ASTM A681-08(2022)

(Specification)Standard Specification for Tool Steels Alloy

Standard Specification for Tool Steels Alloy

ABSTRACT

This specification covers the chemical, mechanical, and physical requirements for available wrought alloy tool steel products. The material shall be made by an electric melting process. It shall be made from ingots that have been reduced in cross section in such a manner and to such a degree as to ensure proper refinement of the ingot structure. Chemical composition, hardness, macrostructure and decarburization of the material shall conform to the requirements in accordance to the referenced ASTM documents itemized herein.

SCOPE

1.1 This specification covers the chemical, mechanical, and physical requirements for available wrought alloy tool steel products.

1.2 These products, which include hot or cold finished bar, plate, sheet, strip, rod, wire, or forgings, are normally fabricated into tools, dies, or fixtures. The selection of a material for a particular application will depend upon design, service conditions, and desired properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A681 −08 (Reapproved 2022)

Standard Specification for

Tool Steels Alloy

This standard is issued under the fixed designation A681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E30 Test Methods for ChemicalAnalysis of Steel, Cast Iron,

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

1.1 This specification covers the chemical, mechanical, and

E45 Test Methods for Determining the Inclusion Content of

physical requirements for available wrought alloy tool steel

Steel

products.

E59 Practice for Sampling Steel and Iron for Determination

of Chemical Composition (Withdrawn 1996)

1.2 These products, which include hot or cold finished bar,

E527 Practice for Numbering Metals and Alloys in the

plate, sheet, strip, rod, wire, or forgings, are normally fabri-

Unified Numbering System (UNS)

cated into tools, dies, or fixtures.The selection of a material for

2.2 Military Standard:

a particular application will depend upon design, service

MIL-STD-163 Steel Mill Products, Preparation for Ship-

conditions, and desired properties.

ment and Storage

1.3 The values stated in inch-pound units are to be regarded 2.3 Federal Standards:

as standard. The values given in parentheses are mathematical Fed. Std. No. 123 Marking and Shipment (Civil Agencies)

Fed. Std. No. 183 Continuous Identification Marking of Iron

conversions to SI units that are provided for information only

and are not considered standard. and Steel Products

2.4 Other Standard:

1.4 This international standard was developed in accor-

SAE J1086 Recommended Practice for Numbering Metals

dance with internationally recognized principles on standard-

and Alloys (UNS)

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3. Classification

mendations issued by the World Trade Organization Technical

3.1 Material in accordance with this specification is classi-

Barriers to Trade (TBT) Committee.

fied by chemical composition. Types correspond to respective

AISI designations.

2. Referenced Documents

3.1.1 Hot Work Tool Steels, Identification H:

2 3.1.1.1 Types H10 to H19 are characterized by a controlled

2.1 ASTM Standards:

chromium content along with other alloying elements.The first

A370 Test Methods and Definitions for Mechanical Testing

four, containing molybdenum, offer excellent toughness and

of Steel Products

high hardenability and are frequently used in cold work

A561 Practice for Macroetch Testing of Tool Steel Bars

applications requiring toughness at relatively high hardness

A600 Specification for Tool Steel High Speed

levels.

A700 Guide for Packaging, Marking, and Loading Methods

3.1.1.2 Types H21 to H26 are characterized by a controlled

for Steel Products for Shipment

tungsten content along with other alloying elements. These

E3 Guide for Preparation of Metallographic Specimens

steels offer greater resistance to the softening effect of elevated

service temperatures but exhibit a lower degree of toughness.

3.1.1.3 Types H41 to H43 are low-carbon modifications of

This specification is under the jurisdiction of ASTM Committee A01 on Steel, molybdenum high speed tool steels (Note 1) and have charac-

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

teristics similar to the tungsten types.

A01.29 on Tool Steels.

Current edition approved Sept. 1, 2022. Published September 2022. Originally

approved in 1973. Last previous edition approved in 2015 as A681 – 08 (2015). The last approved version of this historical standard is referenced on

DOI: 10.1520/A0681-08R22. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A681−08 (2022)

NOTE 1—High-speed tool steels are covered in Specification A600.

