ASTM D3498-03

(Specification)Standard Specification for Adhesives for Field-Gluing Plywood to Lumber Framing for Floor Systems

Standard Specification for Adhesives for Field-Gluing Plywood to Lumber Framing for Floor Systems

ABSTRACT

This specification covers minimum performance standards and test requirements for gap-filling construction adhesives for field-gluing plywood to lumber framing for floor systems. The adhesive shall conform to the strength and durability properties prescribed. The different methods for specimen's preparation are presented in details. The shear strength, gap-filling effect on strength, and durability shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers minimum performance standards and test requirements for gap-filling construction adhesives for bonding plywood to lumber framing, particularly floor joists, at the construction site.

1.2 This specification provides a basis for ensuring the quality of the adhesives and is not intended as an application specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3498 – 03

Standard Specification for

Adhesives for Field-Gluing Plywood to Lumber Framing for

1

Floor Systems

This standard is issued under the fixed designation D3498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4783 Test Methods for Resistance of Adhesive Prepara-

tions in Container toAttack by Bacteria, Yeast, and Fungi

1.1 This specification covers minimum performance stan-

E4 Practices for Force Verification of Testing Machines

dards and test requirements for gap-filling construction adhe-

E177 Practice for Use of the Terms Precision and Bias in

sives for bonding plywood to lumber framing, particularly

ASTM Test Methods

floor joists, at the construction site.

1.2 This specification provides a basis for ensuring the

3. Terminology

quality of the adhesives and is not intended as an application

3.1 Definitions—Many terms in this specification are de-

specification.

fined in Terminology D907.

1.3 The values stated in inch-pound units are to be regarded

3.1.1 gap-filling adhesive, n—an adhesive capable of form-

as the standard. The values given in parentheses are for

ing and maintaining a bond between surfaces that are not

information only.

close-fitting.

1.4 The following precautionary caveat pertains only to the

3.1.1.1 Discussion—Close-fitting is relative to a given ma-

test method portion, Section 11, of this specification: This

terial and industry; for example, standards in construction

standard does not purport to address all of the safety concerns,

differ from standards in electronics. Some adhesives will bond

if any, associated with its use. It is the responsibility of the user

bybridgingwithoutcompletelyfillingthegap;othersbyfilling

of this standard to establish appropriate safety and health

the gap completely.

practices and determine the applicability of regulatory limita-

3.1.2 open assembly time, n—the time interval between

tions prior to use.

applying adhesive on the subtrates and closing them together

2. Referenced Documents before bonding.

2

2.1 ASTM Standards:

4. Significance and Use

D572 Test Method for Rubber—Deterioration by Heat and

4.1 This specification establishes test methods and perfor-

Oxygen

mance requirements for adhesives bonding plywood to wood

D905 Test Method for Strength Properties of Adhesive

framing members.

Bonds in Shear by Compression Loading

4.2 This specification provides a basis for ensuring the

D907 Terminology of Adhesives

3 quality of the adhesives.

D2016 Test Methods for Moisture Content of Wood

4.3 The tests provide shear strength performance data when

D4300 Test Methods for Ability of Adhesive Films to

the substrates are conditioned to simulate various conditions

Support or Resist the Growth of Fungi

that may occur during sub-floor adhesive application and

curing.

1

This specification is under the jurisdiction of ASTM Committee D14 on

4.4 The tests are suitable for product performance certifica-

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

tion and quality control programs, and can be useful to the

Adhesives.

generalpublic,adhesivemanufacturers,distributors,specifiers,

Current edition approved April 10, 2003. Published June 2003. Originally

approved in 1976. Last previous edition approved in 2001 as D3498–01. DOI: architects,contractors,testinglaboratoriesandotherbusinesses

10.1520/D3498-03.

and professionals.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.5 Theresultsdonotincludeallpossibleconditions,which

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

may occur during final assembly, but indicate a set of perfor-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

