ASTM F38-18

(Test Method)Standard Test Methods for Creep Relaxation of a Gasket Material

Standard Test Methods for Creep Relaxation of a Gasket Material

SIGNIFICANCE AND USE

4.1 These test methods are designed to compare related materials under controlled conditions and their ability to maintain a given compressive stress as a function of time. A portion of the torque loss on the bolted flange is a result of creep relaxation. Torque loss can also be caused by elongation of the bolts, distortion of the flanges, and vibration; therefore, the results obtained should be correlated with field results. These test methods may be used as a routine test when agreed upon between the consumer and the producer.

Note 1: Test Method B was developed using asbestos gasket materials and at issuance substantiating data were not available for other gasket materials.

SCOPE

1.1 These test methods provide a means of measuring the amount of creep relaxation of a gasket material at a predetermined time after a compressive stress has been applied.

1.1.1 Test Method A—Creep relaxation measured by means of a calibrated strain gauge on a bolt.

1.1.2 Test Method B—Creep relaxation measured by means of a calibrated bolt with dial indicator.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F38 − 18

Standard Test Methods for

1

Creep Relaxation of a Gasket Material

ThisstandardisissuedunderthefixeddesignationF38;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope dards Related to Rubber and Rubber Testing (Withdrawn

3

1987)

1.1 These test methods provide a means of measuring the

F104Classification System for Nonmetallic Gasket Materi-

amount of creep relaxation of a gasket material at a predeter-

als

mined time after a compressive stress has been applied.

F436/F436MSpecification for Hardened SteelWashers Inch

1.1.1 Test Method A—Creep relaxation measured by means

and Metric Dimensions

of a calibrated strain gauge on a bolt.

2.2 ASTM Adjuncts:

1.1.2 Test Method B—Creep relaxation measured by means

4

Relaxometer, Method A (F38)

of a calibrated bolt with dial indicator.

5

Relaxometer, Method B (F38)

1.2 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

3. Summary of Test Methods

only.

3.1 In both test methods the specimen is subjected to a

1.3 This standard does not purport to address all of the

compressivestressbetweentwoplatens,withthestressapplied

safety concerns, if any, associated with its use. It is the

by a nut and bolt.

responsibility of the user of this standard to establish appro-

3.2 InTestMethodA,normallyrunatroomtemperature,the

priate safety, health, and environmental practices and deter-

stress is measured by a calibrated strain gauge on the bolt. In

mine the applicability of regulatory limitations prior to use.

running the test, strain indicator readings are taken at intervals

1.4 This international standard was developed in accor-

of time, beginning at the loading time, to the end of the test.

dance with internationally recognized principles on standard-

The strain indicator readings are converted to percentages of

ization established in the Decision on Principles for the

the initial stress which are then plotted against the log of time

Development of International Standards, Guides and Recom-

in hours. The percentage of initial stress loss or relaxation can

mendations issued by the World Trade Organization Technical

be read off the curve at any given time, within the limits of the

Barriers to Trade (TBT) Committee.

total test time.

