ASTM A600-92a(2024)

(Specification)Standard Specification for Tool Steel High Speed

Standard Specification for Tool Steel High Speed

ABSTRACT

This specification covers seven tungsten-type (types T1, T2, T4, T5, T6, T8, and T15) and nineteen molybdenum-type high-speed steels (types M1, M2, M3, M4, M6, M7, M10, M30, M33, M34, M36, M41, M42, M43, M44, M46, M47, M48, and M62) in the form of annealed, hot-rolled bars, forgings, plate, sheet, or strip, and annealed, cold-finished bars or forgings used primarily in the fabrication of tools. Two intermediate high speed tool steels designated as M50 and M52 are also covered. Unless otherwise specified, material shall be made by an electric melting process. A chemical analysis of each heat of steel shall be made to determine the percentage of the elements specified (including carbon, manganese, phosphorus, sulfur, silicon, chromium, vanadium, tungsten, molybdenum, and cobalt) and these values shall conform to the requirements as to the prescribed chemical composition. Requirements for: (1) heat treatment such as austenitizing, quenching, and tempering, (2) hardness testing (3) macrostructure and macroetch standard for porosity and ingot pattern, and (4) decarburization determination are detailed. The maximum Brinell hardness and minimum Rockwell C hardness for the tool steels are given.

SCOPE

1.1 This specification covers tungsten-type and molybdenum-type high-speed steels available as annealed, hot-rolled bars, forgings, plate, sheet, or strip, and annealed, cold-finished bars or forgings used primarily in the fabrication of tools.

1.2 Seven types of tungsten high-speed tool steels designated T1, T2, etc., seventeen types of molybdenum high-speed tool steels designated M1, M2, etc., and two intermediate high-speed steels designated as M50 and M52 are covered. Selection will depend upon design, service conditions, and mechanical properties.

1.3 The term “high-speed steel” is described and its minimum requirements are covered in the Annex.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A600 − 92a (Reapproved 2024)

Standard Specification for

Tool Steel High Speed

This standard is issued under the fixed designation A600; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope A561 Practice for Macroetch Testing of Tool Steel Bars

A700 Guide for Packaging, Marking, and Loading Methods

1.1 This specification covers tungsten-type and

for Steel Products for Shipment

molybdenum-type high-speed steels available as annealed,

E3 Guide for Preparation of Metallographic Specimens

hot-rolled bars, forgings, plate, sheet, or strip, and annealed,

E30 Test Methods for Chemical Analysis of Steel, Cast Iron,

cold-finished bars or forgings used primarily in the fabrication

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

of tools.

E45 Test Methods for Determining the Inclusion Content of

1.2 Seven types of tungsten high-speed tool steels desig-

Steel

nated T1, T2, etc., seventeen types of molybdenum high-speed

E59 Practice for Sampling Steel and Iron for Determination

tool steels designated M1, M2, etc., and two intermediate

of Chemical Composition (Withdrawn 1996)

high-speed steels designated as M50 and M52 are covered.

2.2 Military Standard:

Selection will depend upon design, service conditions, and

MIL-STD-163 Steel Mill Products, Preparation for Ship-

mechanical properties.

ment and Storage

1.3 The term “high-speed steel” is described and its mini-

2.3 Federal Standards:

mum requirements are covered in the Annex.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.4 The values stated in inch-pound units are to be regarded

Fed. Std. No. 183 Continuous Identification Marking of Iron

as standard. The values given in parentheses are mathematical

and Steel Products

conversions to SI units that are provided for information only

and are not considered standard.

3. Classification

1.5 This international standard was developed in accor-

3.1 Material in accordance with this specification is classi-

dance with internationally recognized principles on standard-

fied by chemical composition. Types correspond to respective

ization established in the Decision on Principles for the

AISI designations.

Development of International Standards, Guides and Recom-

3.1.1 Types T1, T2, T4, T5, T6, T8, and T15 are character-

mendations issued by the World Trade Organization Technical

ized by a controlled high tungsten content along with other

Barriers to Trade (TBT) Committee.

alloying elements.

