ASTM A697/A697M-03

(Test Method)Standard Test Method for Alternating Current Magnetic Properties of Laminated Core Specimen Using Voltmeter-Ammeter-Wattmeter Methods

Standard Test Method for Alternating Current Magnetic Properties of Laminated Core Specimen Using Voltmeter-Ammeter-Wattmeter Methods

SIGNIFICANCE AND USE

This test method was developed for evaluating the ac magnetic properties of laminated cores made from flat-rolled magnetic materials.

The reproducibility and repeatability of this test method are such that this test method is suitable for design, specification acceptance, service evaluation, and research and development.

SCOPE

1.1 This test method covers the determination of several ac magnetic properties of laminated cores made from flat-rolled magnetic materials.

1.2 This test method covers test equipment and procedures for the determination of impedance permeability and exciting power from voltage and current measurements, and core loss from wattmeter measurements. These tests are made under conditions of sinusoidal flux.

1.3 This test method covers tests for two general categories (1 and 2) of cores based on size and application.

1.4 Tests are provided for power and control size cores (Category 1) operating at inductions of 10 to 15 kG [1.0 to T] and at frequencies of 50, 60, and 400 Hz.

1.5 Procedures and tests are provided for coupling and matching type transformer cores (Category 2) over the range of inductions from 100 G [0.01 T] or lower to 10 kG [1.0 T] and above at 50 to 60 Hz or above when covered by suitable procurement specifications.

1.6 This test method also covers tests for core loss and ac impedance permeability under incremental test conditions (ac magnetization superimposed on dc magnetization) for the above core types and at inductions up to those that cause the ac exciting current to become excessively distorted or reach values that exceed the limits of the individual test equipment components.

1.7 This test method shall be used in conjunction with Practice A 34/A 34M and Terminology A 340. It depends upon these designated documents and a related reference test manual for detailed information which will not be repeated in this test method.

1.8 The values and equations stated in customary (cgs-emu and inch-pound) or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A 697/A697M–03

Standard Test Method for

Alternating Current Magnetic Properties of Laminated Core

1

Specimen Using Voltmeter-Ammeter-Wattmeter Methods

This standard is issued under the fixed designationA697/A 697M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of several ac

responsibility of the user of this standard to establish appro-

magnetic properties of laminated cores made from flat-rolled

priate safety and health practices and determine the applica-

magnetic materials.

bility of regulatory limitations prior to use.

1.2 This test method covers test equipment and procedures

for the determination of impedance permeability and exciting

2. Referenced Documents

power from voltage and current measurements, and core loss

2

2.1 ASTM Standards:

from wattmeter measurements. These tests are made under

A 34/A 34M Practice for Sampling and Procurement Test-

conditions of sinusoidal flux.

ing of Magnetic Materials

1.3 This test method covers tests for two general categories

A 340 Terminology of Symbols and Definitions Relating to

(1 and 2) of cores based on size and application.

Magnetic Testing

1.4 Tests are provided for power and control size cores

(Category 1) operating at inductions of 10 to 15 kG [1.0 to 1.5

3. Terminology

T] and at frequencies of 50, 60, and 400 Hz.

3.1 The terms and symbols listed below apply only to this

1.5 Procedures and tests are provided for coupling and

test method.The official list of symbols and definitions may be

matchingtypetransformercores(Category2)overtherangeof

found in Terminology A 340.

inductions from 100 G [0.01 T] or lower to 10 kG [1.0 T] and

3.2 Symbols:

above at 50 to 60 Hz or above when covered by suitable

A = E lamination surface area, one side only,

s

procurement specifications.

A = EI lamination surface area, one side only,

ss

1.6 This test method also covers tests for core loss and ac

h = lamination stack height,

A = dc ammeter,

impedance permeability under incremental test conditions (ac

dc

I = dc current,

dc

magnetization superimposed on dc magnetization) for the

N = primary turns,

1

above core types and at inductions up to those that cause the ac

N = secondary turns,

2

exciting current to become excessively distorted or reach N = tertiary turns,

3

R = ammeter shunt resistance,

1

values that exceed the limits of the individual test equipment

V = flux voltmeter,

f

components.

w = lamination center leg width,

1.7 This test method shall be used in conjunction with W = wattmeter, and

Z = choke coil impedance.

