ASTM D7492/D7492M-16a(2024)

(Guide)Standard Guide for Use of Drainage System Media with Waterproofing Systems

Standard Guide for Use of Drainage System Media with Waterproofing Systems

SIGNIFICANCE AND USE

5.1 This guide provides information and guidelines for the selection and installation of drainage systems media that are in conjunction with waterproofing systems. This guide is intended to be used in conjunction with Guides C898/C898M, C981, C1471/C1471M, D5898/D5898M, and D6622/D6622M and to provide guidelines for the total waterproofing and drainage system.

SCOPE

1.1 This guide makes recommendations for the selection and application of prefabricated drainage media used in conjunction with waterproofing systems on horizontal and vertical surfaces. Drainage media considered include rigid and semi-rigid insulation boards and rigid materials including plastics. This guide considers drainage media as it relates to the performance of the waterproofing system, so its primary focus is draining water away from the membrane. This guide does not cover in detail other aspects or functions of drainage system performance such as efficiency of soil dewatering. The scope of this guide does not cover other drainage media including gravel and filter fabric systems that can be constructed. The scope of this guide does not cover drainage materials or drainage system designs used for vegetative roof systems. Vegetative roof systems require specialized designs.

1.2 The committee with jurisdiction over this standard is not aware of any other comparable standards published by other organizations.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard may involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7492/D7492M − 16a (Reapproved 2024)

Standard Guide for

Use of Drainage System Media with Waterproofing Systems

This standard is issued under the fixed designation D7492/D7492M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This guide makes recommendations for the selection

and application of prefabricated drainage media used in con-

2. Referenced Documents

junction with waterproofing systems on horizontal and vertical

2.1 ASTM Standards:

surfaces. Drainage media considered include rigid and semi-

C165 Test Method for Measuring Compressive Properties of

rigid insulation boards and rigid materials including plastics.

Thermal Insulations

This guide considers drainage media as it relates to the

C898/C898M Guide for Use of High Solids Content, Cold

performance of the waterproofing system, so its primary focus

Liquid-Applied Elastomeric Waterproofing Membrane

is draining water away from the membrane. This guide does

with Separate Wearing Course

not cover in detail other aspects or functions of drainage

C981 Guide for Design of Built-Up Bituminous Membrane

system performance such as efficiency of soil dewatering. The

Waterproofing Systems for Building Decks

scope of this guide does not cover other drainage media

C1471/C1471M Guide for the Use of High Solids Content

including gravel and filter fabric systems that can be con-

Cold Liquid-Applied Elastomeric Waterproofing Mem-

structed. The scope of this guide does not cover drainage

brane on Vertical Surfaces

materials or drainage system designs used for vegetative roof

D896 Practice for Resistance of Adhesive Bonds to Chemi-

systems. Vegetative roof systems require specialized designs.

cal Reagents

1.2 The committee with jurisdiction over this standard is not

D1079 Terminology Relating to Roofing and Waterproofing

aware of any other comparable standards published by other

D2434 Test Methods for Measurement of Hydraulic Con-

organizations.

ductivity of Coarse-Grained Soils

D3273 Test Method for Resistance to Growth of Mold on the

1.3 The values stated in either SI units or inch-pound units

Surface of Interior Coatings in an Environmental Cham-

are to be regarded separately as standard. The values stated in

ber

each system may not be exact equivalents; therefore, each

D3385 Test Method for Infiltration Rate of Soils in Field

system shall be used independently of the other. Combining

Using Double-Ring Infiltrometer

values from the two systems may result in nonconformance

D4511 Test Method for Hydraulic Conductivity of Essen-

with the standard.

tially Saturated Peat

1.4 This standard may involve hazardous materials, opera-

D4630 Test Method for Determining Transmissivity and

tions and equipment. This standard does not purport to address

Storage Coefficient of Low-Permeability Rocks by In Situ

all of the safety concerns, if any, associated with its use. It is

Measurements Using the Constant Head Injection Test

the responsibility of the user of this standard to establish

D4716/D4716M Test Method for Determining the (In-plane)

appropriate safety, health, and environmental practices and

Flow Rate per Unit Width and Hydraulic Transmissivity

determine the applicability of regulatory limitations prior to

of a Geosynthetic Using a Constant Head

use.

