ASTM F3183-21

(Practice)Standard Practice for Guided Side Bend Evaluation of Polyethylene Pipe Butt Fusion Joint

Standard Practice for Guided Side Bend Evaluation of Polyethylene Pipe Butt Fusion Joint

SIGNIFICANCE AND USE

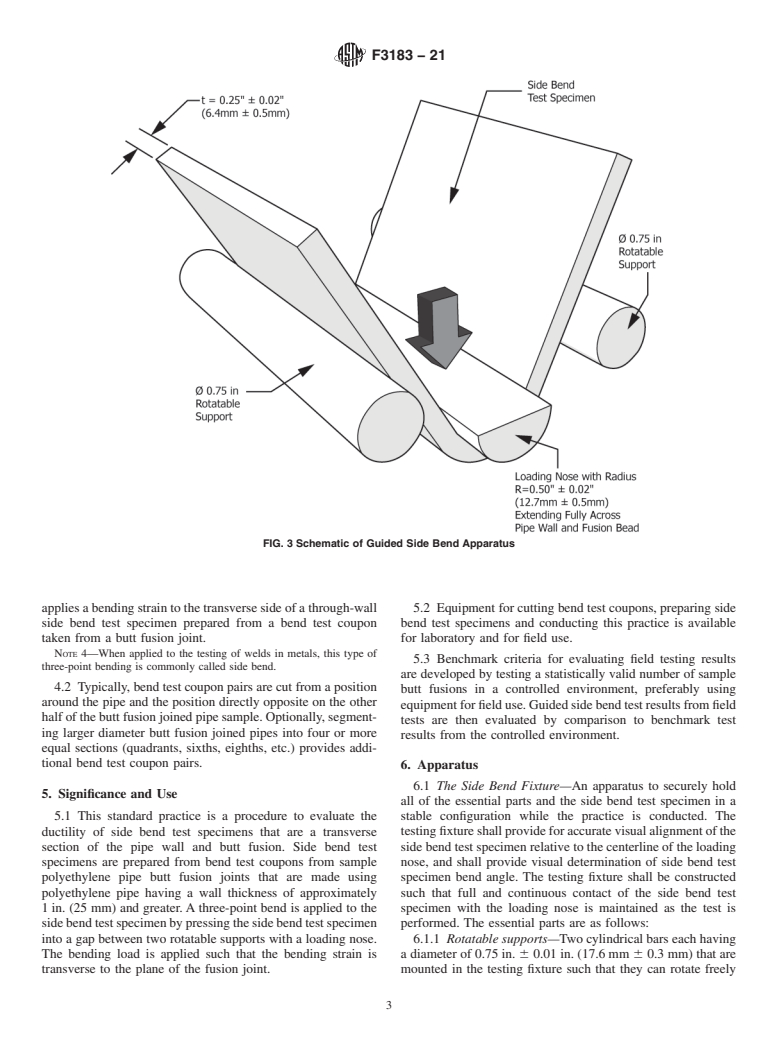

5.1 This standard practice is a procedure to evaluate the ductility of side bend test specimens that are a transverse section of the pipe wall and butt fusion. Side bend test specimens are prepared from bend test coupons from sample polyethylene pipe butt fusion joints that are made using polyethylene pipe having a wall thickness of approximately 1 in. (25 mm) and greater. A three-point bend is applied to the side bend test specimen by pressing the side bend test specimen into a gap between two rotatable supports with a loading nose. The bending load is applied such that the bending strain is transverse to the plane of the fusion joint.

5.2 Equipment for cutting bend test coupons, preparing side bend test specimens and conducting this practice is available for laboratory and for field use.

5.3 Benchmark criteria for evaluating field testing results are developed by testing a statistically valid number of sample butt fusions in a controlled environment, preferably using equipment for field use. Guided side bend test results from field tests are then evaluated by comparison to benchmark test results from the controlled environment.

