ASTM F1803-15(2019)

(Specification)Standard Specification for Poly (Vinyl Chloride)(PVC) Closed Profile Gravity Pipe and Fittings Based on Controlled Inside Diameter

Standard Specification for Poly (Vinyl Chloride)(PVC) Closed Profile Gravity Pipe and Fittings Based on Controlled Inside Diameter

ABSTRACT

This specification covers the requirements for poly(vinyl chloride) closed profile gravity sewer pipe and fittings with integral bell and elastomeric seal joints or plain end pipe with couplings based on a controlled inside diameter intended for non-pressure drainage of sewage and surface water. The integral bell gasketed joint, coupling, or fitting joints shall be designed in such a way that when assembled, the gasket (which is attached to either the bell or the spigot) will be compressed radially on the pipe spigot or in the bell to form a water-tight seal. The pipe and fittings shall comply with the following requirements: inside diameter, wall thickness, bell wall thickness, stiffness, flattening, impact strength, low head application of gasket, joint tightness, and resistance of exposed channels to infiltration, exfiltration, and sewer or drainage environments. Acetone immersion and air tests shall be performed to determine the degree of fusion of extruded plastic pipe and the air tightness or the minimum dwell period of the specimen, respectively.

SCOPE

1.1 This specification covers requirements for poly(vinyl chloride) (PVC) closed profile sewer pipe and fittings with integral bell and elastomeric seal joints or plain end pipe with couplings in sizes (18 to 60 in.) based on a controlled inside diameter.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Pipe and fittings produced to this specification should be installed in accordance with Practice D2321.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1803 −15 (Reapproved 2019)

Standard Specification for

Poly (Vinyl Chloride)(PVC) Closed Profile Gravity Pipe and

Fittings Based on Controlled Inside Diameter

This standard is issued under the fixed designation F1803; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Compounds and Chlorinated Poly(Vinyl Chloride)

(CPVC) Compounds

1.1 This specification covers requirements for poly(vinyl

D2122 Test Method for Determining Dimensions of Ther-

chloride) (PVC) closed profile sewer pipe and fittings with

moplastic Pipe and Fittings

integral bell and elastomeric seal joints or plain end pipe with

D2152 Test Method for Adequacy of Fusion of Extruded

couplings in sizes (18 to 60 in.) based on a controlled inside

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

diameter.

Acetone Immersion

1.2 The values stated in inch-pound units are to be regarded

D2321 PracticeforUndergroundInstallationofThermoplas-

as standard. The values given in parentheses are mathematical

tic Pipe for Sewers and Other Gravity-Flow Applications

conversions to SI units that are provided for information only

D2412 Test Method for Determination of External Loading

and are not considered standard.

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.3 The following safety hazard caveat pertains only to the D2444 Practice for Determination of the Impact Resistance

test methods portion, Section 8, of this specification: This

of Thermoplastic Pipe and Fittings by Means of a Tup

standard does not purport to address all of the safety concerns, (Falling Weight)

if any, associated with its use. It is the responsibility of the user

D2855 Practice for the Two-Step (Primer and Solvent Ce-

of this standard to establish appropriate safety, health, and ment) Method of Joining Poly (Vinyl Chloride) (PVC) or

environmental practices and determine the applicability of

Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and

regulatory limitations prior to use. Piping Components with Tapered Sockets

D3212 Specification for Joints for Drain and Sewer Plastic

NOTE 1—Pipe and fittings produced to this specification should be

Pipes Using Flexible Elastomeric Seals

installed in accordance with Practice D2321.

F402 Practice for Safe Handling of Solvent Cements,

1.4 This international standard was developed in accor-

Primers, and Cleaners Used for Joining Thermoplastic

dance with internationally recognized principles on standard-

Pipe and Fittings

ization established in the Decision on Principles for the

F412 Terminology Relating to Plastic Piping Systems

Development of International Standards, Guides and Recom-

F477 Specification for Elastomeric Seals (Gaskets) for Join-

mendations issued by the World Trade Organization Technical

ing Plastic Pipe

Barriers to Trade (TBT) Committee.