D5898/D5898M Guide for Standard Details for Adhered

1.5 This international standard was developed in accor-

Sheet Waterproofing

dance with internationally recognized principles on standard-

D6622/D6622M Guide for Application of Fully Adhered

ization established in the Decision on Principles for the

Hot-Applied Reinforced Waterproofing Systems

Development of International Standards, Guides and Recom-

E154/E154M Test Methods for Water Vapor Retarders Used

in Contact with Earth Under Concrete Slabs, on Walls, or

as Ground Cover

This guide is under the jurisdiction of ASTM Committee D08 on Roofing and

Waterproofing and is the direct responsibility of Subcommittee D08.22 on Water-

proofing and Dampproofing Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2024. Published January 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2011. Last previous edition approved in 2016 as D7492/D7492M – 16a. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D7492_D7492M-16AR24. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7492/D7492M − 16a (2024)

3. Terminology consist of one or more of the following basic components. The

basic components of typical drainage medium are a mounting

3.1 Refer to Terminology D1079 for definitions of terms

surface that is placed against the waterproofing membrane to

used in this guide.

prevent embedment of the media, a porous core that provides

a drainage path, and a filter surface, often a fabric bonded over

4. Summary of Practice

the porous core to prevent clogging of the drainage paths.

4.1 This guide describes a method to estimate the amount of

Fibrous and foam drainage media are homogeneous materials

water a drainage system may need to carry. The guide also

that are sufficiently dense that they can be placed directly

offers descriptions of the various drainage systems in existence

against the waterproofing membrane. However, fibrous and

today along with suggestions on how different building situa-

foam media may not function properly in horizontal or nearly

tions will require different performance characteristics from the

horizontal (<30°) orientations. Other foam boards merely

drainage medium chosen. Items to be aware of during the

provide periodic grooves creating paths to drain water away

installation of drainage systems are also covered along with

from the waterproofed surface. Where appropriate, a protection

illustrations of typical drainage systems.

board should be installed between the waterproofing and

drainage media to reduce embedment of drainage media into

5. Significance and Use

the waterproofing.

5.1 This guide provides information and guidelines for the

6.4 The drainage media selection should include a consid-

selection and installation of drainage systems media that are in

eration of the forces that will be placed on it, such as backfill

conjunction with waterproofing systems. This guide is intended

pressure, gravity loads, and shear loads both initially and over

to be used in conjunction with Guides C898/C898M, C981,

the expected useful life of the assembly.

C1471/C1471M, D5898/D5898M, and D6622/D6622M and to

provide guidelines for the total waterproofing and drainage

6.5 The construction of drainage media should be consid-

system.

ered relative to the strength and protection of the waterproofing

membrane. The bearing surface of drainage media should place

6. General

no sharp edges against the waterproofing membrane, which

6.1 In selecting a drainage medium for use with could puncture, abrade the membrane, or imprint itself in the

waterproofing, consideration should be given to the design of

membrane. The filter fabric and its bond to the drainage

the waterproofing system. In particular orientation of the medium core should resist impact, compressive, and shear

system, attachment recommendations, connections to interior

loads imposed by backfilling and compaction, and temporary

and exterior drainage systems, and external loads applied to the and permanent construction loads.