3.1.2 Types M1, M2, M3, M4, M6, M7, M10, M30, M33,

2. Referenced Documents

M34, M36, M41, M42, M43, M44, M46, M47, M48, and M62

2.1 ASTM Standards:

are characterized by a controlled high molybdenum content

A370 Test Methods and Definitions for Mechanical Testing

along with other alloying elements.

of Steel Products

3.1.3 Types M2, M3, and M10 are further classified accord-

A388/A388M Practice for Ultrasonic Examination of Steel

ing to carbon range. Type M3 is further classified according to

Forgings

vanadium range.

3.1.4 Types M50 and M52 are considered intermediate

high-speed steels in view of their lower total alloy content than

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

the standard types. These leaner alloy grades normally are

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

limited to less severe service conditions.

A01.29 on Tool Steels.

Current edition approved March 1, 2024. Published March 2024. Originally

approved in 1969. Last previous edition approved in 2016 as A600 – 92a (2016).

DOI: 10.1520/A0600-92AR24.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Avenue,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A600 − 92a (2024)

4. Ordering Information 6. Chemical Composition

4.1 Orders for material under this specification shall include

6.1 An analysis of each heat of steel shall be made by the

the following information, as required to describe adequately

manufacturer to determine the percentage of the elements

the desired material:

specified and these values shall conform to the requirements as

4.1.1 Name of material (high-speed tool steel),

to chemical composition specified in Table 1. If requested or

4.1.2 Type,

required, the chemical composition shall be reported to the

4.1.3 Shape (sheet, strip, plate, flat bar, round bar, square

purchaser or his representative.

bar, hexagon bar, octagon, special shapes),

6.2 Analysis may be made by the purchaser from finished

4.1.4 Dimensions (thickness, width, diameter, length) (For

bars and forgings by machining off the entire cross section and

coils, include the minimum inside diameter or inside diameter

range, the maximum outside diameter, and maximum or drilling parallel to the axis of the bar or forging at any point

minimum coil weight if required. (Minimum coil weights are midway between the center and surface in accordance with the

subject to negotiation.)),

latest issue of Practice E59. The chemical analysis of the

4.1.5 Finish (hot rolled, forged, blasted or pickled, cold

drilling chips shall be made in accordance with the latest issue

drawn, rough machined, ground, precision ground and

of Test Methods E30. The chemical composition thus deter-

polished),

mined shall not vary from the limits specified in Table 1.

