ASTM D7827-12

(Test Method)Standard Test Method for Measuring n-Heptane Induced Phase Separation of Asphaltene from Heavy Fuel Oils as Separability Number by an Optical Device

Standard Test Method for Measuring n-Heptane Induced Phase Separation of Asphaltene from Heavy Fuel Oils as Separability Number by an Optical Device

SIGNIFICANCE AND USE

5.1 This procedure describes a rapid and sensitive method for estimating the stability reserve of an oil. The stability reserve is estimated in terms of a separability number, where a low value of the separability number indicates that there is a stability reserve within the oil. When the separability number is between 0 to 5, the oil can be considered to have a high stability reserve and asphaltenes are not likely to flocculate. If the separability number is between 5 to 10, the stability reserve in the oil will be much lower. However, asphaltenes are, in this case, not likely to flocculate as long as the oil is not exposed to any worse conditions, such as storing, aging, and heating. If the separability number is above 10, the stability reserve of the oil is very low and asphaltenes will easily flocculate, or have already started to flocculate.

5.2 This test method can be used by refiners and users of heavy oils, for which this test method is applicable, to estimate the stability reserves of their oils. Hence, this test method can be used by refineries to control and optimize their refinery processes. Consumers of oils can use this test method to estimate the stability reserve of their oils before, during, and after storage.

5.3 This test method is not intended for predicting whether oils are compatible before mixing, but can be used for determining the separability number of already blended oils. However, experience shows that oils exhibiting a low separability number are more likely to be compatible with other oils than are oils with high separability numbers.

SCOPE

1.1 This test method covers the quantitative measurement, either in the laboratory or in the field, of how easily asphaltene-containing heavy fuel oils diluted in toluene phase separate upon addition of heptane. The result is a separability number (%). See also Test Method D7061.

1.2 The test method is limited to asphaltene-containing heavy fuel oils. ASTM specification fuels that generally fall within the scope of this test method are Specification D396, Grade Nos. 4, 5, and 6, Specification D975, Grade No. 4-D, and Specification D2880, Grade Nos. 3-GT and 4-GT. Refinery fractions from which such blended fuels are made also fall within the scope of this test method.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7827 − 12

Standard Test Method for

Measuring n-Heptane Induced Phase Separation of

Asphaltene from Heavy Fuel Oils as Separability Number by

an Optical Device

This standard is issued under the fixed designation D7827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D7061TestMethodforMeasuringn-HeptaneInducedPhase

Separation of Asphaltene-Containing Heavy Fuel Oils as

1.1 This test method covers the quantitative measurement,

Separability Number by an Optical Scanning Device

eitherinthelaboratoryorinthefield,ofhoweasilyasphaltene-

containing heavy fuel oils diluted in toluene phase separate

3. Terminology

upon addition of heptane. The result is a separability number

3.1 Definitions:

(%). See also Test Method D7061.

3.1.1 asphaltenes (rarely used in the singular), n—in petro-

1.2 The test method is limited to asphaltene-containing

leum technology, represent an oil fraction that is soluble in a

heavy fuel oils. ASTM specification fuels that generally fall

specified aromatic solvent but separates upon addition of an

within the scope of this test method are Specification D396,

excess of a specified paraffinic solvent.

Grade Nos. 4, 5, and 6, Specification D975, Grade No. 4-D,

3.1.1.1 Discussion—In this test method, the aromatic sol-

andSpecificationD2880,GradeNos.3-GTand4-GT.Refinery

vent is toluene and the paraffinic solvent is heptane.

fractions from which such blended fuels are made also fall

3.1.2 compatibility, n—of crude oils or of heavy fuel oils,

within the scope of this test method.

the ability of two or more crude oils or fuel oils to blend

1.3 The values stated in SI units are to be regarded as

together within certain concentration ranges without evidence

standard. No other units of measurement are included in this

of separation, such as the formation of multiple phases.

standard.

