ASTM D6199-97e1

(Practice)Standard Practice for Quality of Wood Members of Containers and Pallets

Standard Practice for Quality of Wood Members of Containers and Pallets

SCOPE

1.1 This practice covers the quality requirements for three classes of hard and soft wood members, excluding man-made or fabricated wood composites, used in the construction of boxes, crates, pallets, and blocking and bracing.

1.2 the values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This practice does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 6199 – 97

Standard Practice for

Quality of Wood Members of Containers and Pallets

This standard is issued under the fixed designation D 6199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made to Table 3 in December 1999.

1. Scope 3.2.3 diagonals, n—frame members placed at angles of

nearly 45° to other frame members, to ensure the rigidity of the

1.1 This practice covers the quality requirements for three

crate.

classes of hard and soft wood members, excluding man–made

3.2.4 linderman joint, n—glued dove–tailed joint between

or fabricated wood composites, used in the construction of

two or more pieces of wood.

boxes, crates, pallets, and blocking and bracing.

3.2.5 longitudinal frame members, n—horizontal members

1.2 The values stated in inch-pound units are to be regarded

of the side, end, and top panels of crates.

as the standard. The SI units given in parentheses are for

3.2.6 punk, n—decay characteristic which is very dry,

information only.

powdery, and crumbly wood.

1.3 This practice does not purport to address all of the

3.2.7 siftproofness, n—the prohibition of the migration of

safety concerns, if any, associated with its use. It is the

material, of any size, from the interior to the exterior of a

responsibility of the user of this standard to establish appro-

container.

priate safety and health practices and determine the applica-

3.2.8 struts, n—vertical frame members placed between the

bility of the regulatory limitations prior to use.

upper and lower frame members of the side and end panels of

2. Referenced Documents

a crate that serve as columns for supporting vertical stacking

loads.

2.1 ASTM Standards:

D 9 Terminology Relating to Wood

4. Significance and Use

D 996 Terminology of Packaging and Distribution Environ-

4.1 Each wood member contains a combination of charac-

ments

teristics which affects the performance of the container or

D 4442 TestMethodsforDirectMoistureContentMeasure-

pallet in which it is used. The requirements for classes, herein

ment of Wood and Wood–Base Materials

specified, have been established as these characteristics are

2.2 ASME/ANSI Standard:

related to the functional application of members in container

ASME/ANSI MH1.8M Wood Pallets

and pallet construction and to the service that the container or

3. Terminology

pallet may be called upon to perform.

4.2 Any other specified requirements or limitations peculiar

3.1 Definitions—General definitions for packaging and dis-

to a particular container or pallet construction or use, such as

tribution environments are found in Terminology D 996. Gen-

prohibiting knotholes or loose knots to provide siftproofness,

eral definitions for wood are found in Terminology D 9.

limitation to certain wood groups or species, or the selection of

3.2 Definitions of Terms Specific to This Standard:

applicable classes for specific members of or types of contain-

3.2.1 brash, n—decay characteristic which is the breaking

ers or pallet shall be the responsibility of the standard for that

of the grain without splintering.

container or pallet.

3.2.2 crate frame members, n—those parts which form the

fundamental structure upon which the strength and rigidity of

5. Wood Member Classification

crates depend.

5.1 Class 1—Structural (highly-stressed members).

5.2 Class 2—Structural (moderately–stressed members).

This practice is under the jurisdiction ofASTM Committee D-10 on Packaging 5.3 Class 3—Non–structural (lightly–stressed members).

and is the direct responsibility of Subcommittee D10.26 on Wooden Crates, Pallets

and Skids.

6. Wood Characteristics

Current edition approved Nov. 10, 1997. Published April 1998.

6.1 Classification:

Annual Book of ASTM Standards, Vol 04.10.

Annual Book of ASTM Standards, Vol 15.09.