F679 Specification for Poly(Vinyl Chloride) (PVC) Large-

Diameter Plastic Gravity Sewer Pipe and Fittings

2. Referenced Documents

2.2 Federal Standard:

2.1 ASTM Standards:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

D618 Practice for Conditioning Plastics for Testing

2.3 Military Standard:

D1600 Terminology forAbbreviatedTerms Relating to Plas-

MIL-STD-129 Marking for Shipment and Storage

tics

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

3. Terminology

3.1 Definitions—Definitions are in accordance with Termi-

nology F412, and abbreviations are in accordance with Termi-

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

nologyD1600,unlessotherwisespecified.Theabbreviationfor

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

Current edition approved Aug. 1, 2019. Published August 2019. Originally poly(vinyl chloride) is PVC.

approved in 1997. Last previous edition approved in 2015 as F1803 – 15. DOI:

3.2 Definitions of Terms Specific to This Standard:

10.1520/F1803-15R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA

the ASTM website. 19111-5094 http://quicksearch.dla.mil/

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1803−15 (2019)

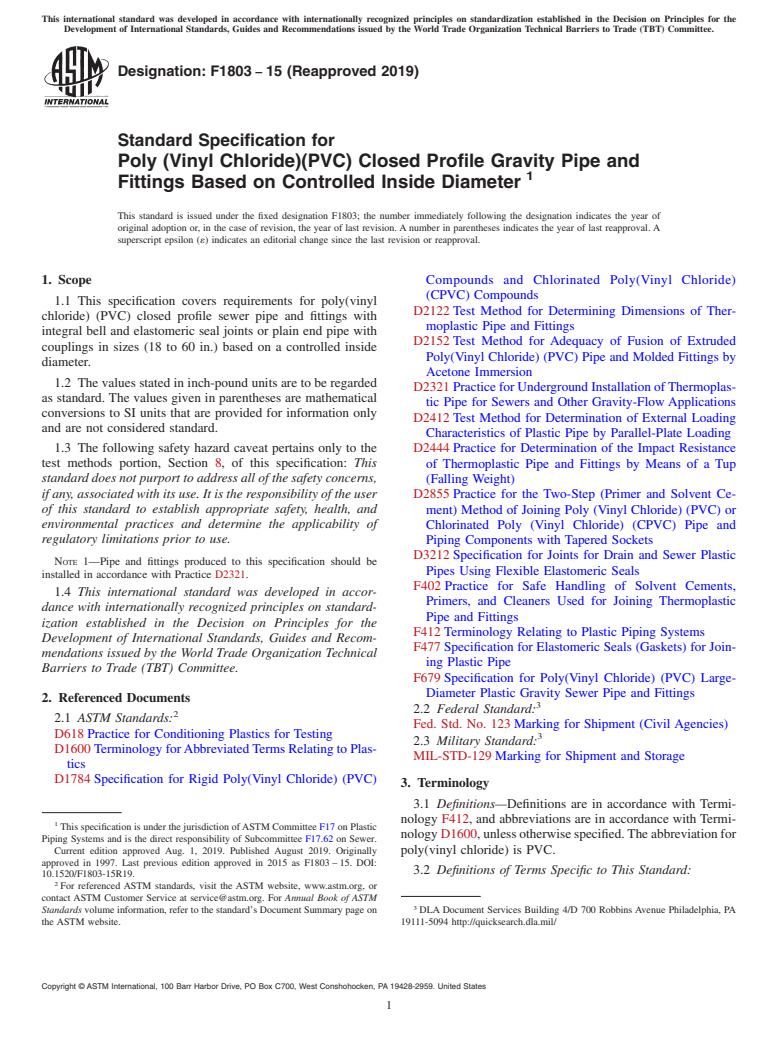

3.2.1 closed profile (CP) gravity sewer pipe, n—a pipe 6.3 The joint shall be designed to avoid displacement of the

product consisting of an essentially smooth waterway braced gasket when assembled in accordance with the manufacturer’s

circumferentially or spirally with projections or ribs that are recommendation.

joined by an essentially smooth outer wall (see Fig. 1).

6.4 The assembly of joints shall be in accordance with the

manufacturer’s recommendations.

