory limitations prior to use.

5. Procedure

2. Referenced Documents

5.1 Test Specimens and Measurements:

2.1 ASTM Standards:

5.1.1 Thetestspecimensshallconsistofthreebrick(Note1)

C24 Test Method for Pyrometric Cone Equivalent (PCE) of

1 1

measuring 9 by 4 ⁄2 by 2 ⁄2 or 3 in. (228 by 114 by 64 or 76

Fireclay and High Alumina Refractory Materials

mm) or three pieces of these dimensions cut out of larger

C155 Classification of Insulating Firebrick

shapes.

E230 Specification and Temperature-Electromotive Force

(EMF) Tables for Standardized Thermocouples

NOTE1—Threesupportingbrickfromthesamelotasthetestspecimens

E1256 Test Methods for Radiation Thermometers (Single are required also, so that the test sample is comprised of six brick.

Waveband Type)

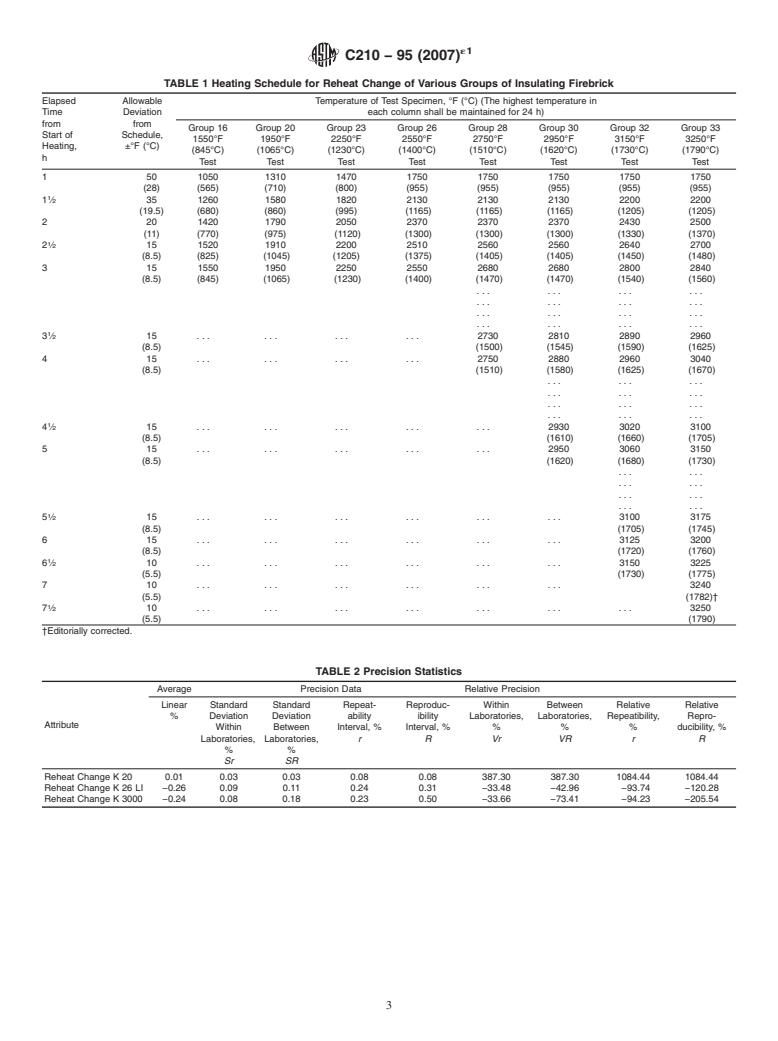

5.1.2 Each specimen shall be labeled with ceramic paint,

and before and after heating they shall be carefully measured

3. Significance and Use

for length (Note 2), width, and thickness. Three measurements

3.1 Insulating firebrick (IFB) are classified by their bulk

(Note3)tothenearest0.02in.(0.5mm)shallbetakenforeach

density and reheat change (see Classification C155). This test

dimension and the average of these shall be used. Each

method defines thermal stability by measurement of IFB’s

dimension shall be measured in three places along the longi-

reheat change following 24 h at a test temperature.

tudinal center line on opposite faces, one measurement at the

center of the line and one ⁄2 in. (13 mm) in from each edge.

3.2 Sincethistestexposestheentiresampletoanisothermal

Fig. 1 shows the location at which these measurements are to

temperature condition, the user should be aware that most

be made.

NOTE 2—For classifying IFB according to Classification C155, obtain

This test method is under the jurisdiction of ASTM Committee C08 on

the reheat change from the 9-in. (228-mm) dimension measurements only.

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

NOTE 3—Because of the large pore size of some IFB, it is difficult to

Properties.

measurebymeansofcalipersdirectlyonthebricksurfaces.Accuracymay

Current edition approved March 1, 2007. Published April 2007. Originally

be obtained by holding two small pieces of flat polished steel plate of

approved in 1946. Last previous edition approved in 2005 as C210 – 95 (2005).

known thickness against the faces between which the dimension is to be

Originally part of C93. DOI: 10.1520/C0210-95R07E01.

obtained, and calipering on the outside steel surfaces rather than directly

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

against the brick surfaces. It is permissible to use a measuring device to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on obtain the dimensions of the brick, provided the measurements are not

the ASTM website. affected by large pores in the surface.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C210 − 95 (2007)

8. Calculation and Report

8.1 Reheat Change—Calculate the reheat change in percent

from the average measurement for the dimension obtained

before and after reheating.

8.2 Reheat Volume Change—When the reheat volume

change is requested, calculate it from the average measurement

for the three dimensions obtained before and after reheating, as

follows:

V 5 @~V 2 V !/V # 3100 (1)

o f o

where:

NOTE 1—The dots on the center line of each face are ⁄2 in. (13 mm) in

V = volume change, percent,

from each edge, and the cross on the axis is in the center. These positions

V = original volume, and

o

indicate the points at which three measurements for each dimensions are

V = final volume.

f

to be made.

FIG. 1 Test Brick Showing Measurement Locations 8.3 Report—When the test is conducted for evaluating IFB

in accordance with Classification C155, the average linear

change for the 9-in. (228-mm) dimension only shall be re-

5.2 Placing Test Specimens in Kiln:

ported; otherwise, or when specified, the average of the reheat

5.2.1 Place the test specimens in the kiln so that each will

1 change for the length, width, and thickness shall be reported

rest on a 9 by 2 ⁄2 or 3-in. (228 by 64 or 76-mm) face. Place

and, if requested, the average reheat volume change.

each specimen upon the 9 by 2 ⁄2 or 3-in. face of a supporting

brick that shall be from the same lot as the test specimen. Place

9. Precision and Bias

between the test specimen and the supporting member a layer

9.1 Interlaboratory Test Program—An interlaboratory test

ofsuitablerefractorymaterial,thatisnonreactiveunderthetest

program between six laboratories was conducted. Each labo-

conditions and passes an ASTM No. 16 (1.18-mm) sieve

ratory received 3 samples each of three IFBs, K-20, K-26 LI,

(equivalent to a 14-mesh Tyler Standard Series) and retained

and K-3000. The bricks were provided by Thermal Ceramics.

on an ASTM No. 40 (425-µm) sieve (equivalent to a 35-mesh

1 The laboratories participating were C.E. Minerals, Orton RRC,

Tyler Standard Series). Place eac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.