ASTM B473-96(2002)e1

(Specification)Standard Specification for UNS N08020, UNS N08024, and UNS N08026 Nickel Alloy Bar and Wire

Standard Specification for UNS N08020, UNS N08024, and UNS N08026 Nickel Alloy Bar and Wire

SCOPE

1.1 This specification covers UNS N08020, UNS N08026, and UNS N08024 bar and wire other than required for reforging.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: B 473 – 96 (Reapproved 2002)

Standard Specification for

UNS N08020, UNS N08024, and UNS N08026 Nickel Alloy

Bar and Wire

This standard is issued under the fixed designation B 473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Paragraph 1.3 was added editorially in June 2002.

1. Scope 3.1.2 bars, n—hot-finished rounds, squares, octagons, and

2 hexagons: ⁄4 in. (6.35 mm) and over in diameter or size.

1.1 This specification covers UNS N08020, UNS N08026,

1 1

Hot-finished flats: ⁄4 to 10 in. (254 mm), inclusive, in width, ⁄8

and UNS N08024 bar and wire other than required for

in. (3.175 mm) and over in thickness. Cold-finished rounds,

reforging.

squares, octagons, hexagons, and shapes: over ⁄2 in. (12.7 mm)

1.2 The values stated in inch-pound units are to be regarded

in diameter or size. Cold-finished flats: ⁄8 in. (9.525 mm) and

as the standard. The values given in parentheses are for

over in width (see Discussion(1)), ⁄8 in. and over in thickness

information only.

(see Discussion(2)).

1.3 This standard does not purport to address all of the

3.1.2.1 Discussion—(1) Widths less than ⁄8 in. (9.525 mm)

safety concerns, if any, associated with its use. It is the

and thicknesses less than ⁄16 in. (4.75 mm) are generally

responsibility of the user of this standard to become familiar

described as flat wire.

with all hazards including those identified in the appropriate

3.1.2.2 Discussion—(2) Thicknesses ⁄8 in. (3.175 mm) to

Material Safety Data Sheet for this product/material as pro-

under ⁄16 in. (4.75 mm) can be cold-rolled strip as well as bar.

vided by the manufacturer, to establish appropriate safety and

3.1.3 wire, n—cold finished only: round, square, octagon,

health practices, and determine the applicability of regulatory

hexagon, and shape wire, ⁄2 in. (12.7 mm) and under in

limitations prior to use.

diameter or size. Cold-finished only: flat wire, ⁄16 in. (4.76

2. Referenced Documents

mm) to under ⁄8 in. (9.525 mm) in width, 0.010 in. (0.254 mm)

to under ⁄16 in. in thickness.

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranu-

4. Ordering Information

lar Attack in Austenitic Stainless Steels

4.1 It is the responsibility of the purchaser to specify all

E 8 Test Methods forTensionTesting of Metallic Materials

requirements that are necessary for the safe and satisfactory

E 1473 Test Methods for Chemical Analysis of Nickel,

performance of material ordered under this specification.

Cobalt, and High-Temperature Alloys

Examples of such requirements include, but are not limited to,

3. Terminology

the following:

4.1.1 Quantity (weight or number of pieces),

3.1 Definitions of Terms Specific to This Standard:

4.1.2 Name of material or UNS number,

3.1.1 The terms bar and wire as used in this specification are

4.1.3 Form (bar or wire),

described as follows:

4.1.4 Dimensions,

4.1.5 Condition,

4.1.6 Finish,

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

4.1.7 ASTM designation and year of issue,

B02.07 on Refined Nickel and Cobalt and Their Alloys.

4.1.8 Inspection (15.1),

Current edition approved May 10, 1996. Published June 1996. Originally

4.1.9 Supplementary requirements, if any, and

published as B 473 – 68. Last previous edition B 473 – 95.

For ASME Boiler and Pressure Vessel Code applications see related Specifi- 4.1.10 If possible, the intended end use.

cation SB-473 in Section II of that Code.

NOTE 1—A typical ordering description is as follows: 200 bars, UNS

Annual Book of ASTM Standards, Vol 01.03.