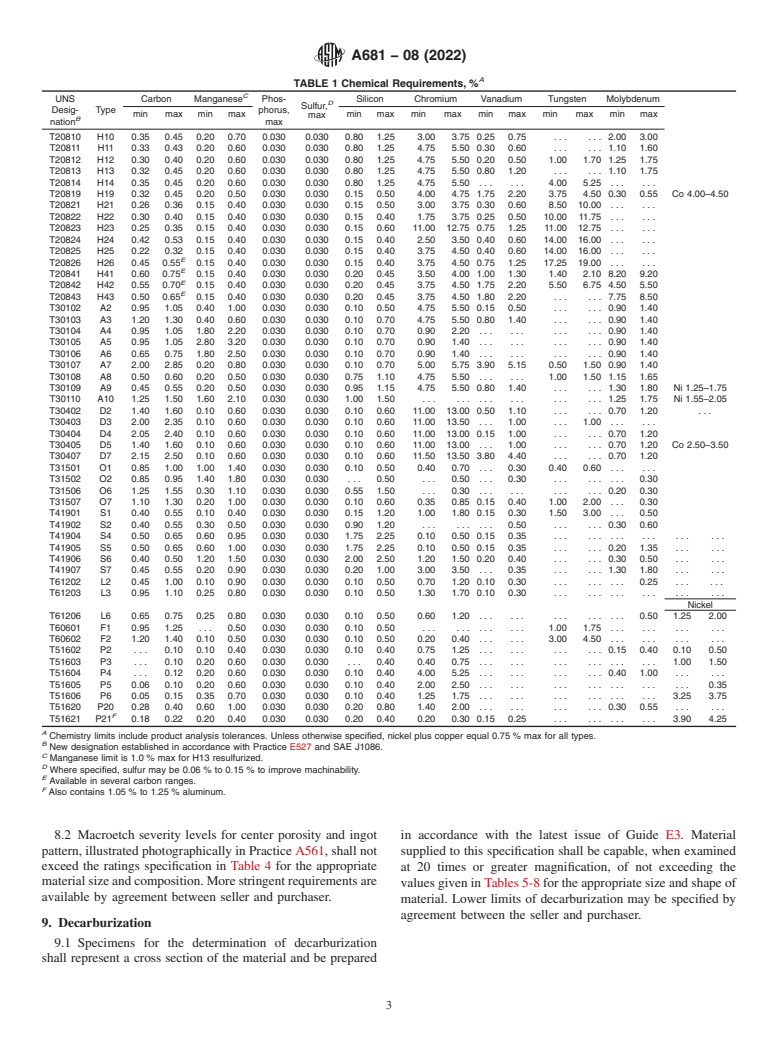

6. Chemical Composition

3.1.2 Cold Work Tool Steels, Identification A—Types A2 to

6.1 An analysis of each heat of steel shall be made by the

A10 cover a wide range of carbon and alloy contents but all

manufacturer to determine the percentage of the elements

have high hardenability and may be hardened in air. The low

specified, and these values shall conform to the requirements

carbon Types A8 and A9 have less wear resistance but offer

for chemical composition specified in Table 1. If requested or

greater toughness than others in this group.TypeA7, with high

required, the chemical composition shall be reported to the

carbon and vanadium, offers exceptional wear resistance but at

purchaser or his representative.

a very low level of toughness.

6.2 Analysis may be made by the purchaser from finished

3.1.3 Cold Work Tool Steels, Identification D—Types D2 to

bars and forgings by machining off the entire cross section and

D7 are characterized by high carbon and high chromium

drilling parallel to the axis of the bar or forging at any point

contents and exhibit high resistance to abrasion. The types

midway between the center and surface in accordance with the

containing molybdenum may be hardened in air and offer a

latest issue of Practice E59. The chemical analysis of the

high degree of dimensional stability in heat treatment.

drilling chips shall be made in accordance with the latest issue

3.1.4 Cold Work Tool Steels, Identification O—Types O1 to

of Test Methods E30. The chemical composition thus deter-

O7 are low-alloy types that must be hardened by quenching in

mined shall not vary from the limits specified in Table 1.

oil. Sizes over about 2 in. (50 mm) in cross section usually

exhibit lower interior hardness.