SCOPE

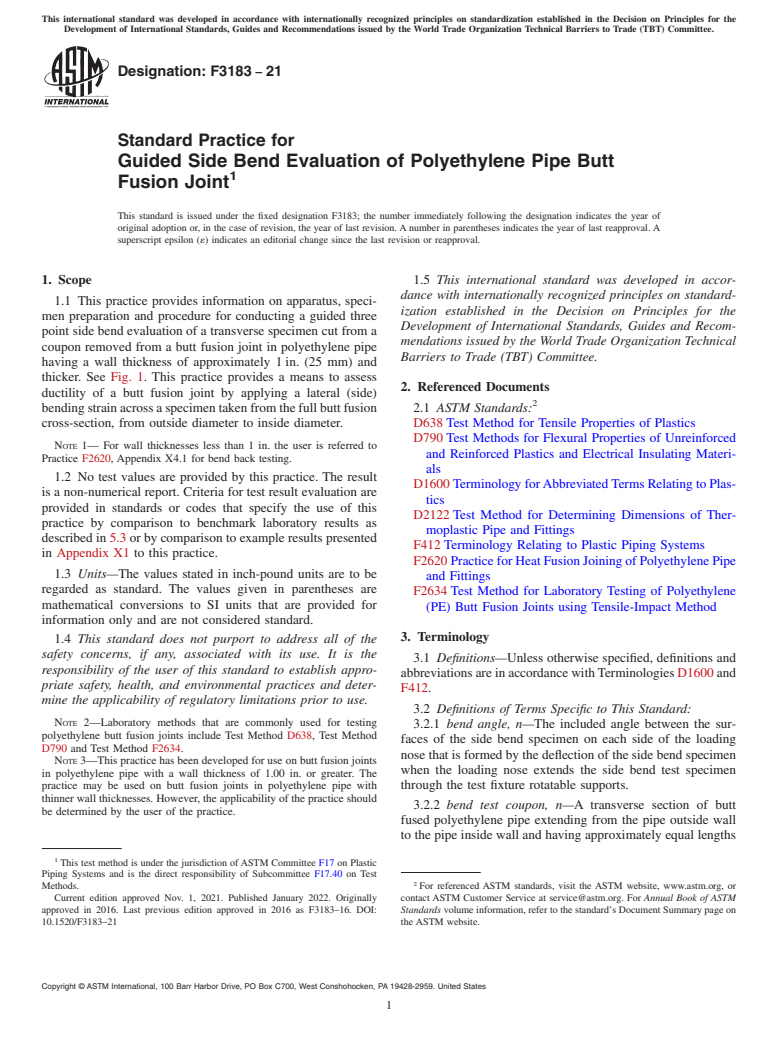

1.1 This practice provides information on apparatus, specimen preparation and procedure for conducting a guided three point side bend evaluation of a transverse specimen cut from a coupon removed from a butt fusion joint in polyethylene pipe having a wall thickness of approximately 1 in. (25 mm) and thicker. See Fig. 1. This practice provides a means to assess ductility of a butt fusion joint by applying a lateral (side) bending strain across a specimen taken from the full butt fusion cross-section, from outside diameter to inside diameter.

Note 1: For wall thicknesses less than 1 in. the user is referred to Practice F2620, Appendix X4.1 for bend back testing.

FIG. 1 Guided Side Bend Conceptual Schematic

1.2 No test values are provided by this practice. The result is a non-numerical report. Criteria for test result evaluation are provided in standards or codes that specify the use of this practice by comparison to benchmark laboratory results as described in 5.3 or by comparison to example results presented in Appendix X1 to this practice.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 2: Laboratory methods that are commonly used for testing polyethylene butt fusion joints include Test Method D638, Test Method D790 and Test Method F2634.