4.1.6 Condition (annealed),

4.1.7 ASTM designation and date of issue, and

7. Hardness Requirements

4.1.8 Special or supplementary requirements.

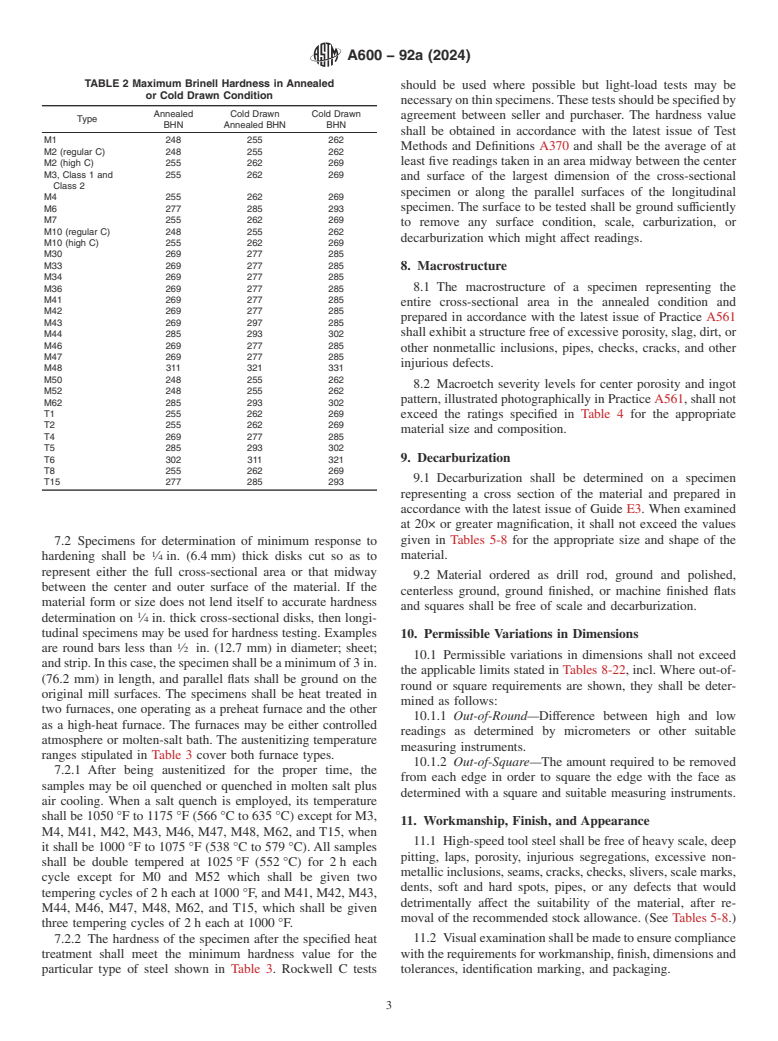

7.1 Annealed hardness values when obtained in accordance

5. Materials and Manufacture

with the latest issue of Test Methods and Definitions A370

5.1 Unless otherwise specified, material covered by this shall not exceed the Brinell hardness values (or equivalent

specification shall be made by an electric melting process. Rockwell hardness values) specified in Table 2.

A

TABLE 1 Chemical Requirements, %

C

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Vanadium Tungsten Molybdenum Cobalt

Designa- phorus

B

tion

min max min max max max min max min max min max min max min max min max

Tungsten-Type High-Speed Steels

T12001 T1 0.65 0.80 0.10 0.40 0.03 0.03 0.20 0.40 3.75 4.50 0.90 1.30 17.25 18.75 . . . . . . . . . . . .

T12002 T2 0.80 0.90 0.20 0.40 0.03 0.03 0.20 0.40 3.75 4.50 1.80 2.40 17.50 19.00 . . . 1.00 . . . . . .

T12004 T4 0.70 0.80 0.10 0.40 0.03 0.03 0.20 0.40 3.75 4.50 0.80 1.20 17.50 19.00 0.40 1.00 4.25 5.75

T12005 T5 0.75 0.85 0.20 0.40 0.03 0.03 0.20 0.40 3.75 5.00 1.80 2.40 17.50 19.00 0.50 1.25 7.00 9.50

T12006 T6 0.75 0.85 0.20 0.40 0.03 0.03 0.20 0.40 4.00 4.75 1.50 2.10 18.50 21.00 0.40 1.00 11.00 13.00

T12008 T8 0.75 0.85 0.20 0.40 0.03 0.03 0.20 0.40 3.75 4.50 1.80 2.40 13.25 14.75 0.40 1.00 4.25 5.75

T12015 T15 1.50 1.60 0.15 0.40 0.03 0.03 0.15 0.40 3.75 5.00 4.50 5.25 11.75 13.00 . . . 1.00 4.75 5.25

Molybdenum-Type High-Speed Steels

T11301 M1 0.78 0.88 0.15 0.40 0.03 0.03 0.20 0.50 3.50 4.00 1.00 1.35 1.40 2.10 8.20 9.20 . . . . . .

T11302 M2 regular C 0.78 0.88 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.50 1.75 2.20 5.50 6.75 4.50 5.50 . . . . . .

high C 0.95 1.05 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.50 1.75 2.20 5.50 6.75 4.50 5.50 . . . . . .

T11313 M3 Class 1 1.00 1.10 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.50 2.25 2.75 5.00 6.75 4.75 6.50 . . . . . .

T11323 Class 2 1.15 1.25 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.50 2.75 3.25 5.00 6.75 4.75 6.50 . . . . . .