system. Additional considerations include the materials and

6.6 The drainage media should always be placed next to the

construction over the drainage medium, installation

waterproofing. This location minimizes the hydrostatic head on

recommendations, durability, and penetrations and joints. (See

top of the waterproofing. If insulation is required the insulation

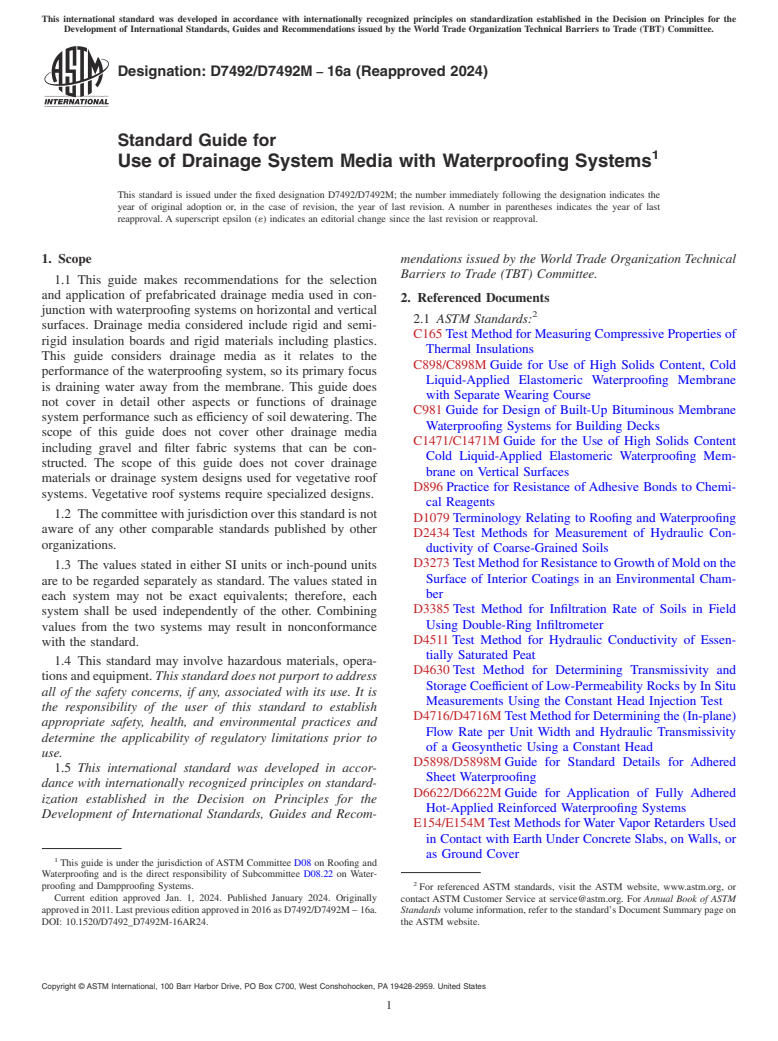

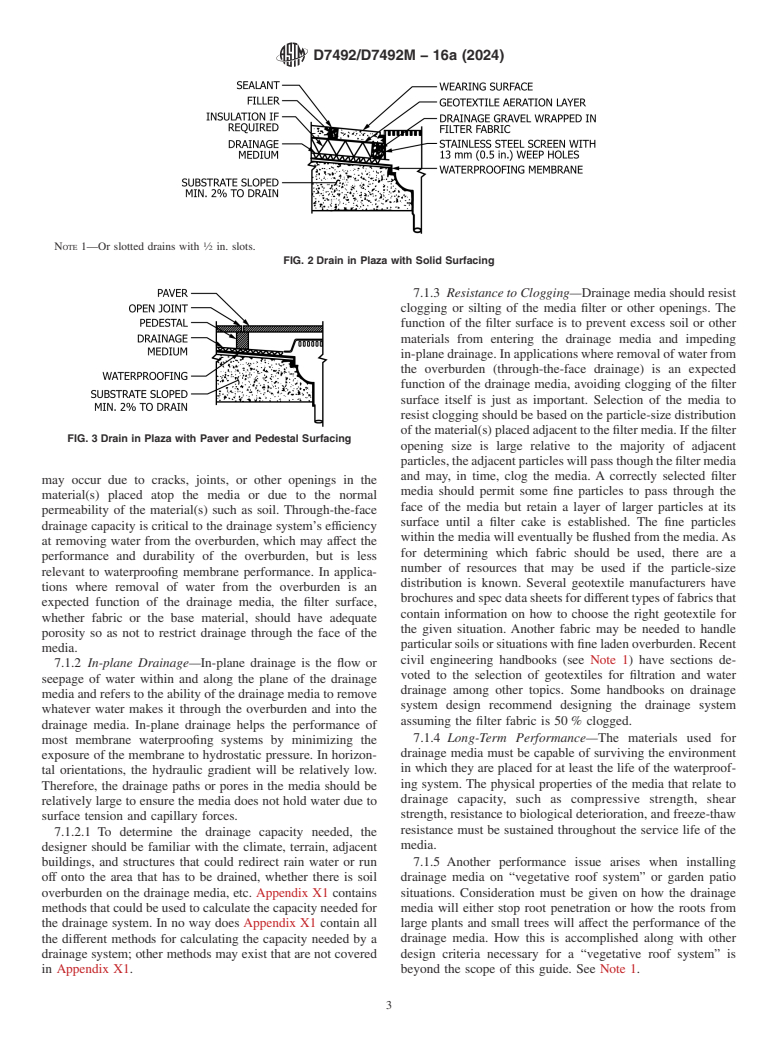

Figs. 1-3.) In all designs, the potential slip planes should be

shall be specified to handle the environment that is present

considered.

outside the drainage media and waterproofing membrane. If the

6.2 Compatibility—It is essential that all components and

insulation is porous, the drainage media must allow the porous

contiguous elements of the waterproofing system are compat-

insulation to drain any water accumulated during construction

ible and that the design of the system’s waterproofing and

or during its service on the wall into either the drainage media

drainage is coordinated to form an integrated waterproofing

or the footing drain tile system. A non-porous insulation is any

system.

insulation with closed cells that prevent water from flowing in

or out, for example extruded polystyrene foam or polystyrene

6.3 Basic Components—The various types of drainage me-

foam bead boards. A porous insulation is any insulation that

dia available are outlined in Section 12 of this guide and all

has open channels that easily allow water to enter and leave the

insulation such as rigid fiberglass boards with a perm rating of

4.6 Darcy (k, mm/s) or more (see X1.1.3).

7. Drainage Capacity

7.1 General—The drainage capacity is the volume of water

that passes through drainage media in a specified direction

under a known hydraulic gradient. The two major drainage

capacities of interest are the in-plane and through-the-face

drainage capacities. The orientation of the media and any slope

of the substrate will have a major effect on the drainage

capacity.

