ASTM A418-99(2003)

(Test Method)Standard Test Method for Ultrasonic Examination of Turbine and Generator Steel Rotor Forgings

Standard Test Method for Ultrasonic Examination of Turbine and Generator Steel Rotor Forgings

SCOPE

1.1 This test method for ultrasonic examination applies to turbine and generator steel rotor forgings covered by Specifications A 293, A 469, and A 470. This standard shall be used for contact testing only.

1.2 This test method describes a basic procedure of ultrasonically inspecting turbine and generator rotor forgings. It shall in no way restrict the use of other ultrasonic methods such as reference block calibrations when required by the applicable procurement documents nor is it intended to restrict the use of new and improved ultrasonic test equipment and methods as they are developed. The procedure utilizes different calibration techniques than had been used in previous issues. The frequency or amplitudes of recordable indications should not be interpreted necessarily as a change in quality of the product being examined.

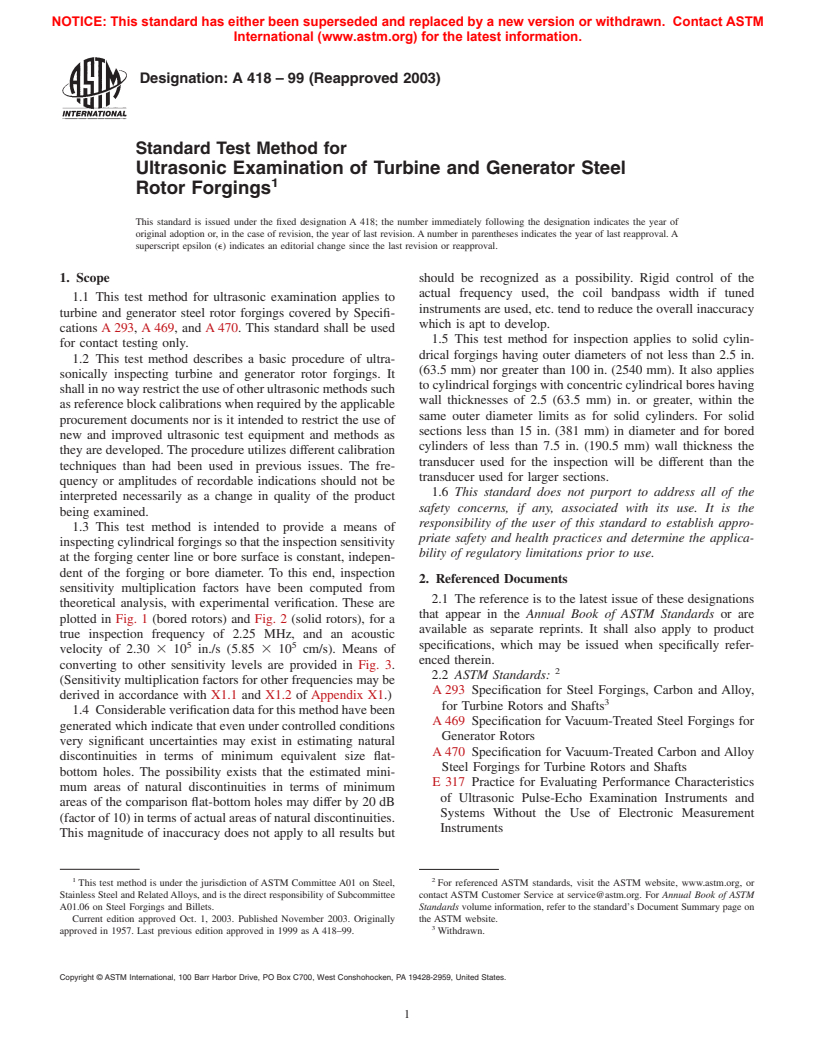

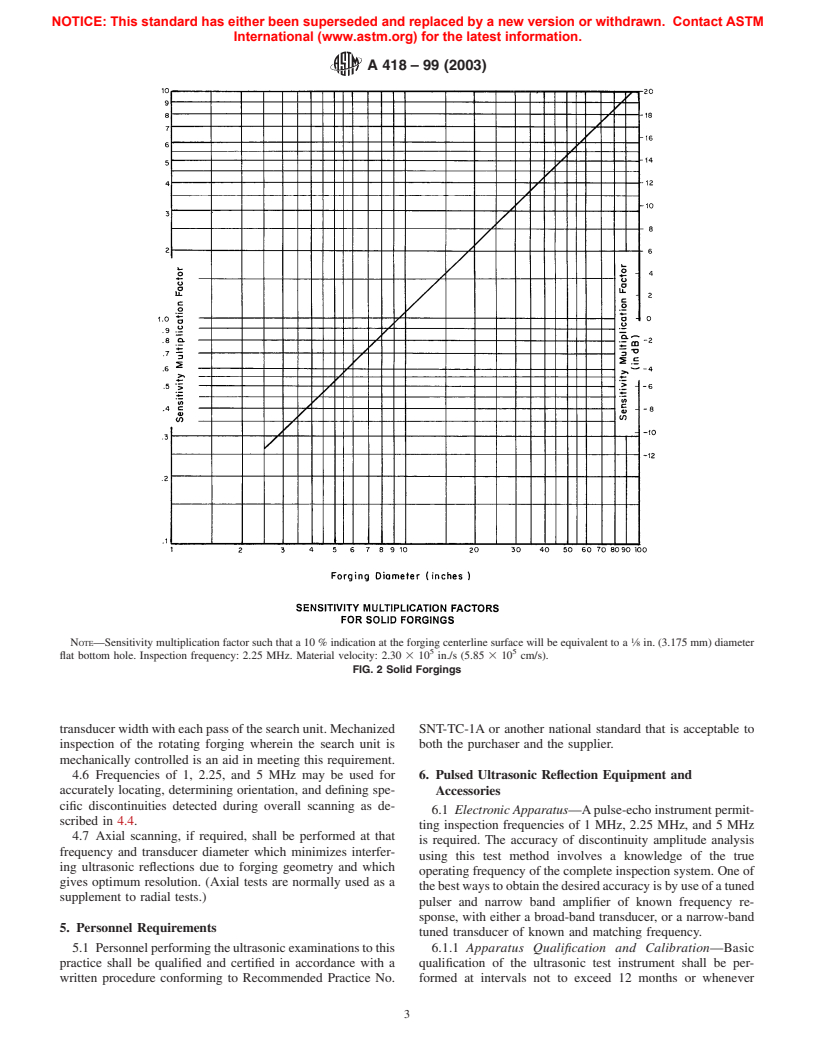

1.3 This test method is intended to provide a means of inspecting cylindrical forgings so that the inspection sensitivity at the forging center line or bore surface is constant, independent of the forging or bore diameter. To this end, inspection sensitivity multiplication factors have been computed from theoretical analysis, with experimental verification. These are plotted in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true inspection frequency of 2.25 MHz, and an acoustic velocity of 2.30 × 105 in./s (5.85 × 105 cm/s). Means of converting to other sensitivity levels are provided in Fig. 3. (Sensitivity multiplication factors for other frequencies may be derived in accordance with X1.1 and X1.2 of Appendix X1.)

1.4 Considerable verification data for this method have been generated which indicate that even under controlled conditions very significant uncertainties may exist in estimating natural discontinuities in terms of minimum equivalent size flat-bottom holes. The possibility exists that the estimated minimum areas of natural discontinuities in terms of minimum areas of the comparison flat-bottom holes may differ by 20 dB (factor of 10) in terms of actual areas of natural discontinuities. This magnitude of inaccuracy does not apply to all results but should be recognized as a possibility. Rigid control of the actual frequency used, the coil bandpass width if tuned instruments are used, etc. tend to reduce the overall inaccuracy which is apt to develop.