Note 3: This practice has been developed for use on butt fusion joints in polyethylene pipe with a wall thickness of 1.00 in. or greater. The practice may be used on butt fusion joints in polyethylene pipe with thinner wall thicknesses. However, the applicability of the practice should be determined by the user of the practice.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3183 − 21

Standard Practice for

Guided Side Bend Evaluation of Polyethylene Pipe Butt

1

Fusion Joint

This standard is issued under the fixed designation F3183; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This practice provides information on apparatus, speci-

ization established in the Decision on Principles for the

men preparation and procedure for conducting a guided three

Development of International Standards, Guides and Recom-

point side bend evaluation of a transverse specimen cut from a

mendations issued by the World Trade Organization Technical

coupon removed from a butt fusion joint in polyethylene pipe

Barriers to Trade (TBT) Committee.

having a wall thickness of approximately 1 in. (25 mm) and

thicker. See Fig. 1. This practice provides a means to assess

2. Referenced Documents

ductility of a butt fusion joint by applying a lateral (side)

2

bendingstrainacrossaspecimentakenfromthefullbuttfusion 2.1 ASTM Standards:

cross-section, from outside diameter to inside diameter. D638 Test Method for Tensile Properties of Plastics

D790 Test Methods for Flexural Properties of Unreinforced

NOTE 1— For wall thicknesses less than 1 in. the user is referred to

and Reinforced Plastics and Electrical Insulating Materi-

Practice F2620, Appendix X4.1 for bend back testing.

als

1.2 No test values are provided by this practice. The result

D1600 Terminology forAbbreviatedTerms Relating to Plas-

is a non-numerical report. Criteria for test result evaluation are

tics

provided in standards or codes that specify the use of this

D2122 Test Method for Determining Dimensions of Ther-

practice by comparison to benchmark laboratory results as

moplastic Pipe and Fittings

described in 5.3 or by comparison to example results presented

F412 Terminology Relating to Plastic Piping Systems

in Appendix X1 to this practice.

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe

1.3 Units—The values stated in inch-pound units are to be

and Fittings

regarded as standard. The values given in parentheses are

F2634 Test Method for Laboratory Testing of Polyethylene

mathematical conversions to SI units that are provided for

(PE) Butt Fusion Joints using Tensile-Impact Method

information only and are not considered standard.

3. Terminology

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1 Definitions—Unless otherwise specified, definitions and

responsibility of the user of this standard to establish appro-

abbreviationsareinaccordancewithTerminologiesD1600and

priate safety, health, and environmental practices and deter-

F412.

