ASTM D20-03(2009)

(Test Method)Standard Test Method for Distillation of Road Tars

Standard Test Method for Distillation of Road Tars

SIGNIFICANCE AND USE

The distillation test separates tar into fractions according to a series of specified temperatures.

SCOPE

1.1 This test method covers the distillation of road tars.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D20 − 03(Reapproved 2009)

Standard Test Method for

Distillation of Road Tars

ThisstandardisissuedunderthefixeddesignationD20;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

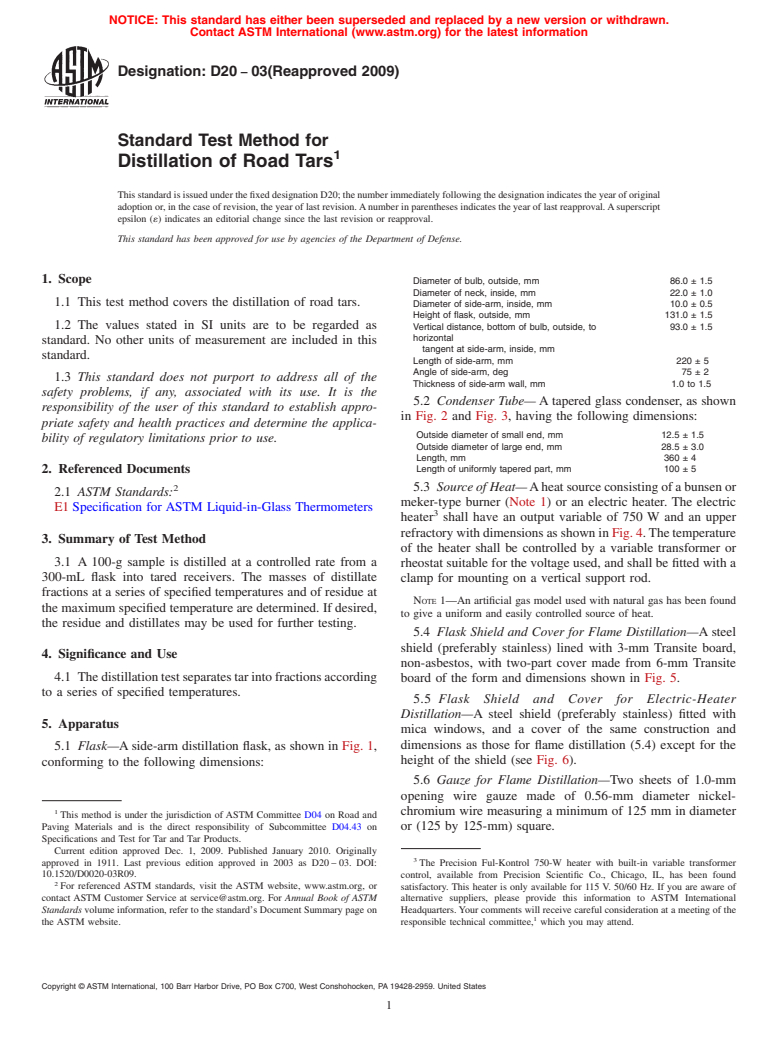

Diameter of bulb, outside, mm 86.0 ± 1.5

Diameter of neck, inside, mm 22.0 ± 1.0

1.1 This test method covers the distillation of road tars.

Diameter of side-arm, inside, mm 10.0 ± 0.5

Height of flask, outside, mm 131.0 ± 1.5

1.2 The values stated in SI units are to be regarded as

Vertical distance, bottom of bulb, outside, to 93.0 ± 1.5

horizontal

standard. No other units of measurement are included in this

tangent at side-arm, inside, mm

standard.

