ASTM D1422-99

(Test Method)Standard Test Method for Twist in Single Spun Yarns by the Untwist-Retwist Method

Standard Test Method for Twist in Single Spun Yarns by the Untwist-Retwist Method

SCOPE

1.1 This test method describes the determination of twist in single spun yarns when only an approximation of the true twist is required. For a more accurate method see Test Method D1423.

1.2 This test method is applicable to spun single yarns in continuous lengths, and also to spun yarns raveled from fabrics, provided specimens at least 200 mm (8 in.) long can be obtained.

1.3 This test method is not applicable to yarns that have been subjected to any chemical treatment or mechanical process that results in a condition that prevents easy removal of twist from the yarn, nor to bast fiber yarns in which the bundles of fibers split, nor to yarns that extend more than 5.0% when tension is increased from 2.5 to 7.5 mN/tex (0.25 to 0.75 gf/tex).

1.4 This test method has been found satisfactory for use in determining twist in all single ring spun yarns and 100% cotton open-end yarns. For all open-end spun yarns that are not 100% cotton this test method has not been found to be satisfactory for determining twist but may be used to measure deviation from an average value.

1.5 This specification shows the values in both inch-pound units and SI units. The "inch-pound" units is the technically correct name for the customary units used in the United States. The "SI" units is the technically corrected name for the system of metric units known as the International System of Units. The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values expressed in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1422–99

Standard Test Method for

Twist in Single Spun Yarns by the Untwist-Retwist Method

This standard is issued under the fixed designation D 1422; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and health practices and determine the applicability of regu-

2 latory limitations prior to use.

1.1 This test method describes the determination of twist in

single spun yarns when only an approximation of the true twist

2. Referenced Documents

is required.

2.1 ASTM Standards:

NOTE 1—For a more accurate method see Test Method D 1423.

D 123 Terminology Relating to Textiles

D 1059 Test Method for Yarn Number Based on Short-

1.2 This test method is applicable to spun single yarns in

continuous lengths, and also to spun yarns raveled from Length Specimens

D 1423 Test Method for Twist in Yarns by the Direct-

fabrics,providedspecimensatleast200mm(8in.)longcanbe

obtained. Counting Method

D 2258 Practice for Sampling Yarn for Testing

1.3 The values stated in either inch-pound or SI units are to

be regarded separately as standard.Within the text, the SI units

3. Terminology

are shown in parentheses. The values stated in each system are

3.1 Definitions:

not exact equivalents; therefore each system shall be used

3.1.1 direction of twist, n—the right or left direction of the

independently of the other. Combining values from the two

helix formed in a twisted strand as indicated by superimposi-

systems may result in nonconformance within this test method.

tion of the capital letter “S” or “Z.”

1.4 This test method has been found satisfactory for use in

3.1.1.1 Discussion—Yarn has S twist if, when the yarn is

determiningtwistinallsingleringspunyarnsand100%cotton

held in a vertical position, the visible spirals or helices around

open-endyarns.Forallopen-endspunyarnsthatarenot100 %

its central axis conform in direction of slope to the central

cottonthistestmethodhasnotbeenfoundtobesatisfactoryfor

portion of the letter“ S,” and Z twist if the visible spirals or

determining twist but may be used to measure deviation from

helices conform in direction of slope to the central portion of

an average value.

the letter “Z.” When two or more yarns, either single or plied,

1.5 This specification shows the values in both inch-pound

are twisted together, the letters “S” and “Z” are used in a

units and SI units. The “inch-pound” units is the technically

similar manner to indicate the direction of the last twist

correct name for the customary units used in the United States.

inserted.

The “SI” units is the technically corrected name for the system

ofmetricunitsknownastheInternationalSystemofUnits.The

3.1.2 single yarn, n—the simplest strand of textile material

values stated in either acceptable metric units or in other units

suitable for operations such as weaving, knitting, etc.

shall be regarded separately as standard. The values expressed

3.1.2.1 Discussion—A single yarn may be formed from

in each system may not be exact equivalents; therefore, each

fibers with more or less twist; from filaments with or without

system must be used independently of the other, without

twist; from narrow strips of materials such as paper, cello-

combining in any way.

phane, or metal foil; or from monofilaments. A yarn which is

1.6 This standard does not purport to address all of the

either twistless or can be rendered twistless in a single

safety concerns, if any, associated with its use. It is the

untwisting operation. When twist is present, it is usually all in

responsibility of this standard to establish appropriate safety

the same direction.

