ASTM D4169-99e1

(Practice)Standard Practice for Performance Testing of Shipping Containers and Systems

Standard Practice for Performance Testing of Shipping Containers and Systems

SCOPE

1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units to withstand the distribution environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements encountered in various distribution cycles. This practice is not intended to supplant material specifications or existing preshipment test procedures.

1.2 The suitability of this practice for use with hazardous materials has not been determined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4169 – 99

Standard Practice for

Performance Testing of Shipping Containers and Systems

This standard is issued under the fixed designation D 4169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—10.2.3 was corrected editorially to reference Test Method D 5276 in October 2000.

1. Scope D 5276 Test Method for Drop Test of Loaded Containers by

Free Fall

1.1 This practice provides a uniform basis of evaluating, in

D 5277 Test Method for Performing Programmed Horizon-

a laboratory, the ability of shipping units to withstand the

tal Impacts Using an Inclined Tester

distribution environment. This is accomplished by subjecting

D 5487 Test Method for Simulated Drop of Loaded Con-

them to a test plan consisting of a sequence of anticipated

tainers by Shock Machines

hazard elements encountered in various distribution cycles.

D 6055 Test Methods for Mechanical Handling of Unitized

This practice is not intended to supplant material specifications

Loads and Large Shipping Cases and Crates

or existing preshipment test procedures.

D 6179 Test Methods for Rough Handling of Unitized

1.2 The suitability of this practice for use with hazardous

Loads and Large Shipping Cases and Crates

materials has not been determined.

2.2 Military Standards:

1.3 This standard does not purport to address all of the

MIL-STD-2073-1 DOD Standard Practice for Military

safety concerns, if any, associated with its use. It is the

Packaging

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use. Specific precau-

3.1 Definitions— General definitions for the packaging and

tionary statements are given in 1.1.

distribution environments are found in Terminology D 996.

2. Referenced Documents 3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptance criteria—the acceptable quality level that

2.1 ASTM Standards:

must be met after the shipping unit has been subjected to the

D 642 Test Method for Determining Compressive Resis-

test plan. See Section 7.

tance of Shipping Containers, Components, and Unit

3.2.2 assurance level—the level of test intensity based on

Loads

its probability of occurring in a typical distribution cycle.

D 880 Test Method for Impact Testing for Shipping Con-

3.2.2.1 Discussion—Level I is a high level of test intensity

tainers and Systems

and has a low probability of occurrence. Level III is a low level

D 951 Test Method for Water Resistance of Shipping Con-

of test intensity, but has a correspondingly high probability of

tainers by Spray Method

occurrence. Level II is between these extremes. For Distribu-

D 996 Terminology of Packaging and Distribution Environ-

2 tion Cycle 18, DC-18 see MIL–STD–2073–1 for definitions of

ments

military levels of protection.

D 999 Test Methods for Vibration Testing of Shipping

2 3.2.3 coeffıcient of restitution—the ratio of the rebound

Containers

velocity to the impact velocity.

D 4003 Methods of Programmable Horizontal Impact Test

2 3.2.4 distribution cycle (DC)—the sequential listing of the

for Shipping Containers

test schedules employed to simulate the hazard elements

D 4332 Practice for Conditioning Containers, Packages, or

2 expected to occur for a specific routing of a shipping unit from

Packaging Components for Testing

production to consumption. See Table 1.

D 4728 Test Method for Random Vibration Testing of

2 3.2.5 hazard element—a specific event that occurs in a

Shipping Containers

distribution cycle that may pose a hazard to a shipping unit.

The element will usually be simulated by a single test schedule.

This practice is under the jurisdiction of ASTM Committee D-10 on Packaging

See Section 9.

and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

Systems-Application of Performance Test Methods.