1.5 This test method for inspection applies to solid cylindrical forgings having outer diameters of not less than 2.5 in. (63.5 mm) nor greater than 100 in. (2540 mm). It also applies to cylindrical forgings with concentric cylindrical bores having wall thicknesses of 2.5 (63.5 mm) in. or greater, within the same outer diameter limits as for solid cylinders. For solid sections less than 15 in. (381 mm) in diameter and for bored cylinders of less than 7.5 in. (190.5 mm) wall thickness the transducer used for the inspection will be different than the transducer used for larger sections.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 418 – 99 (Reapproved 2003)

Standard Test Method for

Ultrasonic Examination of Turbine and Generator Steel

Rotor Forgings

This standard is issued under the fixed designation A 418; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope should be recognized as a possibility. Rigid control of the

actual frequency used, the coil bandpass width if tuned

1.1 This test method for ultrasonic examination applies to

instruments are used, etc. tend to reduce the overall inaccuracy

turbine and generator steel rotor forgings covered by Specifi-

which is apt to develop.

cations A293, A469, and A470. This standard shall be used

1.5 This test method for inspection applies to solid cylin-

for contact testing only.

drical forgings having outer diameters of not less than 2.5 in.

1.2 This test method describes a basic procedure of ultra-

(63.5 mm) nor greater than 100 in. (2540 mm). It also applies

sonically inspecting turbine and generator rotor forgings. It

tocylindricalforgingswithconcentriccylindricalboreshaving

shallinnowayrestricttheuseofotherultrasonicmethodssuch

wall thicknesses of 2.5 (63.5 mm) in. or greater, within the

asreferenceblockcalibrationswhenrequiredbytheapplicable

same outer diameter limits as for solid cylinders. For solid

procurement documents nor is it intended to restrict the use of

sections less than 15 in. (381 mm) in diameter and for bored

new and improved ultrasonic test equipment and methods as

cylinders of less than 7.5 in. (190.5 mm) wall thickness the

they are developed.The procedure utilizes different calibration

transducer used for the inspection will be different than the

techniques than had been used in previous issues. The fre-

transducer used for larger sections.

quency or amplitudes of recordable indications should not be

1.6 This standard does not purport to address all of the

interpreted necessarily as a change in quality of the product

safety concerns, if any, associated with its use. It is the

being examined.

responsibility of the user of this standard to establish appro-

1.3 This test method is intended to provide a means of

priate safety and health practices and determine the applica-

inspectingcylindricalforgingssothattheinspectionsensitivity

bility of regulatory limitations prior to use.

at the forging center line or bore surface is constant, indepen-

dent of the forging or bore diameter. To this end, inspection

2. Referenced Documents

sensitivity multiplication factors have been computed from

2.1 The reference is to the latest issue of these designations

theoretical analysis, with experimental verification. These are

that appear in the Annual Book of ASTM Standards or are

plotted in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a

available as separate reprints. It shall also apply to product

true inspection frequency of 2.25 MHz, and an acoustic

5 5

specifications, which may be issued when specifically refer-

velocity of 2.30 3 10 in./s (5.85 3 10 cm/s). Means of

enced therein.

converting to other sensitivity levels are provided in Fig. 3.

2.2 ASTM Standards:

(Sensitivitymultiplicationfactorsforotherfrequenciesmaybe

A293 Specification for Steel Forgings, Carbon and Alloy,

derived in accordance with X1.1 and X1.2 of Appendix X1.)

for Turbine Rotors and Shafts

1.4 Considerableverificationdataforthismethodhavebeen

A469 Specification for Vacuum-Treated Steel Forgings for

generated which indicate that even under controlled conditions

Generator Rotors

very significant uncertainties may exist in estimating natural

A470 Specification for Vacuum-Treated Carbon and Alloy

discontinuities in terms of minimum equivalent size flat-

Steel Forgings for Turbine Rotors and Shafts

bottom holes. The possibility exists that the estimated mini-

E 317 Practice for Evaluating Performance Characteristics

mum areas of natural discontinuities in terms of minimum

of Ultrasonic Pulse-Echo Examination Instruments and

areas of the comparison flat-bottom holes may differ by 20 dB

Systems Without the Use of Electronic Measurement

(factorof10)intermsofactualareasofnaturaldiscontinuities.

Instruments

This magnitude of inaccuracy does not apply to all results but

1 2

This test method is under the jurisdiction of ASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.06 on Steel Forgings and Billets. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2003. Published November 2003. Originally the ASTM website.

approved in 1957. Last previous edition approved in 1999 as A418–99. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 418 – 99 (2003)

NOTE—Sensitivity multiplication factor such that a 10% indication at the forging bore surface will be equivalent to a ⁄8 in. (3.175 mm) diameter flat

5 5

bottom hole. Inspection frequency: 2.25 MHz. Material velocity: 2.30 3 10 in./s (5.85 3 10 cm/s).

