ASTM A686-92(1999)

(Specification)Standard Specification for Tool Steel, Carbon

Standard Specification for Tool Steel, Carbon

SCOPE

1.1 This specification covers the chemical, mechanical, and physical requirements for available wrought carbon tool steel products.

1.2 These products, which include hot- or cold-finished bar, plate, sheet, rod, wire, or forgings, are normally fabricated into tools, dies, or fixtures. The selection of a material for a particular application will depend upon design, service conditions, and desired properties.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 686 – 92 (Reapproved 1999)

Standard Specification for

Tool Steel, Carbon

This standard is issued under the fixed designation A 686; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.3 Federal Standards:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.1 This specification covers the chemical, mechanical, and

Fed. Std. No. 183 Continuous Identification Marking of

physical requirements for available wrought carbon tool steel

Iron and Steel Products

products.

1.2 These products, which include hot- or cold-finished bar,

3. Classification

plate,sheet,rod,wire,orforgings,arenormallyfabricatedinto

3.1 Material in accordance with this specification is classi-

tools, dies, or fixtures. The selection of a material for a

fied by chemical composition. Types correspond to respective

particular application will depend upon design, service condi-

AISI designations.

tions, and desired properties.

3.1.1 Carbon Tool Steels, Identification W—TypesW1,W2,

1.3 The values stated in inch-pound units are to be regarded

and W5 are often referred to as water hardening tool steels

as the standard. The values given in parentheses are provided

since they require rapid quenching rates to attain the necessary

for information only.

hardness. Except in very small sizes they will harden with a

2. Referenced Documents hard case and a soft core.

3.1.1.1 Type W1 is an unalloyed carbon steel available in

2.1 ASTM Standards:

several carbon ranges.

A370 TestMethodsandDefinitionsforMechanicalTesting

3.1.1.2 Type W2 is characterized by a nominal vanadium

of Steel Products

content of 0.25% and is also available in several carbon

A388/A388M Practice for Ultrasonic Examination of

ranges.

Heavy Steel Forgings

3.1.1.3 Type W5 is characterized by a nominal chromium

A561 Practice for Macroetch Testing of Tool Steel Bars

content of 0.50%.

A700 Practices for Packaging, Marking, and Loading

3 3.1.1.4 A suffix following the type designation is added to

Methods for Steel Products for Domestic Shipment

denote the minimum carbon content of the carbon range to be

E3 Methods of Preparation of Metallographic Specimens

specified.

E30 Test Methods for Chemical Analysis of Steel, Cast

3.1.2 Types W1 and W2 are further classified by quality

Iron, Open-Hearth Iron, and Wrought Iron

levels, namely, Grade A and Grade C.

E45 Test Methods for Determining the Inclusion Content

3.1.2.1 GradeAissometimesreferredtoas Extraor Special.

of Steel

It is controlled for hardenability; the chemical composition is

E59 PracticeforSamplingSteelandIronforDetermination

held to closest limits; and it is subject to rigid tests to ensure

of Chemical Composition

uniformity. GradeAis available with three degrees of harden-

2.2 Military Standard:

ability,namely,shallowhardening,regularhardening,anddeep

MIL-STD-163 Steel Mill Products, Preparation for Ship-

hardening.

ment and Storage

3.1.2.2 Grade C is sometimes referred to as Regular or

Standard. It is intended for applications that do not require

This specification is under the jurisdiction ofASTM CommitteeA-1 on Steel,

controlled hardenability and where some latitude in uniformity

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

is permissible.

A01.29 on Tool Steels.

Current edition approved July 15, 1992. Published September 1992. Originally

4. Ordering Information

published as A686–73. Last previous edition A686–89.

Annual Book of ASTM Standards, Vol 01.03.

4.1 Ordersformaterialunderthisspecificationshallinclude

Annual Book of ASTM Standards, Vol 01.05.

the following information, as required to describe adequately

Annual Book of ASTM Standards, Vol 03.01.

5 the desired material:

Annual Book of ASTM Standards, Vol 03.05.