3.1.3 spun yarn, n—in a staple system, a continuous strand

of fibers held together by some binding mechanism.

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles,

3.1.3.1 Discussion—The binding mechanism most com-

and is the direct responsibility of Subcommittee D13.58 on Yarn Test Methods,

monly used in spun yarns is twist. Other useful mechanisms

General.

Current edition approved Nov. 10, 1999. Published January 2000. Originally

that are used are chemical additives, wrapping, entanglement,

published as D 1422 – 56 T. Last previous edition D 1422 – 92.

This test method is commonly designated by the less precise term“ Untwist-

Twist Method.” Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1422

or some combination of these. Test Method D 1422 is appli- 5. Significance and Use

cable only to yarns which have twist.

5.1 This test method is used for acceptance testing in the

3.1.4 twist, n—in textile strands, the helical or spiral con-

trade for economic reasons even though it is less accurate than

figurations induced by turning a strand about its longitudinal

the direct method, Test Method D 1423.

axis.

5.1.1 If there are differences or practical significance be-

3.1.4.1 Discussion—Twist is usually expressed as the num-

tween reported test results for two laboratories (or more),

ber of turns about the axis that are observed in a specified

comparative tests should be performed to determine if their is

length either metres (tpm) or inches (tpi).

a statistical bias between them, using competent statistical

3.1.5 twist factor, TF, n—the product obtained when the

assistance.As a minimum, the test samples should be used that

twist expressed in turns per centimetre is multiplied by the

are as homogeneous as possible, that are drawn from the

square root of the yarn number expressed in tex:

material from which the disparate test results are obtained, and

Twist factor ~TF!5 tpcm 3 T (1) thatareassignedrandomlyinequalnumberstoeachlaboratory

=

for testing. Other materials with established test values may be

where:

used for this purpose.The test results from the two laboratories

T = yarn number expressed in tex.

should be compared using a statistical test for unpaired data, at

3.1.5.1 Discussion—Twist multiplier and twist factor are a

a probability level chosen prior to the testing series. If a bias is

measure of the “twist hardness” of yarn because they are

found, either its cause must be found and corrected, or future

approximately proportional to the tangent of the angle between

test results must be adjusted in consideration of the known

fibers on the outer yarn surface and the axis of the yarn; the

bias.

larger this angle, the harder the twist. Furthermore, this angle

5.2 The “setting” of twist in some fibers causes excessive

is a function of both the twist content (turns per unit length)

contraction when the yarn is retwisted in the reverse direction.

and the number of fibers per yarn cross section (yarn number).

Therefore, the number of turns required to bring the specimen

Hence, twist content alone cannot provide a measure of the

back to its original length may be less than the number of turns

twist hardness of a yarn. Twist multiplier and twist factor are

removed in untwisting. This effect may be partially offset by

proportional to each other and differ only in the units used.

the use of higher pretensioning loads; but this increases the

The two are related by Eq 2 and Eq 3:

danger of stretching the yarn. Little information is available on

TF 5 k 3 TM (2)

the correct tensions to use for yarns made from different fibers

k 5 277.29/ L (3)

= or with different amounts of twist.

5.3 In addition to being less tedious, this test method

requires fewer specimens than the direct-counting method and

where:

the results may be sufficiently accurate for certain purposes.

L = length in yards of the hank used to define the indirect

This test method can be useful in those cases where the main

yarn number of the type,

objective is to measure variations from an average value.

N = hanks/lb. In particular for cotton count,

Another possible application is where a large amount of twist

k = 9.567 so that Eq 2 becomes Eq 4:

testing is required on yarns of similar type and twist. In this

TF 5 9.567 3 TM (4)

case preliminary tests comparing this method and the direct

3.1.6 twist multiplier, TM, n—the quotient of the twist

method could be used to determine the correct pretension.

expressed in turns per inch and the square root of the yarn

5.4 Twist has important effects on the physical properties of

number in an indirect system.

yarn. Low-twist yarn is lofty and is usually preferred for

Twist multiplier ~TM!5 tpi/ N (5)

=

knitting because of its softness, covering power, and warmth.