Current edition approved Oct. 10, 1999. Published December 1999. Originally

published as D 4169-82. Last previous edition D 4169-98. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 15.09. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4169

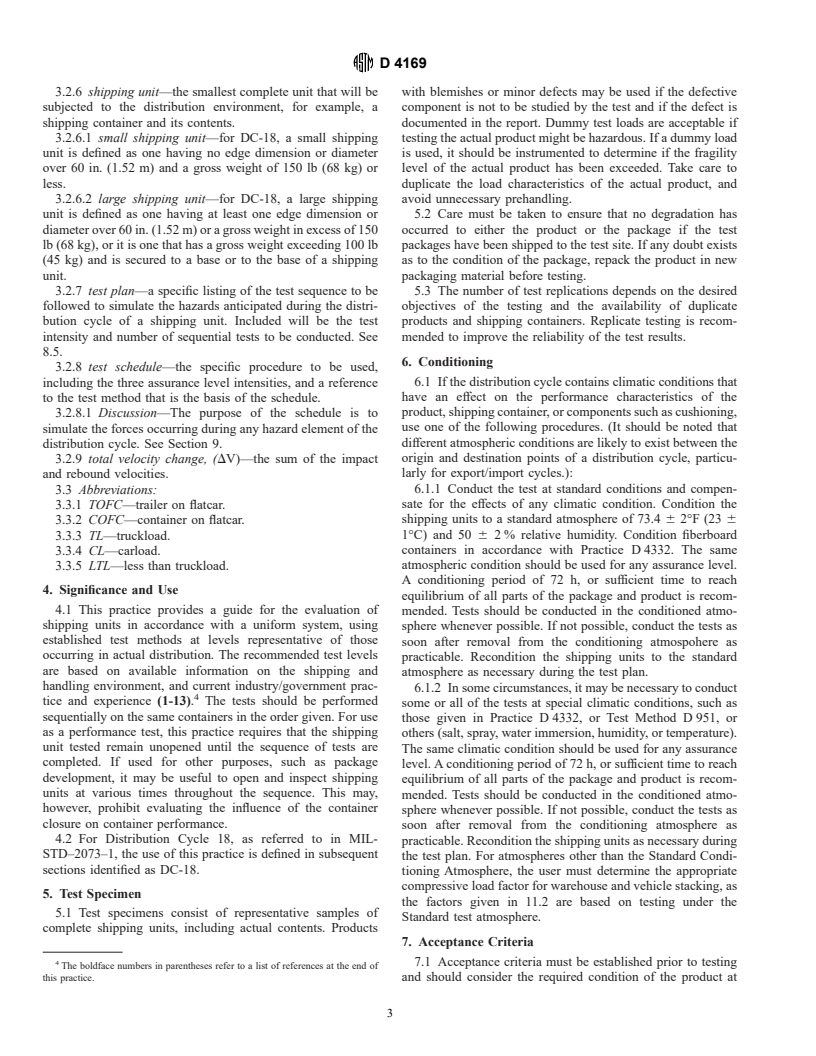

TABLE 1 Distribution Cycles

Performance Test Schedule Sequence

(see Section 9 for Test Schedule definition)

