ASTM E2244-02

(Test Method)Standard Test Method for In-Plane Length Measurements of Thin, Reflecting Films Using an Optical Interferometer

Standard Test Method for In-Plane Length Measurements of Thin, Reflecting Films Using an Optical Interferometer

SCOPE

1.1 This test method covers a procedure for measuring in-plane lengths (including deflections) of patterned thin films. It applies only to films, such as found in microelectromechanical systems (MEMS) materials, which can be imaged using an interferometer.

1.2 There are other ways to determine in-plane lengths. Using the design dimensions typically provides more precise in-plane length values than using measurements taken with an optical interferometer. (Interferometric measurements are typically more precise than measurements taken with an optical microscope.) This test method is intended for use when interferometric measurements are preferred over using the design dimensions (for example, when measuring in-plane deflections and when measuring lengths in an unproven fabrication process).

1.3 This test method uses a non-contact optical interferometer with the capability of obtaining topographical 3-D data sets. It is performed in the laboratory.

1.4 The maximum in-plane length measured is determined by the maximum field of view of the interferometer at the lowest magnification. The minimum deflection measured is determined by the interferometer's pixel-to-pixel spacing at the highest magnification.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2244 – 02

Standard Test Method for

In-Plane Length Measurements of Thin, Reflecting Films

Using an Optical Interferometer

This standard is issued under the fixed designation E2244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure for measuring 3.1 Definitions:

in-plane lengths (including deflections) of patterned thin films. 3.1.1 2-D data trace, n—a two-dimensional data trace that

It applies only to films, such as found in microelectromechani- is extracted from a topographical 3-D data set and that is

cal systems (MEMS) materials, which can be imaged using an parallel to the xz-or yz-plane of the interferometer.

interferometer. 3.1.1.1 Discussion—The height of the sample is measured

1.2 There are other ways to determine in-plane lengths. along the z-axis of the interferometer. The interferometer’s

Using the design dimensions typically provides more precise x-axis (as shown in Figs. 1 and 2) is typically aligned parallel

in-plane length values than using measurements taken with an or perpendicular to the transitional edges to be measured.

optical interferometer. (Interferometric measurements are typi- 3.1.2 3-D data set, n—a three-dimensional data set with a

cally more precise than measurements taken with an optical topographical z-data value for each (x, y) pixel location within

microscope.) This test method is intended for use when the interferometer’s field of view.

interferometric measurements are preferred over using the 3.1.3 anchor, n—in a surface-micromachining process, the

design dimensions (for example, when measuring in-plane portion of the test structure where the mechanical layer makes

deflections and when measuring lengths in an unproven fabri- contact with the underlying layer (see Fig. 2).

cation process). 3.1.4 anchor lip, n—in a surface-micromachining process,

1.3 This test method uses a non-contact optical interferom- the extension of the mechanical layer around the edges of the

eter with the capability of obtaining topographical 3-D data anchor (see Fig. 2).

sets. It is performed in the laboratory. 3.1.5 bulk micromachining, adj—a MEMS fabrication pro-

1.4 The maximum in-plane length measured is determined cess where the substrate is removed at specified locations,

by the maximum field of view of the interferometer at the which can create structures suspended in air.

lowest magnification. The minimum deflection measured is 3.1.6 cantilever, n—a test structure that consists of a beam

determinedbytheinterferometer’spixel-to-pixelspacingatthe suspended in air and anchored or supported at one end.

highest magnification. 3.1.7 fixed-fixed beam, n—a test structure that consists of a

1.5 This standard does not purport to address all of the beam suspended in air and anchored or supported at both ends

safety concerns, if any, associated with its use. It is the (see Figs. 1 and 2, and Fig. X1.1).

responsibility of the user of this standard to establish appro- 3.1.8 in-plane length measurement, n—a length (or deflec-

priate safety and health practices and determine the applica- tion)measurementmadeparalleltotheunderlyinglayer(orthe

bility of regulatory limitations prior to use. xy-plane).