7. Hardness Requirements

3.1.5 Shock-Resisting Steels, Identification S—Types S1 to

S7 vary in alloy content but are intended for shock-resisting

7.1 Annealed hardness values shall be obtained in accor-

applications.

dance with the latest issue of Test Methods and Definitions

3.1.6 Special-Purpose Tool Steels, Identification L—Types

A370, and shall not exceed the Brinell hardness values (or

L2 to L6 are low-alloy steels with a wide range of carbon

equivalent Rockwell hardness values) specified in Table 2.

content. The low-carbon types are generally used for structural

7.2 Specimens for determination of minimum response to

applications requiring good levels of toughness, while the

hardening shall be ⁄4 in. (6.4 mm) thick disks cut so as to

high-carbon types may be used for short-run tools.

represent either the full cross-sectional area or that midway

3.1.7 Special-Purpose Tool Steels, Identification F—Types

between the center and outer surface of the material. If the

F1 to F2 are high-carbon steels with varying tungsten content

material form or size does not lend itself to accurate hardness

used primarily for relatively short-run fine edge cutting tools.

determination on ⁄4 in. thick cross-sectional disks, then longi-

3.1.8 Mold Steels, Identification P:

tudinal specimens may be used for hardness testing. Examples

3.1.8.1 Types P2 to P6 are very low-carbon steels and must

are round bars less than ⁄2 in. (12.7 mm) in diameter or sheet.

be carburized after machining or hubbing.

In this case, the specimen shall be a minimum of 3 in. (76 mm)

3.1.8.2 Types P20 and P21 are usually supplied in the

in length and parallel flats shall be ground on the original mill

prehardened condition and can be placed in service directly

surfaces. The specimens shall be heat treated as prescribed in

after machining.

Table 3.

4. Ordering Information 7.2.1 The hardness of the specimen after the specified heat

treatment shall meet the minimum hardness value for the

4.1 Orders for material under this specification shall include

particular type of steel shown in Table 3. Rockwell C tests

the following information, as required to describe adequately

should be used where possible but light load tests may be

the desired material:

necessaryonthinspecimens.Thesetestsshouldbespecifiedby

4.1.1 Class of material (hot work tool steel, etc.),

agreement between the seller and the purchaser. The hardness

4.1.2 Type (H11, D2, etc.),

value shall be obtained in accordance with the latest issue of

4.1.3 Shape (sheet, strip, plate, flat bar, round bar, square

TestMethodsandDefinitionsA370,andshallbetheaverageof

bar, hexagon bar, octagon, special shapes),

at least five readings taken in an area midway between the

4.1.4 Dimensions (thickness, width, diameter, length),

center and surface of the largest dimension of the cross-

4.1.5 Finish (hot rolled, forged, blasted or pickled, cold

sectional specimen or along the parallel surfaces of the

drawn, machined, ground, precision ground and polished),

longitudinal specimen.

4.1.6 Condition (annealed, hardened and tempered, etc.),

4.1.7 ASTM designation and year of issue, and

8. Macrostructure

4.1.8 Special requirements.

8.1 Specimens for the determination of the macrostructure

5. Materials and Manufacture

shall represent the entire cross-sectional area in the annealed

conditionandbepreparedinaccordancewiththelatestissueof

5.1 Unless otherwise specified, material covered by this

specification shall be made by an electric melting process. It Practice A561. Material supplied to this specification shall be

shall be made from ingots or slabs that have been reduced in capable of exhibiting a structure free of excessive porosity,

crosssectioninsuchamannerandtosuchadegreeastoensure segregation, slag, dirt or other nonmetallic inclusions, pipe,

proper refinement of the solidification structure. checks, cracks, and other injurious defects.