N08020, 1 in. (25.4 mm) round by 10 to 14 ft (3.0 to 3.6 m), centerless

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 03.05. ground, Specification B 473.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 473

TABLE 2 Product Analysis Tolerances

5. Materials and Manufacture

Tolerances Over the Maximum Limit or

5.1 Heat Treatment—The product of UNS N08020 alloy

Under the Minimum Limit

shall be furnished in the stabilized-annealed condition. The

Elements

UNS UNS UNS

product of UNS N08026 alloy shall be furnished in the

N08026 N08020 N08024

solution-annealed condition. The product of UNS N08024

Carbon 0.005 0.01 0.005

alloy shall be furnished in the annealed condition.

Manganese 0.03 0.04 0.03

Phosphorus 0.005 0.005 0.005

NOTE 2—The recommended annealing temperatures all followed by

Sulfur 0.005 0.005 0.005

quenching in water or rapidly cooling by other means are as follows: 1700

Silicon 0.05 0.05 0.05

to 1850°F (927 to 1010°C) for UNS N08020, 2050 to 2200°F (1121 to

Chromium 0.25 0.25 0.25

Nickel 0.30 0.30 0.30

1204°C)forUNSN08026,and1925to1975°F(1052to1079°C)forUNS

Molybdenum 0.10 0.10 0.10

N08024.

Columbium (Nb) + tantalum . 0.05 0.05

Copper 0.10 0.10 0.10

6. Chemical Composition

Nitrogen 0.01 . .

6.1 The material shall conform to the requirements as to

chemical composition prescribed in Table 1.

6.2 If a product (check) analysis is performed by the

purchaser, the material shall conform to the product (check)

11.1.2 A lot for mechanical properties shall consist of all

analysis variations prescribed in Table 2.

material from the same heat, nominal diameter or thickness, of

each heat-treatment charge.

7. Condition

11.2 Test Material Selection:

7.1 Bars shall be furnished annealed and either hot finished

11.2.1 Chemical Analysis—Representative samples shall be

or cold finished. Strain-hardened material is available only as

taken during pouring or subsequent processing.

cold finished.

11.2.1.1 Check analysis shall be wholly the responsibility

7.2 Wire will be furnished only as annealed and cold

of the purchaser.

finished.

11.2.2 Mechanical Properties—Samples of the material to

provide test specimens shall be taken from such locations in

8. Mechanical Properties

each lot as to be representative of that lot.

8.1 The material shall conform to the applicable require-

ments as to mechanical properties prescribed in Table 3.

12. Number of Tests

9. Dimensions and Permissible Variations

12.1 Chemical Analysis—One test per lot.

9.1 Bar—Bars shall conform to the variations in dimensions 12.2 Mechanical Properties—One test per lot.

prescribed in Tables 4-12, inclusive, as applicable.

9.2 Wire—Wire shall conform to the permissible variations

13. Specimen Preparation

in dimensions prescribed in Tables 13-17, inclusive, as appli-

13.1 Tension test specimens shall be taken from the material

cable.

after final heat treatment, and shall be selected in the longitu-

dinal direction.The tension test specimens shall conform to the

10. Workmanship, Finish, and Appearance

appropriate sections of Test Methods E 8.

10.1 The product shall be uniform in quality and condition,

smooth, commercially straight or flat, and free of injurious

14. Test Methods

imperfections.

14.1 The chemical composition and mechanical properties

11. Sampling

of the material as enumerated in this specification shall, in case

11.1 Lot: of disagreement, be determined in accordance with the follow-

11.1.1 A lot for chemical analysis shall consist of one heat. ing methods:

TABLE 1 Chemical Requirements

Composition, %

Element

UNS N08026 UNS N08020 UNS N08024

Carbon, max 0.03 0.07 0.03

Manganese, max 1.00 2.00 1.00

Phosphorus, max 0.03 0.045 0.035

Sulfur, max 0.03 0.035 0.035

Silicon, max 0.50 1.00 0.50

Nickel 33.00 to 37.20 32.00 to 38.00 35.00 to 40.00

Chromium 22.00 to 26.00 19.00 to 21.00 22.50 to 25.00

Molybdenum 5.00 to 6.70 2.00 to 3.00 3.50 to 5.00

Copper 2.00 to 4.00 3.00 to 4.00 0.50 to 1.50

Columbium (Nb) + tantalum . 8 3 carbon–1.00 0.15 to 0.35

Nitrogen 0.10 to 0.16 . .