3.1.9 interferometer, n—a non-contact optical instrument

2. Referenced Documents

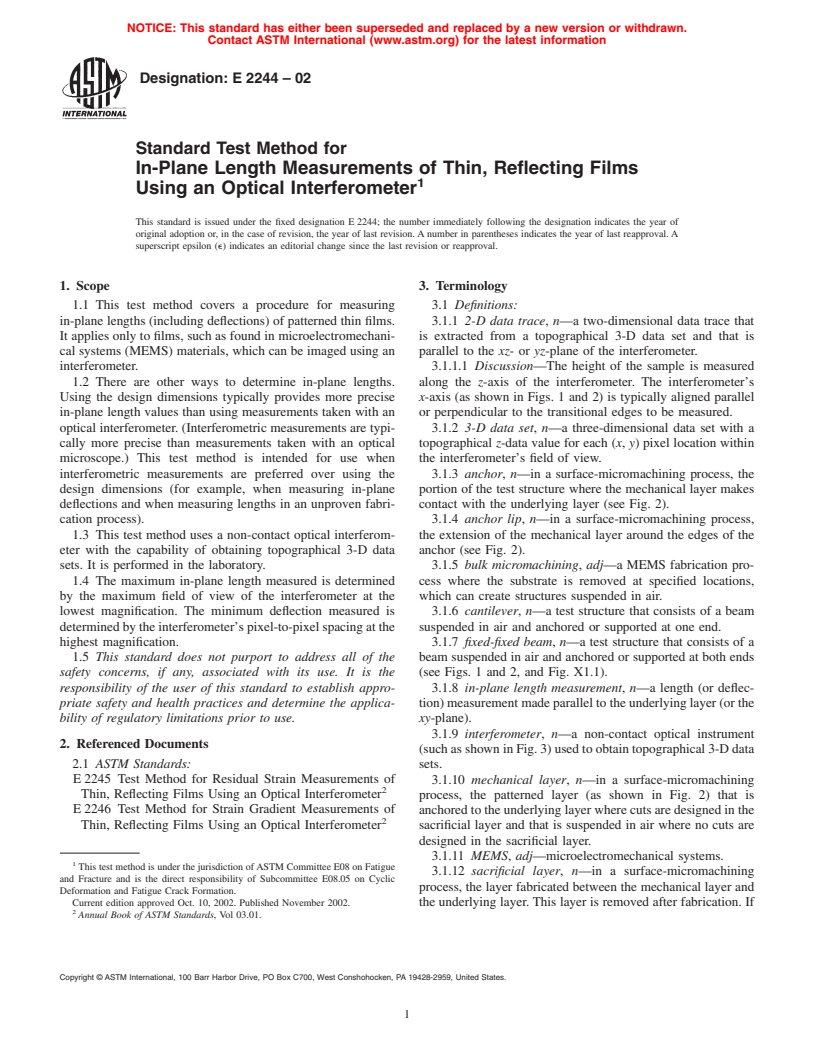

(suchasshowninFig.3)usedtoobtaintopographical3-Ddata

2.1 ASTM Standards:

sets.

E2245 Test Method for Residual Strain Measurements of 3.1.10 mechanical layer, n—in a surface-micromachining

Thin, Reflecting Films Using an Optical Interferometer

process, the patterned layer (as shown in Fig. 2) that is

E2246 Test Method for Strain Gradient Measurements of anchoredtotheunderlyinglayerwherecutsaredesignedinthe

Thin, Reflecting Films Using an Optical Interferometer

sacrificial layer and that is suspended in air where no cuts are

designed in the sacrificial layer.

3.1.11 MEMS, adj—microelectromechanical systems.

This test method is under the jurisdiction ofASTM Committee E08 on Fatigue

3.1.12 sacrificial layer, n—in a surface-micromachining

and Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic

process, the layer fabricated between the mechanical layer and

Deformation and Fatigue Crack Formation.

Current edition approved Oct. 10, 2002. Published November 2002. the underlying layer.This layer is removed after fabrication. If

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2244–02

FIG. 1 Three-Dimensional View of Surface-Micromachined Fixed-Fixed Beam

NOTE 1—The underlying layer is beneath this test structure.

NOTE 2—The mechanical layer is included in both the light and dark gray areas.