7.1.1 Through-the-Face Drainage—Through-the-face

drainage is the flow or seepage of water perpendicular to the

longitudinal axis of the drainage media. When media are

FIG. 1 Drainage at Lot Line Below-Grade Wall installed in a horizontal orientation, through-the-face drainage

D7492/D7492M − 16a (2024)

NOTE 1—Or slotted drains with ⁄2 in. slots.

FIG. 2 Drain in Plaza with Solid Surfacing

7.1.3 Resistance to Clogging—Drainage media should resist

clogging or silting of the media filter or other openings. The

function of the filter surface is to prevent excess soil or other

materials from entering the drainage media and impeding

in-plane drainage. In applications where removal of water from

the overburden (through-the-face drainage) is an expected

function of the drainage media, avoiding clogging of the filter

surface itself is just as important. Selection of the media to

resist clogging should be based on the particle-size distribution

of the material(s) placed adjacent to the filter media. If the filter

FIG. 3 Drain in Plaza with Paver and Pedestal Surfacing

opening size is large relative to the majority of adjacent

particles, the adjacent particles will pass though the filter media

and may, in time, clog the media. A correctly selected filter

may occur due to cracks, joints, or other openings in the

media should permit some fine particles to pass through the

material(s) placed atop the media or due to the normal

face of the media but retain a layer of larger particles at its

permeability of the material(s) such as soil. Through-the-face

surface until a filter cake is established. The fine particles

drainage capacity is critical to the drainage system’s efficiency

within the media will eventually be flushed from the media. As

at removing water from the overburden, which may affect the

for determining which fabric should be used, there are a

performance and durability of the overburden, but is less

number of resources that may be used if the particle-size

relevant to waterproofing membrane performance. In applica-

distribution is known. Several geotextile manufacturers have

tions where removal of water from the overburden is an

brochures and spec data sheets for different types of fabrics that

expected function of the drainage media, the filter surface,

contain information on how to choose the right geotextile for

whether fabric or the base material, should have adequate

the given situation. Another fabric may be needed to handle

porosity so as not to restrict drainage through the face of the

particular soils or situations with fine laden overburden. Recent

media.

civil engineering handbooks (see Note 1) have sections de-

7.1.2 In-plane Drainage—In-plane drainage is the flow or

voted to the selection of geotextiles for filtration and water

seepage of water within and along the plane of the drainage

drainage among other topics. Some handbooks on drainage

media and refers to the ability of the drainage media to remove

system design recommend designing the drainage system

whatever water makes it through the overburden and into the

assuming the filter fabric is 50 % clogged.

drainage media. In-plane drainage helps the performance of

7.1.4 Long-Term Performance—The materials used for

most membrane waterproofing systems by minimizing the

drainage media must be capable of surviving the environment

exposure of the membrane to hydrostatic pressure. In horizon-

in which they are placed for at least the life of the waterproof-

tal orientations, the hydraulic gradient will be relatively low.

ing system. The physical properties of the media that relate to

Therefore, the drainage paths or pores in the media should be

drainage capacity, such as compressive strength, shear

relatively large to ensure the media does not hold water due to

strength, resistance to biological deterioration, and freeze-thaw

surface tension and capillary forces.

resistance must be sustained throughout the service life of the

7.1.2.1 To determine the drainage capacity needed, the

media.

designer should be familiar with the climate, terrain, adjacent

buildings, and structures that could redirect rain water or run 7.1.5 Another performance issue arises when installing

off onto the area that has to be drained, whether there is soil drainage media on “vegetative roof system” or garden patio

overburden on the drainage media, etc. Appendix X1 contains situations. Consideration must be given on how the drainage

methods that could be used to calculate the capacity needed for media will either stop root penetration or how the roots from

the drainage system. In no way does Appendix X1 contain all large plants and small trees will affect the performance of the

the different methods for calculating the capacity needed by a drainage media. How this is accomplished along with other

drainage system; other met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.