DC Distribution Cycle First Second Third Fourth Fifth Sixth

1 General Cycle—undefined distribution system Schedule A Schedule D Schedule F Schedule G Schedule A

Handling Stacked Loose-Load Rail Switching Handling

Vibration Vibration

2 Specially controlled environment, user specified select from Schedules A through H

3 Single package environment, up to 100 lb (45.4 kg) Schedule A Schedule C Schedule F Schedule E Schedule A .

Handling Vehicle Loose-Load Vehicle Handling

Stacking Vibration Vibration

4 Motor freight, single package over 100 lb (45.4 kg) Schedule A Schedule C Schedule F Schedule E Schedule A .

Handling Vehicle Loose-Load Vehicle Handling

Stacking Vibration Vibration

5 Motor freight, TL, not unitized Schedule A Schedule D Schedule E Schedule A . .

Handling Stacked Vehicle Handling

Vibration Vibration

6 Motor freight, TL, or LTL—unitized Schedule A Schedule D Schedule A Schedule B . .

Handling Stacked Handling Warehouse

Vibration Stacking

7 Rail only, bulk loaded Schedule A Schedule D Schedule G Schedule A . .

Handling Stacked Rail Switching Handling

Vibration

8 Rail only, unitized Schedule A Schedule D Schedule G Schedule A Schedule B .

Handling Stacked Rail Switching Handling Warehouse

Vibration Stacking

9 Rail and motor freight, not unitized Schedule A Schedule C Schedule E Schedule G Schedule F Schedule A

Handling Vehicle Vehicle Rail Switching Loose-Load Handling

Stacking Vibration Vibration

10 Rail and motor freight, unitized Schedule A Schedule D Schedule G Schedule A Schedule B .

Handling Stacked Rail Switching Handling Warehouse

Vibration Stacking

11 Rail, TOFC and COFC Schedule A Schedule G Schedule D Schedule F Schedule A .

Handling Rail Switching Stacked Loose-Load Handling

Vibration Vibration

12 Air (intercity) and motor freight (local), over 100 lb (45.4 kg), unitized Schedule A Schedule D Schedule E Schedule A . .

Handling Stacked Vehicle Handling

Vibration Vibration

13 Air (intercity) and motor freight (local, single package up to 100 lb (45.4 Schedule A Schedule C Schedule F Schedule E Schedule A .

kg) Handling Vehicle Loose-Load Vehicle Handling

Stacking Vibration Vibration

14 Warehousing (partial cycle to be added to other cycles as needed) Schedule A Schedule B . . . .

Handling Warehouse

Stacking

15 Export/Import shipment for intermodal container or roll on/roll off trailer Schedule A Schedule C Schedule A . . .

(partial cycle to be added to other cycles as needed) Handling Vehicle Handling

Stacking

16 Export/Import shipment for palletized cargo ship (partial cycle to be Schedule A Schedule C Schedule A . . .

added to other cycles as needed) Handling Vehicle Handling

Stacking

17 Export/Import shipment for break bulk cargo ship (partial cycle to be Schedule A Schedule C Schedule A . . .

added to other cycles as needed) Handling Vehicle Handling

Stacking

Schedule B Schedule H Schedule F

Schedule A Schedule A Schedule A

18 Non-Commercial Government shipments per MIL-STD-2073-1 or Environmental Loose-Load

Handling Handling Handling

A

Schedule C Hazard Vibration

A

For DC-18, perform the stacking test that results in the highest computed load value.

D 4169

3.2.6 shipping unit—the smallest complete unit that will be with blemishes or minor defects may be used if the defective

subjected to the distribution environment, for example, a component is not to be studied by the test and if the defect is

shipping container and its contents. documented in the report. Dummy test loads are acceptable if

3.2.6.1 small shipping unit—for DC-18, a small shipping testing the actual product might be hazardous. If a dummy load

unit is defined as one having no edge dimension or diameter is used, it should be instrumented to determine if the fragility

over 60 in. (1.52 m) and a gross weight of 150 lb (68 kg) or level of the actual product has been exceeded. Take care to

less. duplicate the load characteristics of the actual product, and

3.2.6.2 large shipping unit—for DC-18, a large shipping avoid unnecessary prehandling.

unit is defined as one having at least one edge dimension or 5.2 Care must be taken to ensure that no degradation has

diameter over 60 in. (1.52 m) or a gross weight in excess of 150 occurred to either the product or the package if the test

lb (68 kg), or it is one that has a gross weight exceeding 100 lb packages have been shipped to the test site. If any doubt exists

(45 kg) and is secured to a base or to the base of a shipping as to the condition of the package, repack the product in new

unit. packaging material before testing.

3.2.7 test plan—a specific listing of the test sequence to be 5.3 The number of test replications depends on the desired

followed to simulate the hazards anticipated during the distri- objectives of the testing and the availability of duplicate

bution cycle of a shipping unit. Included will be the test products and shipping containers. Replicate testing is recom-

intensity and number of sequential tests to be conducted. See mended to improve the reliability of the test results.

8.5.