NOTE 3—The dark gray areas (the anchors) are the designed cuts in the sacrificial layer. This is where the mechanical layer contacts the underlying

layer.

NOTE 4—The light gray area is suspended in air after fabrication.

NOTE 5—The 2-D data traces (“a” and “e”) are used to ensure alignment.

NOTE 6—A 2-D data trace (“a” or “e”) is used to determine L.

FIG. 2 Top View of Fixed-Fixed Beam in Fig. 1

cuts are designed in this sacrificial layer (as shown in Fig. 2), 3.1.15 surface micromachining, adj—a MEMS fabrication

an anchor is created allowing the mechanical layer to contact

process where thin, sacrificial layers are removed, which can

the underlying layer in that region.

create structures suspended in air.

3.1.13 substrate, n—the thick, starting material in a MEMS

3.1.16 test structure, n—a structure (such as, a fixed-fixed

fabrication process.

beamorcantilever)thatisusedtoextractinformation(suchas,

3.1.14 support region, n—in a bulk-micromachining pro-

the residual strain or the strain gradient of a layer) about a

cess, the region that marks the end of the suspended structure.

fabrication process.

This region is suspended in air, attached to the substrate, or

both.

E2244–02

FIG. 3 Sketch of Optical Interferometer

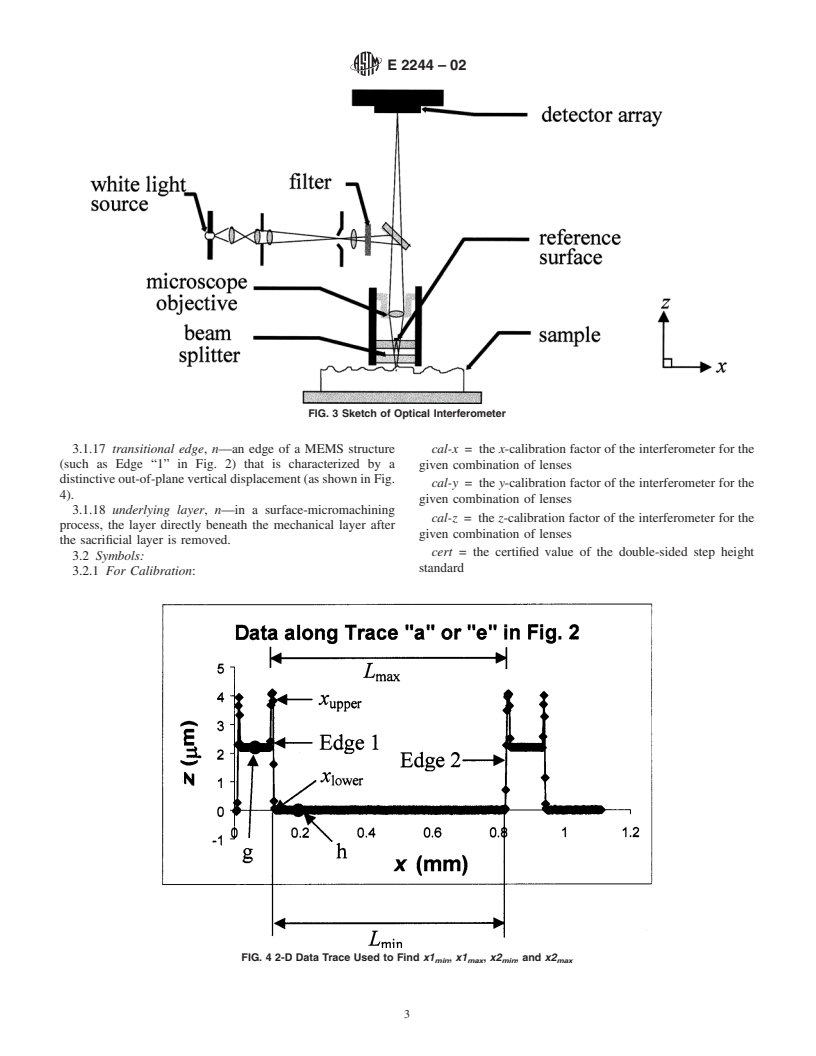

3.1.17 transitional edge, n—an edge of a MEMS structure cal-x = the x-calibration factor of the interferometer for the