PracticeA 34/A 34M and TerminologyA 340. It depends upon

thesedesignateddocumentsandarelatedreferencetestmanual

4. Summary of Test Method

for detailed information which will not be repeated in this test

4.1 For Category 1 cores, the recommended tests are made

method.

at a frequency of 60 Hz and at a test induction within the range

1.8 The values and equations stated in customary (cgs-emu

from 10 through 15 kG [1.0 to 1.5 T].

and inch-pound) or SI units are to be regarded separately as

4.2 For Category 2 cores, the recommended tests are made

standard. Within this standard, SI units are shown in brackets.

at a frequency of 50 or 60 Hz and at inductions of 40, 100 or

The values stated in each system may not be exact equivalents;

200, 2000, 5000, 6000, 7000, and 10 000 G [0.004, 0.01 or

therefore,eachsystemshallbeusedindependentlyoftheother.

0.02, 0.2, 0.5, 0.6, 0.7, and 1.0 T]. Any or all may be required

Combining values from the two systems may result in noncon-

depending on the type of core material.

formance with this standard.

1 2

This test method is under the jurisdiction of Committee A06 on Magnetic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

PropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTestMethods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2003. Published November 2003. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1974. Last previous edition approved in 1998 as A 697 – 98. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 697/A697M–03

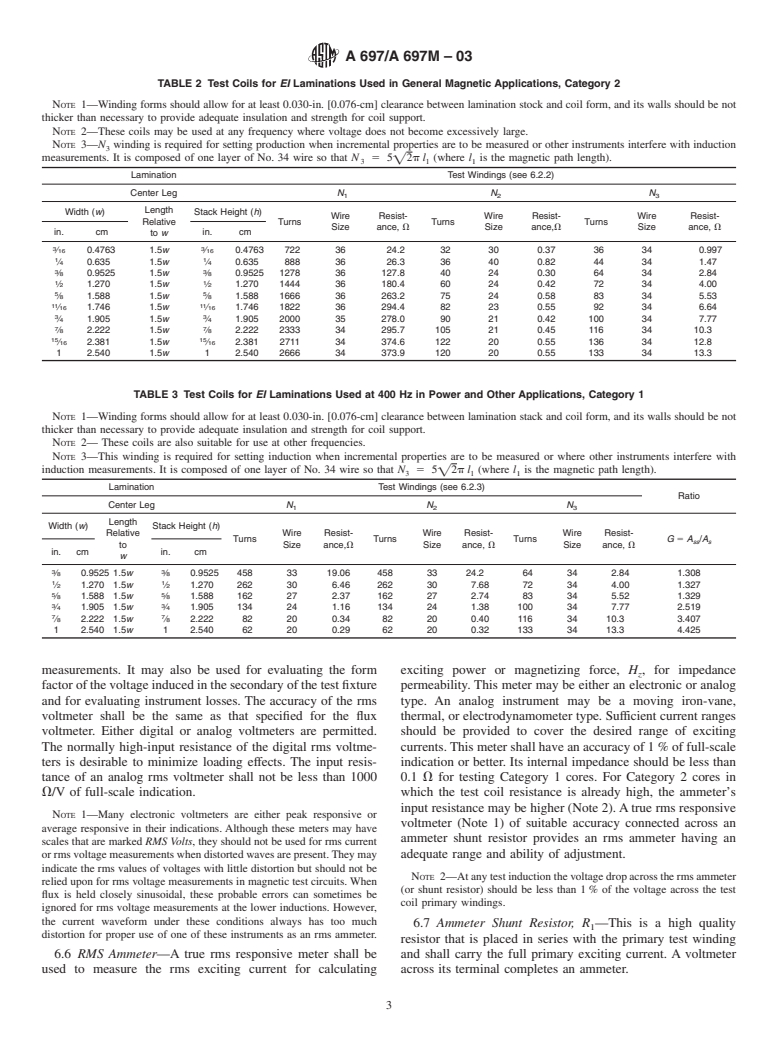

5. Significance and Use the tertiary winding N is designed so that the

3

N 5 5 2 p l (and N /N = 20).

=

3 1 1 3

5.1 This test method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.