Increasing the amount of twist causes an increase in yarn

where:

strength by increasing fiber cohesion, but as the twist angle

N = yarn number in an indirect system, the cotton system

increases beyond an optimum point, strength decreases due to

unless otherwise specified.

a loss in effective fiber contribution. Maximum yarn strength is

3.1.7 yarn, n—a generic term for a continuous strand of

obtained by inserting a medium amount of twist to obtain an

textile fibers, filaments, or material in a form suitable for

optimum balance between these two opposing forces. High

knitting, weaving, or otherwise intertwining to form a textile

twist produces yarns of high density (“hard” or “wiry”) and

fabric.

high elongation and may improve the abrasion and impact

3.2 For definitions of other textile terms used in this test

resistance of fabrics.

method, refer to Terminology D 123.

5.5 The optimum twist for either manufacturing efficiency

4. Summary of Test Method

or physical properties usually increases as staple length de-

creases.

4.1 A specimen is untwisted and then retwisted in the

opposite direction until it contracts to its original length. It is 5.6 The twist in a yarn before it is packaged may be

assumedthatthesameamountoftwisthasbeeninsertedaswas different from that of the yarn after it has been withdrawn from

originally present. Twist, as turns per unit length, is calculated the package because of changes in tension and the effect of the

ashalfthenumberofturnsregisteredonthecounterdividedby method of withdrawal. If the yarn is withdrawn over-end, a

the specimen length. slight increase or decrease in twist will take place, depending

D1422

upon the direction of the twist in the yarn, the direction of not cut the specimen free from the package or from the yarn to

windingonthepackage,andthelengthoftheturn(orwrap)on be discarded until after the yarn is secured in the clamps of the

the package. twist tester. When possible, take the specimen from near the

center of the traverse and not at the traverse reversals.

NOTE 2—The difference in twist between unwinding from the side and

7.3.3 For woven fabric, take warp specimens from separate

over-end is 1/pd, where d is the diameter of the package. Thus, for a

25-mm (1-in.) diameter package, the difference would be about 13 tpm or ends, since each represents a separate package. Because the

about one third tpi.

fabric may have been woven on any of a variety of looms

which are random quilling, sequential quilling or shuttleless,

5.7 When a yarn is taken from a more complex yarn

take filling specimens at random through the whole laboratory

structure or from a fabric, the resultant twist should be

sample to obtain as representative data as possible. If a strip

consideredonlyanapproximationoftheoriginalvaluebecause

about2m(2yd) long is used as a source of specimens.

of alterations that may have occurred as a result of the effects

ofunwinding,handling,andmechanicalstrainsmetinprocess-

7.3.4 For weft-knit fabric known to be multi-feed, take

ing.

specimensfromsuccessivecoursesinoneportionoflaboratory

sample. For weft-knit fabric known to be single-feed or for

6. Apparatus

which the type of feed is not known, take specimens at random

6.1 Twist Tester,consistingofapairofclamps,oneofwhich

from the whole sample.

is rotatable in either direction and positively connected to a

7.3.5 For warp-knit fabrics, cut a walewise strip from which

revolution counter. The tester may be hand- or power-driven.

specimens can be raveled for testing as needed (Note 3). Cut

The position of one clamp (or both clamps) shall be adjustable

strips from which the test specimens can be raveled for testing

to accommodate specimens having the length prescribed in

as needed (Note 4). Cut these strips to provide yarn specimens

10.2. The tester shall be provided with a variable tensioning

at least 75 mm (3 in.) longer than the specimen length and to

devicesoconstructedthataspecificforcemaybeappliedtothe

contain more than the required number of specimens for test. If

specimen at the beginning and end of the test and removed

several strips are cut, divide the number of specimens among

completely during the intervening untwisting and twisting

the strips as nearly equally as possible. Use care to avoid loss

operations.

of twist prior to testing.

6.2 Dissecting needle or stylus.

6.3 Metal ruler to verify gage length (accurate to 2 mm or

NOTE 3—In order to minimize changes in twist, specimens should not

be unraveled from the strips until they are to be placed in the twist tester.

0.1 in.).

