ASTM F2421-19a

(Test Method)Standard Test Method for Measurement of Resilient Floor Plank by Dial Gauge

Standard Test Method for Measurement of Resilient Floor Plank by Dial Gauge

SIGNIFICANCE AND USE

4.1 The combination of both dimensional properties and squareness of resilient floor plank is an important consideration because installed flooring may exhibit an objectionable appearance when either or both characteristics deviate from established tolerances. This test method provides a means of determining length and width dimensions along with squareness, by using a single apparatus and procedure.

SCOPE

1.1 This test method establishes the procedures for determination of both dimension (length and width) and squareness of a rectangular resilient floor plank.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are provided in applicable sections of this test method.

1.4 The values stated in inch-pounds units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2421 −19a

Standard Test Method for

1

Measurement of Resilient Floor Plank by Dial Gauge

This standard is issued under the fixed designation F2421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method establishes the procedures for determi- 3.1 Definitions: For definitions of terms used in this test

nation of both dimension (length and width) and squareness of method, refer to Terminology F141.

a rectangular resilient floor plank. 3.2 resilient floor plank—shape of a modular flooring ele-

ment where the length is generally significantly longer than the

1.2 The values stated in inch-pound units are to be regarded

width, by at least 2/1, L/W (length/width) aspect ratio. Typical

as standard. The values given in parentheses are mathematical

plank maximums for width run ≤18 in. (457.2 mm) and

conversions to SI units that are provided for information only

maximums for length ≤8 ft (2.44 m).

and are not considered standard.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 The combination of both dimensional properties and

responsibility of the user of this standard to establish appro-

squarenessofresilientfloorplankisanimportantconsideration

priate safety, health, and environmental practices and deter-

because installed flooring may exhibit an objectionable appear-

mine the applicability of regulatory limitations prior to use.

ance when either or both characteristics deviate from estab-

Specific precautionary statements are provided in applicable

lished tolerances. This test method provides a means of

sections of this test method.

determining length and width dimensions along with

1.4 The values stated in inch-pounds units are to be re-

squareness, by using a single apparatus and procedure.

garded as the standard. The values given in parentheses are for

information only.

5. Apparatus

1.5 This international standard was developed in accor-

5.1 The example apparatus consists of five dial gauges and

dance with internationally recognized principles on standard-

two reference index strips mounted on a flat bedplate in a

ization established in the Decision on Principles for the

configuration that, by rotation and flipping of the sample,

Development of International Standards, Guides and Recom-

allows the measurement of all four sides of resilient plank

mendations issued by the World Trade Organization Technical

samples. (See Fig. 1). One edge of the bedplate is elevated to

Barriers to Trade (TBT) Committee.

create a test surface, which is offset or tilted 15 6 1 degrees

from horizontal. The offset applies minimal pressure to the test

2. Referenced Documents

specimen against the longer index strip to ensure repeatable

2

2.1 ASTM Standards:

measurement. A reference plate representing target plank size

F141 Terminology Relating to Resilient Floor Coverings

and squareness (see Fig. 2) is used to zero all dial gauges.