T11304 M4 1.25 1.40 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.75 3.75 4.50 5.25 6.50 4.25 5.50 . . . . . .

T11306 M6 0.75 0.85 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.50 1.30 1.70 3.75 4.75 4.50 5.50 11.00 13.00

T11307 M7 0.97 1.05 0.15 0.40 0.03 0.03 0.20 0.55 3.50 4.00 1.75 2.25 1.40 2.10 8.20 9.20 . . . . . .

T11310 M10 regular C 0.84 0.94 0.10 0.40 0.03 0.03 0.20 0.45 3.75 4.50 1.80 2.20 . . . . . . 7.75 8.50 . . . . . .

high C 0.95 1.05 0.10 0.40 0.03 0.03 0.20 0.45 3.75 4.50 1.80 2.20 . . . . . . 7.75 8.50 . . . . . .

T11330 M30 0.75 0.85 0.15 0.40 0.03 0.03 0.20 0.45 3.50 4.25 1.00 1.40 1.30 2.30 7.75 9.00 4.50 5.50

T11333 M33 0.85 0.92 0.15 0.40 0.03 0.03 0.15 0.50 3.50 4.00 1.00 1.35 1.30 2.10 9.00 10.00 7.75 8.75

T11334 M34 0.85 0.92 0.15 0.40 0.03 0.03 0.20 0.45 3.50 4.00 1.90 2.30 1.40 2.10 7.75 9.20 7.75 8.75

T11336 M36 0.80 0.90 0.15 0.40 0.03 0.03 0.20 0.45 3.75 4.50 1.75 2.25 5.50 6.50 4.50 5.50 7.75 8.75

T11341 M41 1.05 1.15 0.20 0.60 0.03 0.03 0.15 0.50 3.75 4.50 1.75 2.25 6.25 7.00 3.25 4.25 4.75 5.75

T11342 M42 1.05 1.15 0.15 0.40 0.03 0.03 0.15 0.65 3.50 4.25 0.95 1.35 1.15 1.85 9.00 10.00 7.75 8.75

T11343 M43 1.15 1.25 0.20 0.40 0.03 0.03 0.15 0.65 3.50 4.25 1.50 1.75 2.25 3.00 7.50 8.50 7.75 8.75

T11344 M44 1.10 1.20 0.20 0.40 0.03 0.03 0.30 0.55 4.00 4.75 1.85 2.20 5.00 5.75 6.00 7.00 11.00 12.25

T11346 M46 1.22 1.30 0.20 0.40 0.03 0.03 0.40 0.65 3.70 4.20 3.00 3.30 1.90 2.20 8.00 8.50 7.80 8.80

T11347 M47 1.05 1.15 0.15 0.40 0.03 0.03 0.20 0.45 3.50 4.00 1.15 1.35 1.30 1.80 9.25 10.00 4.75 5.25

. . . M48 1.42 1.52 0.15 0.40 0.03 0.07 0.15 0.40 3.50 4.00 2.75 3.25 9.50 10.50 4.75 5.50 8.00 10.00

. . . M62 1.25 1.35 0.15 0.40 0.03 0.07 0.15 0.40 3.50 4.00 1.80 2.10 5.75 6.50 10.00 11.00 . . . . . .

Intermediate High Speed Steels

T11350 M50 0.78 0.88 0.15 0.45 0.03 0.03 0.20 0.60 3.75 4.50 0.80 1.25 . . . . . . 3.90 4.75 . . . . . .

T11352 M52 0.85 0.95 0.15 0.45 0.03 0.03 0.20 0.60 3.50 4.30 1.65 2.25 0.75 1.50 4.00 4.90 . . . . . .

A

Chemistry limits include product analysis tolerances. Unless otherwise specified, nickel plus copper equals 0.75 % max for all types.

B

New designation established in accordance with Practice E527 and SAE J 1086.

C

Where specified, sulfur may be 0.06 % to 0.15 % to improve machinability.