A A A

Iron remainder remainder remainder

A

By difference

B 473

A

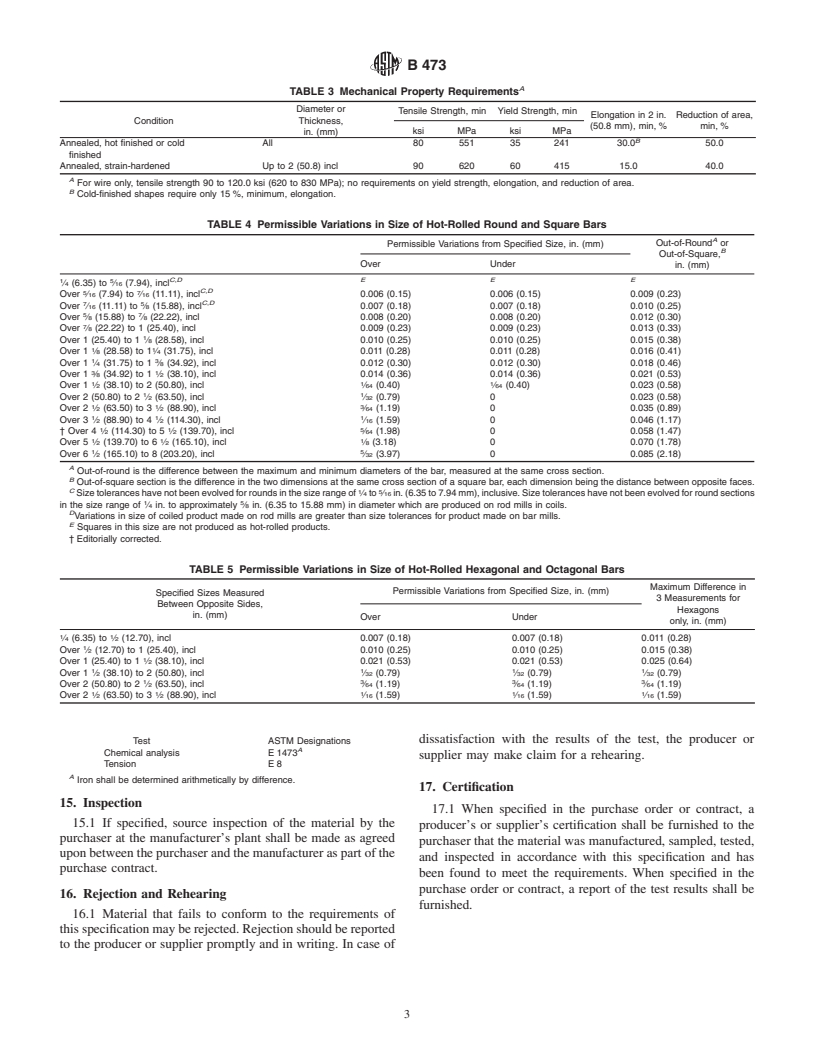

TABLE 3 Mechanical Property Requirements

Diameter or

Tensile Strength, min Yield Strength, min

Elongation in 2 in. Reduction of area,

Condition Thickness,

(50.8 mm), min, % min, %

ksi MPa ksi MPa

in. (mm)

B

Annealed, hot finished or cold All 80 551 35 241 30.0 50.0

finished

Annealed, strain-hardened Up to 2 (50.8) incl 90 620 60 415 15.0 40.0

A

For wire only, tensile strength 90 to 120.0 ksi (620 to 830 MPa); no requirements on yield strength, elongation, and reduction of area.

B

Cold-finished shapes require only 15 %, minimum, elongation.