Available fromAmerican Society of Mechanical Engineers, 345 E. 47th Street,

NYC, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

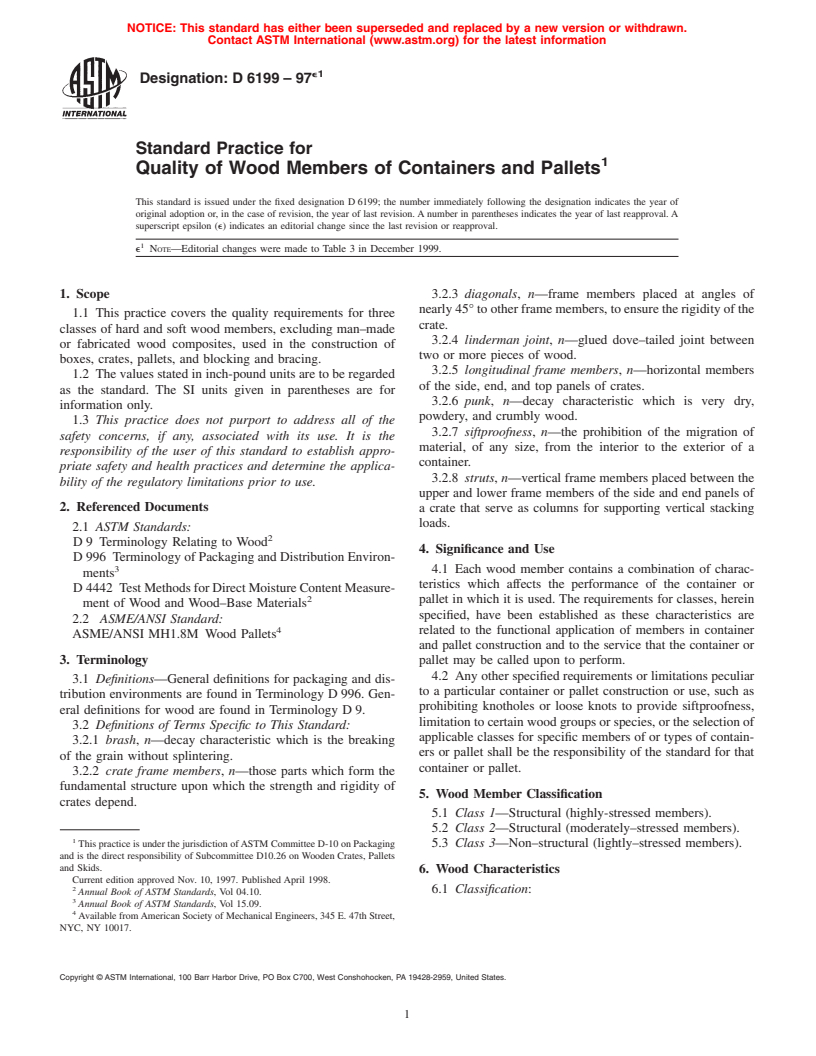

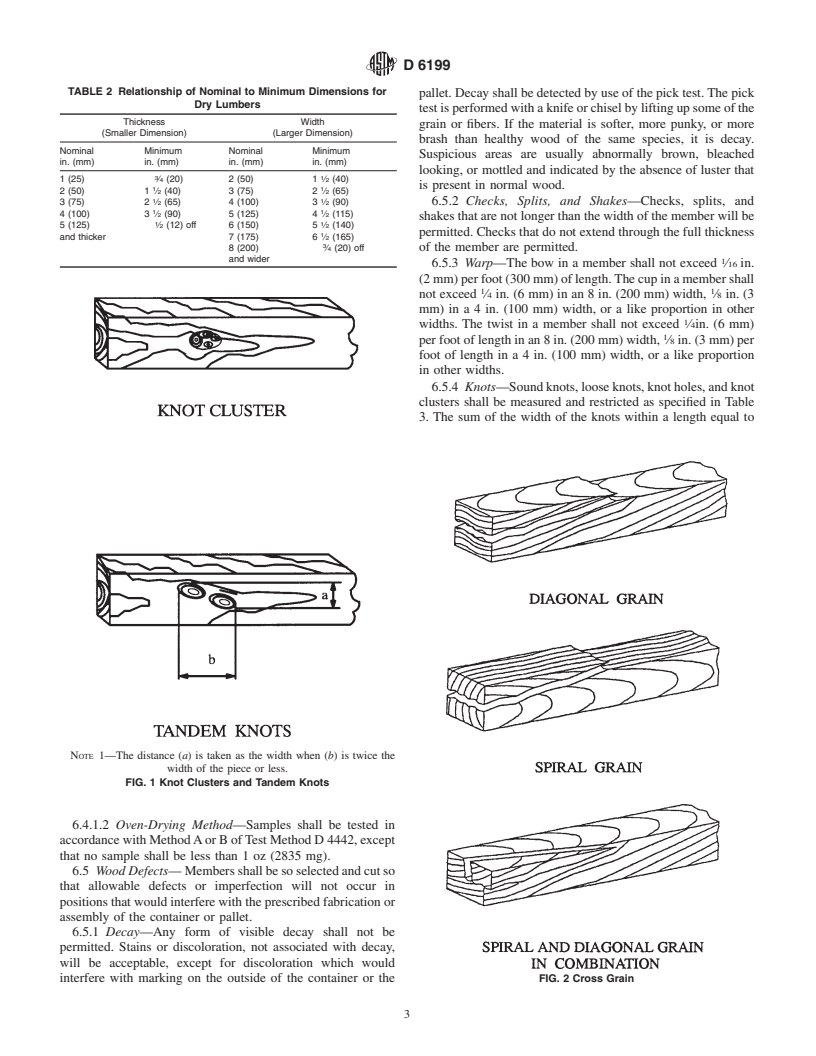

D 6199

6.1.1 Groups—For the purposes of this practice, wood is stipulated that members shall be fabricated from a particular

broken into four groupings. These groupings are general in wood group, the species within that group may be mixed

nature and do not include all species of wood. Woods used together or used interchangeably.