7.4 Number of Specimens:

7. Sampling

7.4.1 Spun Yarn Singles—Take 25 specimens from each

7.1 Lot Sample—Select one or more shipping units taken at

laboratory sampling unit of spun yarn singles.

random to represent an acceptance sampling lot and used as a

source of laboratory samples.

8. Conditioning

7.2 Laboratory Sample—For packaged yarns, take a mini-

mum of five packages for the laboratory sample unless

8.1 Conditioning is not required for this test method.

otherwise agreed upon between purchaser and seller. For yarns

from woven or knitted fabrics, the sample must be large

9. Procedure

enough to furnish specimens of the length and number speci-

9.1 To Determine Twist:

fied in 7.3.3.

9.1.1 Check the twist tester to be sure that the longitudinal

7.3 Selection of Specimens:

play and radial play of the clamp assemblies are small enough

7.3.1 As nearly as possible take an equal number of speci-

to secure the required precision.

mens from each package or unit of the laboratory sample.Take

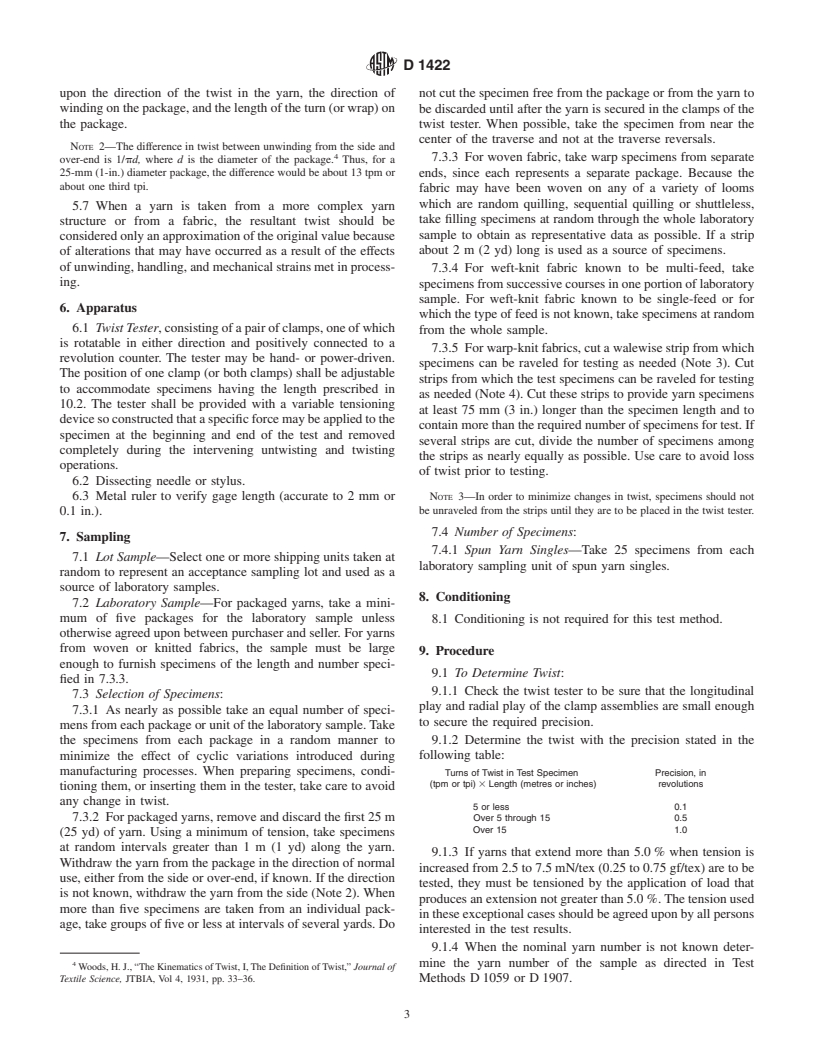

9.1.2 Determine the twist with the precision stated in the

the specimens from each package in a random manner to

minimize the effect of cyclic variations introduced during following table:

manufacturing processes. When preparing specimens, condi- Turns of Twist in Test Specimen Precision, in

(tpm or tpi) 3 Length (metres or inches) revolutions

tioning them, or inserting them in the tester, take care to avoid

any change in twist.

5 or less 0.1

7.3.2 For packaged yarns, r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.