TABLE 4 Permissible Variations in Size of Hot-Rolled Round and Square Bars

A

Out-of-Round or

Permissible Variations from Specified Size, in. (mm)

B

Out-of-Square,

Over Under

in. (mm)

C,DE E E

1 5

⁄4 (6.35) to ⁄16 (7.94), incl

5 7 C,D

Over ⁄16 (7.94) to ⁄16 (11.11), incl 0.006 (0.15) 0.006 (0.15) 0.009 (0.23)

C,D

7 5

Over ⁄16 (11.11) to ⁄8 (15.88), incl 0.007 (0.18) 0.007 (0.18) 0.010 (0.25)

5 7

Over ⁄8 (15.88) to ⁄8 (22.22), incl 0.008 (0.20) 0.008 (0.20) 0.012 (0.30)

Over ⁄8 (22.22) to 1 (25.40), incl 0.009 (0.23) 0.009 (0.23) 0.013 (0.33)

Over 1 (25.40) to 1 ⁄8 (28.58), incl 0.010 (0.25) 0.010 (0.25) 0.015 (0.38)

1 1

Over 1 ⁄8 (28.58) to 1 ⁄4 (31.75), incl 0.011 (0.28) 0.011 (0.28) 0.016 (0.41)

1 3

Over 1 ⁄4 (31.75) to 1 ⁄8 (34.92), incl 0.012 (0.30) 0.012 (0.30) 0.018 (0.46)

3 1

Over 1 ⁄8 (34.92) to 1 ⁄2 (38.10), incl 0.014 (0.36) 0.014 (0.36) 0.021 (0.53)

1 1 1

Over 1 ⁄2 (38.10) to 2 (50.80), incl ⁄64 (0.40) ⁄64 (0.40) 0.023 (0.58)

1 1

Over 2 (50.80) to 2 ⁄2 (63.50), incl ⁄32 (0.79) 0 0.023 (0.58)

1 1 3

Over 2 ⁄2 (63.50) to 3 ⁄2 (88.90), incl ⁄64 (1.19) 0 0.035 (0.89)

1 1 1

Over 3 ⁄2 (88.90) to 4 ⁄2 (114.30), incl ⁄16 (1.59) 0 0.046 (1.17)

1 1 5

† Over 4 ⁄2 (114.30) to 5 ⁄2 (139.70), incl ⁄64 (1.98) 0 0.058 (1.47)

1 1 1

Over 5 ⁄2 (139.70) to 6 ⁄2 (165.10), incl ⁄8 (3.18) 0 0.070 (1.78)

1 5

Over 6 ⁄2 (165.10) to 8 (203.20), incl ⁄32 (3.97) 0 0.085 (2.18)

A

Out-of-round is the difference between the maximum and minimum diameters of the bar, measured at the same cross section.

B

Out-of-square section is the difference in the two dimensions at the same cross section of a square bar, each dimension being the distance between opposite faces.

C

1 5

Size tolerances have not been evolved for rounds in the size range of ⁄4 to ⁄16 in. (6.35 to 7.94 mm), inclusive. Size tolerances have not been evolved for round sections

1 5

in the size range of ⁄4 in. to approximately ⁄8 in. (6.35 to 15.88 mm) in diameter which are produced on rod mills in coils.

D

Variations in size of coiled product made on rod mills are greater than size tolerances for product made on bar mills.

E

Squares in this size are not produced as hot-rolled products.

† Editorially corrected.

TABLE 5 Permissible Variations in Size of Hot-Rolled Hexagonal and Octagonal Bars

Maximum Difference in

Permissible Variations from Specified Size, in. (mm)

Specified Sizes Measured

3 Measurements for

Between Opposite Sides,

Hexagons

in. (mm)

Over Under

only, in. (mm)

1 1

⁄4 (6.35) to ⁄2 (12.70), incl 0.007 (0.18) 0.007 (0.18) 0.011 (0.28)

Over ⁄2 (12.70) to 1 (25.40), incl 0.010 (0.25) 0.010 (0.25) 0.015 (0.38)

Over 1 (25.40) to 1 ⁄2 (38.10), incl 0.021 (0.53) 0.021 (0.53) 0.025 (0.64)

1 1 1 1

Over 1 ⁄2 (38.10) to 2 (50.80), incl ⁄32 (0.79) ⁄32 (0.79) ⁄32 (0.79)

1 3 3 3

Over 2 (50.80) to 2 ⁄2 (63.50), incl ⁄64 (1.19) ⁄64 (1.19) ⁄64 (1.19)

1 1 1 1 1

Over 2 ⁄2 (63.50) to 3 ⁄2 (88.90), incl ⁄16 (1.59) ⁄16 (1.59) ⁄16 (1.59)

dissatisfaction with the results of the test, the producer or

Test ASTM Designations

A

Chemical analysis E 1473

supplier may make claim for a rehearing.