A600 − 92a (2024)

TABLE 2 Maximum Brinell Hardness in Annealed

should be used where possible but light-load tests may be

or Cold Drawn Condition

necessary on thin specimens. These tests should be specified by

Annealed Cold Drawn Cold Drawn

agreement between seller and purchaser. The hardness value

Type

BHN Annealed BHN BHN

shall be obtained in accordance with the latest issue of Test

M1 248 255 262

Methods and Definitions A370 and shall be the average of at

M2 (regular C) 248 255 262

M2 (high C) 255 262 269 least five readings taken in an area midway between the center

M3, Class 1 and 255 262 269

and surface of the largest dimension of the cross-sectional

Class 2

specimen or along the parallel surfaces of the longitudinal

M4 255 262 269

specimen. The surface to be tested shall be ground sufficiently

M6 277 285 293

M7 255 262 269

to remove any surface condition, scale, carburization, or

M10 (regular C) 248 255 262

decarburization which might affect readings.

M10 (high C) 255 262 269

M30 269 277 285

M33 269 277 285

8. Macrostructure

M34 269 277 285

8.1 The macrostructure of a specimen representing the

M36 269 277 285

M41 269 277 285

entire cross-sectional area in the annealed condition and

M42 269 277 285

prepared in accordance with the latest issue of Practice A561

M43 269 297 285

shall exhibit a structure free of excessive porosity, slag, dirt, or

M44 285 293 302

M46 269 277 285

other nonmetallic inclusions, pipes, checks, cracks, and other

M47 269 277 285

injurious defects.

M48 311 321 331

M50 248 255 262

8.2 Macroetch severity levels for center porosity and ingot

M52 248 255 262

pattern, illustrated photographically in Practice A561, shall not

M62 285 293 302

T1 255 262 269

exceed the ratings specified in Table 4 for the appropriate

T2 255 262 269

material size and composition.

T4 269 277 285

T5 285 293 302

9. Decarburization

T6 302 311 321

T8 255 262 269

9.1 Decarburization shall be determined on a specimen

T15 277 285 293

representing a cross section of the material and prepared in

accordance with the latest issue of Guide E3. When examined

at 20× or greater magnification, it shall not exceed the values

given in Tables 5-8 for the appropriate size and shape of the

7.2 Specimens for determination of minimum response to

material.

hardening shall be ⁄4 in. (6.4 mm) thick disks cut so as to

represent either the full cross-sectional area or that midway

9.2 Material ordered as drill rod, ground and polished,

between the center and outer surface of the material. If the

centerless ground, ground finished, or machine finished flats

material form or size does not lend itself to accurate hardness

and squares shall be free of scale and decarburization.

determination on ⁄4 in. thick cross-sectional disks, then longi-

tudinal specimens may be used for hardness testing. Examples

10. Permissible Variations in Dimensions

are round bars less than ⁄2 in. (12.7 mm) in diameter; sheet;

10.1 Permissible variations in dimensions shall not exceed

and strip. In this case, the specimen shall be a minimum of 3 in.

the applicable limits stated in Tables 8-22, incl. Where out-of-

(76.2 mm) in length, and parallel flats shall be ground on the

round or square requirements are shown, they shall be deter-

original mill surfaces. The specimens shall be heat treated in

mined as follows:

two furnaces, one operating as a preheat furnace and the other

10.1.1 Out-of-Round—Difference between high and low

as a high-heat furnace. The furnaces may be either controlled

readings as determined by micrometers or other suitable

atmosphere or molten-salt bath. The austenitizing temperature

measuring instruments.

ranges stipulated in Table 3 cover both furnace types.

10.1.2 Out-of-Square—The amount required to be removed

7.2.1 After being austenitized for the proper time, the

from each edge in order to square the edge with the face as

samples may be oil quenched or quenched in molten salt plus

determined with a square and suitable measuring instruments.

air cooling. When a salt quench is employed, its temperature

shall be 1050 °F to 1175 °F (566 °C to 635 °C) except for M3,

11. Workmanship, Finish, and Appearance

M4, M41, M42, M43, M46, M47, M48, M62, and T15,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.