specifically in pallet construction include additional species

6.2 Surfaces—Rough lumber is permitted in the construc-

that are listed in ASME/ANSI MH1.8M. Table X1.1 provides

tion of the crate bases, sheathed–crate framing, boxes, and

a cross reference between the wood groups used herein and

pallets. For box and crate sheathing, at least one surface of all

those listed in ASME/ANSI MH1.8M.

wood members will be sufficiently smooth to permit legible

6.1.1.1 Group I—This group embraces the softer woods of

marking.

both the coniferous and the broad–leafed species.These woods

6.3 Dimensional Requirements:

are relatively free from splitting in nailing, have moderate

6.3.1 When nominal sizes of lumber are specified, the

fastener withdrawal resistance, moderate strength as a beam,

minimum sizes shall be as shown in Table 2.

and moderate shock resisting capacity. They are soft, light in

6.3.2 When sizes of wood members other than the nominals

weight,easytowork,holdtheirshapewellinmanufacture,and

cited in Table 2 are specified, undersizing in thickness and

are normally easy to dry.

width shall not be permitted in more than 10 % of the number

6.1.1.2 Group II—This group consists of heavier coniferous

of pieces. In addition, these parts shall be no thinner than ⁄8 of

woods, only. These woods usually have a pronounced contrast

the stated thickness and no narrower than ⁄4 in. (6 mm) less

in the hardness of the springwood and the summerwood. They

than the stated width. An exception to this requirement is that

have a greater fastener withdrawal resistance than Group I

if members of nailed–wood boxes ⁄8 in. (10 mm) or more in

woods, but are more likely to split, and the hard summerwood

thickness are surfaced on both sides (to protect the contents)

bands occasionally deflect the nails causing them to run out at

then the thickness may be ⁄32 in. (1 mm) less than stated.

the sides of the piece.

6.3.3 Whennominal2in.(50mm)thicklumberisresawnto

6.1.1.3 Group III—This group consists of hardwoods of

obtain 1 in. (25 mm) nominal thick members, the resulting

medium density. These woods have about the same fastener

minimum thickness shall be ⁄16 in. (18 mm) for dry lumber;

withdrawal resistance and strength as a beam as the Group II

except that for Class 1 structural members, which shall be ⁄4

woods, but are less likely to split and shatter under impacts.

in. (20 mm).

The species in this group are the most useful for constructing

6.4 Moisture Content— Container and pallet members shall

box ends and cleats. They also furnish most of the rotary–cut

have a moisture content (as measured by an electric type

veneers for wirebound boxes and plywood panels for construc-

moisture meter or by the oven drying method), at the time of

tion of plywood boxes.

fabrication, of not greater than 19 % nor less than 9 % of their

6.1.1.4 Group IV—This group consists of the high density

ovendry weight.

hardwood species. They have both the greatest shock resisting

6.4.1 Methods of Determination:

capacity and fastener withdrawal resistance, but because of

their extreme hardness present difficulties with respect to the 6.4.1.1 Moisture Meters— Meters measuring moisture con-

driving of nails, plus the greatest tendency to split at the nails. tents ranging as high as 30 % shall be used to determine

They are the heaviest and hardest domestic woods and are

moisture content of Group IV pallet members. Meters measur-

difficult to work. They are especially useful where high ingmoisturecontentsashighas25 %shallbeusedforallother

fastener withdrawal resistance is required and many of them wood members. The accuracy of the meter used shall be +/–

make excellent rotary cut veneers for wirebound and plywood 1 % of true moisture content. Electric–type moisture meters

boxes. may be either the resistance type or radio frequency power loss

6.1.2 Species—Thespeciesofwood,inthefourgroups,that type except that only the resistance type may be used on rough

may be used for wood members of containers or pallets are sawn lumber. In addition, readings using the resistance type

classified as indicated in Table 1 (see Appendix X1, Table meters shall be made only after the pins have penetrated to a

X1.1, for groups specific to pallet construction). When it is depth of one–fourth the thickness of the piece being tested.

TABLE 1 Wood Groups

Group I

Aspen Basswood Buckeye Cedar Chestnut

A

Cottonwood Cypress Fir (true firs) M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.