3

2.2 ANSI Standards:

Referenceplatemustbesubstantialandnotreadilysubjectedto

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

1

deflection or distortion, i.e. ⁄2 in. (12.7 mm) aluminum,

spection by Attributes

60.001 in. (0.025 mm) tolerance for stated length and width

and for squareness allowable tolerance shall be 90 degrees 6

10 s (1.57080 6 0.0005 rad). Dial gauges should be mounted

1

This test method is under jurisdiction of ASTM F06 Committee on Resilient

on adjustable height brackets to allow for optimizing measure-

Floor Coverings and is the direct responsibility of subcommittee F06.20 on Test

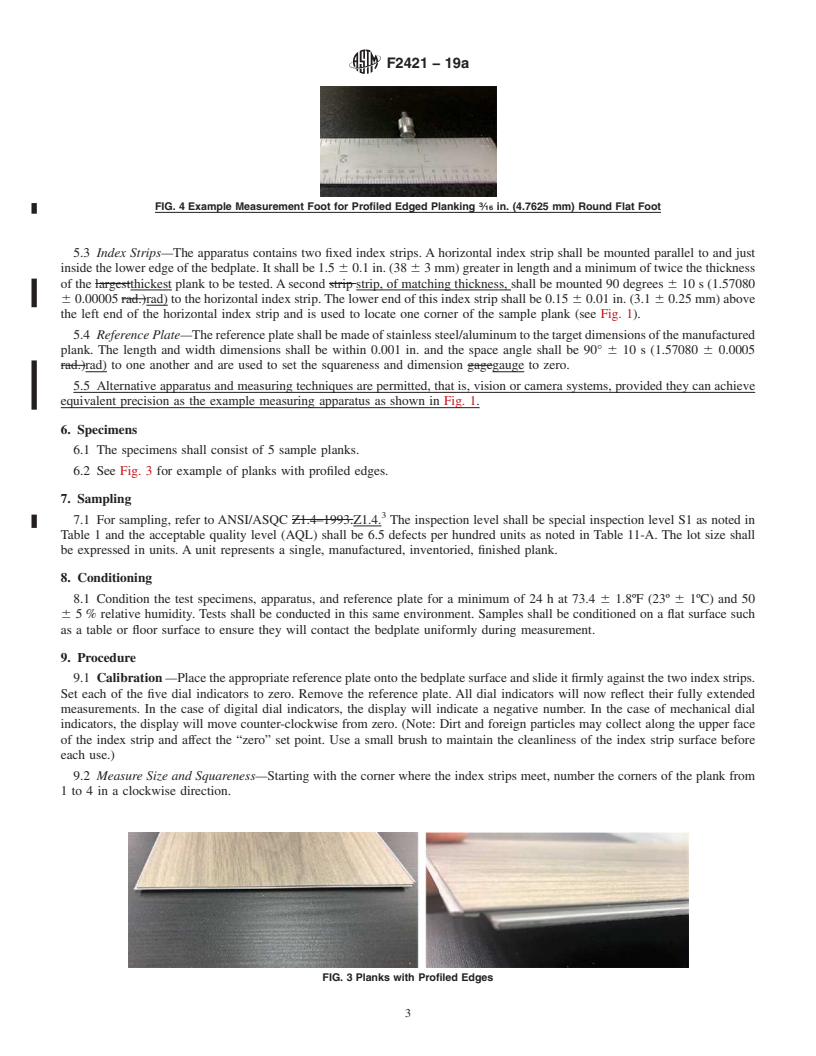

ment location, especially for planks with profiled edges (see

Methods

Fig. 3) and 5.2.

Current edition approved Feb. 1, 2019. Published March 2019. Originally

approved in 2005. Last previous edition approved in 2019 as F2421–19. DOI:

5.2 Dial Gauges—The five dial gauges are mounted in

10.1520/F2421-19A.

2

guide slots, which are machined into the bedplate to allow for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

measurement of various plank sizes. For the two corner gauges

Standards volume information, refer to the standard’s Document Summary page on

(B & D) and the squareness gauge (A) the position must be at

the ASTM website.

3

least within 10 % of the corner edge relative to the respective

Available from American N

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2421 − 19 F2421 − 19a

Standard Test Method for

1

Measurement of Resilient Floor Plank by Dial GageGauge

This standard is issued under the fixed designation F2421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method establishes the procedures for determination of both dimension (length and width) and squareness of a

rectangular resilient floor plank. This test method is intended for use with rectangular plank up to 36 in. (915 mm).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific precautionary statements are provided in applicable sections of this test method.

1.4 The values stated in inch-pounds units are to be regarded as the standard. The values given in parentheses are for information

only.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

F141 Terminology Relating to Resilient Floor Coverings

3

2.2 ANSI Standards:

ANSI/ASQC Z1.4-1993Z1.4 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions: For definitions of terms used in this test method, refer to Terminology F141.

3.2 resilient floor plank—shape of a modular flooring element where the length is generally significantly longer than the width,

by at least 2/1, L/W (length/width) aspect ratio. Typical plank maximums for width run ≤18 in. (457.2 mm) and maximums for

length ≤8 ft (2.44 m).

4. Significance and Use

4.1 The combination of both dimensional properties and squareness of resilient floor plank is an important consideration

because installed flooring may exhibit an objectionable appearance when either or both characteristics deviate from established

tolerances. This test method provides a means of determining length and width dimensions along with squareness, by using a single

apparatus and procedure.

5. Apparatus

5.1 The apparatusexample shall consistapparatus consists of five dial gagesgauges and two reference index strips mounted on

a flat bedplate in a configuration that, by rotation and flipping of the sample, allows the measurement of all four sides of resilient

plank samples. (See Fig. 1). One edge of the bedplate is elevated to create a test surface, which is offset or tilted 15+/-1 15 6 1

degrees from horizontal. The offset applies minimal pressure to the test specimen against the longer index strip to ensure repeatable

1

This test method is under jurisdiction of ASTM F06 Committee on Resilient Floor Coverings and is the direct responsibility of subcommittee F06.20 on Test Methods

Current edition approved Jan. 1, 2019Feb. 1, 2019. Published February 2019March 2019. Originally approved in 2005. Last previous edition approved in 20112019 as

F2421–05 (2011). –19. DOI: 10.1520/F2421-19.10.1520/F2421-19A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute, Institute (ANSI), 25 WestW. 43rd St., 4th Floor, New York, NY 10036.10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2421 − 19a

FIG. 1 Example Plank Measurement Apparatus

measurement. A reference plate representing target plank size and squareness (see Fig. 2) is used to zero all dial gages.gauges.

1

Reference plate must be substantial and not readily subjected to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.