A681−08 (2022)

A

TABLE 1 Chemical Requirements,%

C

UNS Carbon Manganese Phos- Silicon Chromium Vanadium Tungsten Molybdenum

D

Sulfur,

Desig- Type phorus,

min max min max max min max min max min max min max min max

B

nation max

T20810 H10 0.35 0.45 0.20 0.70 0.030 0.030 0.80 1.25 3.00 3.75 0.25 0.75 . . . . . . 2.00 3.00

T20811 H11 0.33 0.43 0.20 0.60 0.030 0.030 0.80 1.25 4.75 5.50 0.30 0.60 . . . . . . 1.10 1.60

T20812 H12 0.30 0.40 0.20 0.60 0.030 0.030 0.80 1.25 4.75 5.50 0.20 0.50 1.00 1.70 1.25 1.75

T20813 H13 0.32 0.45 0.20 0.60 0.030 0.030 0.80 1.25 4.75 5.50 0.80 1.20 . . . . . . 1.10 1.75

T20814 H14 0.35 0.45 0.20 0.60 0.030 0.030 0.80 1.25 4.75 5.50 . . . . . . 4.00 5.25 . . . . . .

T20819 H19 0.32 0.45 0.20 0.50 0.030 0.030 0.15 0.50 4.00 4.75 1.75 2.20 3.75 4.50 0.30 0.55 Co 4.00–4.50

T20821 H21 0.26 0.36 0.15 0.40 0.030 0.030 0.15 0.50 3.00 3.75 0.30 0.60 8.50 10.00 . . . . . .

T20822 H22 0.30 0.40 0.15 0.40 0.030 0.030 0.15 0.40 1.75 3.75 0.25 0.50 10.00 11.75 . . . . . .

T20823 H23 0.25 0.35 0.15 0.40 0.030 0.030 0.15 0.60 11.00 12.75 0.75 1.25 11.00 12.75 . . . . . .

T20824 H24 0.42 0.53 0.15 0.40 0.030 0.030 0.15 0.40 2.50 3.50 0.40 0.60 14.00 16.00 . . . . . .

T20825 H25 0.22 0.32 0.15 0.40 0.030 0.030 0.15 0.40 3.75 4.50 0.40 0.60 14.00 16.00 . . . . . .

E

T20826 H26 0.45 0.55 0.15 0.40 0.030 0.030 0.15 0.40 3.75 4.50 0.75 1.25 17.25 19.00 . . . . . .

E

T20841 H41 0.60 0.75 0.15 0.40 0.030 0.030 0.20 0.45 3.50 4.00 1.00 1.30 1.40 2.10 8.20 9.20

E

T20842 H42 0.55 0.70 0.15 0.40 0.030 0.030 0.20 0.45 3.75 4.50 1.75 2.20 5.50 6.75 4.50 5.50

E

T20843 H43 0.50 0.65 0.15 0.40 0.030 0.030 0.20 0.45 3.75 4.50 1.80 2.20 . . . . . . 7.75 8.50

T30102 A2 0.95 1.05 0.40 1.00 0.030 0.030 0.10 0.50 4.75 5.50 0.15 0.50 . . . . . . 0.90 1.40

T30103 A3 1.20 1.30 0.40 0.60 0.030 0.030 0.10 0.70 4.75 5.50 0.80 1.40 . . . . . . 0.90 1.40

T30104 A4 0.95 1.05 1.80 2.20 0.030 0.030 0.10 0.70 0.90 2.20 . . . . . . . . . . . . 0.90 1.40

T30105 A5 0.95 1.05 2.80 3.20 0.030 0.030 0.10 0.70 0.90 1.40 . . . . . . . . . . . . 0.90 1.40

T30106 A6 0.65 0.75 1.80 2.50 0.030 0.030 0.10 0.70 0.90 1.40 . . . . . . . . . . . . 0.90 1.40

T30107 A7 2.00 2.85 0.20 0.80 0.030 0.030 0.10 0.70 5.00 5.75 3.90 5.15 0.50 1.50 0.90 1.40

T30108 A8 0.50 0.60 0.20 0.50 0.030 0.030 0.75 1.10 4.75 5.50 . . . . . . 1.00 1.50 1.15 1.65

T30109 A9 0.45 0.55 0.20 0.50 0.030 0.030 0.95 1.15 4.75 5.50 0.80 1.40 . . . . . . 1.30 1.80 Ni 1.25–1.75