3.1.2.1 Discussion—Incompatible heavy fuel oils or crude

oils, when mixed or blended, result in the flocculation or

1.4 This standard does not purport to address all of the

precipitation of asphaltenes. Some oils may be compatible

safety concerns, if any, associated with its use. It is the

within certain concentration ranges in specific mixtures, but

responsibility of the user of this standard to establish appro-

incompatible outside those ranges.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.1.3 flocculation, n—of asphaltenes from crude oils or

heavy fuel oils, the aggregation of colloidally dispersed as-

2. Referenced Documents

phaltenes into visibly larger masses that may or may not settle.

2.1 ASTM Standards:

3.1.4 peptization, n—of asphaltenes in crude oils or heavy

D396Specification for Fuel Oils

fuel oils, the dispersion of asphaltenes to produce a colloidal

D975Specification for Diesel Fuel Oils

dispersion.

D2880Specification for Gas Turbine Fuel Oils

3.1.5 stability reserve, n—in petroleum technology, the

D4057Practice for Manual Sampling of Petroleum and

property of an oil to maintain asphaltenes in a peptized state

Petroleum Products

and prevent flocculation of the asphaltenes.

D4177Practice for Automatic Sampling of Petroleum and

3.1.5.1 Discussion—An oil with a low stability reserve is

Petroleum Products

likelytoundergoflocculationofasphalteneswhenstressed(for

example, extended heated storage) or blended with a range of

otheroils.Twooilseachwithahighstabilityreservearelikely

This test method is under the jurisdiction of ASTM Committee D02 on

to maintain asphaltenes in a peptized state and not lead to

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

flocculation when blended together.

Current edition approved Nov. 1, 2012. Published March 2013. DOI: 10.1520/

3.1.6 transmittance, n—of light, the fraction of the incident

D7827-12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or light of a given wavelength that is not reflected or absorbed,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

but passes through a substance.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.2 Definitions of Terms Specific to This Standard:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7827 − 12

3.2.1 SEPView 6.1, n—the name of a proprietary computer is very low and asphaltenes will easily flocculate, or have

program designed to allow automatic control of test and already started to flocculate.

calculations of the results in Test Method D7827.

5.2 This test method can be used by refiners and users of

3.2.2 separability number, n—in petroleum technology, the heavyoils,forwhichthistestmethodisapplicable,toestimate

standard deviation of the average transmittance, determined in the stability reserves of their oils. Hence, this test method can

this test method, expressed as a percentage figure.

be used by refineries to control and optimize their refinery

processes. Consumers of oils can use this test method to

3.2.2.1 Discussion—The separability number estimates the

stability reserve of the oil, where a high separability number estimate the stability reserve of their oils before, during, and

after storage.

indicates that the oil has a low stability reserve and a low

separability number that the oil has a high stability reserve.

5.3 This test method is not intended for predicting whether

3.2.3 SEPCalc, n—the name of a proprietary computer oils are compatible before mixing, but can be used for

program modul of SEPView, designed to allow automatic determining the separability number of already blended oils.

calculation of the results in Test Method D7827. However, experience shows that oils exhibiting a low separa-