mance characteristics for laboratory controlled bonding vari-

3

Withdrawn. The last approved version of this historical standard is referenced

ables.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

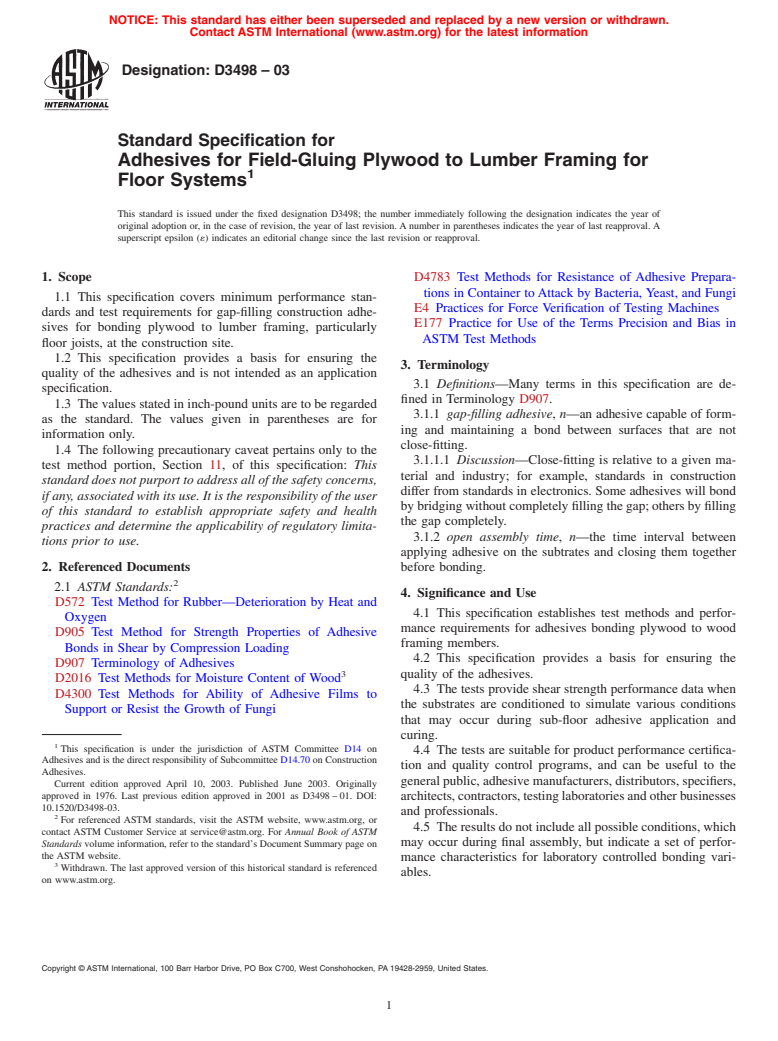

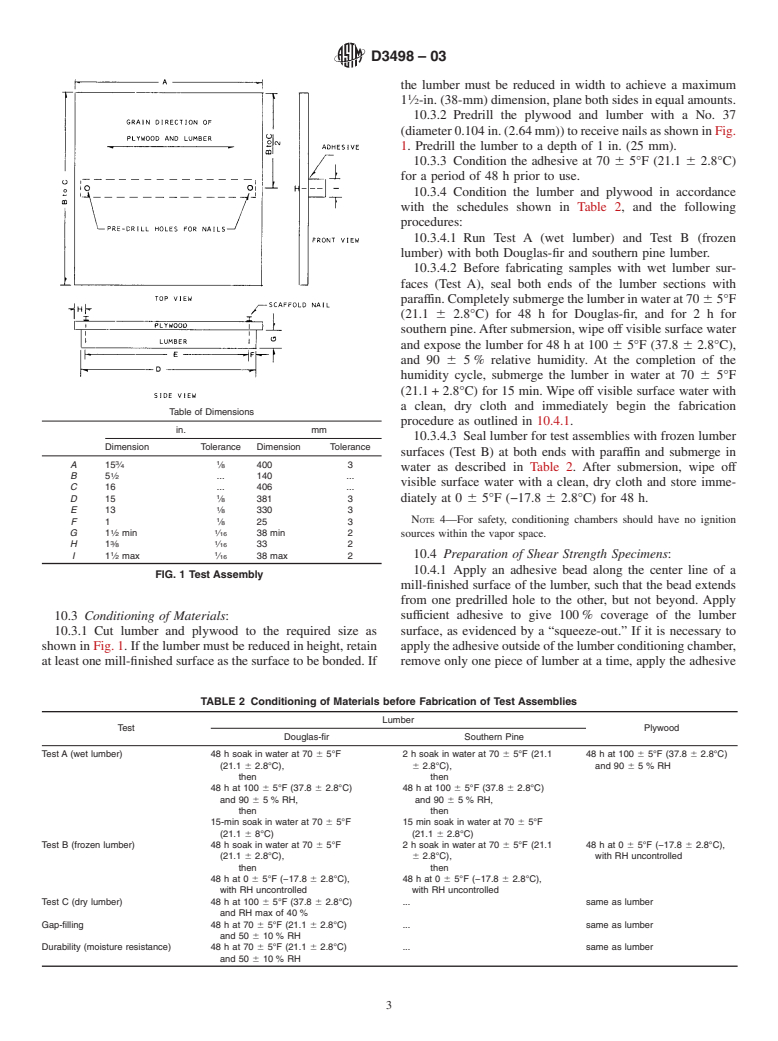

---------------------- Page: 1 ----------------------

D3498 – 03

5. Ordering Information 8. Sampling

5.1 The adhesive may be furnished by the manufacturer in 8.1 Arepresentative sample totaling not less than 1 qt (946

3

any suitable form agreeable to the purchaser. cm ) of the adhesive shall be taken from each lot to be tested.

8.2 For the purpose of sampling, a lot shall consist of

6. Materials material from the same batch or blending operation subject to

the same processing operations and conditions.

6.1 Theadhesiveshallbeagap-fillingconstructionadhesive

that sets at

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.