4.1.1 Class of material (carbon tool steel),

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 686 – 92 (1999)

4.1.2 Type (W1, W2, W5), 7. Hardness Properties

4.1.3 Suffix denoting carbon range (where applicable, such

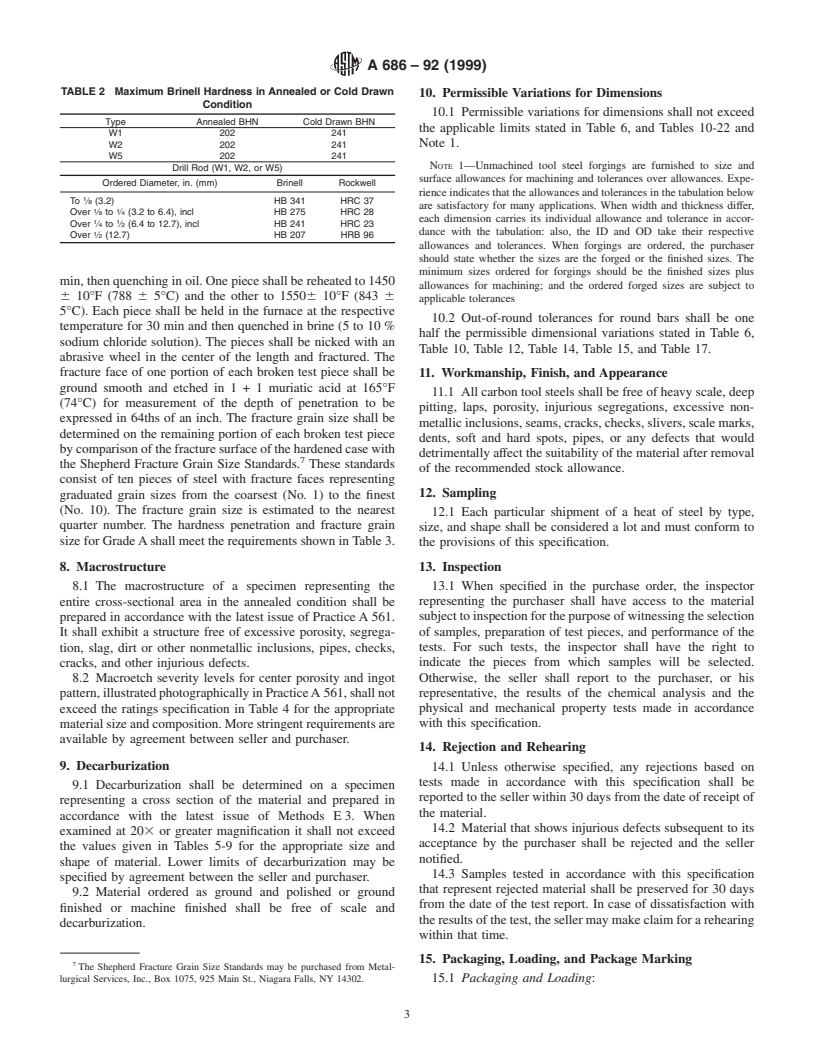

7.1 Annealed hardness values shall be obtained in accor-

as W1–9, W2–10, etc.),

dance with the latest issue of Test Methods and Definitions

4.1.4 Grade and hardenability (where applicable, for ex-

A370, and shall not exceed the Brinell hardness values (or

ample, Grade A deep hardening, and so forth),

equivalent Rockwell hardness values) specified in Table 2.

4.1.5 Shape (sheet, plate, flat bar, round bar, square bar,

7.2 Specimens for determination of minimum response to

hexagon bar, octagon, special shapes),

hardening shall be ¼-in. (6.4-mm) thick disks cut so as to

4.1.6 Dimensions (thickness, width, diameter, length),

represent either the full cross-sectional area or that midway

4.1.7 Finish (hot rolled, forged, blasted or pickled, cold

between the center and outer surface of the material. If the

drawn, machined, ground, precision ground and polished),

material form or size does not lend itself to accurate hardness

4.1.8 Condition (annealed, unannealed, hardened and tem-

determination on ¼-in. (6.4-mm) thick cross-sectional disks,

pered, and so forth),

then longitudinal specimens may be used for hardness testing.

4.1.9 ASTM specification number and date of issue, and

Examplesareroundbarslessthan ⁄2in.(12.7mm)indiameter

4.1.10 Special requirements.

orsheet.Inthiscase,thespecimenshallbeaminimumof3in.