2. Referenced Documents

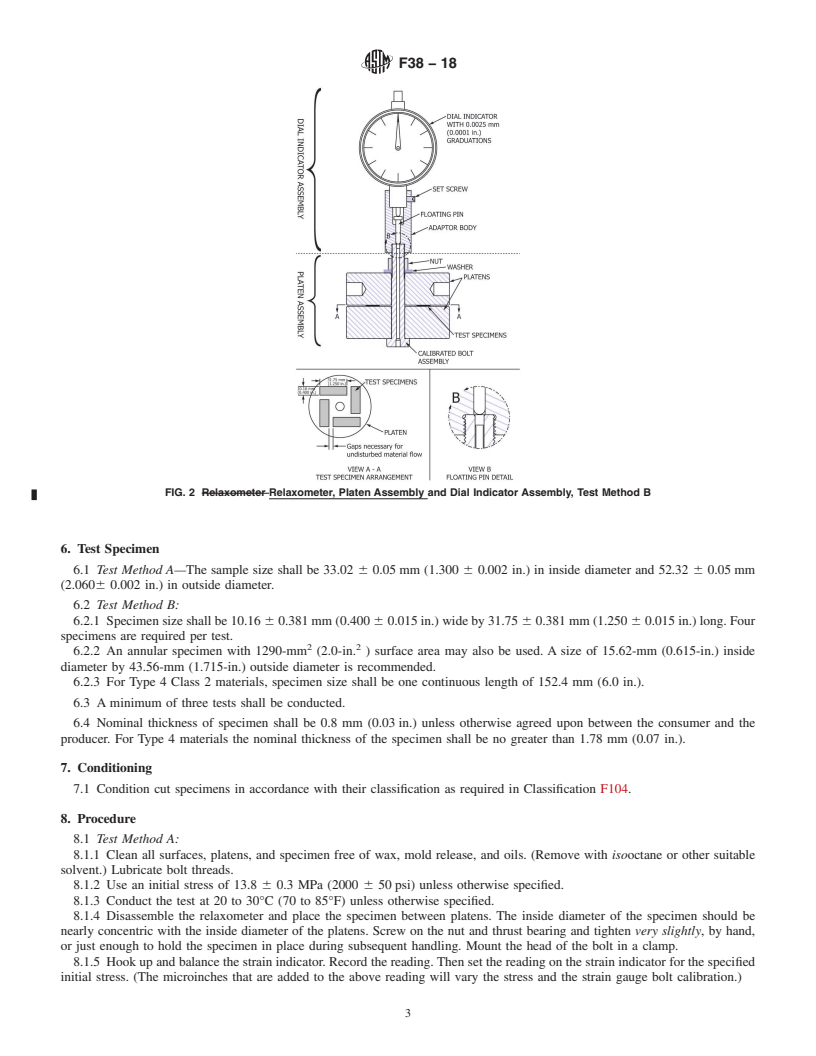

3.3 InTestMethodB,runatroomorelevatedtemperatures,

2

the stress is determined by measuring the change in length of

2.1 ASTM Standards:

the calibrated bolt with a dial indicator. The bolt length is

A193/A193MSpecification for Alloy-Steel and Stainless

measured at the beginning of the test and at the end of the test;

Steel Bolting for High Temperature or High Pressure

from this the percentage of relaxation is calculated.

Service and Other Special Purpose Applications

B637Specification for Precipitation-Hardening and Cold

4. Significance and Use

Worked Nickel Alloy Bars, Forgings, and Forging Stock

4.1 These test methods are designed to compare related

for Moderate or High Temperature Service

materials under controlled conditions and their ability to

D3040Practice for Preparing Precision Statements for Stan-

maintain a given compressive stress as a function of time. A

portion of the torque loss on the bolted flange is a result of

1

These test methods are under the jurisdiction of ASTM Committee F03 on

Gaskets and are the direct responsibility of Subcommittee F03.20 on Mechanical

3

Test Methods. The last approved version of this historical standard is referenced on

Current edition approved Aug. 1, 2018. Published November 2018. Originally www.astm.org.

4

approvedin1962.Lastpreviouseditionapprovedin2014asF38–00(2014).DOI: AprintofthisapparatusisavailableatanominalcostfromASTMInternational

10.1520/F0038-18. Headquarters. OrderAdjunct No. ADJF003801. Original adjunct produced in 1965.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Detailed working drawings of this apparatus are available from ASTM

Standards volume information, refer to the standard’s Document Summary page on International Headquarters. Order Adjunct No. ADJF003802. Original adjunct

the ASTM website. produced in 1965.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -----------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F38 − 00 (Reapproved 2014) F38 − 18

Standard Test Methods for

1

Creep Relaxation of a Gasket Material

This standard is issued under the fixed designation F38; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods provide a means of measuring the amount of creep relaxation of a gasket material at a predetermined

time after a compressive stress has been applied.

1.1.1 Test Method A—Creep relaxation measured by means of a calibrated strain gauge on a bolt.

1.1.2 Test Method B—Creep relaxation measured by means of a calibrated bolt with dial indicator.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other

Special Purpose Applications

B637 Specification for Precipitation-Hardening and Cold Worked Nickel Alloy Bars, Forgings, and Forging Stock for Moderate

or High Temperature Service

3

D3040 Practice for Preparing Precision Statements for Standards Related to Rubber and Rubber Testing (Withdrawn 1987)

F104 Classification System for Nonmetallic Gasket Materials

F436/F436M Specification for Hardened Steel Washers Inch and Metric Dimensions

2.2 ASTM Adjuncts:

4

Relaxometer, Method A (F38)

5

Relaxometer, Method B (F38)

3. Summary of Test Methods

3.1 In both test methods the specimen is subjected to a compressive stress between two platens, with the stress applied by a nut

and bolt.

3.2 In Test Method A, normally run at room temperature, the stress is measured by a calibrated strain gauge on the bolt. In

running the test, strain indicator readings are taken at intervals of time, beginning at the loading time, to the end of the test. The

strain indicator readings are converted to percentages of the initial stress which are then plotted against the log of time in hours.

The percentage of initial stress loss or relaxation can be read off the curve at any given time, within the limits of the total test time.

1

These test methods are under the jurisdiction of ASTM Committee F03 on Gaskets and are the direct responsibility of Subcommittee F03.20 on Mechanical Test Methods.

Current edition approved March 1, 2014Aug. 1, 2018. Published April 2014November 2018. Originally approved in 1962. Last previous edition approved in 20062014

as F38 – 00 (2006).(2014). DOI: 10.1520/F0038-00R14. 10.1520/F0038-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

A print of this apparatus is available at a nominal cost from ASTM International Headquarters. Order Adjunct No. ADJF003801. Original adjunct produced in 1965.

5

Detailed working drawings of this apparatus are available from ASTM International Headquarters. Order Adjunct No. ADJF003802. Original adjunct produced in 1965.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F38 − 18

3.3 In Test Method B, run at room or elevated temperatures, the stress is determined by measuring the change in length of the

calibrated bolt with a dial indicator. The bolt length is measured at the beginning of the test and at the end of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.