bility number are more likely to be compatible with other oils

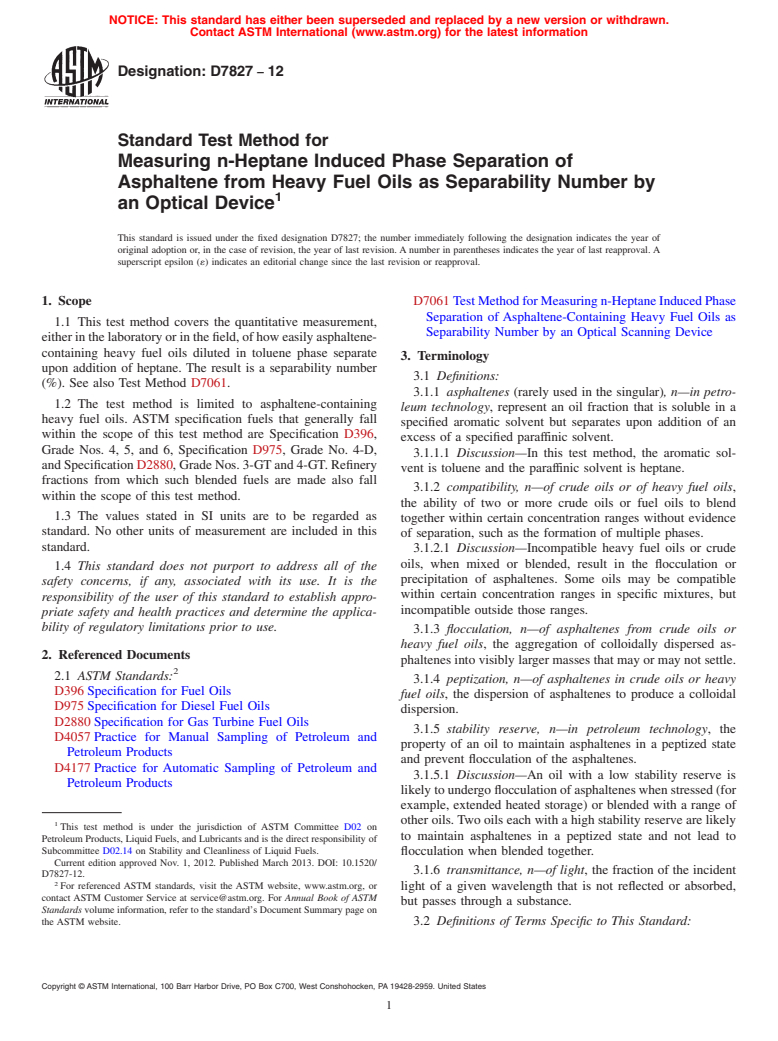

3.2.4 STEP-Technology, n—parallellight(I )illuminatesthe

than are oils with high separability numbers.

entire sample cell and the transmitted light I is detected by

multiple sensors with a µm-scale resolution arranged linearly

6. Apparatus

from top to bottom. Transmission is recorded time- and

space-resolvedandmaybeconvertedintoextinctionbylgI/I . 6.1 Computer executing software SEPView ,fromaportable