(76.2 mm) in length and parallel flats shall be ground on the

5. Materials and Manufacture

original mill surfaces. The specimens shall be heat treated as

5.1 Unless otherwise specified, material covered by this

prescribed in Table 3.

specification shall be made by an electric melting process. It

7.2.1 The hardness of the specimen after the specified heat

shall be made from ingots that have been reduced in cross

treatment shall meet the minimum hardness value for the

section in such a manner and to such a degree as to ensure

particular type of steel shown in Table 3. Rockwell C tests

proper refinement of the ingot structure.

should be used where possible but light load tests may be

6. Chemical Composition

necessaryonthinspecimens.Thesetestsshouldbespecifiedby

agreement between seller and purchaser. The hardness value

6.1 An analysis of each heat of steel shall be made by the

shall be obtained in accordance with the latest issue of Test

manufacturer to determine the percentage of the elements

Methods and DefinitionsA370, and shall be the average of at

specified and these values shall conform to the chemical

least five readings taken in an area midway between the center

composition specified in Table 1. If requested or required, the

and surface of the largest dimension of the cross-sectional

chemical composition shall be reported to the purchaser or his

specimen or along the parallel surfaces of the longitudinal

representative.

specimen. The surface to be tested shall be ground sufficiently

6.2 Analysis may be made by the purchaser from finished

to remove any surface condition, scale, carburization, or

bars and forgings by machining off the entire cross section and

decarburization which might affect readings.

drilling parallel to the axis of the bar or forging at any point

midway between the center and surface in accordance with the 7.2.2 HardnesspenetrationandfracturegrainsizeforGrade

latest issue of Method E59. The chemical analysis of the A shall be determined on test pieces of ⁄4 in. (19.1 mm)

drilling chips shall be made in accordance with the latest issue diameter and 3 in. (76.2 mm) length. Two pieces for each test

of Methods E30. The chemical composition thus determined shall be given a preliminary treatment by heating uniformly to

shall not vary from the limits specified in Table 1. 1600 6 10°F (871 6 5°C) and holding at temperature for 40

A

TABLE 1 Chemical Composition, %

UNS Type Grade Carbon Man- Silicon Phos- Sulfur, Chromium Vanadium Tung- Molyb- Copper, Nickel,

Desig- ganese phorus, max sten, denum, max max

nation max max max

min max min max min max min max min max

BB

T72301 W1 A 0.10 0.40 0.10 0.40 0.030 0.030 . . . 0.15 . . . 0.10 0.15 0.10 0.20 0.20

BB

T72301 W1 C 0.10 0.40 0.10 0.40 0.030 0.030 . . . 0.30 . . . 0.10 0.15 0.10 0.20 0.20

CC

T72302 W2 A 0.10 0.40 0.10 0.40 0.030 0.030 . . . 0.15 0.15 0.35 0.15 0.10 0.20 0.20

CC

T72302 W2 C 0.10 0.40 0.10 0.40 0.030 0.030 . . . 0.30 0.15 0.35 0.15 0.10 0.20 0.20

T72305 W5 . 1.05 1.15 0.10 0.40 0.10 0.40 0.030 0.030 0.40 0.60 . . . 0.10 0.15 0.10 0.20 0.20

A

Chemistry limits include product analysis tolerances.

B

The carbon ranges for W1 and their respective suffix identification, sometimes referred to as tempers, are as follows:

Suffix Carbon Range, % Suffix Carbon Range, %

8 0.80–0.90 10 1.00–1.10

8½ 0.85–0.95 10½ 1.05–1.15

9 0.90–1.00 11 1.10–1.20

9½ 0.95–1.05 11½ 1.15–1.25

C

The carbon ranges for W2 and their respective suffix identification are as follows:

Suffix Carbon Range, %

8½ 0.85–0.95

9 0.90–1.00

9½ 0.95–1.10

13 1.30–1.50

A 686 – 92 (1999)

TABLE 2 Maximum Brinell Hardness in Annealed or Cold Drawn

10. Permissible Variations for Dimensions

Condition

10.1 Permissible variations for dimensions shall not exceed

Type Annealed BHN Cold Drawn BHN

the applicable limits stated in Table 6, and Tables 10-22 and

W1 202 241

W2 202 241 Note 1.