(such as Edge “1” in Fig. 2) that is characterized by a

given combination of lenses

distinctiveout-of-planeverticaldisplacement(asshowninFig.

cal-y = the y-calibration factor of the interferometer for the

4).

given combination of lenses

3.1.18 underlying layer, n—in a surface-micromachining

cal-z = the z-calibration factor of the interferometer for the

process, the layer directly beneath the mechanical layer after

given combination of lenses

the sacrificial layer is removed.

cert = the certified value of the double-sided step height

3.2 Symbols:

standard

3.2.1 For Calibration:

FIG. 4 2-D Data Trace Used to Find x1 , x1 , x2 , and x2

min max min max

E2244–02

inter-x = theinterferometer’smaximumfieldofviewinthe z = in a bulk-micromachining process, the value for z

upper-t

x-direction for the given combination of lenses when the thickness of the support region, t , is subtracted

support

inter-y = theinterferometer’smaximumfieldofviewinthe from z

upper

y-direction for the given combination of lenses 3.2.4 Discussion—The symbols above are used throughout

mean = the mean value of the step-height measurements this test method. However, the letter “D” can replace the letter

(on the double-sided step height standard) used to calculate “L” in the symbols above when referring to in-plane deflection

cal-z measurements. Also, when referring to y values, the letter “y”

ruler-x = theinterferometer’smaximumfieldofviewinthe can replace the first letter in the symbols above that start with

x-direction for the given combination of lenses as measured the letter “x.”

with a 10-µm grid ruler

4. Summary of Test Method

ruler-y = theinterferometer’smaximumfieldofviewinthe

y-direction for the given combination of lenses as measured

4.1 Any in-plane length measurement can be made if each

with a 10-µm grid ruler

endisdefinedbyatransitionaledge.Toobtaintheendpointsof

3.2.2 For Alignment:

the in-plane length measurement for a surface-micromachined

x1 = the x-datavaluealongEdge“1”(suchasshownin

lower structure,fourstepsaretaken:(1)selectfourtransitionaledges,

Fig. 4) locating the lower part of the transition

(2) obtain a 3-D data set, (3) ensure alignment, and (4)

x1 = the x-datavaluealongEdge“1”(suchasshownin

upper determine the endpoints. (This procedure is presented in

Fig. 4) locating the upper part of the transition

Appendix X1 for a bulk-micromachined structure.)

x2 = the x-datavaluealongEdge“2”(suchasshownin

lower 4.2 At the transitional edges defining L, the endpoints are

Fig. 4) locating the lower part of the transition

x1 , x1 , x2 , and x2 . L and L are calculated

min max min max min max

x2 = the x-datavaluealongEdge“2”(suchasshownin

upper from these values. L is the average of L and L .

min max

Fig. 4) locating the upper part of the transition

4.3 Alternatively for a surface-micromachining process, if

x = the x-data value along the transitional edge of

lower the transitional edges that define L face the same way (for

interest locating the lower part of the transition (see Fig. 4)

example, two right-hand edges) and have similar slopes and

x = the x-data value along the transitional edge of

upper magnitudes, a different approach can be taken. Here, L is the

interest locating the upper part of the transition (see Fig. 4)

positive difference between the endpoints x1 and x2

lower lower

3.2.3 For In-plane Length Measurement:

(or x1 and x2 ).

upper upper

L = the in-plane length measurement

L = the maximum in-plane length measurement

5. Significance and Use

max

L = the minimum in-plane length measurement

min

5.1 In-plane length measurements are used in calculations

sep = the average calibrated separation between two inter-

of parameters, such as residual strain and Young’s modulus.

ferometric pixels (in either the x-or y-direction) as applies to

5.2 In-plane deflection measurements are required for spe-

a given measurement or sep=(sep + sep)/2

1 2

cific test structures. Parameters, including residual strain, are

sep = the average calibrated separation between two inter-

calculated given these in-plane deflection measurements.