mine the applicability of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

NOTE 2—Laboratory methods that are commonly used for testing

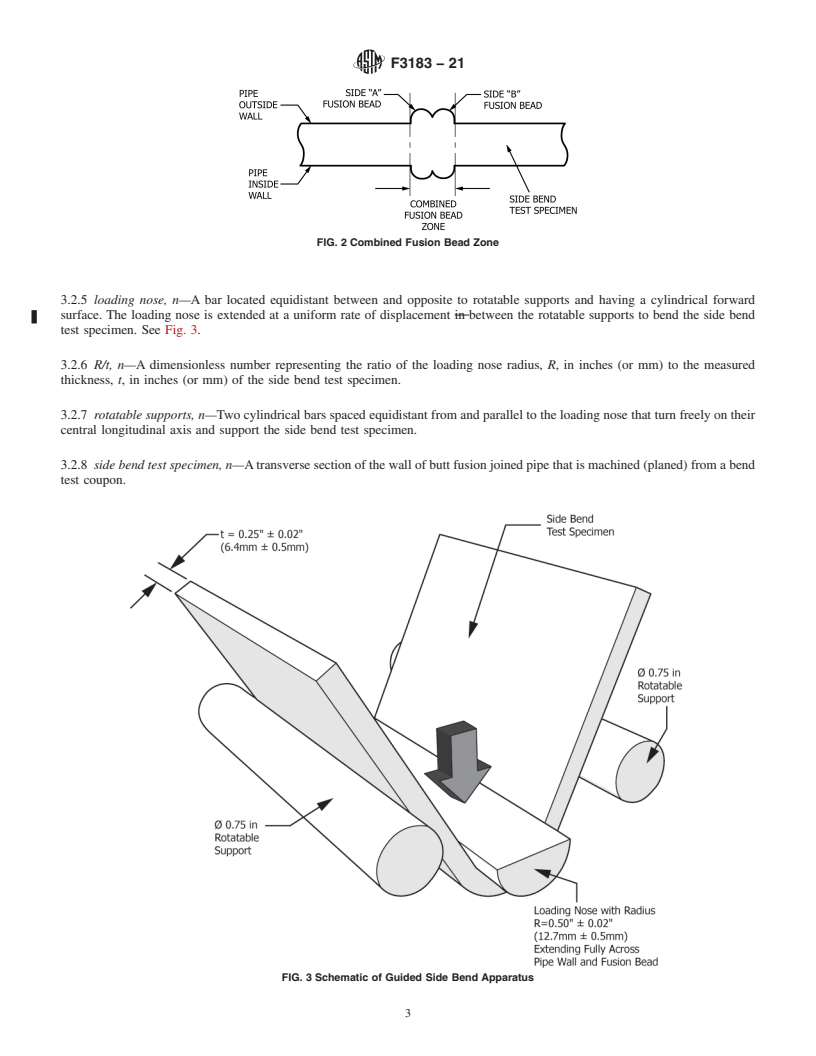

3.2.1 bend angle, n—The included angle between the sur-

polyethylene butt fusion joints include Test Method D638, Test Method

faces of the side bend specimen on each side of the loading

D790 and Test Method F2634.

nose that is formed by the deflection of the side bend specimen

NOTE 3—This practice has been developed for use on butt fusion joints

when the loading nose extends the side bend test specimen

in polyethylene pipe with a wall thickness of 1.00 in. or greater. The

practice may be used on butt fusion joints in polyethylene pipe with through the test fixture rotatable supports.

thinner wall thicknesses. However, the applicability of the practice should

3.2.2 bend test coupon, n—A transverse section of butt

be determined by the user of the practice.

fused polyethylene pipe extending from the pipe outside wall

to the pipe inside wall and having approximately equal lengths

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

2

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2021. Published January 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2016. Last previous edition approved in 2016 as F3183–16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F3183–21 the ASTM website.

Copyright © ASTM Internationa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3183 − 16 F3183 − 21

Standard Practice for

Guided Side Bend Evaluation of Polyethylene Pipe Butt

1

Fusion Joint

This standard is issued under the fixed designation F3183; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides information on apparatus, specimen preparation and procedure for conducting a guided three point side

bend evaluation of a transverse specimen cut from a coupon removed from a butt fusion joint in polyethylene pipe having a wall

thickness 1.00 in. (25.4 of approximately 1 in. (25 mm) and thicker. See Fig. 1. This practice provides a means to assess ductility

of a butt fusion joint by applying a lateral (side) bending strain across a specimen taken from the full butt fusion cross-section,

from outside diameter to inside diameter.

NOTE 1— For wall thicknesses less than 1 in. the user is referred to Practice F2620, Appendix X4.1 for bend back testing.

1.2 No test values are provided by this practice. The result is a non-numerical report. Criteria for test result evaluation are provided

in standards or codes that specify the use of this practice by comparison to benchmark laboratory results, results as described in

5.3 or by comparison to example results presented in Appendix X1 to this practice.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—Laboratory methods that are commonly used for testing polyethylene butt fusion joints include Test Method D638 and Test Method F2634.

NOTE 2—This practice has been developed for use on butt fusion joints in polyethylene pipe with a wall thickness of 1.00 in. or greater. The practice may

be used on butt fusion joints in polyethylene pipe with thinner wall thicknesses. However, the applicability of the practice should be determined by the

user of the practice.

NOTE 2—Laboratory methods that are commonly used for testing polyethylene butt fusion joints include Test Method D638, Test Method D790 and Test

Method F2634.

NOTE 3—This practice has been developed for use on butt fusion joints in polyethylene pipe with a wall thickness of 1.00 in. or greater. The practice may

be used on butt fusion joints in polyethylene pipe with thinner wall thicknesses. However, the applicability of the practice should be determined by the

user of the practice.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test Methods.

Current edition approved May 1, 2016Nov. 1, 2021. Published July 2016January 2022. Originally approved in 2016. Last previous edition approved in 2016 as F3183–16.

DOI: 10.1520/F3183–1610.1520/F3183–21

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3183 − 21

FIG. 1 Guided Side Bend Conceptual Schematic

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings

F2634 Test Method for Laboratory Testing of Polyethylene (PE) Butt Fusion Joints using Tensile-Impact Method

3. Terminology

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.