Length of side-arm, mm 220 ± 5

Angle of side-arm, deg 75 ± 2

1.3 This standard does not purport to address all of the

Thickness of side-arm wall, mm 1.0 to 1.5

safety problems, if any, associated with its use. It is the

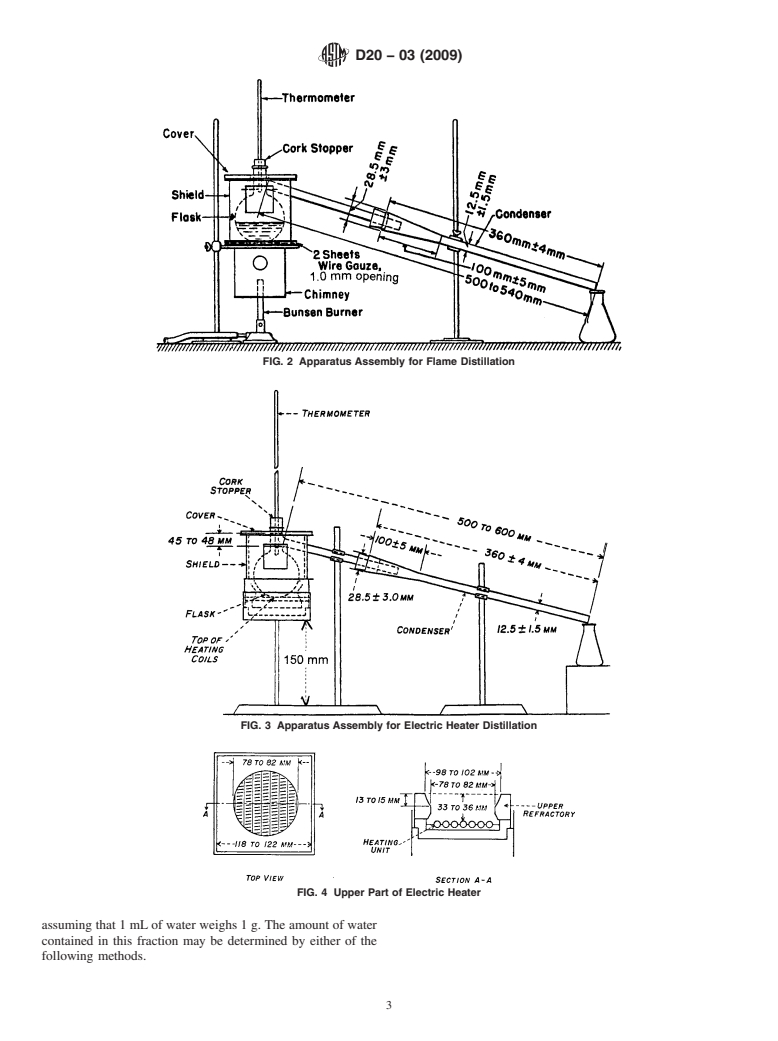

5.2 Condenser Tube—Atapered glass condenser, as shown

responsibility of the user of this standard to establish appro-

in Fig. 2 and Fig. 3, having the following dimensions:

priate safety and health practices and determine the applica-

Outside diameter of small end, mm 12.5 ± 1.5

bility of regulatory limitations prior to use.

Outside diameter of large end, mm 28.5 ± 3.0

Length, mm 360 ± 4

Length of uniformly tapered part, mm 100 ± 5

2. Referenced Documents

2 5.3 SourceofHeat—Aheatsourceconsistingofabunsenor

2.1 ASTM Standards:

meker-type burner (Note 1) or an electric heater. The electric

E1Specification for ASTM Liquid-in-Glass Thermometers

heater shall have an output variable of 750 W and an upper

refractorywithdimensionsasshowninFig.4.Thetemperature

3. Summary of Test Method

of the heater shall be controlled by a variable transformer or

3.1 A 100-g sample is distilled at a controlled rate from a

rheostat suitable for the voltage used, and shall be fitted with a

300-mL flask into tared receivers. The masses of distillate

clamp for mounting on a vertical support rod.

fractions at a series of specified temperatures and of residue at

NOTE 1—An artificial gas model used with natural gas has been found

themaximumspecifiedtemperaturearedetermined.Ifdesired,

to give a uniform and easily controlled source of heat.

the residue and distillates may be used for further testing.

5.4 Flask Shield and Cover for Flame Distillation—Asteel

shield (preferably stainless) lined with 3-mm Transite board,

4. Significance and Use

non-asbestos, with two-part cover made from 6-mm Transite

4.1 Thedistillationtestseparatestarintofractionsaccording

board of the form and dimensions shown in Fig. 5.

to a series of specified temperatures.

