ASTM D3893-99

(Test Method)Standard Test Method for Purity of Methyl Amyl Ketone and Methyl Isoamyl Ketone by Gas Chromatography

Standard Test Method for Purity of Methyl Amyl Ketone and Methyl Isoamyl Ketone by Gas Chromatography

SCOPE

1.1 This test method covers the determination of the purity of methyl amyl ketone and methyl isoamyl ketone. In addition, the method determines total ketones and various impurities which may include acetone, isopropyl alcohol, methyl propyl ketone, methyl isobutyl ketone, methyl butyl ketone, methyl isobutyl carbinol, mesityl oxide, methyl isoamyl ketone, methyl butyl carbinol, methyl amyl ketone, and diisobutyl ketone.

1.2 Water and acid cannot be determined by this test method and must be measured by other appropriate ASTM procedures and the results used to normalize the chromatographic data.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 For hazard information and guidance, see the supplier's Material Safety Data Sheet.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3893 – 99

Standard Test Method for

Purity of Methyl Amyl Ketone and Methyl Isoamyl Ketone by

Gas Chromatography

This standard is issued under the fixed designation D 3893; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

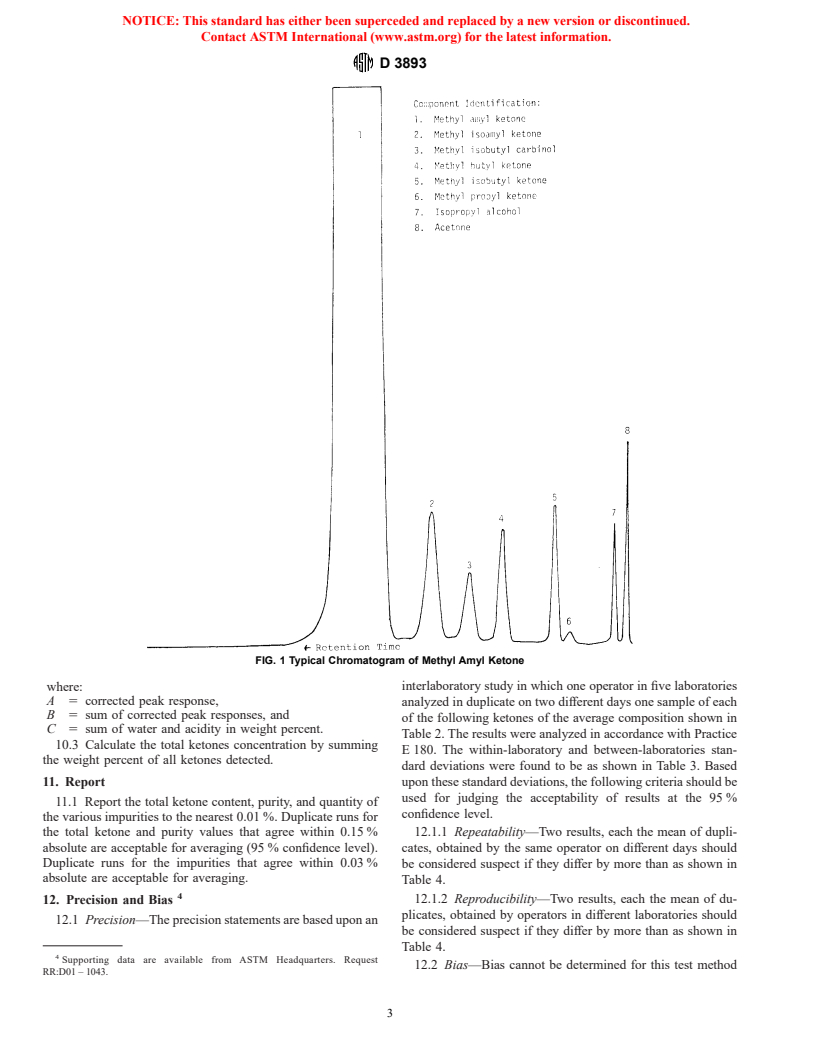

1. Scope * vidual peak responses to the total peak response. Water and

acidity are measured by Test Methods D 1364 and D 1613,

1.1 This test method covers the determination of the purity

respectively, and the results are used to normalize the values

of methyl amyl ketone and methyl isoamyl ketone. In addition,

obtained by gas chromatography.

the method determines total ketones and various impurities

which may include acetone, isopropyl alcohol, methyl propyl

4. Significance and Use

ketone, methyl isobutyl ketone, methyl butyl ketone, methyl

4.1 This procedure is designed to determine the purity of the

isobutyl carbinol, mesityl oxide, methyl isoamyl ketone, me-

two ketones, methyl isoamyl ketone and methyl amyl ketone,

thyl butyl carbinol, methyl amyl ketone, and diisobutyl ketone.

and to obtain the concentration of their various impurities,

1.2 Water and acid cannot be determined by this test

several of which are critical in the application of these solvents.

method. They must be determined by other appropriate ASTM

procedures, and the results used to normalize the chromato-

5. Apparatus

graphic data.

5.1 Chromatograph—Any gas-liquid chromatographic in-

1.3 This standard does not purport to address all of the

strument having either a thermal conductivity or flame ioniza-

safety concerns, if any, associated with its use. It is the

tion detector and sufficient sensitivity and stability to obtain for

responsibility of the user of this standard to establish appro-

0.01 % impurity in the specimen a recorder deflection of at

priate safety and health practices and determine the applica-

least 20 mm at a signal-to-noise ratio of at least 5 to 1. A

bility of regulatory limitations prior to use.

recording integrator or computer data processing system may

1.4 For hazard information and guidance, see the supplier’s

also be used.