T30110 A10 1.25 1.50 1.60 2.10 0.030 0.030 1.00 1.50 . . . . . . . . . . . . . . . . . . 1.25 1.75 Ni 1.55–2.05

T30402 D2 1.40 1.60 0.10 0.60 0.030 0.030 0.10 0.60 11.00 13.00 0.50 1.10 . . . . . . 0.70 1.20 . . .

T30403 D3 2.00 2.35 0.10 0.60 0.030 0.030 0.10 0.60 11.00 13.50 . . . 1.00 . . . 1.00 . . . . . .

T30404 D4 2.05 2.40 0.10 0.60 0.030 0.030 0.10 0.60 11.00 13.00 0.15 1.00 . . . . . . 0.70 1.20

T30405 D5 1.40 1.60 0.10 0.60 0.030 0.030 0.10 0.60 11.00 13.00 . . . 1.00 . . . . . . 0.70 1.20 Co 2.50–3.50

T30407 D7 2.15 2.50 0.10 0.60 0.030 0.030 0.10 0.60 11.50 13.50 3.80 4.40 . . . . . . 0.70 1.20

T31501 O1 0.85 1.00 1.00 1.40 0.030 0.030 0.10 0.50 0.40 0.70 . . . 0.30 0.40 0.60 . . . . . .

T31502 O2 0.85 0.95 1.40 1.80 0.030 0.030 . . . 0.50 . . . 0.50 . . . 0.30 . . . . . . . . . 0.30

T31506 O6 1.25 1.55 0.30 1.10 0.030 0.030 0.55 1.50 . . . 0.30 . . . . . . . . . . . . 0.20 0.30

T31507 O7 1.10 1.30 0.20 1.00 0.030 0.030 0.10 0.60 0.35 0.85 0.15 0.40 1.00 2.00 . . . 0.30

T41901 S1 0.40 0.55 0.10 0.40 0.030 0.030 0.15 1.20 1.00 1.80 0.15 0.30 1.50 3.00 . . . 0.50

T41902 S2 0.40 0.55 0.30 0.50 0.030 0.030 0.90 1.20 . . . . . . . . . 0.50 . . . . . . 0.30 0.60

T41904 S4 0.50 0.65 0.60 0.95 0.030 0.030 1.75 2.25 0.10 0.50 0.15 0.35 . . . . . . . . . . . . . . . . . .

T41905 S5 0.50 0.65 0.60 1.00 0.030 0.030 1.75 2.25 0.10 0.50 0.15 0.35 . . . . . . 0.20 1.35 . . . . . .

T41906 S6 0.40 0.50 1.20 1.50 0.030 0.030 2.00 2.50 1.20 1.50 0.20 0.40 . . . . . . 0.30 0.50 . . . . . .

T41907 S7 0.45 0.55 0.20 0.90 0.030 0.030 0.20 1.00 3.00 3.50 . . . 0.35 . . . . . . 1.30 1.80 . . . . . .

T61202 L2 0.45 1.00 0.10 0.90 0.030 0.030 0.10 0.50 0.70 1.20 0.10 0.30 . . . . . . . . . 0.25 . . . . . .

T61203 L3 0.95 1.10 0.25 0.80 0.030 0.030 0.10 0.50 1.30 1.70 0.10 0.30 . . . . . . . . . . . . . . . . . .

Nickel

T61206 L6 0.65 0.75 0.25 0.80 0.030 0.030 0.10 0.50

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.