ASTM E18-05

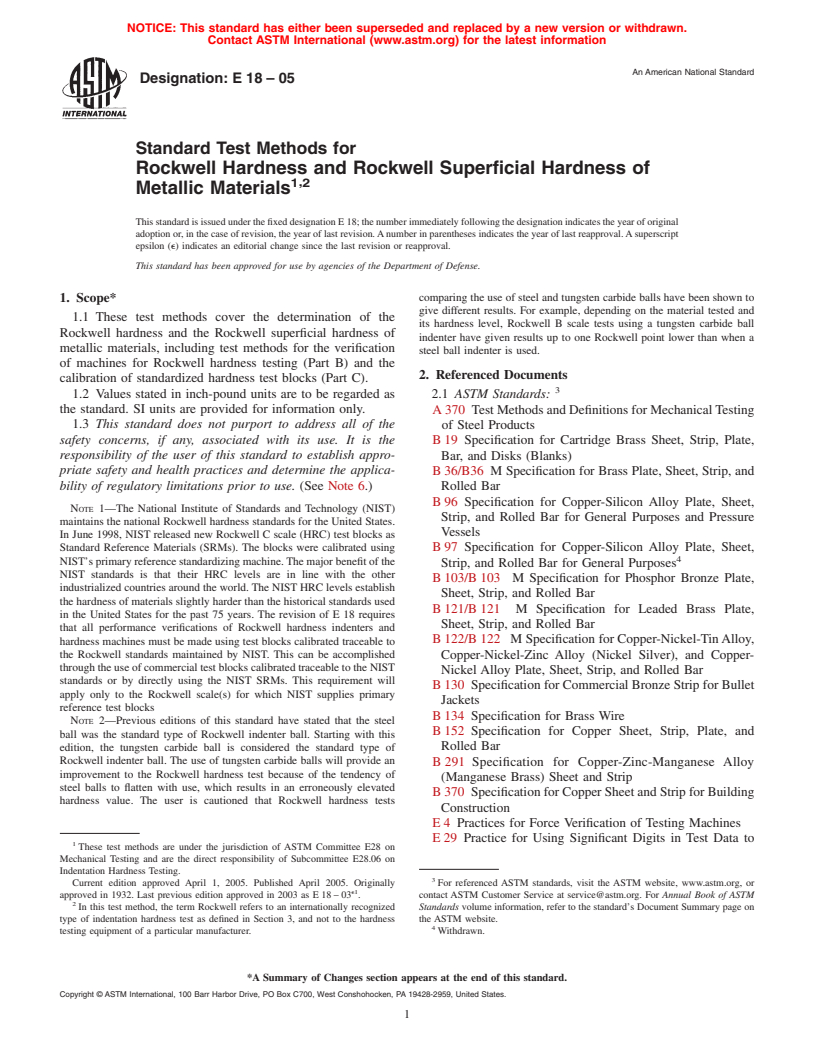

(Test Method)Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

SCOPE

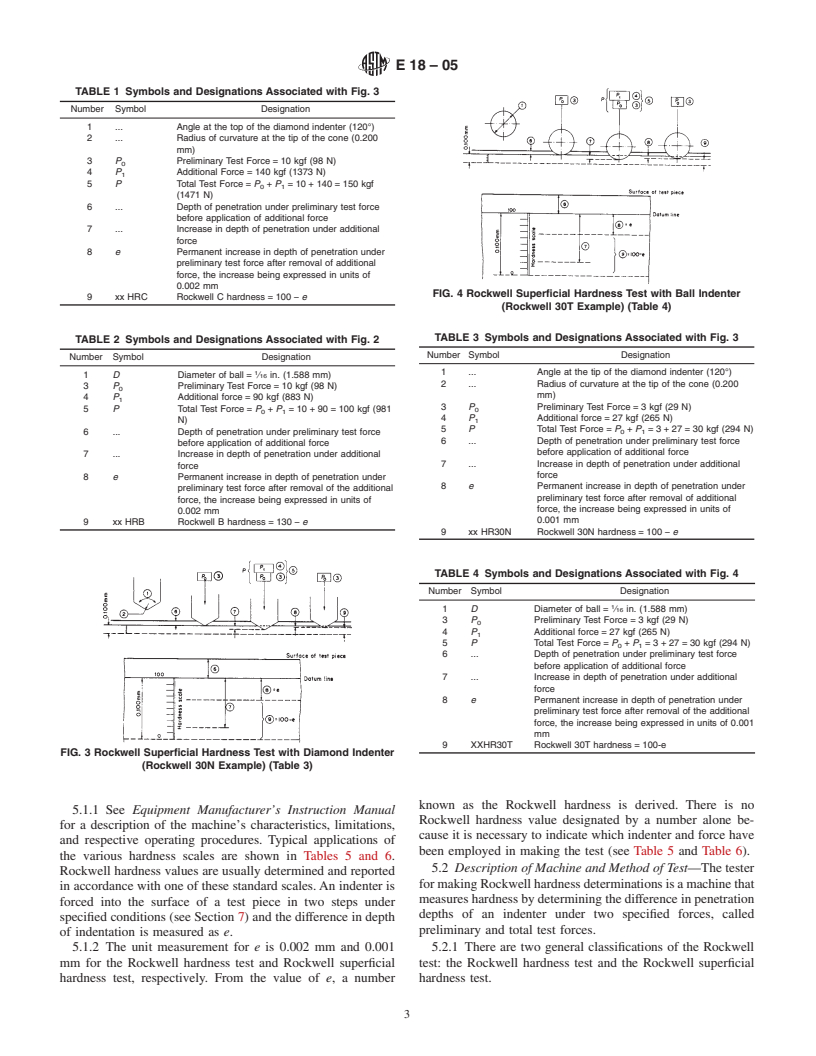

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C).