5.5 Flask Shield and Cover for Electric-Heater

Distillation—A steel shield (preferably stainless) fitted with

5. Apparatus

mica windows, and a cover of the same construction and

dimensions as those for flame distillation (5.4) except for the

5.1 Flask—Aside-arm distillation flask, as shown in Fig. 1,

height of the shield (see Fig. 6).

conforming to the following dimensions:

5.6 Gauze for Flame Distillation—Two sheets of 1.0-mm

opening wire gauze made of 0.56-mm diameter nickel-

1 chromium wire measuring a minimum of 125 mm in diameter

This method is under the jurisdiction of ASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.43 on

or (125 by 125-mm) square.

Specifications and Test for Tar and Tar Products.

Current edition approved Dec. 1, 2009. Published January 2010. Originally

approved in 1911. Last previous edition approved in 2003 as D20–03. DOI: The Precision Ful-Kontrol 750-W heater with built-in variable transformer

10.1520/D0020-03R09. control, available from Precision Scientific Co., Chicago, IL, has been found

For referenced ASTM standards, visit the ASTM website, www.astm.org, or satisfactory. This heater is only available for 115 V. 50/60 Hz. If you are aware of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM alternative suppliers, please provide this information to ASTM International

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

the ASTM website. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D20 − 03 (2009)

7.1.3 When using the flame distillation apparatus, place the

flask in the flask shield with its bulb resting on the gauze.

Positiontheburnersothatitisdirectlybeneaththepointwhere

the bulb of the flask contacts the gauze. If the electric heater is

used, place the flask in the flask shield and support the flask so

that its bottom is between 4 and 7 mm above the heating coils.

7.1.4 Connectthecondensertubetotheside-armoftheflask

withatightcorkjoint,havingtheside-armproject30to50mm

throughthecork.Thedistancefromtheneckoftheflasktothe

outlet end of the condenser tube shall be between 500 and 600

mm. Support the condenser tube in a position such that it is in

alignment with the side-arm of the flask, and the thermometer

FIG. 1 Distillation Flask

is vertical. Place the shield cover over the flask shield around

the neck of the flask.

8. Procedure

5.7 Burner Chimney for Flame Distillation—Construct a

8.1 Weigh the flask (along with the thermometer and cork)

cylindricalmetalshieldapproximately100mmhigh,95to105

tothenearest0.1gandthenweigh100.0 60.1gofthesample

mm in diameter, and having a peephole 25 mm in diameter

into the flask.

centered about 32 mm below the ring support. The top of the

shield shall be flanged to permit its being suspended from the

8.2 Apply heat to the flask so that the first drop of distillate

ring support. (oil or water) falls from the end of the condenser tube in 5 to

15 min. Within 2 min after the first drop, adjust the rate of

5.8 Receivers—Erlenmeyerflasksorbeakershavinganomi-

distillation,andsubsequentlymaintaintherate,sothatfrom50

nal capacity of 50 to 125 mL, and tared to the nearest 0.1 g.

to 70 drops per min fall from the end of the condenser. Warm

5.9 Balance and Masses, accurate to 0.1 g.

the condenser tube whenever necessary to prevent accumula-

5.10 Thermometer—AnASTMHighDistillationThermom- tion of solid distillates in the tube.

eterhavingarangefrom−2to+400°Candconformingtothe

8.3 Collect the distillate fractions in tared receivers, chang-

requirements for Thermometer 8C as prescribed in Specifica-

ing receivers as the thermometer indicates the maximum

tion E1.

temperature, corrected as described in 8.4, for each specified

fraction. The following fractions are usually specified.

6. Preparation of Sample

Up to 170°C

6.1 Thoroughly stir or otherwise mix the sample immedi- 170 to 235°C

235 to 270°C

ately before removing the portion for testing, to ensure that

270 to 300°C

suchportionwillberepresentativeofthesample.Ifwarmingis

Residue at 300°C

necessary, take care to avoid loss of volatile material.

Fractions at other temperatures, such as 170 to 200°C and

200 to 235°C, or 300 to 355°C and residue at 355°C, are

7. Preparation of Apparatus

sometimes required.

7.1 Assemble the apparatus as follows (see Fig.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.