ASTM D6908-05

(Practice)Standard Practice for Integrity Testing of Water Filtration Membrane Systems

Standard Practice for Integrity Testing of Water Filtration Membrane Systems

SCOPE

1.1 This standard covers the determination of the integrity of water filtration membrane elements and systems using air based tests (pressure decay and vacuum hold), soluble dye, and TOC monitoring tests for the purpose of rejecting particles and microbes. The tests are applicable to systems with membranes that have a nominal pore size less than about 1 m. The TOC and Dye tests are generally applicable to NF and RO class membranes only.

1.2 This standard does not purport to cover all available methods of integrity testing.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6908 – 05

Standard Practice for

1

Integrity Testing of Water Filtration Membrane Systems

This standard is issued under the fixed designation D6908; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D5904 Total Carbon, Inorganic Carbon and Organic Car-

bon in Water by Ultraviolet, Persulfate Oxidation and

1.1 This standard covers the determination of the integrity

Membrane Conductivity Detection

of water filtration membrane elements and systems using air

D5997 On-Line Monitoring of Total Carbon, Inorganic

based tests (pressure decay and vacuum hold), soluble dye,

Carbon in Water by Ultraviolet, Persulfate Oxidation, and

continuous monitoring particulate light scatter techniques, and

Membrane Conductivity Detection

TOCmonitoringtestsforthepurposeofrejectingparticlesand

D6161 Terminology Used for Crossflow Microfiltration,

microbes. The tests are applicable to systems with membranes

Ultrafiltration, Nanofiltration and Reverse Osmosis Mem-

that have a nominal pore size less than about 1 µm. The TOC,

brane Processes

and Dye, tests are generally applicable to NF and RO class

D6698 Test Method for the On-Line Measurement of

membranes only.

Turbidity Below 5 NTU in Water

1.2 This standard does not purport to cover all available

E20 Practice for Particle Size Analysis of Particulate Sub-

methods of integrity testing.

stances in the Range of 0.2 to 75 Micrometers by Optical

1.3 This standard does not purport to address all of the

Microscopy

safety concerns, if any, associated with its use. It is the

E128 Maximum Pore Diameter and Permeability of Rigid

responsibility of the user of this standard to establish appro-

Porous Filters for Laboratory Use

priate safety and health practices and determine the applica-

F658 Practice for Defining Size Calibration, Resolution,

bility of regulatory limitations prior to use.

and CountingAccuracy of a Liquid-borne Particle Counter

2. Referenced Documents

Using Nearmonodisperse Spherical Particulate Material

2

2.1 ASTM Standards:

3. Terminology

D1129 Terminology Relating to Water

3.1 Definitions—For definitions of terms used in this prac-

D2777 Determination of Precision and Bias of Applicable

tice, refer to Terminologies D6161 and D1129.

Tests Methods of Committee D19 on Water

3.1.1 For description of terms relating to cross flow mem-

D3370 PracticesforSamplingWaterfromClosedConduits

brane systems, refer to Terminology D6161.

D3864 Guide for Continual On-Line Monitoring Systems

3.1.2 For definition of terms relating to dissolved carbon

for Water Analysis

and carbon analyzers, refer to D5173, D5904 and D5997.

D3923 Practice for the Determination of Leaks Within a

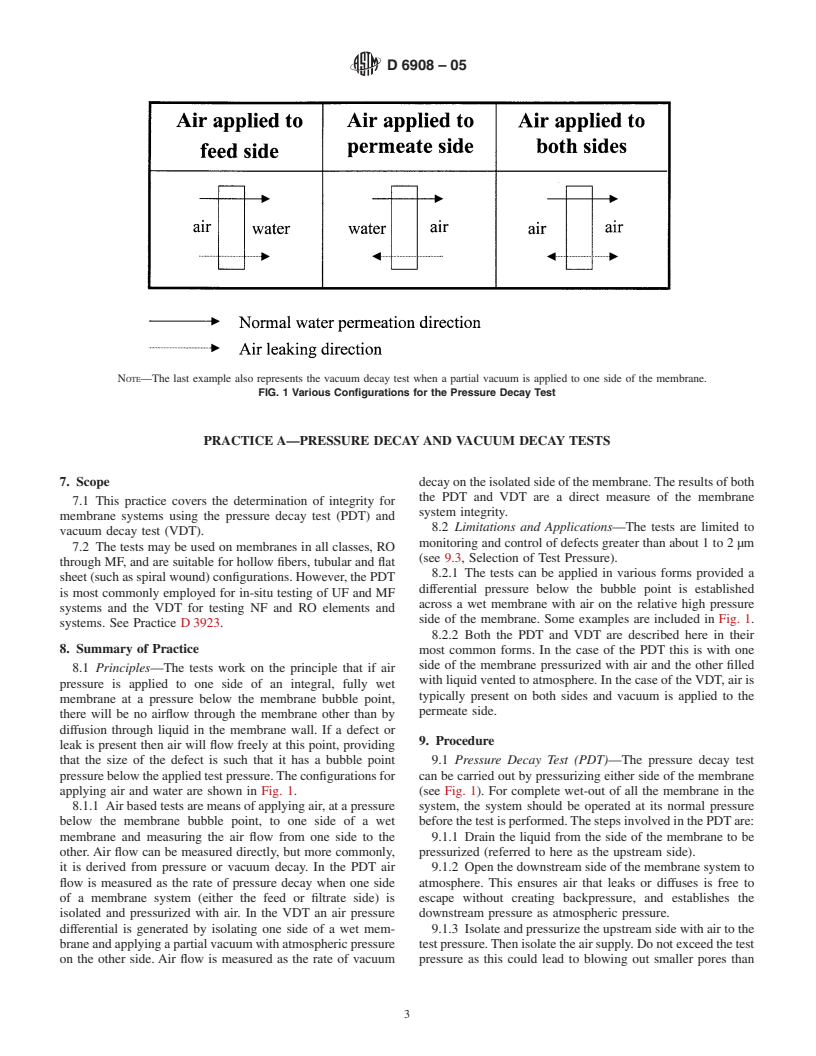

3.1.3 bubble point—when the pores of a membrane are

Reverse Osmosis Device

filled with liquid and air pressure is applied to one side of the

D4839 Total Carbon and Organic Carbon in Water by

membrane, surface tension prevents the liquid in the pores

Ultraviolet, or Persulfate Oxidation, or Both, and Infrared

from being blown out by air pressure below a minimum

Detection

pressure known as the bubble point.

D5173 On-Line Monitoring of Carbon Compounds in Wa-

3.1.4 equivalent diameter—the diameter of a pore or defect

ter by Chemical Oxidation, by UV Light Oxidation, by

calculated from its bubble point using Eq 1 (see 9.3). This is

Both, or by High Temperature Combustion Followed by

not necessarily the same as the physical dimensions of the

Gas Phase NDIR or by Electrolytic Conductivity

defect(s).

3.1.5 integrity—measure of the degree to which a mem-

1

This practice is under the jurisdiction ofASTM Committee D19 on Water and brane system rejects particles of interest. Usually expressed as

is the direct responsibility of Subcommittee D19.08 on Membranes and Ion

a log reduction value (LRV).

Exchange Materials.

3.1.6 log reduction value (LRV)—a measure of the particle

Current edition approved Oct. 1, 2005. Published December 2005. Originally

removal efficiency of the membrane system expressed as the

approved in 2003. Last previous edition approved in 2003 as D6908–03.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

log of the ratio of the particle concentration in the untreated

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and treated fluid. For example, a 10-fold reduction in particle

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 -

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.