Material Safety Data Sheet.

5.1.1 The injection port of the chromatograph must have a

2. Referenced Documents volume of at least 1.2 mL to provide for proper vaporization of

the specimen. The use of a smaller injection port or on-column

2.1 ASTM Standards:

injection causes peak broadening and tailing.

D 1364 Test Method for Water in Volatile Solvents (Karl

2 5.2 Column—Four and one half m of 3.2-mm stainless steel

Fischer Reagent Titration Method)

tubing packed with 80 to 90-mesh acid-washed, base-washed,

D 1613 Test Method for Acidity in Volatile Solvents and

and silanized diatomaceous earth support coated with 10.0 %

Chemical Intermediates Used in Paint, Varnish, Lacquer,

2 20 000 molecular weight polyethylene glycol and a 8.33 %

and Related Products

phenyl methyl (50:50) silicone. A capillary column, capable of

E 180 Practice for Determining the Precision of ASTM

3 the required separation may also be used.

Methods for Analysis and Testing of Industrial Chemicals

5.3 Specimen Introduction System—Any system capable of

3. Summary of Method introducing a representative specimen onto the column. Micro-

liter syringes have been used successfully.

3.1 A representative specimen is introduced onto a gas-

5.4 Recorder—A recording potentiometer with a full-scale

liquid partition column. The separated components are mea-

deflection of 1 mV, full-scale response time of1sor less, and

sured in the effluent by a detector and recorded as a chromato-

sufficient sensitivity and stability to meet the requirements of

gram. The chromatogram is interpreted by applying component

5.1.

attenuation and detector response factors to the peak areas and

relative concentrations are determined by relating the indi-

6. Reagents and Materials

6.1 Carrier Gas, appropriate to the type of detector used.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

Helium or hydrogen may be employed with thermal conduc-

and Related Coatings, Materials, and Applications and is the direct responsibility of

tivity detectors and nitrogen, helium, or argon with flame

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

Current edition approved Dec. 10, 1999. Published February 2000. Originally ionization detectors. The minimum purity of the carrier gas

published as D 3893 – 80. Last previous edition D 3893 – 95.

used should be 99.95 mol %. An oxygen removal system is

Annual Book of ASTM Standards, Vol 06.04.

recommended for the carrier gas.

Annual Book of ASTM Standards, Vol 15.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3893

TABLE 1 Instrument Conditions and Retention Times

6.1.1 Warning—If hydrogen is used, take special safety

precautions to ensure that the system is free of leaks and that Temperature,° C:

Column, isothermal 100

the effluent is vented properly.

Injection port 170

6.2 Column Materials:

Detector block 210

6.2.1 Liquid Phase—20 000 molecular weight polyethyl- Carrier gas Helium

Flow rate, mL/min 25

ene glycol and phenyl methyl (50:50) silicone.

Methyl Methyl

6.2.2 Solid Support—Acid-washed, base-washed, and si-

Amyl Isoamyl

lanized diatomaceous earth, 80 to 90 mesh.

Ketone Ketone

6.2.3 Solvents—Methylene chloride, reagent grade.

Relative retention times,

6.2.4 Tubing Material—The stainless steel tubing must be

major component 5 1.00

of uniform internal diameter and must be clean. Wash the Air 0.04 0.05

Acetone 0.14 0.18

inside of the tubing with methylene chloride, then water, and

Isopropyl alcohol 0.18 0.23

finally methyl alcohol and blow dry with nitrogen.

Methyl propyl ketone 0.31 0.38

Methyl isobutyl ketone 0.35 0.45

6.3 Standards for Calibration and Identification—Standard

Methyl butyl ketone 0.51 0.64

samples of all components are needed for establishing identi-

Methyl isobutyl carbinol 0.61 0.77

fication by retention time and for calibration for quantitative

Mesityl oxide 0.65 0.83

Methyl isoamyl ketone 0.73 1.00

measurements. In most cases, the pure compounds required for

Methyl butyl carbinol 0.82 1.02

calibration cannot be purchased and must be purified by

Methyl amyl ketone 1.00 1.16

distillation before use.

Diisobutyl ketone 1.04 1.25

7. Preparation of Column

7.1 Place 50 g of the solid support, 80 to 90 mesh, in a large

and measuring the response of pure components or known

evaporating dish. Dissolve 12.5 g of the polyethylene glycol in

blends. For accurate determination of the impurities, prepare

about 40 mL of methylene chloride and add to the solid

and analyze a known blend containing the impurities in

support. Add additional methylene chloride to wet and cover

concentrations that approximate the maximum specification

the solid support. Evaporate the methylene chloride in a fume

limit. Calculate the response factors relative to unity for the

hood with gentle stirring and under a gentle stream of nitrogen.

7.2 Place 50 g of the solid support in a large evaporating major ketone.

dish. Dissolve 10 g of the phenyl methyl silicone in about 40

9. Procedure

mL of methylene chloride and add to the solid support. Add

additional methylene chloride to wet and cover the solid

9.1 Introduce a representative specimen into the chromato-

support. Evaporate the methylene chloride in a fume hood with

graph

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.