4. Significance and Use

4.1 The requirements of this specification are intended to

7. Requirements

provide pipe and fittings suitable for nonpressure drainage of

7.1 Workmanship—The pipe and fittings shall be essentially

sewage and surface water.

uniform in color, opacity, density, and other properties. The

NOTE 2—Industrial waste disposal lines should be installed only with

inside and outside surfaces shall be semimatte or glossy in

the specific approval of the governing code authority since chemicals not

appearance and free of chalking, sticky, or tacky material. The

commonly found in drains and sewers and temperatures in excess of

surfaces shall be free of excess bloom; that is, slight bloom is

140°F may be encountered.

acceptable. The pipe walls shall be free of cracks, holes,

blisters, voids, foreign inclusions, or other defects that are

5. Material

visible to the naked eye and that may affect the wall integrity.

5.1 Basic Materials—The pipe and fittings shall be made of

Bloom or chalking may develop in pipe exposed to direct rays

PVC plastic having a minimum cell classification of 12454 or

of the sun (ultraviolet radiant energy) for extended periods and

12364 as defined in Specification D1784. Homopolymer PVC

consequently these requirements do not apply to pipe after

compounds must meet or exceed the requirements of the above

extended exposure to direct rays of the sun.

listed minimum cell classification number.

7.2 Pipe Fitting Dimensions:

5.2 Rework Material—Clean rework material generated

7.2.1 Diameter—The inside diameter of the pipe shall meet

from the manufacturer’s own pipe or fittings production may

the requirements given in Table 1 when measured in accor-

be used by the same manufacturer provided pipe or fittings

dance with 8.4.1.

produced meet all the requirements of this specification.

7.2.2 Wall Thickness—The minimum wall thickness of the

5.3 Gaskets—Elastomeric gaskets shall comply with the

waterway of pipe and fittings fabricated from pipe sections

requirements described in Specification F477.

shall meet the requirements given in Table 1 when measured in

5.4 Lubricant—The lubricant used for assembly shall be

accordance with 8.4.2. The wall thickness of fittings fabricated

suitable for use with PVC pipe and elastomeric seals for this

from pipes meeting the requirements of Specification F679 are

application and have no detrimental effect on the gasket or on

also satisfactory.

the pipe.

7.2.3 Bell Wall Thickness—In the case of belled pipe and

fittings fabricated from pipe sections, the thickness of the wall

6. Joining Systems

in the bell shall be considered satisfactory if it was formed

6.1 Gasketed Joint—The integral bell gasketed joint,

from pipe meeting the previous requirements. For reducing

coupling, or fitting joints shall be designed so that when

fittings or those with smaller inlets, the minimum wall thick-

assembled, the gasket (which is attached to either the bell or ness for each inlet shall be no less than the minimum wall

the spigot) will be compressed radially on the pipe spigot or in

thickness for that size pipe.

the bell to form a water-tight seal. The joints shall be designed

7.2.4 Fittings:

to comply with and show no sign of leakage when tested in

7.2.4.1 Molded Fittings—Molded fittings conforming to the

accordance with 7.7 when assembled with pipe for which they

requirements of Specification F679 may also be used with

are intended.

profile gravity sewer pipe provided an adapter (when required)

6.2 Couplings shall form a water-tight seal when assembled is used to make the connection. The minimum wall thickness

with plain end pipe and show no sign of leakage when tested of the molded fittings and adapter shall coincide with the

in accordance with 7.7 when assembled with pipe for which values listed in Table 1 of Specification F679. The thickness in

they are intended. the wall of the adapter bell shall be considered satisfactory if

formed from pipe meeting the previous requirements.

NOTE 3—The outside diameters of products manufactured to this

7.2.4.2 Fabricated Fittings—Fabricated fittings shall be

specification are not specified and therefore joint compatibility should be

reviewed.

made from the pipe meeting the requirements of this

specification, or Specification F679. Fabricated fittings with

solvent cement components shall be made in accordance with

Practice D2855 and taking cognizance of Practice F402.

Unreinforced solvent cement mitred joints shall not be used.