FIG. 1 Bored Forgings

E 1065 Guide for Evaluating Characteristics of Ultrasonic 4.2 The ultrasonic inspection shall be performed after final

Search Units heat treatment of the forging. In those cases in which wheels,

slots, or similar features are machined into the forging before

3. Application

heat treatment, the entire forging shall be inspected ultrasoni-

3.1 This test method shall be used when ultrasonic inspec- cally before such machining, and as completely as practicable

tion is required by the order or specification for inspection after the final heat treatment.

purposes where the acceptance of the forging is based on 4.3 For overall scanning, the ultrasonic beam shall be

limitations of the number, amplitude or location of disconti- introducedradially.Toconformwiththisrequirement,external

nuities or a combination thereof, which give rise to ultrasonic conical surfaces of the forging shall be replaced by stepped

indications. surfacesinordertomaintaintheultrasonicbeamperpendicular

3.2 The acceptance criteria shall be clearly stated as order to the longitudinal axis. Such stepped surfaces shall be shown

requirements. on the forging drawing.

4.4 Forgingsmaybetestedeitherstationaryorwhilerotated

4. General Requirements

bymeansofalatheorrollers.Ifnotspecifiedbythepurchaser,

4.1 Asfaraspossible,theentirevolumeoftheforgingshall either method may be used at the manufacturer’s option.

be subjected to ultrasonic inspection. Because of fillets at Scanning speed shall not exceed 6 in./s (15.24 cm/s).

stepdownsandotherlocalconfigurations,itmaybeimpossible 4.5 To ensure complete coverage of the forging volume, the

to inspect some small portions of a forging. search unit shall be indexed approximately 75% of the

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 418 – 99 (2003)

NOTE—Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a ⁄8 in. (3.175 mm) diameter

5 5

flat bottom hole. Inspection frequency: 2.25 MHz. Material velocity: 2.30 3 10 in./s (5.85 3 10 cm/s).

FIG. 2 Solid Forgings

transducerwidthwitheachpassofthesearchunit.Mechanized SNT-TC-1A or another national standard that is acceptable to

inspection of the rotating forging wherein the search unit is both the purchaser and the supplier.

mechanically controlled is an aid in meeting this requirement.

4.6 Frequencies of 1, 2.25, and 5 MHz may be used for 6. Pulsed Ultrasonic Reflection Equipment and

accurately locating, determining orientation, and defining spe- Accessories

cific discontinuities detected during overall scanning as de-

6.1 Electronic Apparatus—Apulse-echoinstrumentpermit-

scribed in 4.4.

ting inspection frequencies of 1 MHz, 2.25 MHz, and 5 MHz

4.7 Axial scanning, if required, shall be performed at that

is required. The accuracy of discontinuity amplitude analysis

frequency and transducer diameter which minimizes interfer-

using this test method involves a knowledge of the true

ing ultrasonic reflections due to forging geometry and which

operating frequency of the complete inspection system. One of

gives optimum resolution. (Axial tests are normally used as a

thebestwaystoobtainthedesiredaccuracyisbyuseofatuned

supplement to radial tests.)

pulser and narrow band amplifier of known frequency re-

sponse, with either a broad-band transducer, or a narrow-band

5. Personnel Requirements

tuned transducer of known and matching frequency.

5.1 Personnelperformingtheultrasonicexaminationstothis 6.1.1 Apparatus Qualification and Calibration—Basic

practice shall be qualified and certified in accordance with a qualification of the ultrasonic test instrument shall be per-

written procedure conforming to Recommended Practice No. formed at intervals not to exceed 12 months or whenever

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 418 – 99 (2003)

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is

Required

maintenance is performed that affects the equipment function. decrease of the higher order reflections is the greater of 65%

Thedateofthelastcalibrationandthedateofthenextrequired of the expected back reflection height or 62% of full screen

height.

calibration shall be displayed on the test equipment.