Tension E 8

A

Iron shall be determined arithmetically by difference.

17. Certification

15. Inspection

17.1 When specified in the purchase order or contract, a

15.1 If specified, source inspection of the material by the

producer’s or supplier’s certification shall be furnished to the

purchaser at the manufacturer’s plant shall be made as agreed

purchaser that the material was manufactured, sampled, tested,

upon between the purchaser and the manufacturer as part of the

and inspected in accordance with this specification and has

purchase contract.

been found to meet the requirements. When specified in the

purchase order or contract, a report of the test results shall be

16. Rejection and Rehearing

furnished.

16.1 Material that fails to conform to the requirements of

this specification may be rejected. Rejection should be reported

to the producer or supplier promptly and in writing. In case of

B 473

TABLE 6 Permissible Variations in Thickness and Width for Hot-Rolled Flat Bars

Permissible Variations in Thickness for Thicknesses Given, in. (mm)

1 1 1

Specified Width, in. (mm) ⁄8 (3.18) to ⁄2 (12.70), incl Over ⁄2 (12.70) to 1 (25.40), incl Over 1 (25.40) to 2 (50.80), incl

Over Under Over Under Over Under

To 1 (25.40), incl 0.008 (0.20) 0.008 (0.20) 0.010 (0.25) 0.010 (0.25) . .

Over 1 (25.40) to 2 (50.80), incl 0.012 (0.30) 0.012 (0.30) 0.015 (0.38) 0.015 (0.38) 0.031 (0.79) 0.031 (0.79)

Over 2 (50.80) to 4 (101.60), incl 0.015 (0.38) 0.015 (0.38) 0.020 (0.51) 0.020 (0.51) 0.031 (0.79) 0.031 (0.79)

Over 4 (101.60) to 6 (152.40), incl 0.015 (0.38) 0.015 (0.38) 0.020 (0.51) 0.020 (0.51) 0.031 (0.79) 0.031 (0.79)

Over 6 (152.40) to 8 (203.20), incl 0.016 (0.41) 0.016 (0.41) 0.025 (0.64) 0.025 (0.64) 0.031 (0.79) 0.031 (0.79)

Over 8 (203.20) to 10 (254.00), incl 0.021 (0.53) 0.021 (0.53) 0.031 (0.79) 0.031 (0.79) 0.031 (0.79) 0.031 (0.79)

Over 2 (50.80) to 4 (101.60), incl Over 4 (101.60) to 6 (152.40), incl Over 6 (152.40) to 8 (203.20), incl

Over Under Over Under Over Under

To 1 (25.40), incl . . . . . .

Over 1 (25.40) to 2 (50.80), incl . . . . . .

Over 2 (50.80) to 4 (101.60), incl 0.062 (1.57) 0.031 (0.79) . . . .

Over 4 (101.60) to 6 (152.40), incl 0.062 (1.57) 0.031 (0.79) 0.093 (2.36) 0.062 (1.57) . .

Over 6 (152.40) to 8 (203.20), incl 0.062 (1.57) 0.031 (0.79) 0.093 (2.36) 0.062 (1.57) 0.125 (3.18) 0.156 (3.96)

Over 8 (203.20) to 10 (154.00), incl 0.062 (1.57) 0.031 (0.79) 0.093 (2.36) 0.062 (1.57) 0.125 (3.18) 0.156 (3.96)

Permissible Variations in Width, in. (mm)

Specified Width, in. (mm)

Over Under

To 1 (25.40), incl 0.015 (0.38) 0.015 (0.38)

Over 1 (25.40) to 2 (50.80), incl 0.031 (0.79) 0.031 (0.79)

Over 2 (50.80) to 4 (101.60), incl 0.062 (1.57) 0.031 (0.79)

Over 4 (101.60) to 6 (152.40), incl 0.093 (2.36) 0.062 (1.57)

Over 6 (152.40) to 8 (203.20), incl 0.125 (3.18) 0.156 (3.96)

Over 8 (203.20) to 10 (254.00), incl 0.156 (3.96) 0.187 (4.75)

TABLE 7 Permissible Variations in Size of Cold-Finished Rou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.