Fabricated joints shall be adequately lapped or fusion butt

welded and, when needed, additionally reinforced.

7.3 Pipe Flattening—There shall be no evidence of

splitting, cracking, breaking, or separation of ribs or seams

FIG. 1Typical Closed Profile (CP) (A) Waterway minimum wall

(B) Average inside diameter when pipe is tested in accordance with 8.5.

F1803−15 (2019)

TABLE 1 Pipe Dimensions and Stiffness

Nominal Minimum Inside Tolerance on Minimum Pipe Waterway Minimum

A

Pipe Size, Diameter, Inside Diameter, Stiffness Series 46, Wall Series 46,

in. in. (mm) in. (mm) lbf/in. (kPa) in. (mm)

18 17.595 (446.91) +0.110 (+2.79) 46 (320) 0.070 (1.78)

21 20.690 (525.53) +0.120 (+3.05) 46 (320) 0.080 (2.03)

24 23.430 (595.12) +0.140 (+3.56) 46 (320) 0.100 (3.54)

27 26.420 (671.01) +0.160 (+4.06) 46 (320) 0.115 (2.92)

30 29.410 (747.01) +0.180 (+4.57) 46 (320) 0.125 (3.18)

33 32.405 (823.09) +0.190 (+4.83) 46 (320) 0.140 (3.56)

36 35.395 (899.03) +0.210 (+5.33) 46 (320) 0.150 (3.81)

39 38.385 (974.98) +0.230 (+5.84) 46 (320) 0.165 (4.19)

42 41.375 (1050.93) +0.250 (+6.35) 46 (320) 0.180 (4.57)

45 44.370 (1127.00) +0.260 (+6.60) 46 (320) 0.195 (4.95)

48 47.360 (1202.94) +0.280 (+7.11) 46 (320) 0.210 (5.33)

54 53.350 (1355.09) +0.300 (+7.62) 46 (320) 0.225 (5.72)

60 59.340 (1507.24) +0.320 (+8.128) 46 (320) 0.240 (6.10)

A

In-plant quality control manufacturing. Base inside diameter calculations should include out-of-roundness as a result of shipping and handling.

7.4 Pipe Impact Strength—The impact strength shall not be

less than the values shown in Table 2 when tested in accor-

dance with 8.6.

NOTE 4—This requirement is intended only for use as a quality control

test, not a simulated service test.

7.5 Pipe Stiffness—Pipe stiffness values for the pipe shall

comply with Table 1 when tested in accordance with 8.7.

