ASTM A722/A722M-12

(Specification)Standard Specification for Uncoated High-Strength Steel Bars for Prestressing Concrete

Standard Specification for Uncoated High-Strength Steel Bars for Prestressing Concrete

ABSTRACT

This specification covers uncoated high-strength steel bars intended for use in pretensioned and post-tensioned prestressed concrete construction or in prestressed ground anchors. Two types of bars are considered: Type I bar, which has a plain surface and Type II bar, which has surface deformations. The bars shall be rolled from properly identified heats of ingot cast or strand cast steel. The bars shall be subjected to cold-stressing and then shall be stress-relieved to produce the prescribed mechanical properties. Yield strength, elongation, and tension tests shall be performed.

SCOPE

1.1 This specification covers uncoated high-strength steel bars intended for use in pretensioned and post-tensioned prestressed concrete construction or in prestressed ground anchors. Bars are of a minimum ultimate tensile strength level of 1035 MPa (150 000 psi).

1.2 Two types of bars are provided: Type I bar has a plain surface and Type II bar has surface deformations.

1.3 Supplementary requirements of an optional nature are provided. They shall apply only when specified by the purchaser.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A722/A722M −12

StandardSpecification for

Uncoated High-Strength Steel Bars for Prestressing

1

Concrete

This standard is issued under the fixed designationA722/A722M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope* 2.3 U.S. Federal Standards:

Fed. Std. 123Marking for Shipment (Civil Agencies)

1.1 This specification covers uncoated high-strength steel

bars intended for use in pretensioned and post-tensioned

3. Ordering Information

prestressed concrete construction or in prestressed ground

3.1 Orders for material under this specification should

anchors. Bars are of a minimum ultimate tensile strength level

include the following information:

of 1035 MPa (150 000 psi).

3.1.1 Quantity,

1.2 Two types of bars are provided: Type I bar has a plain

3.1.2 Name of material (uncoated high-strength bars for

surface and Type II bar has surface deformations.

prestressing concrete),

1.3 Supplementary requirements of an optional nature are

3.1.3 ASTM designation and year of issue,

provided. They shall apply only when specified by the pur-

3.1.4 Size and length,

chaser.

3.1.5 Type,

3.1.6 Special inspection requirements, if desired (see Sec-

1.4 The values stated in either SI units or inch-pound units

tion 12),

are to be regarded separately as standard. The values stated in

3.1.7 Special preparation for delivery, if desired (see Sec-

each system may not be exact equivalents; therefore, each

tion 11),

system shall be used independently of the other. Combining

3.1.8 Load-elongation curve, if required (see Section 15),

values from the two systems may result in non-conformance

and

with the specification.

3.1.9 Supplementary requirements, if desired.

2. Referenced Documents

NOTE 1—A typical ordering description is as follows: 50 uncoated

2

2.1 ASTM Standards: high-strength steel bars for prestressing concrete to ASTM A722/

A722M–__; 26 mm diameter, 12.20 m long, Type II; packed in

A370Test Methods and Definitions for Mechanical Testing

accordance with A700; meeting supplementary bending properties.