W5 202 241

NOTE 1—Unmachined tool steel forgings are furnished to size and

Drill Rod (W1, W2, or W5)

surface allowances for machining and tolerances over allowances. Expe-

Ordered Diameter, in. (mm) Brinell Rockwell

rienceindicatesthattheallowancesandtolerancesinthetabulationbelow

To ⁄8 (3.2) HB 341 HRC 37

are satisfactory for many applications. When width and thickness differ,

1 1

Over ⁄8 to ⁄4 (3.2 to 6.4), incl HB 275 HRC 28

each dimension carries its individual allowance and tolerance in accor-

1 1

Over ⁄4 to ⁄2 (6.4 to 12.7), incl HB 241 HRC 23

1 dance with the tabulation: also, the ID and OD take their respective

Over ⁄2 (12.7) HB 207 HRB 96

allowances and tolerances. When forgings are ordered, the purchaser

should state whether the sizes are the forged or the finished sizes. The

minimum sizes ordered for forgings should be the finished sizes plus

min,thenquenchinginoil.Onepieceshallbereheatedto1450

allowances for machining; and the ordered forged sizes are subject to

6 10°F (788 6 5°C) and the other to 15506 10°F (843 6

applicable tolerances

5°C). Each piece shall be held in the furnace at the respective

10.2 Out-of-round tolerances for round bars shall be one

temperature for 30 min and then quenched in brine (5 to 10%

half the permissible dimensional variations stated in Table 6,

sodium chloride solution). The pieces shall be nicked with an

Table 10, Table 12, Table 14, Table 15, and Table 17.

abrasive wheel in the center of the length and fractured. The

fracture face of one portion of each broken test piece shall be 11. Workmanship, Finish, and Appearance

ground smooth and etched in1+1 muriatic acid at 165°F

11.1 Allcarbontoolsteelsshallbefreeofheavyscale,deep

(74°C) for measurement of the depth of penetration to be

pitting, laps, porosity, injurious segregations, excessive non-

expressed in 64ths of an inch. The fracture grain size shall be

metallicinclusions,seams,cracks,checks,slivers,scalemarks,

determined on the remaining portion of each broken test piece

dents, soft and hard spots, pipes, or any defects that would

bycomparisonofthefracturesurfaceofthehardenedcasewith

detrimentallyaffectthesuitabilityofthematerialafterremoval

the Shepherd Fracture Grain Size Standards. These standards

of the recommended stock allowance.

consist of ten pieces of steel with fracture faces representing

12. Sampling

graduated grain sizes from the coarsest (No. 1) to the finest

(No. 10). The fracture grain size is estimated to the nearest

12.1 Each particular shipment of a heat of steel by type,

quarter number. The hardness penetration and fracture grain

size, and shape shall be considered a lot and must conform to

sizeforGradeAshallmeettherequirementsshowninTable3.

the provisions of this specification.

13. Inspection

8. Macrostructure

8.1 The macrostructure of a specimen representing the 13.1 When specified in the purchase order, the inspector

representing the purchaser shall have access to the material

entire cross-sectional area in the annealed condition shall be

prepared in accordance with the latest issue of PracticeA561. subjecttoinspectionforthepurposeofwitnessingtheselection

of samples, preparation of test pieces, and performance of the

It shall exhibit a structure free of excessive porosity, segrega-

tion, slag, dirt or other nonmetallic inclusions, pipes, checks, tests. For such tests, the inspector shall have the right to

indicate the pieces from which samples will be selected.

cracks, and other injurious defects.

8.2 Macroetch severity levels for center porosity and ingot Otherwise, the seller shall report to the purchaser, or his

representative, the results of the chemical analysis and the

pattern,illustratedphotographicallyinPracticeA561,shallnot

exceed the ratings specification in Table 4 for the appropriate physical and mechanical property tests made in accordance

with this specification.

materialsizeandcomposition.Morestringentrequirementsare

available by agreement between seller and purchaser.

14. Rejection and Rehearing

9. Decarburization

14.1 Unless otherwise specified, any rejections based on

tests made in accordance with this specification shall be

9.1 Decarburization shall be determined on a specimen

reportedtothesellerwithin30daysfromthedateofreceiptof

representing a cross section of the material and prepared in

the material.

accordance with the latest issue of Methods E3. When

14.2 Material that shows injurious defects subsequent to its

examined at 203 or greater magnification it shall not exceed

acceptance by the purchaser shall be rejected and the seller

the values given in Tables 5-9 for the appropriate size and

notified.

shape of material. Lower limits of decarburization may be

14.3 Samples tested in accordance with this specification

specified by agreement between the seller and purchaser.

that represent rejected material shall be preserved for 30 days

9.2 Material ordered as ground and polished or ground

from the date of the test report. In case of dissatisfaction with

finished or machine finished shall be free of scale and

theresultsofthetest,th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.