1.2 Values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See Note 0.)Note 2

The National Institute of Standards and Technology (NIST) maintains the national Rockwell hardness standards for the United States. In June 1998, NIST released new Rockwell C scale (HRC) test blocks as Standard Reference Materials (SRMs). The blocks were calibrated using NIST's primary reference standardizing machine. The major benefit of the NIST standards is that their HRC levels are in line with the other industrialized countries around the world. The NIST HRC levels establish the hardness of materials slightly harder than the historical standards used in the United States for the past 75 years. The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell standards maintained by NIST. This can be accomplished through the use of commercial test blocks calibrated traceable to the NIST standards or by directly using the NIST SRMs. This requirement will apply only to the Rockwell scale(s) for which NIST supplies primary reference test blocksNote 3

Previous editions of this standard have stated that the steel ball was the standard type of Rockwell indenter ball. Starting with this edition, the tungsten carbide ball is considered the standard type of Rockwell indenter ball. The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously elevated hardness value. The user is cautioned that Rockwell hardness tests comparing the use of steel and tungsten carbide balls have been shown to give different results. For example, depending on the material tested and its hardness level, Rockwell B scale tests using a tungsten carbide ball indenter have given results up to one Rockwell point lower than when a steel ball indenter is used.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 18 – 05

Standard Test Methods for

Rockwell Hardness and Rockwell Superficial Hardness of

,

1 2

Metallic Materials

ThisstandardisissuedunderthefixeddesignationE18;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

comparing the use of steel and tungsten carbide balls have been shown to

1. Scope*

give different results. For example, depending on the material tested and

1.1 These test methods cover the determination of the

its hardness level, Rockwell B scale tests using a tungsten carbide ball

Rockwell hardness and the Rockwell superficial hardness of

indenter have given results up to one Rockwell point lower than when a

metallic materials, including test methods for the verification

steel ball indenter is used.

of machines for Rockwell hardness testing (Part B) and the

2. Referenced Documents

calibration of standardized hardness test blocks (Part C).

3

1.2 Values stated in inch-pound units are to be regarded as 2.1 ASTM Standards:

the standard. SI units are provided for information only.

A370 TestMethodsandDefinitionsforMechanicalTesting

1.3 This standard does not purport to address all of the of Steel Products

safety concerns, if any, associated with its use. It is the

B19 Specification for Cartridge Brass Sheet, Strip, Plate,

responsibility of the user of this standard to establish appro- Bar, and Disks (Blanks)

priate safety and health practices and determine the applica-

B36/B36 M Specification for Brass Plate, Sheet, Strip, and

bility of regulatory limitations prior to use. (See Note 6.) Rolled Bar

B96 Specification for Copper-Silicon Alloy Plate, Sheet,

NOTE 1—The National Institute of Standards and Technology (NIST)

Strip, and Rolled Bar for General Purposes and Pressure

maintains the national Rockwell hardness standards for the United States.

Vessels

In June 1998, NIST released new Rockwell C scale (HRC) test blocks as

Standard Reference Materials (SRMs). The blocks were calibrated using B97 Specification for Copper-Silicon Alloy Plate, Sheet,

4

NIST’sprimaryreferencestandardizingmachine.Themajorbenefitofthe

Strip, and Rolled Bar for General Purposes

NIST standards is that their HRC levels are in line with the other

B103/B103 M Specification for Phosphor Bronze Plate,

industrializedcountriesaroundtheworld.TheNISTHRClevelsestablish

Sheet, Strip, and Rolled Bar

thehardnessofmaterialsslightlyharderthanthehistoricalstandardsused

B121/B121 M Specification for Leaded Brass Plate,

in the United States for the past 75 years. The revision of E 18 requires

Sheet, Strip, and Rolled Bar

that all performance verifications of Rockwell hardness indenters and

B122/B122 MSpecificationforCopper-Nickel-TinAlloy,

hardness machines must be made using test blocks calibrated traceable to

the Rockwell standards maintained by NIST. This can be accomplished Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-

throughtheuseofcommercialtestblockscalibratedtraceabletotheNIST

Nickel Alloy Plate, Sheet, Strip, and Rolled Bar

standards or by directly using the NIST SRMs. This requirement will

B130 SpecificationforCommercialBronzeStripforBullet

apply only to the Rockwell scale(s) for which NIST supplies primary

Jackets

reference test blocks

B134 Specification for Brass Wire

NOTE 2—Previous editions of this standard have stated that the steel

B152 Specification for Copper Sheet, Strip, Plate, and

ball was the standard type of Rockwell indenter ball. Starting with this

Rolled Bar

edition, the tungsten carbide ball is considered the standard type of

Rockwell indenter ball. The use of tungsten carbide balls will provide an

B 291 Specification for Copper-Zinc-Manganese Alloy

improvement to the Rockwell hardness test because of the tendency of

(Manganese Brass) Sheet and Strip

steel balls to flatten with use, which results in an erroneously elevated

B370 SpecificationforCopperSheetandStripforBuilding

hardness value. The user is cautioned that Rockwell hardness tests

Construction

E4 Practices for Force Verification of Testing Machines

E29 Practice for Using Significant Digits in Test Data to

1

These test methods are under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and are the direct responsibility of Subcommittee E28.06 on

Indentation Hardness Testing.

3

Current edition approved April 1, 2005. Published April 2005. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

e1

approved in 1932. Last previous edition approved in 2003 as E18–03 . contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.