ASTM B527-93(1997)

(Test Method)Standard Test Method for Determination of Tap Density of Metallic Powders and Compounds

Standard Test Method for Determination of Tap Density of Metallic Powders and Compounds

SCOPE

1.1 This test method specifies a method for the determination of tap density (packed density) of metallic powders and compounds, that is, the density of a powder that has been tapped, to settle contents, in a container under specified conditions.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 527 – 93 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of Tap Density of Metallic Powders and

Compounds

This standard is issued under the fixed designation B 527; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

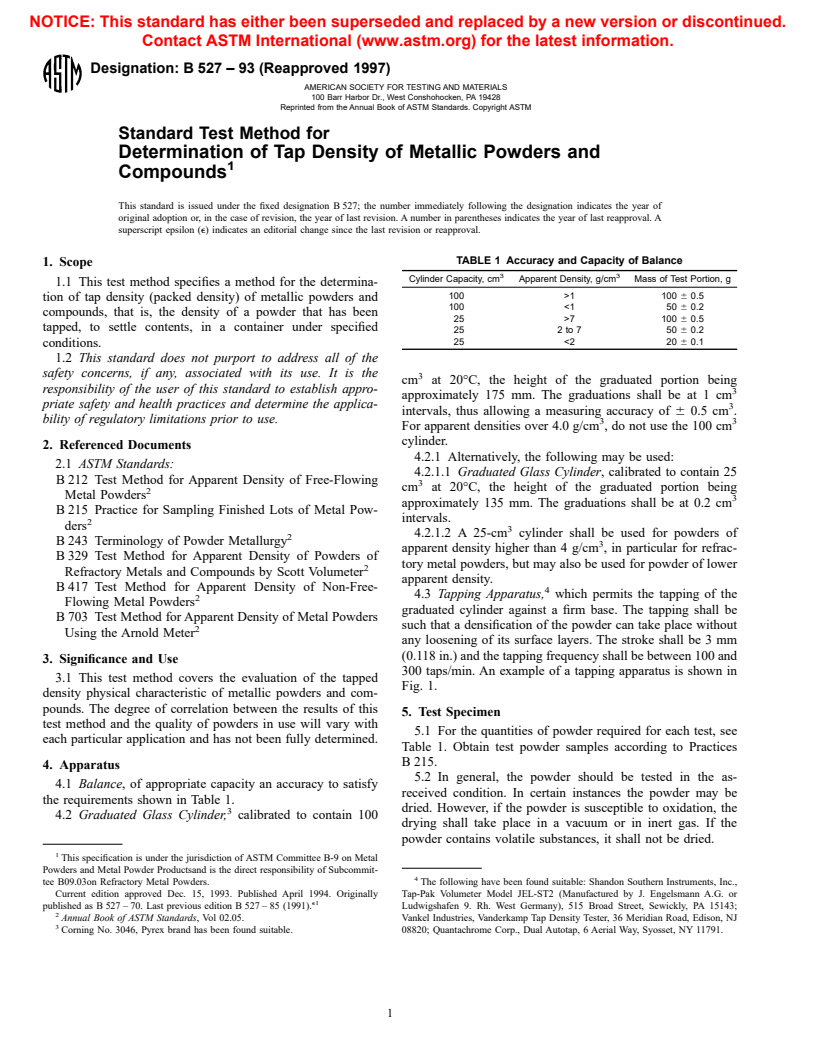

TABLE 1 Accuracy and Capacity of Balance

1. Scope

3 3

Cylinder Capacity, cm Apparent Density, g/cm Mass of Test Portion, g

1.1 This test method specifies a method for the determina-

100 >1 100 6 0.5

tion of tap density (packed density) of metallic powders and

100 <1 50 6 0.2

compounds, that is, the density of a powder that has been

25 >7 100 6 0.5

tapped, to settle contents, in a container under specified

25 2to7 50 6 0.2

25 <2 20 6 0.1

conditions.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3

cm at 20°C, the height of the graduated portion being

responsibility of the user of this standard to establish appro-

approximately 175 mm. The graduations shall be at 1 cm

priate safety and health practices and determine the applica-

intervals, thus allowing a measuring accuracy of 6 0.5 cm .

bility of regulatory limitations prior to use.

3 3

For apparent densities over 4.0 g/cm , do not use the 100 cm

cylinder.

2. Referenced Documents

4.2.1 Alternatively, the following may be used:

2.1 ASTM Standards:

4.2.1.1 Graduated Glass Cylinder, calibrated to contain 25

B 212 Test Method for Apparent Density of Free-Flowing

cm at 20°C, the height of the graduated portion being

Metal Powders

approximately 135 mm. The graduations shall be at 0.2 cm

B 215 Practice for Sampling Finished Lots of Metal Pow-

intervals.

ders

4.2.1.2 A 25-cm cylinder shall be used for powders of

B 243 Terminology of Powder Metallurgy

apparent density higher than 4 g/cm , in particular for refrac-

B 329 Test Method for Apparent Density of Powders of

tory metal powders, but may also be used for powder of lower

Refractory Metals and Compounds by Scott Volumeter

apparent density.

B 417 Test Method for Apparent Density of Non-Free-

4.3 Tapping Apparatus, which permits the tapping of the

Flowing Metal Powders

graduated cylinder against a firm base. The tapping shall be

B 703 Test Method for Apparent Density of Metal Powders

such that a densification of the powder can take place without

Using the Arnold Meter

any loosening of its surface layers. The stroke shall be 3 mm

(0.118 in.) and the tapping frequency shall be between 100 and

3. Significance and Use

300 taps/min. An example of a tapping apparatus is shown in

3.1 This test method covers the evaluation of the tapped

Fig. 1.

density physical characteristic of metallic powders and com-

pounds. The degree of correlation between the results of this

5. Test Specimen

test method and the quality of powders in use will vary with

5.1 For the quantities of powder required for each test, see

each particular application and has not been fully determined.

Table 1. Obtain test powder samples according to Practices

B 215.

4. Apparatus

5.2 In general, the powder should be tested in the as-

4.1 Balance, of appropriate capacity an accuracy to satisfy

received condition. In certain instances the powder may be

the requirements shown in Table 1.

dried. However, if the powder is susceptible to oxidation, the

4.2 Graduated Glass Cylinder, calibrated to contain 100

drying shall take place in a vacuum or in inert gas. If the

powder contains volatile substances, it shall not be dried.

This specification is under the jurisdiction of ASTM Committee B-9 on Metal

Powders and Metal Powder Productsand is the direct responsibility of Subcomm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.