6.3 Signal Attenuator—The instrument shall contain a cali-

6.1.2 Thehorizontallinearityshallbecheckedonadistance

brated gain control or signal attenuator that meets the require-

calibrationbarusingthemultipleordertechnique.SeePractice

ments of Practice E317 (in each case, accurate within 65%)

E317. The horizontal linearity shall be 62 % of the metal

that will allow indications beyond the linear range of the

path.

instrument to be measured. It is recommended that these

6.1.3 If the rotor has a coupling or similar thin axial section

controls permit signal adjustments up to 25 to 1 (28 dB). See

with parallel sides, the accuracy of the linearity shall be

Fig. 1 and Fig. 2.

checked by ultrasonically verifying the thickness of the cou-

6.4 Search Units—Longitudinal wave search units of

pling or axial section. If necessary, minor adjustments for

known effective frequency should be used for radial scanning.

differences in the ultrasonic velocities between the calibration

A ⁄4 by 1 in. (6.35 by 25.4 mm) 2.25 MHz transducer, used

bar and the forging shall then be made.

with the 1 in. dimension parallel to the forging axis, will give

6.2 Amplifier—The amplifier and the cathode ray tube shall

a desirable combination of resolution and beam width on large

providelinearresponsewithin 62%,upto100%offullscreen

sections15in.(381mm)indiameterorlargerifsolidor7.5in.

height.

(190.5 mm) or greater wall thickness if bored. A 1 in. (25.4

6.2.1 Amplifier Calibration—An amplifier vertical linearity

mm) diameter, 2.25 MHz transducer may be used. If a

check shall be made prior to performing the test by observing

transducer with dimension circumferentially oriented to the

a multiple order pattern from a calibration block using a 2.25 1

forging, larger than ⁄4 in. (6.35 mm) is used, additional

MHz transducer. See Practice E317. The first back reflection

inspection at lower frequency is recommended to provide a

shall be set at 100% of full screen height. The higher order

wide beam for off-axis inspection. A0.5 in. (12.7 mm) diam-

back reflections, 10% and higher in amplitude, shall also be

eter2.25MHztransducerissuitableforsolidsectionsunder15

positioned on the screen and their amplitudes noted. The first

in. (381 mm) in diameter and bored sections under 7.5 in.

back reflection shall be reduced to 50% and then 25% of full

(190.5 mm) in wall thickness.The multiplication factors given

screen height. The amplitudes of the higher order back reflec-

are valid for the frequency and material velocity indicated

tions shall be noted at each step. The vertical linearity will be

provided they are used in the far field. (The near field is a

considered acceptable if the signal heights of the higher order characteristicthatisdependentonthetransducerfrequencyand

reflections decrease in proportion to the decrease set for the

size.) For other frequencies and material velocities, applicable

first back reflection. The maximum acceptable error for the sensitivity multiplication factors shall be computed.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 418 – 99 (2003)

6.4.1 Search Unit Calibration—The transducers used in unit on the surface of the forging when indications are

performing the tests described in this test method shall be observed so that they may be investigated in accordance with

calibrated in accordance with Guide E1065. 8.1.7 and 8.2.2.

8.1.6 When the forgings are tested while they are rotated,

the maximum speed of rotation shall be calculated as follows:

7. Preparation of Forging for Ultrasonic Inspection

7.1 Machine turn the forging to provide cylindrical surfaces

for the radial test.

360/pd = maximum revolutions per min.

7.2 The end faces of the shaft extensions and of the body of

d = diameter of forging in inches.

the forging shall be sufficiently perpendicular to the axis of the 915/pd = maximum revolutions per min.

forging to permit axial test. d = diameter of forging in centimetres.

The search unit may be held by a suitable fixture attached to

7.3 The surface roughness of exterior finishes shall not

the tool post of the lathe and traversed mechanically for

exceed 250 µin. (6.35 µm) and the surface waviness shall not

scanning of the rotating forging or may be hand-held. If not

interfere with the ultrasonic test.

specified by the purchaser, either method may be used at the

7.4 At the time of ultrasonic testing, the surfaces of the

manufacturer’s option.

forging shall be free of tool tears, loose s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.