6. Conditioning

3.2.8 test schedule—the specific procedure to be used,

including the three assurance level intensities, and a reference 6.1 If the distribution cycle contains climatic conditions that

have an effect on the performance characteristics of the

to the test method that is the basis of the schedule.

3.2.8.1 Discussion—The purpose of the schedule is to product, shipping container, or components such as cushioning,

use one of the following procedures. (It should be noted that

simulate the forces occurring during any hazard element of the

distribution cycle. See Section 9. different atmospheric conditions are likely to exist between the

origin and destination points of a distribution cycle, particu-

3.2.9 total velocity change, (DV)—the sum of the impact

and rebound velocities. larly for export/import cycles.):

6.1.1 Conduct the test at standard conditions and compen-

3.3 Abbreviations:

sate for the effects of any climatic condition. Condition the

3.3.1 TOFC—trailer on flatcar.

shipping units to a standard atmosphere of 73.4 6 2°F (23 6

3.3.2 COFC—container on flatcar.

1°C) and 50 6 2 % relative humidity. Condition fiberboard

3.3.3 TL—truckload.

containers in accordance with Practice D 4332. The same

3.3.4 CL—carload.

atmospheric condition should be used for any assurance level.

3.3.5 LTL—less than truckload.

A conditioning period of 72 h, or sufficient time to reach

4. Significance and Use

equilibrium of all parts of the package and product is recom-

4.1 This practice provides a guide for the evaluation of

mended. Tests should be conducted in the conditioned atmo-

shipping units in accordance with a uniform system, using

sphere whenever possible. If not possible, conduct the tests as

established test methods at levels representative of those

soon after removal from the conditioning atmospohere as

occurring in actual distribution. The recommended test levels

practicable. Recondition the shipping units to the standard

are based on available information on the shipping and

atmosphere as necessary during the test plan.

handling environment, and current industry/government prac-

6.1.2 In some circumstances, it may be necessary to conduct

tice and experience (1-13). The tests should be performed

some or all of the tests at special climatic conditions, such as

sequentially on the same containers in the order given. For use

those given in Practice D 4332, or Test Method D 951, or

as a performance test, this practice requires that the shipping

others (salt, spray, water immersion, humidity, or temperature).

unit tested remain unopened until the sequence of tests are

The same climatic condition should be used for any assurance

completed. If used for other purposes, such as package

level. A conditioning period of 72 h, or sufficient time to reach

development, it may be useful to open and inspect shipping

equilibrium of all parts of the package and product is recom-

units at various times throughout the sequence. This may,

mended. Tests should be conducted in the conditioned atmo-

however, prohibit evaluating the influence of the container

sphere whenever possible. If not possible, conduct the tests as

closure on container performance.

soon after removal from the conditioning atmosphere as

4.2 For Distribution Cycle 18, as referred to in MIL-

practicable. Recondition the shipping units as necessary during

STD–2073–1, the use of this practice is defined in subsequent

the test plan. For atmospheres other than the Standard Condi-

sections identified as DC-18.

tioning Atmosphere, the user must determine the appropriate

compressive load factor for warehouse and vehicle stacking, as

5. Test Specimen

the factors given in 11.2 are based on testing under the

5.1 Test specimens consist of representative samples of

Standard test atmosphere.

complete shipping units, including actual contents. Products

7. Acceptance Criteria

7.1 Acceptance criteria must be established prior to testing

The boldface numbers in parentheses refer to a list of references at the end of

this practice. and should consider the required condition of the product at

D 4169

receipt. The organizations conducting the test may choose any for clarification of the equipment and techniques to be used to

acceptance criteria suitable for their purpose. It is advisable to conduct the test.

compare the type and quantity of damage that occurred to the 8.5.1 Sample test plans are provided in Appendix X1.

test specimens with the damage that occurs during actual 8.6 Select Samples for Test—See Section 5.

distribution and handling or with test results of similar con- 8.7 Condition Samples—See Section 6.

tainers whose shipping history is known. 8.8 Perform Tests— Perform tests as directed in reference

ASTM standards and as further modified in the special

7.2 In many cases, the acceptance criteria can be the

following: in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.