ferometric pixels at one end of the in-plane length measure-

ment 4

6. Apparatus

sep = the average calibrated separation between two inter-

6.1 Non-contact Optical Interferometer, capable of obtain-

ferometric pixels at the other end of the in-plane length

ing a topographical 3-D data set and has software that can

measurement

export a 2-D data trace. Fig. 3 is a sketch of a suitable

t = in a bulk-micromachining process, the thickness

support

non-contact optical interferometer. However, any non-contact

of the support region where it is intersected by the 2-D data

opticalinterferometerthathaspixel-to-pixelspacingsasspeci-

trace of interest (such as, Trace “a” or “e” in Fig. X1.1, as

fied in Table 1 and that is capable of performing the test

shown in Fig. X1.2)

procedurewithaverticalresolutionlessthan1nmispermitted.

u = the combined standard uncertainty value (that is, the

c

The interferometer must be capable of measuring step heights

estimated standard deviation of the result)

from 0.1 nm to at least 10 µm higher than the step height to be

x1 = the smaller of the two x values (x1 or x1 )

max lower upper

measured.

used to calculate L

max

x1 = the larger of the two x values (x1 or x1 )

min lower upper

used to calculate L

min

x2 = the larger of the two x values (x2 or x2 )

max lower upper

ThesameapparatusisusedasinTestMethodE2245andTestMethodE2246.

used to calculate L

max

x2 = the smaller of the two x values (x2 or x2 )

min lower upper

TABLE 1 Interferometer Pixel-to-Pixel Spacing Requirements

used to calculate L

min

z = the z-data value associated with x Magnification, 3 Pixel-to-pixel spacing, µm

upper upper

5 < 1.57

10 < 0.83

20 < 0.39

Taylor, B. N. and Kuyatt, C. E., “Guidelines for Evaluating and Expressing the

40 < 0.21

Uncertainty of NIST Measurement Results,” NIST Technical Note 1297, National 80 < 0.11

Institute of Standards and Technology, September 1994.

E2244–02

NOTE 1—The 1 nm resolution is not mandatory for this test method. In NOTE 4—Obtain at least five data sets representative of the field of

reality, the vertical resolution can be as much as 5 nm. However, the view.

constraint is supplied to alert the user of this instrumental constraint for

8.1.2.9 Foreach3-Ddataset,extracta2-Ddatatraceinthe

out-of-plane measurements leading to residual strain and strain gradient

xz-plane at the same location on the ruler, if possible.

calculations.

8.1.2.10 Record in tabular form the ruler measurements

6.2 10-µm-grid Ruler, for calibrating the interferometer in

versus x for each y.

the xy-plane.

8.1.2.11 Orient the ruler in the y-direction along the left-

6.3 Double-sided Step Height Standard, for calibrating the

hand edge of the field of view. Repeat the above steps in a

interferometer in the out-of-plane z-direction.

similar manner.

7. Test Units

NOTE 5—This step can be skipped if the in-plane measurements are

restricted to the x-direction due to a smaller pixel-to-pixel spacing in that

7.1 The two transitional edges (for example, Edges “1” and

direction.

“2”inFigs.1and2)definingthein-planelength(ordeflection)

8.1.2.12 By interpolating or extrapolating, or both, use the

measurement.

newly created calibrated lookup table(s) to find the calibrated

NOTE 2—In a surface-micromachining process, if a transitional edge is

x (and/or y) values for pertinent pixels within the field of view.

on one side of an anchor lip, the anchor lip should be wide enough to

8.2 Calibrate the interferometer in the out-of-plane

include at least three data points. If the pixel-to-pixel spacing is 1.56 µm,

z-direction using the certified value of a double-sided step

then the anchor lip should be at least 3.2 times greater (or 5.0 µm).

height standard. Do this for each combination of lenses used

8. Calibration

for the measurements.

8.1 Calibrate the interferometer in the x- and y-directions 6

NOTE 6—Calibrating the step height at NIST lowers the total uncer-

using a 10-µm-grid ruler. Do this for each combination of

tainty in the certified value.

lenses used for the measurements. Calibrate in the xy-plane on

8.2.1 Before the data session, record the height of the step

a yearly basis.

height standard at six locations, three on each side of the step

8.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.