7.6 Gaskets—Gaskets shall meet the low head application

requirements of Specification F477 and be molded into a

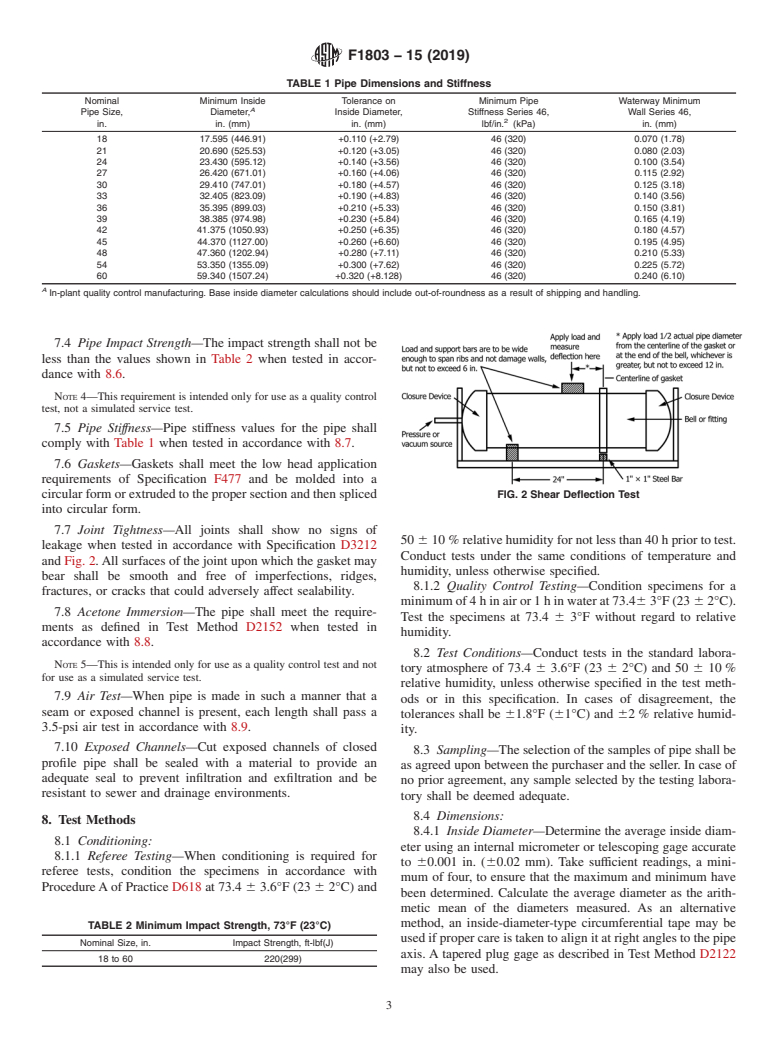

FIG. 2Shear Deflection Test

circular form or extruded to the proper section and then spliced

into circular form.

7.7 Joint Tightness—All joints shall show no signs of

50 6 10 % relative humidity for not less than 40 h prior to test.

leakage when tested in accordance with Specification D3212

Conduct tests under the same conditions of temperature and

and Fig. 2.All surfaces of the joint upon which the gasket may

humidity, unless otherwise specified.

bear shall be smooth and free of imperfections, ridges,

8.1.2 Quality Control Testing—Condition specimens for a

fractures, or cracks that could adversely affect sealability.

minimumof4hinairor1hinwaterat73.463°F(23 62°C).

7.8 Acetone Immersion—The pipe shall meet the require-

Test the specimens at 73.4 6 3°F without regard to relative

ments as defined in Test Method D2152 when tested in

humidity.

accordance with 8.8.

8.2 Test Conditions—Conduct tests in the standard labora-

NOTE 5—This is intended only for use as a quality control test and not

tory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 6 10 %

for use as a simulated service test.

relative humidity, unless otherwise specified in the test meth-

7.9 Air Test—When pipe is made in such a manner that a

ods or in this specification. In cases of disagreement, the

seam or exposed channel is present, each length shall pass a

tolerances shall be 61.8°F (61°C) and 62 % relative humid-

3.5-psi air test in accordance with 8.9.

ity.

7.10 Exposed Channels—Cut exposed channels of closed

8.3 Sampling—The selection of the samples of pipe shall be

profile pipe shall be sealed with a material to provide an

as agreed upon between the purchaser and the seller. In case of

adequate seal to prevent infiltration and exfiltration and be

no prior agreement, any sample selected by the testing labora-

resistant to sewer and drainage environments.

tory shall be deemed adequate.

8.4 Dimensions:

8. Test Methods

8.4.1 Inside Diameter—Determine the average inside diam-

8.1 Conditioning:

eter using an internal micrometer or telescoping gage accurate

8.1.1 Referee Testing—When conditioning is required for

to 60.001 in. (60.02 mm). Take sufficient readings, a mini-

referee tests, condition the specimens in accordance with

mum of four, to ensure that the maximum and minimum have

ProcedureAof Practice D618 at 73.4 6 3.6°F (23 6 2°C) and

been determined. Calculate the average diameter as the arith-

metic mean of the diameters measured. As an alternative

method, an inside-diameter-type circumferential tape may be

TABLE 2 Minimum Impact Strength, 73°F (23°C)

used if proper care is taken to align it at right angles to the pipe

Nominal Size, in. Impact Strength, ft-lbf(J)

axis. A tapered plug gage as described in Test Method D2122

18 to 60 220(299)

may also be used.

F1803−15 (2019)

8.4.2 Wall Thickness—Measure the wall thickness of the indicated by reaction to immersion in anhydrous acetone. It is

thinnest cross section of the waterway in the gaps between ribs applicable only for distinguishing between unfused and prop-

in accordance with Test Met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.