storagemediaordirectlyfromthecomputer.SEPViewcontrols

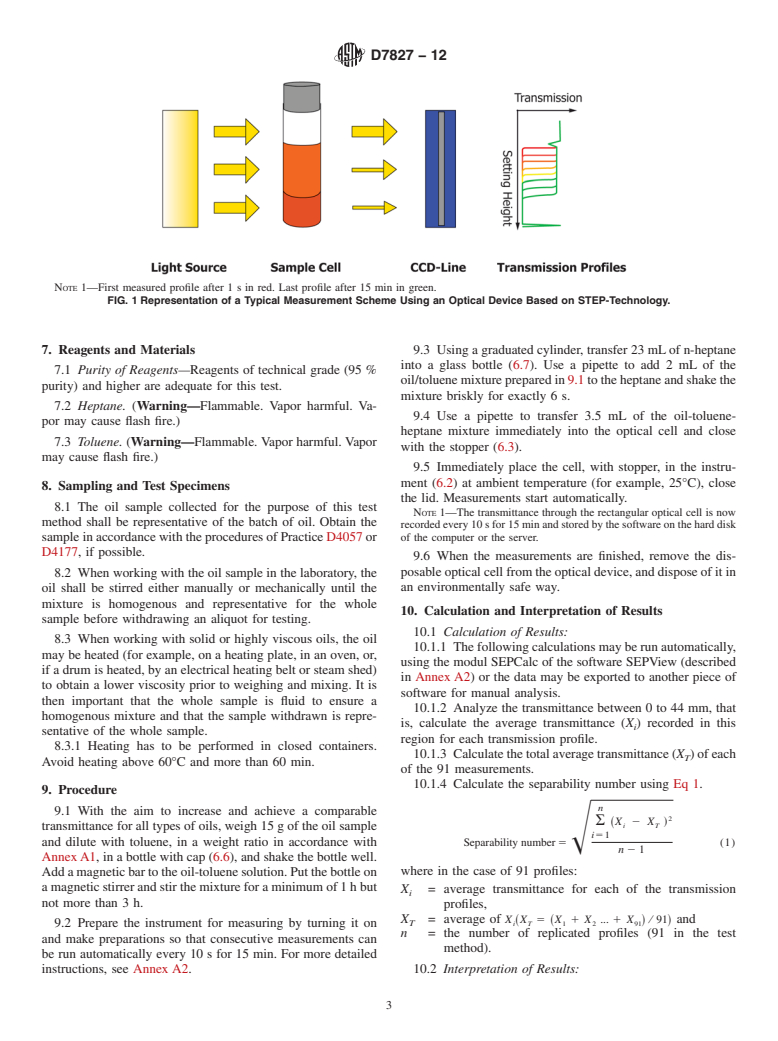

4. Summary of Test Method the apparatus, acquires the data and accumulates it in a

database on the portable storage media, the hard disk in the

4.1 Dilution of oil with toluene followed by addition of

computer or at a server.

heptane causes asphaltenes to flocculate, and the oil to phase

6.2 Optical Device—The apparatus consists of an illumi-

separate. The rate of the phase separation is determined by

nation system, composed of a pulsed infrared light source that

measuring the increase in transmittance in the sample from the

uses a wavelength of 870 nm (6 10 nm) and means to

bottomofatesttubetothetop(oraportionthereof)overtime.

parallelize and expand the light to illuminate the entire

The standard deviation of the average transmittance from a

specimen height. A high-resolution line detector is situated

number of consecutive automatic measurements gives a sepa-

opposite from the light source and reads the transmittance

rability number (%).

through the vertical midline of the optical cell (6.3) containing

4.2 The oil is diluted with toluene in ratios that depend on

the specimen. The transmittance is automatically and instanta-

the oil type. Mix 2 mL of the oil/toluene solution with 23 mL

neously recorded at every pixel with a position resolution of

of heptane. Transfer 3.5 mLof the oil/toluene/heptane mixture

0.007 mm (STEP-Technology (trademarked) ). Time interval

into a disposable optical cell that is inserted into an optical

between each recording shall be 10 s. Total measurement time

scanning device.

shall be 15 min. The measuring principle is schematically

4.3 The change in light transmittance through the cell is

showninFig.1.Eachmeasuredtransmittanceprofilealongthe

recorded by proprietary STEP-Technology instantaneously optical cell is automatically stored on the hard disk in the

over the entire sample height without scanning. Measurements

computer or at a server and can be further processed as

are taken periodically every 10 s for 15 min.An average of the described in Section 10 and Annex A2.

transmittance is calculated from each reading of each of the 91

6.3 Rectangular Transparent Disposable Optical Polyamid

transmission profiles at each 0.007 mm distance along the

cells (PA-cells) with PP-stopper,5mLcapacity,cross-section8

opticalcell,startingfromthebottomofthecellandcontinuing

mm × 10 mm (optical path), wall thickness 1 mm and 80 mm

up to 44 mm.The separability number from multiple measure-

high, shall be used as a sample container.

ments is calculated and reported.

6.4 Pipette, Graduated or Automatic, 5 and 10 mL.

5. Significance and Use 6.5 Graduated Cylinder, 25 mL.

6.6 Clear Glass Bottle with Cap, 250 mL.

5.1 This procedure describes a rapid and sensitive method

for estimating the stability reserve of an oil. The stability

6.7 Clear Glass Bottle with Cap, 50 mL.

reserve is estimated in terms of a separability number, where a

6.8 Magnetic Bar, PTFE-coated.

low value of the separability number indicates that there is a

stabilityreservewithintheoil.Whentheseparabilitynumberis 6.9 Magnetic Stirrer.

between 0 to 5, the oil can be considered to have a high

6.10 Balance, precision 60.01 g.

stability reserve and asphaltenes are not likely to flocculate. If

theseparabilitynumberisbetween5to10,thestabilityreserve

intheoilwillbemuch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.