of Steel Products

A700Practices for Packaging, Marking, and Loading Meth-

4. Materials and Manufacture

ods for Steel Products for Shipment

4.1 Thebarsshallberolledfromproperlyidentifiedheatsof

E30TestMethodsforChemicalAnalysisofSteel,CastIron,

3

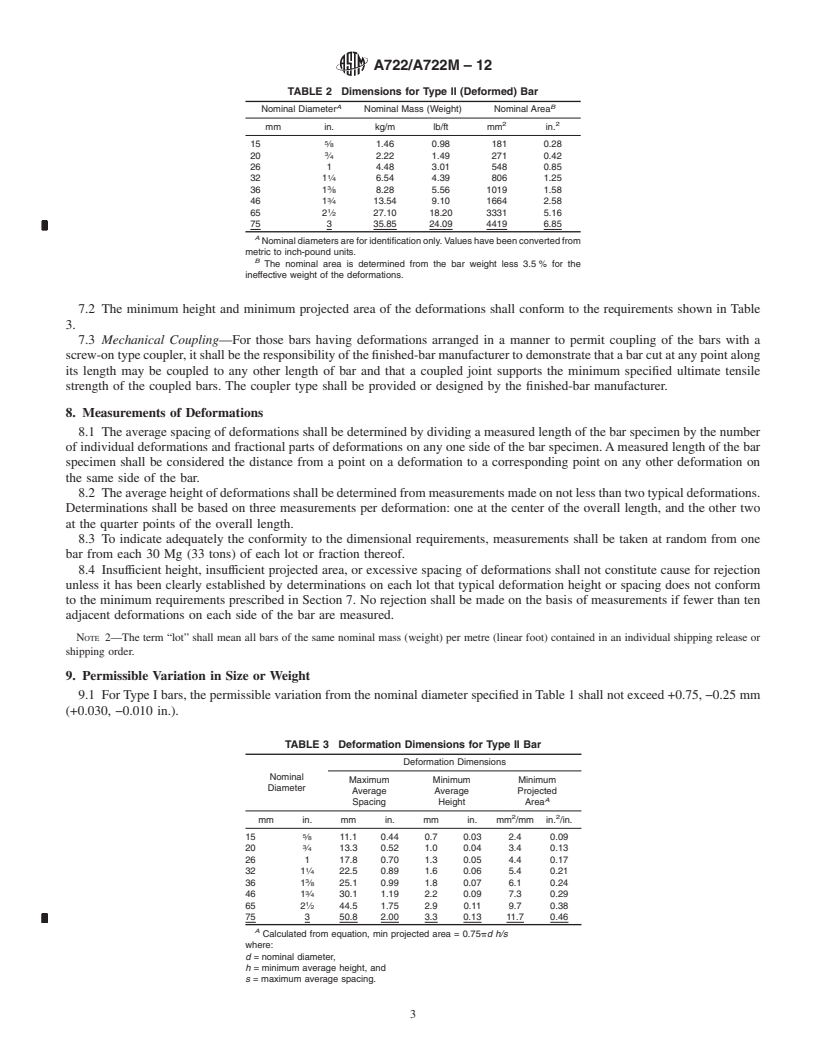

ingot cast or strand cast steel. The standard sizes and dimen-

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

4

sions of Type I and II bars shall be those listed in Table 1 and

2.2 Government Standards:

Table 2, respectively.

MIL-STD-129Marking for Shipment and Storage

4.2 The bars shall be subjected to cold-stressing to not less

than 80% of the minimum ultimate strength, and then shall be

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

stress-relieved, to produce the prescribed mechanical proper-

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement.

ties.

Current edition approved May 1, 2012. Published May 2012. Originally

approved in 1975. Last previous edition approved in 2007 as A722/A722M–07.

5. Chemical Composition

DOI: 10.1520/A0722_A0722M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 An analysis of each heat of steel shall be made by the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

manufacturer from test samples taken during the pouring of

Standards volume information, refer to the standard’s Document Summary page on

each heat.

the ASTM website.

3

The last approved version of this historical standard is referenced on

5.1.1 Choice and use of chemical composition and alloying

www.astm.org.

elements, to produce the mechanical properties of the finished

4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

bar prescribed in 6.2, shall be made by the manufacturer,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. subject to the limitations in 5.1.2.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A722/A722M−12

TABLE 1 Dimensions for Type I (Plain) Bar

shall be based on the nominal area shown in Table 1 or the

A

Nominal Diameter Nominal Mass (Weight) Nominal Area effective area shown in Table 2.

2 2

mm in. kg/m lb/ft mm in.

6.4 Number of Tests—The number of tensile specimens

3

19 ⁄4 2.23 1.50 284 0.44

tested shall be one from each 36 Mg (39 tons) or fraction

7

22 ⁄8 3.04

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A722/A722M–07 Designation: A722/A722M – 12

Standard Specification for

Uncoated High-Strength Steel Bars for Prestressing

1

Concrete

This standard is issued under the fixed designationA722/A722M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers uncoated high-strength steel bars intended for use in pretensioned and post-tensioned prestressed

concrete construction or in prestressed ground anchors. Bars are of a minimum ultimate tensile strength level of 1035 MPa

(150 000 psi).

1.2 Two types of bars are provided: Type I bar has a plain surface and Type II bar has surface deformations.

1.3 Supplementary requirements of an optional nature are provided. They shall apply only when specified by the purchaser.

1.4The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the specification.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

E30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron

3

2.2 Government Standards:

MIL-STD-129 Marking for Shipment and Storage

3

2.3 U.S. Federal Standards:

Fed. Std. 123 Marking for Shipment (Civil Agencies)

3. Ordering Information

3.1 Orders for material under this specification should include the following information:

3.1.1 Quantity,

3.1.2 Name of material (uncoated high-strength bars for prestressing concrete),

3.1.3 ASTM designation and year of issue,

3.1.4 Size and length,

3.1.5 Type,

3.1.6 Special inspection requirements, if desired (see Section 12),

3.1.7 Special preparation for delivery, if desired (see Section 11),

3.1.8Load-elongation3.1.8 Load-elongation curve, if required (see Section 15), and

3.1.9 Supplementary requirements, if desired.

NOTE 1—Atypical ordering description is as follows: 50 uncoated high-strength steel bars for prestressing concrete toASTMA722/A722M–__; 26

mm diameter, 12.20 m long, Type II; packed in accordance with A700; meeting supplementary bending properties.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.05

on Steel Reinforcement.

Current edition approved March 1, 2007. Published March 2007. Originally approved in 1975. Last previous edition approved in 2005 as A722/A722M– 06. DOI:

10.1520/A0722_A0722M-07.

Current edition approved May 1, 2012. Published May 2012. Originally approved in 1975. Last previous edition approved in 2007 as A722/A722M–07. DOI:

10.1520/A0722_A0722M-12.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A722/A722M – 12

4. Materials and Manufacture

4.1 The bars shall be rolled from properly identified heats of ingot cast or strand cast steel. The standard sizes and dimensions

of Type I and II bars shall be those listed in Table 1 and Table 2, respectively.

4.2 The bars shall be subjected to cold-stressing to not less than 80% of the minimum ultimate strength, and then shall be

stress-relieved, to produce the prescribed mechanical properties.

5. Chemical Composition

5.1 Ananalysisofeachheatofsteelshallbemadebythemanufacturerfromtestsamplestakenduringthepouringofeachheat.

5.1.1 Choice and use of chemical composition and alloying elements, to produce the mechanical properties of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.